A solid state relay, often just called an SSR, is an entirely electronic switch. It lets you control a large, high-power electrical load using just a tiny, low-power signal. Unlike the chunky mechanical relays you might be used to, an SSR has absolutely no moving parts.

It’s best to think of it as a silent, lightning-fast digital switch that works with incredible precision.

Unpacking the Solid State Relay

At its heart, an SSR is the modern answer to a classic engineering problem: how do we switch a circuit on and off more reliably? The solution is in its solid-state design. Instead of a physical contact physically closing, a small electrical signal triggers an internal optical sensor. This, in turn, tells a powerful semiconductor—like a TRIAC or a MOSFET—to let the main power flow through.

This completely contactless design is where all the magic happens. By getting rid of moving components, you eliminate the mechanical wear and tear that inevitably kills traditional electromechanical relays (EMRs). An SSR can perform millions upon millions of cycles without breaking a sweat, giving it a ridiculously long operational life.

From Mechanical Clicks to Silent Switches

You know that audible "clack" an old thermostat or a big industrial contactor makes? That's the sound of metal contacts physically smacking together. An SSR, on the other hand, operates in total silence. This is a huge deal in noise-sensitive places like hospitals or quiet control rooms.

But the silence is just the start. For those of us in industrial settings, this lack of mechanical action brings some serious advantages:

- Extreme Durability: With no physical parts to fatigue or break, SSRs just shrug off shock and vibration. They're perfect for the rugged, unforgiving environment of a manufacturing floor.

- Blazing-Fast Switching: We're talking microseconds. An SSR can turn on and off far faster than any mechanical device could ever hope to. This speed is non-negotiable for applications needing tight control, like PID temperature loops in industrial heaters or high-frequency motor drives.

- Reduced Electrical Noise: The semiconductor switch is designed to turn on and off smoothly, which creates significantly less electromagnetic interference (EMI). That means less noise to potentially disrupt other sensitive electronics packed into your control panel.

An electromechanical relay might last for 100,000 to 500,000 cycles before its mechanical parts finally give out. A solid state relay, when installed correctly, can easily blow past 10 to 50 million cycles. That’s a massive reduction in maintenance headaches and costly downtime.

For any plant engineer or system integrator, getting what a solid state relay is means grasping a fundamental shift from clunky mechanical actuation to clean electronic control. It’s a move toward building more reliable, precise, and long-lasting automated systems.

This table gives a quick rundown of how SSRs stack up against their mechanical cousins.

Quick Look Solid State Relay vs Electromechanical Relay

| Attribute | Solid State Relay (SSR) | Electromechanical Relay (EMR) |

|---|---|---|

| Switching Method | Electronic (Semiconductors) | Mechanical (Moving Contacts) |

| Operational Lifespan | Extremely Long (Millions of Cycles) | Limited (Thousands of Cycles) |

| Switching Speed | Very Fast (Microseconds) | Slower (Milliseconds) |

| Operating Noise | Silent | Audible Click |

| Shock Resistance | High | Low |

As you can see, the differences are stark. Choosing between them comes down to the specific demands of your application—whether you need raw speed and longevity or if a simple, low-cost mechanical switch will do the job.

How a Solid State Relay Works Internally

To really get what a solid state relay is all about, you have to look under the hood. From the outside, it's just a simple switch. Internally, though, an SSR is a sophisticated team of three distinct stages working in perfect sync. Each one has a specific job, passing the signal along to switch a heavy load without a single moving part.

This elegant three-part design is the secret sauce behind the speed, reliability, and sheer durability of SSRs. Let's walk through how a tiny control signal can command a massive industrial motor to life.

The Input Circuit: The Starting Signal

It all starts at the input circuit, which acts as the SSR's "ears." This is where the low-voltage control signal—coming from a PLC, a sensor, or a computer—gets picked up. This circuit is designed to listen for a specific voltage range, like 3-32V DC or 90-280V AC.

Its job is simple but absolutely critical: correctly interpret the incoming signal. When the right voltage hits it, the input circuit kicks the next stage into action. Think of it as the person who answers the phone and immediately routes the call to the right department.

