Ever wondered how massive industrial machines can run with such precision and efficiency? In many cases, the secret lies in a Variable Speed Drive, or VSD.

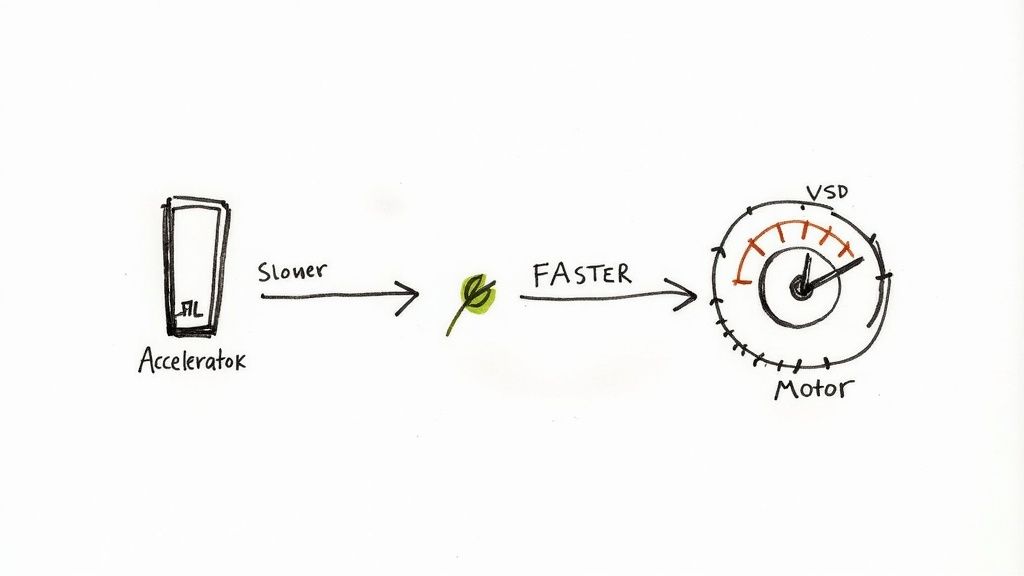

So, what exactly is it? Think of a VSD as the accelerator pedal for an electric motor. Instead of flooring it and then slamming the brakes to manage speed, a VSD gives the motor just enough "gas" to match the exact demands of the job. This simple-yet-brilliant concept is a game-changer for industrial energy consumption.

What a Variable Speed Drive Does

At its heart, a Variable Speed Drive is an intelligent throttle for your motor. Before VSDs became common, the standard practice for controlling systems like pumps or fans was incredibly wasteful. You'd run the motor at 100% speed and then use a mechanical valve or damper to choke the output down to the level you needed.

It’s the industrial equivalent of driving your car with one foot on the gas—pushed to the floor—and the other on the brake to control your speed. It works, sure, but you’re burning through fuel and putting massive stress on your engine and brakes for no reason. A VSD gets rid of that entire wasteful process.

By perfectly matching the motor's speed to what the load actually requires, a VSD stops energy waste in its tracks. It delivers only the power needed for the task at hand, which can slash energy costs by 30-50% in the right applications.

Breaking Down VSD Functions

How does it pull this off? Instead of relying on crude mechanical dampers, a VSD intelligently adjusts the electrical power going into the motor. This gives you a far more sophisticated and efficient method of control, unlocking some major operational benefits.

Here’s a quick look at what a VSD brings to the table:

| Function | Description | Practical Benefit |

|---|---|---|

| Speed Control | Varies the motor's rotational speed on demand—from a slow crawl to full tilt. | Match fan speed to cooling needs or adjust a pump to maintain precise pressure. |

| Soft Starting | Gently ramps the motor up to speed, eliminating the sudden power jolt of a direct start. | Reduces mechanical shock on belts, gears, and couplings, extending their lifespan. |

| Energy Savings | Draws only the power needed for the current load, especially at slower speeds. | Drastically cuts electricity bills for systems like pumps, fans, and compressors. |

| Process Optimization | Allows for fine-tuning system performance, leading to better product quality. | Get total control over conveyor speeds, mixer torque, or fluid flow rates. |

