Think of a Variable Speed Drive (VSD) as the accelerator for an electric motor. Instead of being stuck at one speed—full throttle—it lets the motor run at the exact speed needed for the job at hand. This simple but powerful capability is what unlocks incredible energy savings and precise process control.

It all comes down to adjusting the electrical frequency fed to the motor.

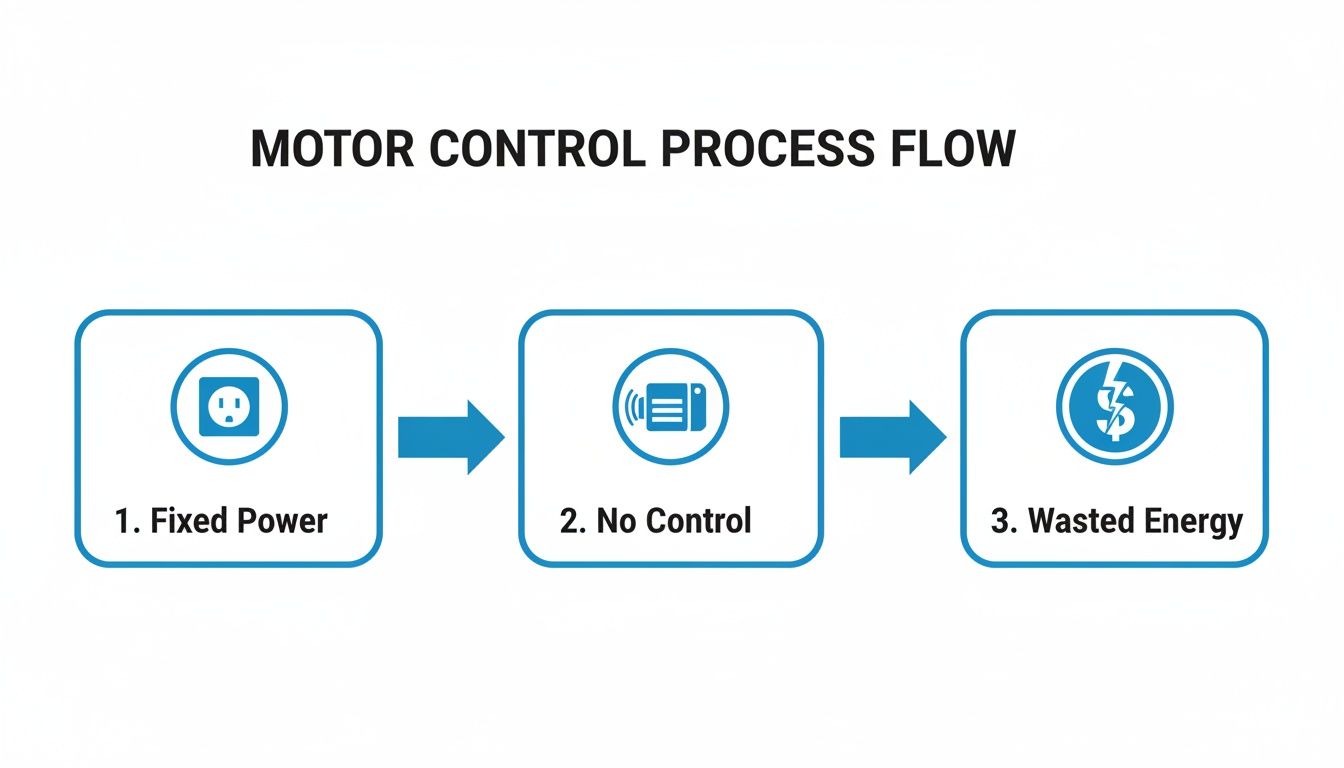

Unlocking Smarter Motor Control

Imagine trying to drive your car with only two options: full stop or pedal to the floor. That’s essentially how countless traditional electric motors work. They’re either off or running at a constant, maximum speed. While simple, this all-or-nothing approach is wildly inefficient for most real-world jobs.

A VSD completely flips that script. Instead of relying on clumsy mechanical parts like dampers or valves to throttle down the output, the VSD acts as the motor's brain. It intelligently dials the motor's speed up or down to perfectly match the application's real-time demand, ensuring not a single watt of power is wasted.

From Wasted Energy to Precise Performance

At its core, a VSD takes the standard, fixed-frequency power from the grid and converts it into a variable-frequency power source for the motor. Since an AC motor's speed is directly linked to the frequency of its power supply, changing the frequency means you change the speed. Simple as that.