This stage is the first step in the invention that truly marked a shift from older mechanical technology. Solid-state relays were invented in 1971, representing a major leap forward from the clunky mechanical relays that had been around since the 19th century. This new approach eliminated problems like mechanical wear and contact arcing, offering operational lifespans that can exceed 10 million cycles. For anyone in an industrial setting, that’s a massive improvement. You can dig deeper into the history of this technology and its impact on Wikipedia.

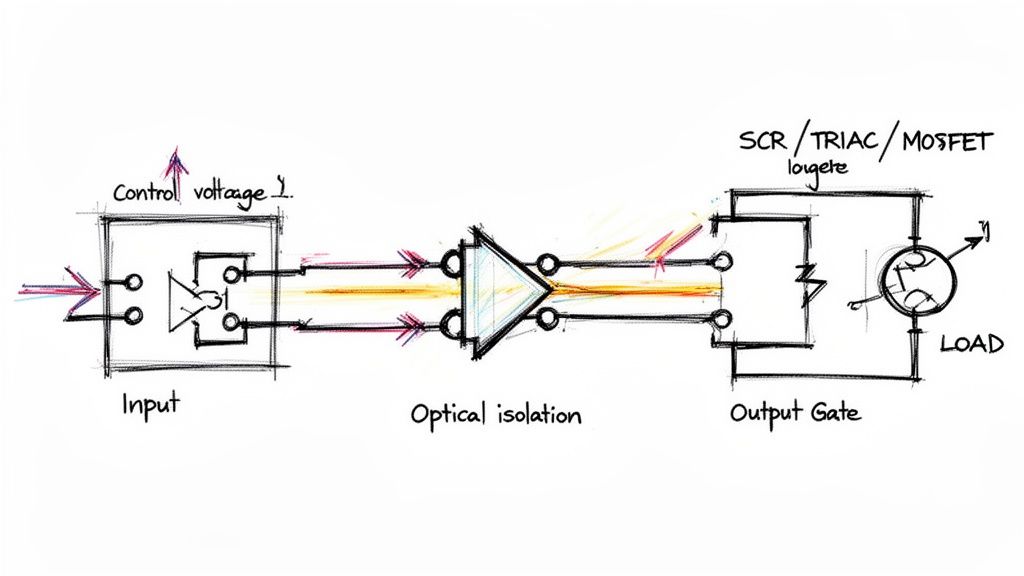

The Isolation Stage: The Protective Light Bridge

Once the input circuit gets a valid signal, it passes the command to the isolation circuit. This is, without a doubt, the most ingenious part of an SSR's design. Its sole purpose is to create a rock-solid barrier between your delicate, low-voltage control electronics and the high-power load circuit.

So, how does it pull this off? Most SSRs use an optocoupler, which is basically a tiny "light bridge."

- The input circuit fires up a small internal LED.

- This LED shoots a beam of infrared light across a tiny, sealed gap.

- On the other side, a photosensitive transistor or photodiode "sees" this light.

- As soon as it detects the light, it triggers the output switching circuit.

This method of using light to send the signal is what provides galvanic isolation. There is zero direct electrical connection between the input and the output. That means a massive voltage spike on the load side can't travel backward and fry your expensive PLC. It’s the ultimate electrical firewall.

This optical separation is a key reason SSRs are so trusted in sensitive control systems. It lets your control logic and high-power equipment live together safely in the same panel.

The Output Circuit: The Electronic Gate

The final handoff happens at the output circuit—the "muscle" of the solid state relay. After getting the "go" signal from the isolation stage, this powerful semiconductor does the actual heavy lifting of switching the load. It acts as a lightning-fast electronic gate.

The type of semiconductor used here depends entirely on whether the SSR is built for AC or DC loads:

- For AC Loads: You'll typically find a TRIAC (Triode for Alternating Current) or a pair of back-to-back SCRs (Silicon-Controlled Rectifiers). These components are champs at managing the back-and-forth nature of AC power.