From Brute Force to Finesse

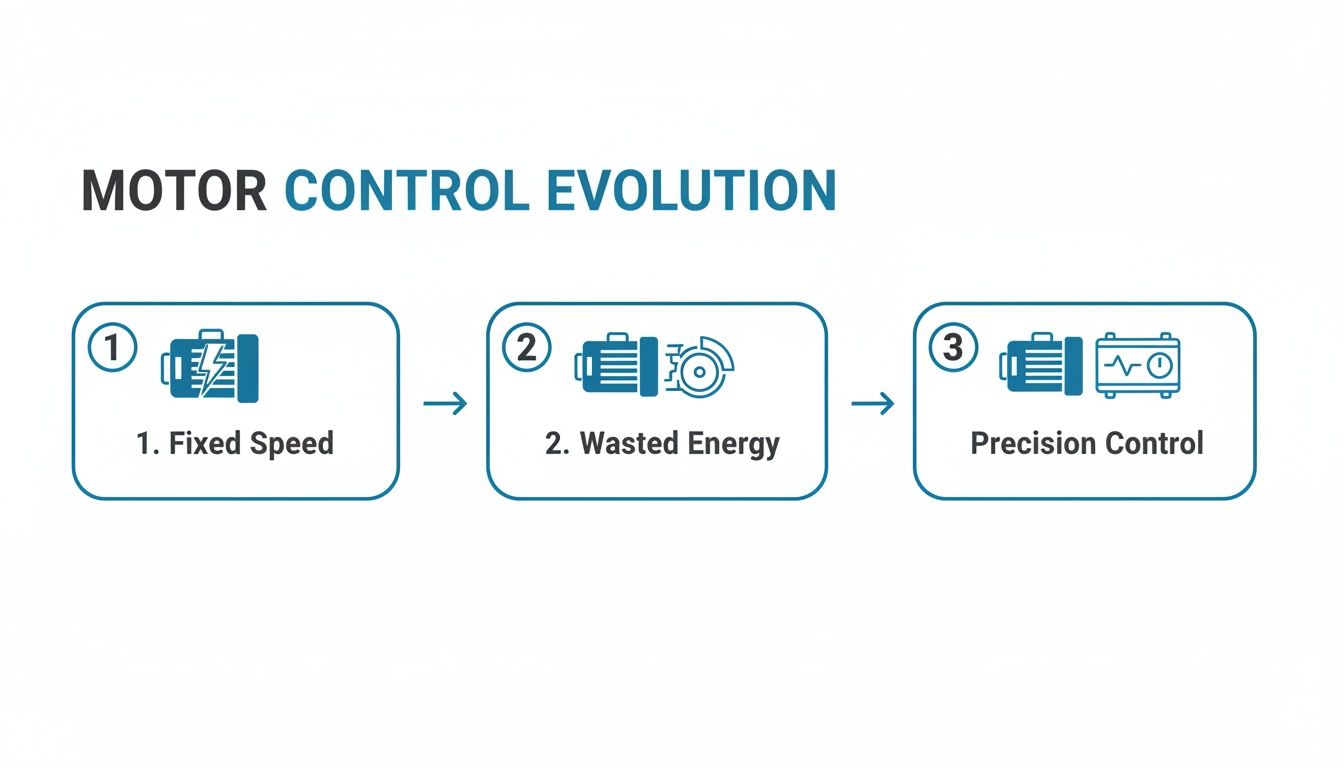

To really get what a variable speed drive brings to the table, you have to look at the world it replaced. For decades, industrial motor control was a pretty blunt instrument. The go-to tool was the direct-on-line (DOL) starter, which was basically a big switch that slammed a motor from zero to full blast in an instant.

It was a simple and reliable method, but it was incredibly crude. There was no speed adjustment, just a massive mechanical shock to the motor and everything connected to it every single time it started. Think of it like a traffic light with only red and green—no yellow light to ease the transition, just jarring, abrupt stops and starts.

The Old Way: Mechanical Throttling

When a process needed less than full power, the "solution" was wildly inefficient. Engineers had no choice but to run the motor at 100% speed and then physically block the output to get the result they wanted.

This usually involved things like:

- Valves: On a pump system, they'd just partially close a valve to restrict the flow of water.

- Dampers: For a fan, they'd slide a damper into the ductwork to block the airflow.

This approach is profoundly wasteful. It’s like flooring the gas pedal in your car while riding the brake to control your speed. The engine is screaming, guzzling fuel, and all that power is just turned into useless heat by the brakes. For a long, long time, this was the accepted standard.

This constant-speed, mechanically throttled approach forced systems into a state of continuous conflict. It was a constant battle between the motor and the restriction, wasting incredible amounts of energy and accelerating wear on every single component.