This opens the door to some serious benefits:

- Massive Energy Savings: Just by running a motor only as fast as it needs to, VSDs can slash energy consumption by up to 60%, especially in common applications like pumps and fans.

- Enhanced Process Control: VSDs give you pinpoint control over flow, pressure, and speed. This leads directly to higher-quality products and more consistent operations.

- Reduced Mechanical Stress: The soft-start and stop capabilities of a VSD get rid of the sudden jolt that hammers equipment. This extends the life of critical components like belts, gears, and bearings.

It’s a common myth that VSDs are only for complex, high-tech systems. The truth is, their ability to match a motor’s output to the actual load makes them a smart financial move for almost anything, from a simple conveyor belt to a sophisticated HVAC system.

VSD vs. VFD: What's the Difference?

You'll often hear the terms VSD (Variable Speed Drive) and VFD (Variable Frequency Drive) thrown around like they're the same thing—and for the most part, they are.

When we're talking about AC motors, they refer to the exact same technology. VFD is just a more specific term that describes how the drive controls speed: by varying the frequency. VSD is a broader, more general term. But in today's industrial world, if someone says VSD, they almost always mean a VFD. If you want to get into the technical nitty-gritty, you can learn more about AC motor variable speed control and the principles behind it.

To put it all in perspective, here’s a quick rundown of how a VSD changes the game compared to old-school motor control.

VSD Control vs Traditional Motor Control At a Glance

| Feature | Traditional Motor (Fixed Speed) | VSD Controlled Motor (Variable Speed) |

|---|---|---|

| Speed Control | Runs at a single, constant speed. | Speed is fully adjustable from zero to maximum. |

| Energy Efficiency | Often inefficient, especially at partial loads. | Highly efficient, matching energy use to demand. |

| Process Control | Limited; requires mechanical throttling. | Precise and immediate control over processes. |

| Equipment Wear | High mechanical stress during startup. | Smooth starts and stops reduce wear and tear. |

As you can see, the difference is night and day. A VSD gives you the flexibility, efficiency, and control that a fixed-speed motor simply can't match.

How a Variable Speed Drive Actually Works

At its core, a variable speed drive is like a sophisticated power translator for an electric motor. It takes the standard, fixed-frequency AC power from the grid and cleverly transforms it into a new AC power source where the frequency can be adjusted on the fly. This ability to manipulate frequency is the secret to controlling a motor’s speed with surgical precision.

Think of it as a three-stage journey that turns raw, inflexible power into smart, adaptable energy. Each stage has a specific job, working in perfect sync to give you total command over your motor. The entire process is a seamless AC-to-DC-to-AC conversion that happens in the blink of an eye.

This is a big deal because, without this control, you’re stuck with a motor that only knows one speed: full blast.

As the graphic shows, running a motor at full speed when it isn't needed is the same as leaving cash on the table. A VSD fixes that.

Stage 1: The Rectifier Converts AC to DC

The journey starts at the rectifier, which is the VSD’s front door for incoming power. Its one and only job is to take the alternating current (AC) from your facility and convert it into direct current (DC). The AC power from the wall outlet naturally flows back and forth in a sine wave, which is great for long-distance transmission but terrible for precise control.

To build an adjustable output, the VSD first needs a stable, one-way power source to work with. The rectifier, usually built with high-power diodes, acts like a series of one-way valves. It lets electricity flow in but not back out, effectively ironing out the AC waves into a steady stream of DC voltage.

Stage 2: The DC Bus Stores and Smooths the Power

Once converted, this raw DC power flows into the DC bus, which acts like a power reservoir. It’s mainly made up of big capacitors that store the electrical energy, making sure a clean and stable supply is ready for the final stage.

Picture the DC bus as the calm water held in a reservoir behind a dam. The rectifier fills it up, and the capacitors ensure the water level (voltage) stays perfectly constant, filtering out any ripples or hiccups from the conversion. This smooth, stored DC power is absolutely essential for creating a clean AC waveform on the other side.

A stable DC bus is the foundation of the drive's performance. Without it, the final AC output to the motor would be choppy and erratic, leading to poor performance and even potential damage.

Stage 3: The Inverter Creates a New, Adjustable AC Signal

This is it—the final and most critical stage is the inverter. This is where the real magic of variable speed control happens. The inverter takes that smooth DC power from the bus and, using a set of incredibly fast electronic switches (typically Insulated Gate Bipolar Transistors, or IGBTs), chops it up into thousands of precisely timed pulses per second.