- For DC Loads: These SSRs use power transistors like MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) or IGBTs (Insulated-Gate Bipolar Transistors), which are built specifically to switch direct current.

When it gets the signal, this semiconductor gate slams shut, allowing current to flow to the load—be it a motor, heater, or bank of lights. When the control signal vanishes, the gate snaps open instantly, cutting off the power. This completely silent, arc-free process is what gives the SSR its incredible speed and longevity.

SSRs vs. Traditional Electromechanical Relays: A Head-to-Head Comparison

Choosing between a solid state relay (SSR) and a classic electromechanical relay (EMR) is a bit like picking between a brand-new electric vehicle and a trusted gas-powered car. Both will get the job done, but how they work, how they perform, and how long they last are worlds apart. For any plant engineer or system integrator, getting this choice right is fundamental to building a control system that's both robust and efficient.

The core difference is simple. An EMR uses a physical, moving contact to make or break a circuit. You can often hear it click. An SSR, on the other hand, does the exact same job silently and electronically, with no moving parts at all. This single distinction is the source of almost every performance advantage that solid state technology brings to the table, especially in demanding industrial environments.

The Lifespan and Reliability Divide

The most glaring difference between the two is their operational lifespan. An electromechanical relay is a mechanical device, plain and simple. It has coils and physical contacts that literally smack together every single time it cycles. All that motion creates wear and tear, which ultimately limits its life.

In stark contrast, an SSR’s solid-state design means there are no parts to wear out. Its lifespan is defined by the incredible endurance of its electronic components, not by mechanical fatigue.

This is a true game-changer in any industrial setting. Solid-state relays can achieve over 10 million switching cycles without breaking a sweat, absolutely dwarfing the 100,000 to 1,000,000 cycles you'd be lucky to get from a typical EMR. For maintenance managers, that translates to 90% less downtime from relay failures. SSRs also don't create the destructive arcing sparks that can slash an EMR's life by up to 80% when switching inductive loads. If you want to dig into the numbers, there are durability assessments out there that detail how SSRs slash total ownership costs over the long haul.

Switching Speed and Electrical Noise

Speed is another arena where there's no contest. An EMR is held back by the physical time it takes for its electromagnet to energize and pull the contact closed—a process we measure in milliseconds. An SSR switches in microseconds.

That incredible speed is vital for applications that demand precise, rapid control, such as:

- PID Temperature Control: Think industrial ovens or plastic molding machines. An SSR can cycle heaters on and off in the blink of an eye to hold a temperature rock-steady.

- High-Frequency Motor Control: For certain specialized applications, that fast response time leads to much smoother and more accurate motor actuation.

- Lighting Dimmers: SSRs switch so quickly that they can dim lights flawlessly without any of the flicker you might see with slower devices.

On top of that, the mechanical "clack" of an EMR creates an electrical arc every time it switches. This generates a burst of electromagnetic interference (EMI)—electrical noise that can play havoc with sensitive electronics in a crowded control panel. SSRs, especially the zero-crossing types, switch cleanly and silently, producing minimal EMI and keeping the electronic environment much more stable.

Key Takeaway: An electromechanical relay works by physically moving a contact, which creates an audible "click," causes wear, and generates electrical noise. A solid state relay switches electronically, resulting in silent, faster, and more reliable operation without the wear-and-tear of moving parts.

Durability in Harsh Environments

Let's face it, industrial plants aren't gentle places. Vibration from heavy machinery, shocks from equipment, and relentless cycling can destroy mechanical components. Because EMRs have moving parts, they are particularly vulnerable to these kinds of environmental beatings.

An SSR is essentially a solid block of potted electronics, making it inherently tough and resistant to shock and vibration. This makes it a far more dependable choice for mounting directly on machinery or in mobile equipment where physical ruggedness is a must.

While both SSRs and EMRs are technically relays, they often live in different parts of a control system, working alongside other components like contactors. To get the full picture, you might find our guide on the difference between a contactor and a relay helpful. It clarifies where each component really shines. In the end, the choice between an SSR and an EMR boils down to the specific needs of your application—balancing the upfront cost against the long-term demand for speed, precision, and maintenance-free operation.