The Shift to Smart Control

The glaring inefficiency of fixed-speed systems was a huge engineering problem that people chipped away at for decades. While early concepts for adjusting DC motor speed go back to the 1920s, the modern VSD era really kicked off in 1968 with the first commercial AC drive built with Silicon-Controlled Rectifiers (SCRs).

That breakthrough opened the floodgates. Microprocessors showed up in the 1970s, followed by the far more efficient IGBTs (Insulated-Gate Bipolar Transistors) in the 1980s, which made today’s compact, incredibly precise drives possible. To see just how far the technology has come, it's worth exploring the variable frequency drive market evolution and its key technological milestones.

This evolution was more than just new hardware; it was a complete change in thinking. Instead of overpowering a system and then choking it back, the VSD introduced the simple, elegant idea of giving the motor only the energy it needs to do the job at hand.

This move from fixed-speed to precision control finally solved a century-old problem, paving the way for the efficient, automated, and responsive industrial world we have today. The variable speed drive stopped being just a motor controller and became a cornerstone of modern industry.

How a Variable Speed Drive Actually Works

So, how does a VSD pull this off? It’s not just a fancy dimmer switch. A modern drive doesn't just restrict power; it completely rebuilds it from the ground up to give the motor exactly what it needs for a specific task.

The entire process happens in three quick steps. Think of it like a power-supply chain inside a single box: raw AC power comes in, gets converted and smoothed into stable DC, and then is rebuilt into a brand-new, fully controllable AC output.

The diagram below really shows the leap from older, energy-wasting motor control methods to the precision and efficiency we get with a VSD.

You can see how we moved past simply throttling a motor running at full tilt to a much smarter approach that saves energy and gives us total control.

Step 1: The Rectifier – Flipping AC to DC

The first thing that happens when utility power hits the drive is that it flows into the rectifier. Its only job is to take the incoming alternating current (AC) and turn it into direct current (DC).

AC power from the grid naturally flows back and forth in a sine wave. The rectifier, usually a set of six diodes, acts like a series of one-way electrical gates. It forces that alternating flow into a single direction, creating a rough, pulsating DC voltage. You have to start here because it’s much easier to manipulate DC power than to try and alter an AC frequency directly.

Step 2: The DC Bus – Smoothing Everything Out

That pulsating DC from the rectifier isn't clean enough to work with yet. It still has "ripples" left over from the original AC wave. This is where the DC Bus takes over.

Made up of large capacitors, the DC Bus works like a reservoir. It takes that bumpy DC voltage, stores it, and smooths it out into a stable, clean supply of DC power. Think of it as a shock absorber for electricity, ensuring the next stage has a perfectly steady source to draw from.

Without a clean, stable DC bus, the drive's output would be erratic, causing poor motor performance and even potential damage over time. This step is non-negotiable for reliable operation.

Now we have a perfect block of DC power, ready to be carved into whatever the motor needs.

Step 3: The Inverter – Building a New AC Wave

This is where the real control happens. The inverter takes that smooth DC power and, using incredibly fast switches, chops it up to build a brand-new AC waveform to send to the motor.

Inside the inverter are high-speed transistors (IGBTs) that can switch on and off thousands of times per second. By controlling the precise timing and duration of these switches, the drive creates a simulated AC sine wave at any frequency or voltage required. This technique is called Pulse Width Modulation (PWM).

Instead of a perfect, smooth curve, the VSD creates a series of square DC pulses with varying widths. The motor’s natural inductance smooths these rapid pulses out, interpreting them as a clean AC signal. This gives the VSD pinpoint control over the motor's speed and torque.

Of course, this high-frequency switching can create electrical noise (harmonics) that gets sent back into your electrical system. In many cases, it's worth looking into a harmonic filter for a VFD to keep your power clean and your other equipment happy.

By mastering this three-step process—rectify, smooth, invert—a VSD gives you complete authority over your motor, unlocking huge gains in process control and energy savings.

The Real-World Benefits of Using a VSD

It’s one thing to understand the theory behind a variable speed drive, but it's another thing entirely to see what it can do for your bottom line. Once you move past the technical specs, you find a powerful tool that unlocks some serious financial and operational wins. A VSD isn't just another motor controller; it's a strategic asset that pays you back in more ways than one.