By controlling the timing and width of these pulses—a technique called Pulse Width Modulation (PWM)—the inverter can build a brand-new, synthetic AC sine wave from scratch. And here's the key: the frequency of this new wave is completely under your control.

- To run the motor slower, the inverter creates a lower-frequency AC waveform.

- To run the motor faster, it generates a higher-frequency waveform.

This newly minted, variable-frequency AC power is then fed to the motor, dictating its exact rotational speed. The motor simply follows the frequency it’s given, giving you the power to match its output perfectly to what your application actually needs. No more waste, just pure, precise control.

The Main Components and Types of VSDs

To really get what a variable speed drive is, you have to look under the hood. Think of it like a car engine—you have the block, pistons, and crankshaft all working in concert. A VSD is no different; it’s an assembly of key electronic components that have to work together perfectly to give you that precise motor control.

Each part has a specific job in the AC-to-DC-to-AC power conversion process that makes the whole thing possible.

While the big hardware handles the power, a sophisticated control unit is the maestro orchestrating the whole performance.

Unpacking the Core Hardware

A VSD isn't just one magic box. It’s a system made up of four essential parts, and knowing what each one does makes it much clearer how the drive pulls off its magic trick.

- Rectifier: This is where the power from the grid first enters the drive. Its only job is to take that incoming alternating current (AC) and, using a series of diodes, turn it into direct current (DC).

- DC Bus: Basically a big electrical reservoir made of capacitors. The DC bus takes the power from the rectifier, smooths it out, and stores it. This ensures the next stage gets a stable, clean supply of DC power to work with.

- Inverter: This is the real heart of the VSD. It takes that smooth DC power from the bus and, using incredibly fast-switching transistors (usually IGBTs), chops it up to build a brand-new, synthetic AC waveform with whatever frequency and voltage is needed.

- Control Unit: The brain of the whole operation. This microprocessor is constantly monitoring motor feedback, user commands, and system status. It tells the inverter exactly what kind of waveform to create to hit the target speed and torque.

These four pieces work in lockstep to turn a simple command—like "run this pump at 75% speed"—into a precisely engineered electrical output.

The Major Categories of VSDs

Not all drives are built the same. They come in different flavors, each designed with specific technologies for different jobs, from simply slowing down a fan to running high-precision robotics. The two main categories are defined by how they handle the power internally.

Choosing the right type of VSD is less about which one is "better" and more about matching the technology to the demands of the job. A high-performance drive is overkill for a simple pump, while a basic drive can't handle a complex servo application.

The most common distinction you'll run into is between Voltage Source Inverters and Current Source Inverters.

- Voltage Source Inverters (VSI): This is the workhorse of the industry. By far the most common type of VSD you’ll find, a VSI creates a variable voltage output. This makes them incredibly versatile, cost-effective, and a perfect fit for the vast majority of industrial applications.

- Current Source Inverters (CSI): You don't see these as often. CSIs are typically reserved for very high-power, medium-voltage applications—think massive industrial fans or pumps. They regulate current instead of voltage, which gives them unique advantages for controlling huge motors, but they come with a higher price tag and more complexity.

Beyond that fundamental split, VSDs are also grouped by their performance capabilities. A standard drive, often called a V/Hz or scalar drive, is perfect for simple tasks where you just need to adjust speed, like on a fan or pump, and don't need dead-on torque control.

For the more demanding jobs, you step up to vector control or servo drives. These high-performance drives use sophisticated algorithms to independently manage both the motor's speed and torque with incredible accuracy. This makes them essential for things like machine tools, complex conveyors, and robotics, where precise positioning and a dynamic response are non-negotiable.

The Business Case for Installing VSDs

While the tech behind a variable speed drive is interesting, the real question for any business is simple: why should you invest in one?

It really comes down to a powerful mix of massive energy savings, tighter process control, and better long-term equipment health. A VSD isn't just an operational upgrade; it’s a smart financial move with a clear—and often very quick—return on investment.

The biggest benefit, the one that gets everyone’s attention, is the dramatic drop in energy consumption. This is especially true for anything with pumps and fans, which follow a fascinating set of rules known as the Affinity Laws.

These laws show a powerful link between a motor's speed and its power draw. In short, the power needed is proportional to the cube of the motor's speed. This creates an exponential curve where even a tiny reduction in speed leads to a massive drop in energy use.