Breaking Down the Different Types of SSRs

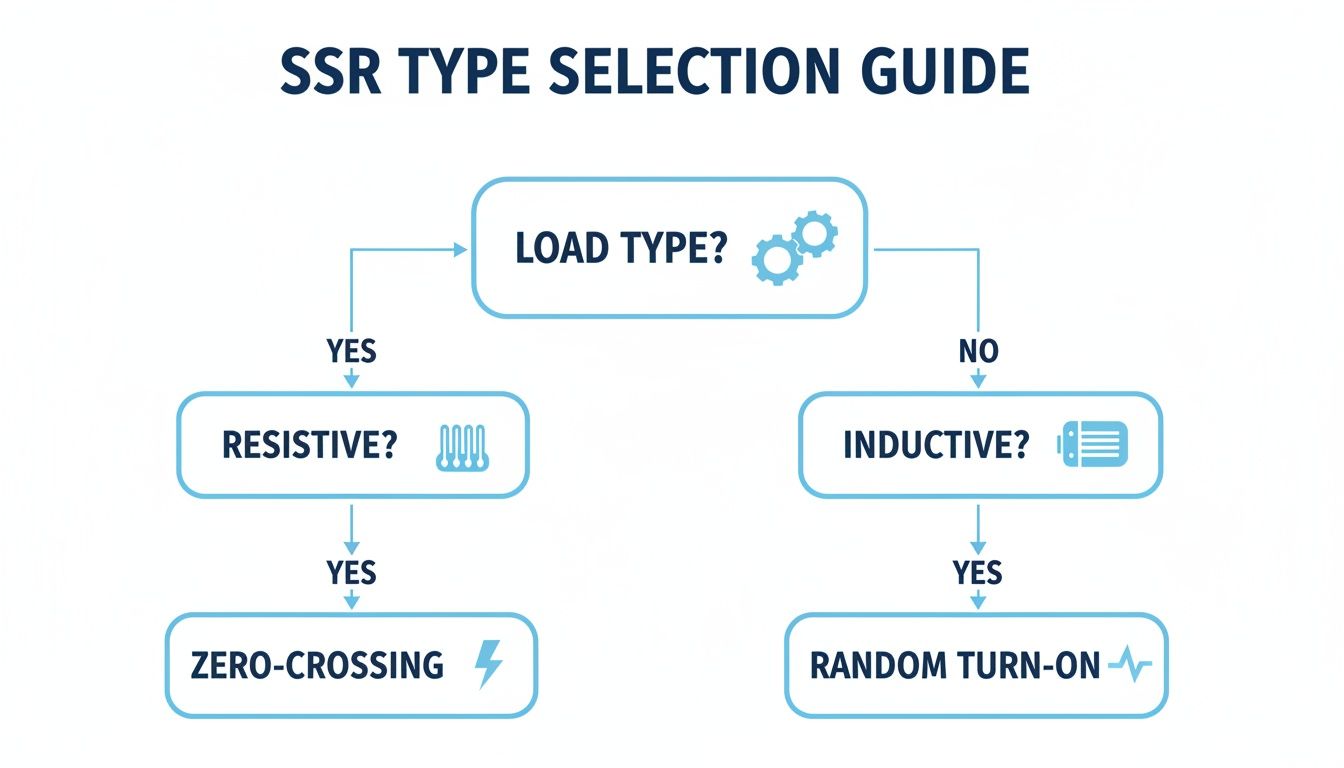

Not all solid state relays are built the same. Just like you wouldn't use a Phillips head screwdriver on a flathead screw, picking the right SSR is absolutely critical for the safety and reliability of your system. The real trick is matching the relay's switching style to the specific electrical load it’s going to control.

To get it right, you first have to understand the main flavors they come in, which are mostly defined by how and when they switch on. The decision you make here will impact everything from electrical noise to how well the relay handles the demands of different loads, whether it's a simple resistive heater or a heavy-duty inductive motor.