The most obvious and immediate payoff is a massive drop in your energy bill. In most industrial plants, motor-driven systems are the biggest power hogs, often chewing up between 50-70% of the total electricity. VSDs go right for the jugular, cutting out the incredible waste you find in fixed-speed systems and delivering energy savings of up to 30-50%.

This is all thanks to a simple set of principles called the Affinity Laws, which are especially powerful for centrifugal equipment like pumps and fans. These laws highlight an incredible, almost magical relationship between speed and power.

For instance, dropping a fan's motor speed by a modest 20% doesn't just cut power by 20%. Instead, it slashes energy consumption by a jaw-dropping 49%. This is where the real money is saved—even small tweaks in speed can lead to huge savings.

Unlocking Massive Energy Savings

It’s no surprise the global VFD market is sitting at around USD 24.68 billion and is expected to hit USD 32.00 billion by 2030. With electricity costs soaring and a major push for efficiency, businesses are hunting for proven ways to cut their operating expenses, and VSDs are at the top of the list. You can see the full breakdown by checking out the latest VFD market trends from MarketsandMarkets.

By perfectly matching motor output to what the application actually needs right now, a VSD makes sure you aren't wasting a single kilowatt. Think about it: instead of running a pump at 100% and choking the flow with a valve, the drive just tells the motor to slow down. It’s an elegant solution that’s not just more efficient but is also a lot gentler on your whole system. To see how this works in the real world, you can learn more about how VFD energy savings are calculated in different industrial setups.

Smoother Operations and Tighter Process Control

Beyond the killer cost savings, a VSD gives you a level of control that old-school mechanical methods can't even touch. It lets you make incredibly fine-tuned adjustments to speed, torque, and pressure, which has a direct impact on your product quality and consistency.

Just look at these examples:

- Conveyor Systems: A VSD can sync up multiple belts perfectly, stopping products from piling up, spilling, or getting damaged.

- Industrial Mixers: It can tweak the motor torque on the fly as a material’s viscosity changes, guaranteeing a perfect blend every single time.

- HVAC Fans: In a building's climate control, a VSD can adjust airflow smoothly to hold the perfect temperature, getting rid of those jarring on-off cycles of a fixed-speed motor.

This superior control makes your entire process more stable and reliable. By getting rid of sudden, jerky changes and allowing for smooth, gradual adjustments, VSDs help you run a much more predictable operation with way fewer headaches.

Reducing Mechanical Wear and Slashing Maintenance Costs

Here’s the benefit that often gets overlooked: a VSD can dramatically extend the life of your equipment. A traditional direct-on-line starter is just brutal on machinery. It slams the motor from zero to full speed in an instant, creating a huge current surge and a violent mechanical jolt.

That "whiplash" sends a shockwave through the entire system, putting stress on every single part connected to that motor. Do that over and over, and you’re just asking for premature failure of your most critical components.

A VSD changes the game completely by introducing soft starting. It gently ramps the motor up to speed, getting rid of that violent jolt. This one feature has a massive impact:

- It drastically reduces stress on belts, gears, and couplings.

- It protects the motor's windings from the thermal shock of high inrush current.

- It minimizes pressure spikes in your piping, cutting the risk of leaks and bursts.

This gentler approach means fewer breakdowns, less unplanned downtime, and a serious reduction in maintenance bills. By taking care of your mechanical assets, a VSD delivers a powerful ROI that goes way beyond just your monthly power bill. It’s worth exploring the differences between predictive vs. preventive maintenance strategies to see how this fits into a bigger asset management plan.

VSD Benefits Breakdown: Energy Savings vs. Process Improvements

To put it all in perspective, here's a look at how VSDs deliver value across different applications, balancing the direct financial wins from energy savings with the crucial operational improvements they bring to the table.

| Application Area | Primary Energy Saving Mechanism | Key Process Control Benefit | Mechanical Wear Reduction Impact |

|---|---|---|---|

| Pumps & Fans | Affinity Laws: Cubic power reduction with speed decrease. | Precise pressure/flow control without throttling valves. | High: Eliminates water hammer and pressure surges. |

| Conveyors | Matching speed to production throughput. | Smooth start/stop; synchronization of multiple lines. | High: Reduces stress on belts, chains, and gearboxes. |

| Mixers & Agitators | Adapting torque to material viscosity. | Consistent product quality; prevents motor overload. | Medium: Protects gearbox from shock loads. |

| Extruders | Holding precise speed under varying loads. | Tighter tolerances and improved end-product consistency. | Medium: Reduces wear on screws and barrels. |

Ultimately, whether you're chasing lower energy bills or a more reliable production line, a VSD delivers on both fronts. The combined effect is what makes it such a fundamental piece of modern industrial automation.