The Power of the Affinity Laws

Think about it like this: if you slow a fan down by just 20%, you don't save 20% on your energy bill. Thanks to the Affinity Laws, that 20% speed reduction actually slashes the fan's energy use by nearly 50%.

That’s a complete game-changer for facilities with big HVAC systems or fluid-pumping operations. A seemingly minor tweak becomes a major cost-cutting measure. You can see how this plays out in the real world in our detailed look at VFD energy savings.

This is where VSDs really shine. Instead of running a pump at full blast and using a valve to choke the flow—which is like driving with one foot on the gas and the other on the brake—a VSD just slows the motor down to deliver the exact flow you need.

By precisely matching motor speed to the load demand, a VSD eliminates the wasted energy inherent in fixed-speed systems. This isn’t just incremental improvement; for many businesses, it’s the single most impactful energy efficiency upgrade they can make.

More Than Just Energy Savings

The energy savings are fantastic, but the business case for VSDs goes way beyond a lower utility bill. The enhanced control and gentler operation they provide bring a ton of other valuable perks to the table.

- Improved Process Control: For any application needing precise pressure, flow, or tension, VSDs offer incredible accuracy. They can hold a setpoint with rock-solid stability, which leads to better product quality, less wasted material, and more consistent output.

- Reduced Mechanical Stress: A standard motor kicks on with a violent, instant jolt of power. That shockwave slams into belts, gears, and couplings. A VSD, on the other hand, gives you a smooth, controlled "soft start," gradually ramping up the motor's speed. This gentle acceleration drastically cuts down on mechanical wear and tear, making your equipment last longer and lowering maintenance costs.

- Lower Maintenance and Repair Costs: When equipment runs smoother and only as fast as necessary, parts don't wear out as quickly. Fewer emergency repairs mean less unplanned downtime, which directly protects your bottom line.

The market is certainly taking notice. Global VFD market projections show growth from USD 24.7 billion in 2025 to USD 32.0 billion by 2030. This trend is fueled by real results; in water treatment plants, for example, VFDs can cut pumping energy by 20-60%. A single 100 kW pump with a VFD can save 200,000 kWh a year, which can mean over $20,000 back in your pocket.

For manufacturers, figuring out smart strategies to reduce manufacturing costs is always a priority, and VSDs are a huge piece of that puzzle. By combining direct energy savings with less maintenance and better process quality, a VSD is a multi-pronged attack on operational spending that directly boosts profitability.

How to Select the Right VSD for Your Application

Choosing the right variable speed drive isn't just about grabbing one off the shelf. It’s a crucial decision that hinges on a deep understanding of your motor, the job it’s doing, and the environment it lives in. Get this right, and you'll unlock those promised energy savings and gain incredible process control. Get it wrong, and you're looking at performance headaches, premature failure, and money down the drain.

The whole process kicks off with the basics: your motor’s nameplate. That little metal plate is packed with the critical data you need to size the VSD correctly.

Sizing Your Drive with Motor and Application Data

Properly sizing a VSD is hands-down the most important first step. An undersized drive will constantly trip on faults and eventually burn out, while an oversized one is just a waste of capital. The goal is to perfectly match the drive's capabilities to both the motor it's controlling and the actual work that motor has to do.

First things first, grab these key details from the motor’s nameplate:

- Full Load Amps (FLA): This is the big one. Your VSD absolutely must be rated to handle the motor’s maximum current draw when it's working its hardest.

- Horsepower (HP) or Kilowatts (kW): While amps are the priority, the HP rating is a great way to double-check that you’re in the right ballpark.

- Voltage: Simple but critical. The drive's input voltage has to match your available power supply, whether that’s 480V, 240V, or something else.

Beyond the motor itself, you have to think about the application’s torque requirements—the amount of rotational force the motor needs to generate. You can dive deeper into the fundamentals in our guide on how to calculate motor torque.

A common mistake is sizing a drive based on horsepower alone. Always, always prioritize the motor's Full Load Amps (FLA). It’s a far more accurate measure of the electrical load the VSD will actually see.

Applications typically fall into two torque profiles, and your VSD choice needs to reflect which one you're dealing with:

- Variable Torque: Think centrifugal fans and pumps. The torque needed goes up as the speed increases. Since they require very little torque at low speeds, these applications are the superstars for massive energy savings.

- Constant Torque: This is your world of conveyors, mixers, and extruders. They demand the same amount of muscle from the motor whether it’s crawling or running at full tilt. These loads need a robust VSD that can deliver consistent, high torque even at very low RPMs.