Zero-Crossing SSRs: The Quiet Achievers

The Zero-Crossing SSR is your go-to for a huge range of jobs, and for good reason. Its brilliance is in its timing. When you send it a control signal, it doesn't just flip on instantly. Instead, it waits for the perfect moment—when the AC voltage waveform naturally crosses or gets close to zero—before it kicks into action.

This tiny delay, maybe just a few milliseconds, makes a massive difference. By switching when there's virtually no voltage, it dramatically cuts down on the sudden inrush of current and chokes off a major source of electromagnetic interference (EMI). That makes it the ideal choice for powering resistive loads without polluting your electrical environment.

Think of it like smoothly merging onto a busy highway. The Zero-Crossing SSR waits for a natural gap in traffic (the zero-volt point) before pulling out, causing almost no disruption.

You’ll find Zero-Crossing SSRs in applications like:

- Industrial Heaters: Crucial for ovens, plastic molding machines, and packaging equipment where you need clean, precise temperature control.

- Static Lighting Control: Perfect for switching large banks of lights on and off without creating electrical noise that could mess with other sensitive gear.

- Resistive Loads: Any application where the load is basically a big resistor will run better and cleaner with this type of relay.

Random Turn-On SSRs: The Instant Responders

On the other end of the spectrum, you have the Random Turn-On SSR, also called an instantaneous SSR. This one is all about speed. Just as the name implies, it switches the load on the very instant it gets the green light from the control signal, no matter where the AC waveform happens to be.

That immediate response is exactly what you need for applications requiring pinpoint timing, like phase-angle control, where you’re intentionally trying to switch at a specific point in the AC cycle to control power. It's also the relay of choice for highly inductive loads, such as motors and transformers. Trying to switch these kinds of loads at zero voltage can sometimes cause problems, making an instant-on relay the more robust solution.

Here's the bottom line: a Zero-Crossing SSR waits for the safest moment to switch to keep electrical noise to a minimum. A Random Turn-On SSR switches right now, giving you the instant response needed for phase control and certain inductive loads.

AC vs. DC Output SSRs: Speaking Different Electrical Languages

Finally, SSRs are split into two major camps based on the power they switch: Alternating Current (AC) or Direct Current (DC). This isn't a minor detail you can overlook—using the wrong one will lead to a fried component in a hurry.

- AC Output SSRs: These are the most common and are built with powerful semiconductors like TRIACs or back-to-back SCRs. These components are specifically engineered to handle the constant back-and-forth flow of AC power. A key trait is that they naturally turn off when the AC current hits zero. This is exactly why an AC SSR will get stuck in the "on" position if you try to use it on a DC load—the current never crosses zero to shut it off.

- DC Output SSRs: To switch DC power, you need a different set of tools inside. These relays typically use beefy transistors like MOSFETs or IGBTs. These semiconductors are champs at managing the steady, one-way flow of DC current and can turn on and off cleanly without needing a zero-crossing point.

This distinction is completely non-negotiable. Always double-check that the SSR's output rating (AC or DC) matches the load you're connecting it to. An AC relay simply can't switch a DC load, and a DC relay won't last long if you feed it AC power.

How to Select and Install a Solid State Relay

Getting the right solid state relay and installing it correctly is everything. It's the one thing that will determine whether your system runs without a hitch for years or fails prematurely. With old-school electromechanical relays, you worried about moving parts wearing out. For an SSR, its entire life story is written by how well you manage its electrical and thermal environment.

Even a small mistake in selection or a shortcut on installation can lead to a fried relay. So, let's get this right from the start. This is your hands-on guide to the essentials, from making sense of a datasheet to critical tips on heat management and protection.

Decoding the Datasheet for Proper Selection

Think of the datasheet as your blueprint for success. It’s got all the critical specs you need to perfectly match the relay to your application. It might look like a wall of technical jargon at first, but if you focus on a few key parameters, you'll be 90% of the way there.

Here are the non-negotiable specs to nail down first:

- Load Voltage: This is the voltage range the SSR is built to switch. If you're running a 480V AC motor, you need an SSR explicitly rated for it (like a common 48-660V AC model).