Choosing the Right Type of VSD

Just like you wouldn't use a pickup truck for a Formula 1 race, not all VSDs are designed for the same job. Picking the wrong drive can lead to shaky performance, wasted money, or even damaged equipment. It's all about matching the right technology to the task at hand.

The world of variable speed drives really boils down to three main categories. Each offers a different level of performance and precision. Getting a handle on this hierarchy makes it much clearer which drive is the right fit for your application, whether you're just controlling simple airflow or choreographing complex robotic movements.

Standard Variable Frequency Drives (VFDs)

The most common and versatile type is the standard Variable Frequency Drive (VFD), which you’ll often hear called a scalar or V/Hz drive. Think of this as the reliable workhorse of the VSD family. It’s perfect for the vast majority of industrial applications where pinpoint-accurate torque control isn't the number one priority.

Its main job is to keep a constant ratio between voltage and frequency. This straightforward control method is incredibly effective for variable torque loads, where the muscle needed from the motor changes as the speed changes.

You’ll see standard VFDs everywhere, especially in applications like:

- Pumps: Dialing in flow rates for water treatment or irrigation systems.

- Fans: Controlling airflow in HVAC systems to manage building climates.

- Blowers: Regulating air pressure for industrial drying or ventilation.

For these kinds of jobs, a VFD delivers fantastic energy savings and provides a gentle soft start, all without the cost and complexity of more advanced drives. It's the go-to solution for about 80% of all motor control needs out there.

Vector Control Drives

Now, when your application needs better torque control and a much quicker response, it’s time to step up to a Vector Control Drive. These drives are a whole lot smarter than standard VFDs. They run sophisticated algorithms and often use feedback to build a precise mathematical model of the motor's internal magnetic field.

This allows the drive to control the motor's speed and torque independently, giving you incredible precision even at very low—or even zero—speeds. Imagine a crane holding a heavy load perfectly steady; that requires powerful, unwavering torque, which is exactly where a vector drive shines.

A standard VFD just tells the motor how fast to spin. A vector control drive tells it how fast to spin and how hard to push, giving it the muscle to handle tough, constant-torque loads.

Key applications for vector control drives include:

- Cranes and Hoists: Delivering the high starting torque needed to lift heavy loads off the ground.

- Industrial Mixers: Keeping torque consistent even as the viscosity of the material changes.

- Extruders: Maintaining exact speed under heavy and often fluctuating loads.

Vector drives come in two main flavors: open-loop (or sensorless), which offers great performance at a moderate cost, and closed-loop, which uses an encoder for feedback to achieve the highest degree of accuracy.

Servo Drives

At the absolute peak of the performance pyramid, you’ll find Servo Drives. If a standard VFD is a dependable family sedan and a vector drive is a heavy-duty truck, then a servo drive is a high-performance race car. It’s built for one thing: extreme precision and lightning-fast response.

Servo drives operate in a tightly managed closed-loop system, constantly processing high-resolution feedback from an encoder or resolver attached right to the motor. This allows the drive to make thousands of tiny adjustments every second, instantly correcting any deviation in position, velocity, or torque.

Their ability to execute exact, repeatable movements makes them indispensable for high-tech automation. They are the brains and the brawn behind applications that demand a level of accuracy other drives simply can't touch.

You'll find servo drives running:

- Robotics: Enabling the smooth, precise motions of robotic arms on an assembly line.

- CNC Machines: Guiding cutting tools with micron-level accuracy.

- Automated Packaging: Ensuring products are placed and wrapped perfectly at incredible speeds.

Of course, this level of performance comes with a higher price tag. But for those critical applications where speed and accuracy are completely non-negotiable, servo drives are the only way to go.

Where You See VSDs in Action

Variable speed drives are the unsung heroes of the modern industrial world. They work quietly behind the scenes, making countless systems more efficient, reliable, and precise. Once you know what to look for, you’ll start seeing their impact everywhere—from the building you work in to the products you use every day.

Think of them as the invisible force optimizing the complex systems we often take for granted. By providing intelligent motor control, a VSD can solve nagging operational headaches and unlock serious savings in ways that old-school, fixed-speed methods never could.