Tackling Power Quality and Harmonic Distortion

One of the biggest hurdles when integrating a VSD is harmonic distortion. In plain English, the super-fast electronic switching happening inside the drive creates electrical "noise" that can pollute your facility's power grid. This distortion can wreak havoc on other sensitive electronic equipment sharing the same circuit, causing bizarre malfunctions or even permanent damage.

Luckily, this is a well-known issue with proven fixes. The most common way to fight back is by installing a line reactor or a specialized harmonic filter. A line reactor is basically an inductor coil that you place on the input side of the VSD. It acts like an electrical shock absorber, smoothing out the current and filtering out a huge chunk of those damaging harmonics. For more severe cases, you might step up to a dedicated active or passive harmonic filter to guarantee clean power.

Considering Environmental and Compliance Factors

Finally, a VSD has to be tough enough to survive in its home. The drive's enclosure is rated to protect its delicate electronics from things like dust, moisture, and chemical spray. These ratings are standardized by NEMA (National Electrical Manufacturers Association).

- NEMA 1: Your standard choice for clean, dry, indoor spots.

- NEMA 12: Offers protection from circulating dust and light, non-corrosive drips.

- NEMA 4X: The workhorse for harsh, wet, or wash-down areas, built to resist corrosion.

Meeting safety standards from organizations like UL (Underwriters Laboratories) is also completely non-negotiable. A properly rated and certified drive is essential for meeting regulations and protecting both people and equipment. This kind of foresight is becoming even more critical as the VSD market continues to explode, with projections showing it growing from USD 28.38 billion in 2024 to USD 39.67 billion by 2030, largely thanks to energy efficiency mandates.

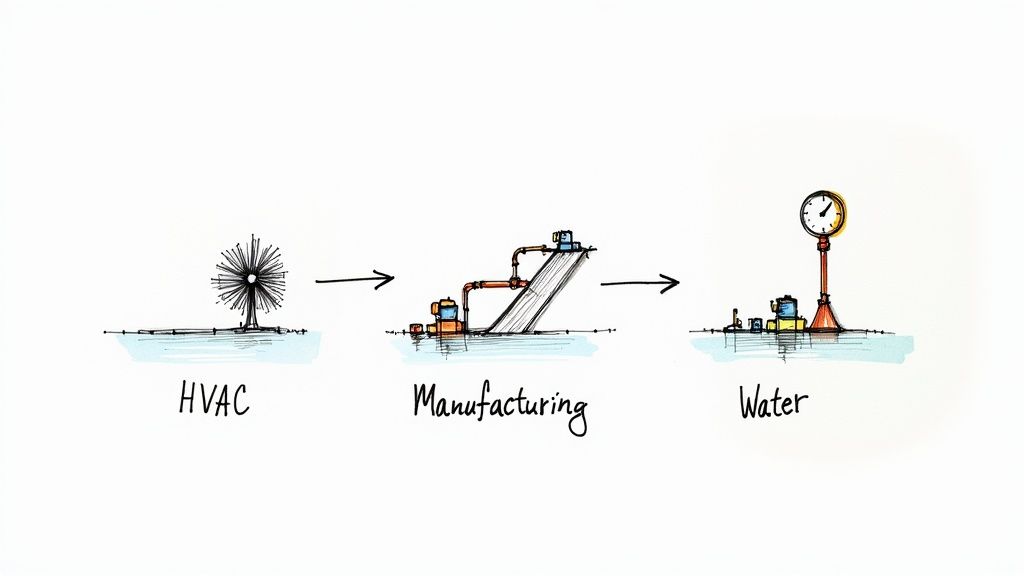

VSDs in Action Across Different Industries

The theory behind a variable speed drive is one thing, but seeing it solve real-world problems is where the magic happens. This isn't just about technical specs on a data sheet; it's about making industrial and commercial operations smarter, more efficient, and a whole lot more reliable.

From keeping a massive office building comfortable to making sure your city's water flows steadily, VSDs are the unsung heroes working behind the scenes. Their core strength is simple but powerful: they match a motor's speed to the actual work that needs to be done. This is what unlocks huge benefits across completely different sectors.

Optimizing Commercial HVAC Systems

In any large commercial building, the Heating, Ventilation, and Air Conditioning (HVAC) system is an absolute energy hog. Traditionally, the fans and pumps that push air and water just run at full tilt all day long. To control the output, they use mechanical dampers or valves to choke off the flow—basically like driving your car with the gas pedal floored and using the brake to control your speed. It’s incredibly wasteful.