- Load Current: This is the maximum continuous current the SSR can safely handle. You absolutely must pick a relay with a current rating higher than your load’s normal operating current. You need that safety margin.

- Control Voltage: This tells you what kind of signal it takes to turn the SSR on. It has to match the output from your PLC or control device, which is often in the 3-32V DC range.

- Surge Current Rating: This one is huge for inductive loads. Motors, for instance, can draw a massive inrush of current the moment they start. The SSR has to survive that momentary punch, so check that its surge rating is well above the motor’s locked rotor amps (LRA).

Pro Tip: Never, ever run a solid state relay at its absolute maximum current rating without factoring in derating. Heat is the big variable here. Always check the datasheet’s derating curve—it shows you exactly how much the maximum load current drops as the ambient temperature climbs.

The Golden Rule of SSR Installation: Thermal Management

If you remember only one thing about installing an SSR, make it this: heat is the enemy. An SSR naturally generates heat as it switches current, a byproduct of its internal resistance. While that's normal, letting that heat build up will absolutely cook the semiconductor components inside.

For any load pulling more than a couple of amps, a heat sink is not optional; it is mandatory. A heat sink is like a radiator for your SSR. It provides a huge surface area to pull heat away from the relay and dump it into the surrounding air, keeping the sensitive internal junction temperature from hitting the danger zone.

Sizing that heat sink correctly is crucial. The goal is to keep the SSR's base plate temperature below the maximum listed on the datasheet, even on the hottest day with your system running at full tilt. As a simple rule of thumb, the higher the load current, the bigger the heat sink you'll need. To see how this fits into the bigger picture, take a look at our guide on industrial control panel design.

This flowchart gives you a quick visual guide for picking the right SSR type for your load.

As you can see, resistive loads like heaters are a perfect match for Zero-Crossing SSRs to keep electrical noise to a minimum. On the other hand, inductive loads like motors often need the immediate response you get from a Random Turn-On SSR.

Best Practices for Wiring and Protection

You've got the right SSR and a proper heat sink. The last piece of the puzzle is a clean, safe installation. Follow these best practices to guarantee both reliability and safety.

- Use Thermal Compound: Always apply a thin, even layer of thermal grease or a thermal pad between the SSR and the heat sink. This stuff fills in microscopic air gaps to ensure the best possible heat transfer. Skimping here is a bad idea.

- Mount it Right: Secure the SSR to the heat sink using the manufacturer’s recommended torque specs. If you over-tighten it, you can warp the SSR's base and create a poor thermal connection. Too loose, and you'll leave air gaps that trap heat.

- Secure Your Wires: Make sure all your wire terminals are crimped properly and tightened to the correct torque. A loose connection is just a hot spot waiting to happen, leading to all sorts of intermittent failures.

- Protect Against Overcurrent: An SSR is a switch, not a bodyguard. It has virtually no ability to withstand a short circuit. You must protect it with a fast-acting fuse or a Type B/C circuit breaker sized for your load. This is your only defense against a catastrophic failure if a fault occurs.

Where SSRs Shine and How to Fix Them When They Don't

Knowing the theory is great, but seeing where a solid state relay actually gets put to work on the plant floor is where its value really clicks. An SSR’s unique strengths—blazing speed, dead-silent operation, and incredible longevity—make it the go-to choice for a ton of industrial jobs where precision and uptime are everything.

SSRs have become the unsung heroes in countless industrial processes. Their ability to switch on and off in the blink of an eye, with no moving parts to wear out, makes them perfect for applications that would grind a mechanical relay into dust in no time.

- Precise Temperature Control: Think industrial ovens, plastic molding machines, and packaging lines. SSRs are the brains behind keeping temperatures locked in. They can pulse heating elements on and off thousands of times a minute, holding a setpoint with a precision an old-school EMR couldn't even dream of.

- High-Frequency Motor Starting: For applications with small motors that start and stop constantly, the smooth, arc-free switching of an SSR is a lifesaver. It dramatically cuts down on electrical stress and helps the motor last longer.