Optimizing Commercial and Municipal Systems

Take a large commercial skyscraper. The heating, ventilation, and air conditioning (HVAC) system is a massive energy hog. A VSD installed on the building's fans and pumps can adjust airflow and water circulation in real-time based on occupancy and the temperature outside. This simple change can prevent millions in wasted energy costs every year.

It's a similar story in a municipal water treatment plant. VSDs are absolutely essential for managing the pressure in water mains by adjusting pump speeds. This prevents the dangerous pressure spikes that can burst aging pipes, saving cities from costly emergency repairs and service disruptions.

These applications reveal a core principle of using a VSD: matching output to real-time demand. Instead of running a motor at full blast and using a mechanical valve to throttle it down, the VSD simply slows the motor itself—achieving the same result with just a fraction of the energy.

Boosting Precision in Manufacturing

In the world of manufacturing, the precision offered by a variable speed drive is indispensable. Imagine a bottling plant where thousands of bottles fly down conveyor belts. VSDs synchronize the speed of multiple conveyor sections, ensuring a smooth, steady flow and preventing the kind of pile-ups that could shut down production and damage products.

This level of control is what separates a well-run facility from one that's constantly fighting fires. The ability to fine-tune motor speed directly impacts everything from product consistency to operational uptime. To get a better handle on how this all works, you can dig into the fundamentals of AC motor variable speed control and its applications.

Driving a Global Push for Efficiency

The adoption of VSDs isn't just a local trend; it's a worldwide phenomenon, driven by the dual needs of industrial growth and energy conservation. The Asia-Pacific region, for instance, leads the variable speed drive market, capturing about 40.9% of the global share. This growth is fueled by rapid industrialization and government initiatives focused on energy efficiency in countries like China, India, and Japan. You can discover more insights about this global VFD market growth on Precedence Research.

This trend is even pushing into emerging technologies. For example, VSDs are fundamental to the efficient power management required for the growing electrification of medium- and heavy-duty fleets. From skyscraper climate control to advanced manufacturing and logistics, the sheer versatility of the variable speed drive proves its value across nearly every industry shaping our modern lives.

Got Questions About VSDs? We've Got Answers.

When you start digging into Variable Speed Drives, a few key questions always seem to pop up. These are the practical, real-world concerns that can make or break a project. Let's tackle some of the most common ones we hear from the field.

Can I Slap a VSD on Any Old Motor?

Not exactly. While VSDs are the perfect partner for most standard three-phase AC induction motors, they aren't a one-size-fits-all solution. Trying to run a single-phase motor or a specialized synchronous reluctance motor on a standard drive will end in frustration. They need drives built specifically for them.

More importantly, you should always pair your drive with an inverter-duty rated motor. These motors are built tougher, with better insulation to handle the unique electrical stresses a VSD puts out. Skimping on this can lead to fried motor windings and a much shorter service life for your equipment.

When is a VSD Actually a Bad Idea?

Believe it or not, there are times when a VSD is the wrong tool for the job. If your application—say, a simple exhaust fan that always needs to run at maximum—is pegged at 100% speed, 100% of the time, a drive is overkill.

The magic of a VSD is its ability to save energy by matching motor speed to a changing load. If the load never changes, you get no savings. In fact, the drive itself uses a little power, making the system slightly less efficient than just starting the motor across the line.

Another red flag is an extremely dirty or dusty environment. The sensitive electronics inside a VSD can't handle being choked with debris. Without a proper, sealed enclosure, you're just asking for overheating and a premature failure.

Do I Need a Bigger Motor if I'm Using a VFD?

This is a great question, and the answer is often yes—or you need to make other adjustments. Think about it: the cooling fan on most motors is attached directly to the shaft. When you run the motor at a very low speed for a long time, that fan barely spins. It can't move enough air, and the motor starts to heat up.

To get around this, you have a couple of solid options:

- Derate the motor: This just means you oversize it. You might use a 10 HP motor for a 7.5 HP load, giving you plenty of thermal headroom to keep things cool.

- Add a separate blower: You can install a small, independently powered fan that provides constant airflow over the motor, no matter how slowly it's spinning.

Always check the manuals for both the motor and the drive. They'll give you the specific guidance you need to protect your investment and keep your system running safely within its thermal limits.

At E & I Sales, we live and breathe this stuff. If you're looking to boost your system's efficiency and control with the right motor and drive package, our team is here to help spec the perfect VSD and UL control panel for your needs. Contact us today to get started.