This is where VSDs completely change the game. By installing a VSD on an HVAC fan motor, the system can dial its speed up or down based on what’s actually happening, like building occupancy or the outside temperature. On a mild day, the fan just slows down, and because of the Fan Affinity Laws, it consumes exponentially less power while keeping everyone perfectly comfortable. This intelligent control not only crushes energy bills but also makes the building quieter and helps the equipment last longer.

Synchronizing Manufacturing Production Lines

Manufacturing plants live and die by precision and timing. Picture a production line with multiple conveyor belts moving products from one station to the next. If one belt runs just a little too fast or slow, you get bottlenecks, damaged products, or even a full-blown line shutdown, all of which cost a fortune.

VSDs are the perfect fix. They give operators pinpoint control over each individual conveyor motor. You can fine-tune the speed of different sections to create a perfectly synchronized flow, ensuring a seamless handoff from one process to the next. This kind of control slashes downtime, improves product quality by stopping pile-ups, and makes the whole plant run more efficiently. The smooth starts and stops also eliminate mechanical shock, which protects expensive machinery from wear and tear.

The global impact of this technology is undeniable. The top 10 VSD manufacturers now hold over 60% of the global market share, a testament to the technology's widespread adoption and proven value in optimizing industrial operations.

Ensuring Reliable Municipal Water Pressure

For a city's water system, keeping water pressure consistent across miles of pipes is a massive challenge. Running pumps at full speed 24/7 burns through an insane amount of electricity and puts constant stress on the infrastructure, leading to damaging pressure surges (water hammer) and expensive leaks.

By putting VSDs on their water pumps, municipalities can hold a steady, reliable pressure no matter how much water people are using. When everyone wakes up and starts their morning showers, the VSD seamlessly ramps the pumps up. In the middle of the night, when demand drops, it dials them way back down. This prevents dangerous water hammer, reduces the number of pipe breaks, and leads to huge energy savings for the community.

You see a similar logic in the oil & gas sector, where applying VFDs to pumps can cut downtime by 15%, saving millions at a single site every year. If you want to dig deeper, you can learn more about the growth and dynamics of the VFD market and its massive industrial impact.

Common Questions About Variable Speed Drives

We’ve covered a lot of ground on what a variable speed drive is and how it works. But if you’ve still got a few questions rattling around, you’re not alone. Let’s tackle some of the most common ones we hear from folks in the field.

What Is the Difference Between a VSD and a VFD?

Walk onto any plant floor, and you'll hear people use VSD (Variable Speed Drive) and VFD (Variable Frequency Drive) interchangeably. For all practical purposes, they're talking about the same piece of equipment.

Technically, VFD is the more precise term because it describes how the drive controls the motor's speed—by changing the electrical frequency. VSD is more of a catch-all term. But in the real world, if someone's talking about a VSD for an AC motor, they mean a VFD. Simple as that.

Can You Use a VSD on Any Motor?

That’s a hard no. Slapping a VSD on a standard motor is a recipe for disaster. Drives are designed to work with special inverter-duty motors. These motors have beefed-up insulation and a design that can handle the unique electrical stress a drive puts on them.

If you try to run a general-purpose motor with a VSD, you’re asking for trouble. It’ll likely overheat, the insulation will break down, and you’ll burn out the motor long before its time. Always check the motor's nameplate—if it doesn’t say "inverter-duty" or "VFD-rated," don't pair it with a drive.

The biggest win with a VSD is the hit it makes on your power bill. The Compressed Air & Gas Institute found that a variable speed drive can knock energy costs down by an average of 33% in many setups, often paying for itself in just two to five years.

How Much Energy Can a VSD Really Save?

The savings can be massive, especially for pump and fan applications. It all comes down to a bit of physics called the Affinity Laws, which show that even a small drop in motor speed creates a huge drop in energy use.

Think about it this way: slowing a fan down by just 20% can cut its energy consumption by almost 50%. While your exact savings will depend on your specific setup, it's not uncommon to see reductions anywhere from 20% to 60%.

At E & I Sales, we do more than just sell parts—we build complete motor control solutions that work. From picking out the perfect VSD to designing, building, and commissioning a UL-listed control panel, our experts are here to make sure your project is a success from start to finish. See what our custom integration and packaging services can do for you.