- Silent Lighting Control: In theaters, commercial buildings, or any spot where noise is a problem, SSRs are perfect for managing big lighting arrays. You get all the control without the constant clack-clack-clack of mechanical contactors kicking in.

A Practical Guide to Troubleshooting

Even with their rock-solid reliability, SSRs can hit a snag now and then. The culprit is almost always an external issue, like a wiring mistake or an electrical gremlin in the system. Knowing how to spot the signs can save you a world of downtime.

A multimeter is your best friend for diagnosing SSR problems. A few simple voltage checks across the input and output can usually tell you in minutes whether the issue is the control signal, the load, or the relay itself.

Let's walk through the most common headaches and how to fix them. To get a better handle on the bigger picture, it’s worth digging deeper into process control and instrumentation to see how these parts all work together.

1. SSR Won't Turn On

So, you're sending a control signal, but the load isn't doing anything. First, grab your meter and check the basics. Is the right control voltage (like 24V DC) actually hitting the SSR's input terminals? If you have a good signal but the output is still open, the relay might have failed internally. Don't forget to check for a broken wire or open connection in the load circuit, too.

2. SSR Is Stuck On

If the load stays powered up even when you kill the control signal, the SSR has likely failed in a short-circuited state. This is almost always the result of a massive overcurrent event or a big voltage spike that fried the internal semiconductor. A shorted SSR has to be replaced, no question. But more importantly, you need to find out why it failed—like a shorted motor winding—or the new one will suffer the same fate.

3. The SSR Is Overheating

Heat is the #1 killer of solid state relays. If the relay's case is too hot to comfortably touch, you've got a thermal management problem, guaranteed. This will cause intermittent failures at first and, eventually, a total burnout. The fix is to make sure it’s mounted on a correctly sized heat sink with a good layer of thermal paste and has plenty of airflow to keep it cool.

SSR FAQs: Your Questions Answered

Let's dig into some of the most common questions we hear from engineers and techs out in the field. These are the practical, real-world concerns that pop up when you're working with solid state relay technology.

Do Solid State Relays Wear Out?

This is a great question. Unlike their mechanical cousins with clanking armatures, SSRs don't "wear out" from switching. They have absolutely no moving parts, so there's no physical fatigue. Their lifespan is really about the endurance of the internal electronic components.

So, what does cause them to fail? It's almost always external stress, not old age. The two biggest culprits are heat damage from poor thermal management and electrical damage from a big power surge.

If you select the right relay for the load, pair it with a properly sized heat sink, and protect it from overvoltage, an SSR can easily hit tens of millions of cycles. It’ll likely outlast the machine it's installed in.

Why Is a Heat Sink So Important for an SSR?

Every SSR generates a small amount of heat during normal operation—it’s just a byproduct of the tiny bit of internal electrical resistance. That trickle of heat doesn't seem like much, but it becomes a serious problem when you start switching high currents.

Without a heat sink to pull that thermal energy away, the SSR's internal temperature can skyrocket. It doesn't take long for that kind of heat to cook the delicate semiconductor components inside, leading to a sudden, catastrophic failure.

Think of the heat sink as the SSR's radiator. It's absolutely essential for keeping the relay within its safe operating temperature range, and that’s the single biggest factor in ensuring a long, reliable service life.

Can I Use an AC Solid State Relay for a DC Load?

Short answer: No, absolutely not. It’s a common mistake, but one that will leave you with a relay that won't turn off.

Here's why. The internal components in a standard AC SSR—usually TRIACs or SCRs—are designed to turn off when the AC voltage waveform crosses zero. That little dip to zero volts is what allows the switch to open.

But DC voltage is a flat, constant line. It never crosses zero. Once you trigger an AC SSR with a DC load, it latches on and stays on, permanently. For DC switching, you have to use a dedicated DC solid state relay, which is built with components like MOSFETs that are designed to handle that steady current.

For expert guidance in selecting the right components for your next project, from motor control centers to complete automation systems, trust the team at E & I Sales. Find out how we can help at https://eandisales.com.