Ever tried to start a high-powered electric motor by just flipping a switch? It's a bit like trying to stop a freight train with a fishing net. You're going to have a bad time. That's where a motor starter comes in—it’s the muscle and the brains behind safely starting and stopping your most critical machinery.

Think of it less like a simple on/off switch and more like an intelligent gatekeeper for your motor.

What Does a Motor Starter Actually Do?

At its heart, a motor starter is the crucial intermediary between your facility's power supply and the motor itself. If you were to connect a big industrial motor directly to the line, the result would be a massive, uncontrolled surge of electricity known as inrush current.

This isn't a small jolt. We're talking about a power draw that can spike to six to eight times the motor's normal running current. That kind of surge can trip breakers across your entire facility, cause voltage sags that mess with other sensitive equipment, and put incredible mechanical stress on the motor's shafts, bearings, and windings.

A motor starter tames that chaos. It makes the whole process smooth, safe, and reliable, which is why you'll find one on just about every significant motor in an industrial plant.

The Three Critical Jobs of a Motor Starter

A starter isn't just a one-trick pony; it juggles three vital tasks that a simple breaker can't touch. These functions are the real reason they're a cornerstone of motor control. Let's break down exactly what a motor starter brings to the table.

Core Functions of a Motor Starter at a Glance

| Function | Description | Why It Matters |

|---|---|---|

| Safe Start/Stop Control | Provides a controlled method to energize and de-energize the motor, often via remote pushbuttons. | It prevents abrupt, jarring starts and allows operators to control heavy machinery from a safe distance. |

| Overload Protection | Continuously monitors the motor's current draw and trips if it pulls too much power for too long. | This is the motor's lifeline. It prevents overheating and burnout, saving you from costly motor replacements and downtime. |

| Advanced Operations | Enables functions like reversing motor direction, and in advanced units, controls acceleration and speed. | Adds a layer of process control and flexibility that a basic switch can't offer, adapting the motor's performance to the job at hand. |

Understanding these three pillars makes it clear why a starter is so much more than a switch—it’s a comprehensive control and protection system wrapped into one device.

So, Why Is It a Must-Have?

Simply put, running an industrial motor without a starter is asking for trouble. You'd be dealing with constant electrical issues, frequent equipment failures, and a whole lot of unplanned downtime.

The starter is the component that prevents catastrophic motor burnout, keeps your plant's electrical system stable, and ensures your machinery operates predictably every single time. It's one of those foundational essential industrial equipment parts that forms the backbone of reliable operations. In the end, the starter is what turns raw, untamed power into productive, controlled work.

A Look Inside the Box: The Key Components of a Motor Starter

A motor starter might just look like another gray box on the wall, but pop the cover, and you'll find a team of specialized components working in concert to wrangle some serious electrical power. Once you know what these parts do, the starter stops being a mystery and becomes a logical, effective system. Think of it like looking under the hood of a car—every part has a specific and critical job to do.

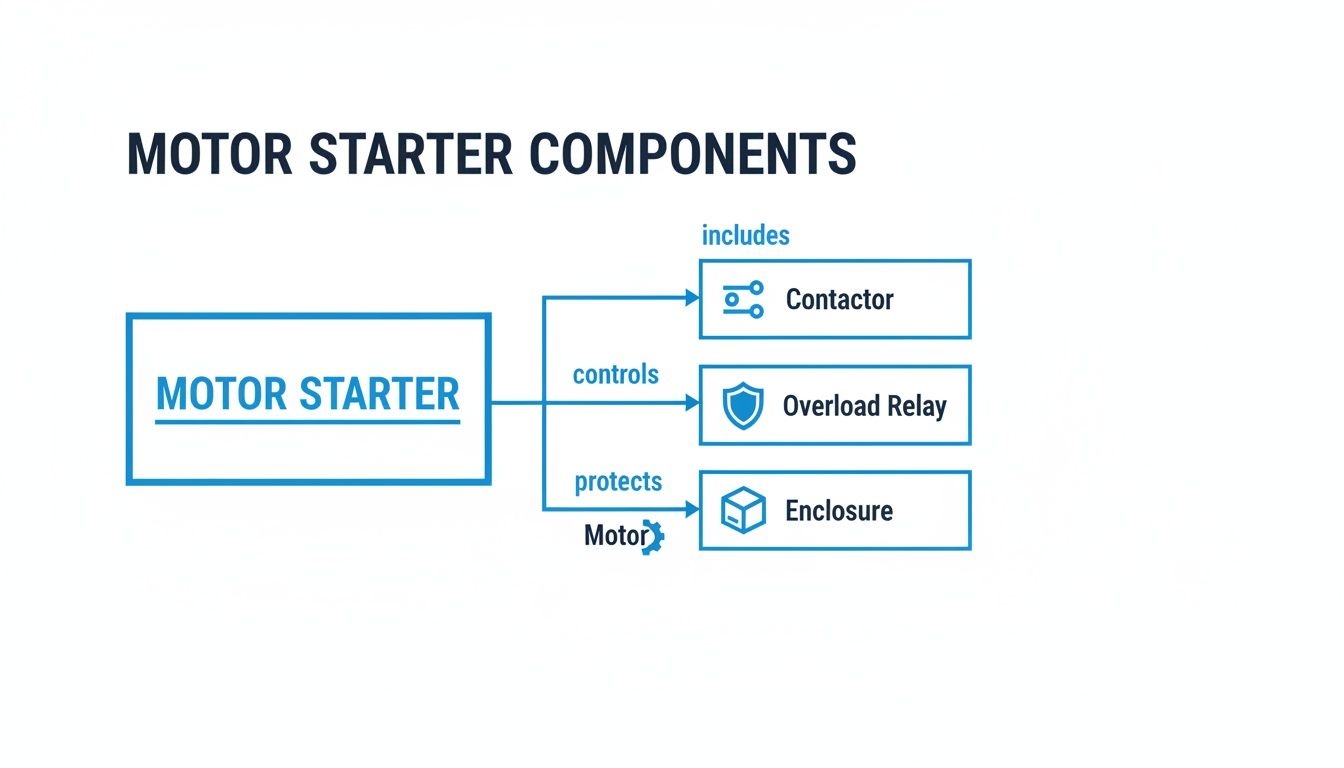

At the heart of it all, you have two main players: the contactor and the overload relay. This duo is the core of the starter, handling both the control and the protection. Everything else in that enclosure is there to support them in their mission to safely manage your motor.

The Contactor: The Heavy-Duty Switch

Ever tried to power a massive industrial fan with a standard light switch? You’d get a spectacular pop, a bit of smoke, and a melted switch. That’s because a regular switch just can't handle the massive inrush of electricity. That's exactly where the contactor steps in. It's a beefy, heavy-duty switch built specifically to handle the high currents motors need to get going and stay running.

When an operator hits the "start" button, a small control signal energizes an electromagnetic coil inside the contactor. This creates a powerful magnetic field that slams a set of large electrical contacts shut, completing the high-power circuit and sending the juice to the motor.

- Function: To safely connect and disconnect the motor from its main power source.

- Mechanism: It uses a small electromagnetic coil to open and close a set of much larger, high-power contacts.

- Analogy: It’s the bouncer at a nightclub door. It only opens the door for the huge crowd (the current) when the manager (the operator) gives the signal.

When the "stop" button is pushed, the coil loses its power, the magnetic field collapses, and heavy-duty springs instantly snap the contacts apart, cutting power to the motor safely and decisively.

The Overload Relay: The Motor's Bodyguard

If the contactor provides the muscle, the overload relay is the vigilant bodyguard. Its entire purpose is to protect the motor from its greatest enemy: too much current over time. A motor that draws excessive current starts to overheat, which will quickly cook the insulation on its internal windings and lead to a complete, and often catastrophic, failure.

An overload isn't a dead short—it's more of a slow burn. It's a sustained period of high current draw, often caused by something like a mechanical jam, failing bearings, or even low supply voltage. The overload relay is always watching, constantly monitoring the current flowing to the motor. If it sees a dangerously high level for too long, it "trips."

Here's the key part: The overload relay doesn't actually cut the main power to the motor itself. Instead, it opens a tiny contact in the control circuit, which kills power to the contactor's coil. The contactor then does the heavy lifting, opening its main contacts and shutting down the motor. This indirect action is a brilliant and fundamental safety feature.

This protective role is so vital that a contactor without an overload relay isn't a motor starter at all—it's just a simple switch. To really get into the weeds on this, check out our guide on the fundamentals of the protection of motors to see how all these pieces fit into the bigger picture of motor longevity.

Types of Overload Relays

Overload relays generally come in two flavors, each using a different trick to spot an overcurrent.

- Thermal Overload Relays: These are the old-school, tried-and-true workhorses. They use a bimetallic strip that heats up as current flows through it. If too much current flows for too long, the strip gets hot, bends, and physically trips a switch that interrupts the control circuit. They’re simple, tough, and get the job done without breaking the bank.

- Electronic (Solid-State) Overload Relays: The modern approach. These relays use current transformers for hyper-accurate current measurement. They give you a much wider range of settings, faster trip times, and can even include extra features like phase loss detection. They're the go-to choice for protecting more expensive motors or for applications where downtime is not an option.

The Supporting Cast

Beyond the big two, a few other components play essential supporting roles inside the starter enclosure.

- Control Transformer: The motor itself might be running on 480V, but the control circuit with the pushbuttons and contactor coil often uses a much safer, lower voltage like 120V or 24V. A control transformer is there to step down the main voltage to power these components safely.

- Pilot Lights and Pushbuttons: This is how humans interact with the machine. Green and red lights (pilot lights) give you a clear visual on the motor's status (running or stopped). Pushbuttons provide the simple start, stop, and sometimes jog or reverse commands.

- Enclosure: This is the steel box that keeps all the important stuff inside safe from the outside world—whether that’s dust in a woodshop or corrosive wash-downs in a food processing plant.

Put them all together, and you have a seamless system that delivers both precise control and rock-solid protection, keeping your motors running safely and reliably, day in and day out.

Comparing the Different Types of Motor Starters

Picking the right motor starter is a lot like choosing the right tool for the job. You wouldn't use a sledgehammer to tap in a finishing nail, right? In the same way, the simple starter that's perfect for a small workshop grinder is completely wrong for a massive industrial pump.

Each type of starter strikes a different balance between cost, complexity, and control. Getting this choice right is fundamental to protecting your equipment, keeping things running efficiently, and staying on budget. Let’s break down the main categories, starting with the most basic and working our way up.

The Foundational Choice: Across-the-Line Starters

The Across-the-Line (ATL) starter is the most straightforward and common type you'll find. It's often called a Direct-On-Line (DOL) starter, and you can think of it as a heavy-duty light switch. When you hit the "start" button, it slams the motor with full line voltage, instantly delivering 100% of its starting torque.

This direct approach is both its greatest strength and its biggest weakness. For smaller motors—usually under 10 horsepower—it's simple, cheap, and incredibly reliable. But that massive jolt of power draws an inrush current that can be six to eight times the motor's normal running current. On a big motor, that surge can cause voltage to sag across your entire facility and puts brutal mechanical stress on couplings, belts, and gearboxes.

Stepping Up: Reduced-Voltage Starters

When the electrical and mechanical shock from an ATL starter is just too much to handle, a Reduced-Voltage Starter is the next logical step up. The whole idea is to soften the blow by starting the motor with less voltage and then switching to full power once it gets spinning.

One of the most common ways to do this is with a Star-Delta (or Wye-Delta) starter.

- How It Works: This is a clever trick of temporarily rewiring the motor's internal connections. During startup, it uses a "star" (or wye) configuration, which drops the voltage across each winding to about 58% of the full line voltage.

- The Result: This simple change slashes both the starting current and torque down to about one-third of what a direct start would produce. Once the motor is up to speed, a timer flips the connections over to the standard "delta" configuration for full-power operation.

It’s a cost-effective way to get a smoother start for medium-sized motors, making it a popular choice where you need to reduce the initial jolt but don't need pinpoint control.

This diagram shows the core components that make these electromechanical starters tick.

As you can see, the contactor and overload relay do all the heavy lifting, all packaged safely inside an enclosure.

The Modern Era: Solid-State Soft Starters

Now we're getting into electronic control with the Solid-State Soft Starter. Unlike the clunky, stepped approach of a Star-Delta, a soft starter gives you a perfectly smooth, linear ramp-up of voltage. It uses electronics called SCRs to precisely "chop" the AC waveform, gradually feeding more power to the motor over a time you can set.

A soft starter is like gently pressing the accelerator in a car instead of stomping on it. The result is an exceptionally smooth, jolt-free start that minimizes both electrical and mechanical stress on the entire system.

This controlled acceleration is perfect for things like conveyor belts, where a sudden start would send products flying, or in pumping systems, where it eliminates the damaging "water hammer" effect. Many soft starters also include a soft stop, ramping the voltage down for an equally smooth shutdown.

The Ultimate Solution: Variable Frequency Drives

At the very top of the performance pyramid is the Variable Frequency Drive (VFD), sometimes called an inverter. A VFD isn't just a starter; it’s a complete motor control system. It takes the incoming AC power, converts it to DC, and then uses that to build a brand new AC output where both the voltage and frequency are completely adjustable.

By controlling the frequency, a VFD gives you precise control over the motor's speed at all times. This is an absolute game-changer for countless industrial processes.

- Total Control: You can set exact acceleration and deceleration ramps, control torque, and change the motor's running speed on the fly.

- Energy Savings: For equipment with variable loads, like fans and pumps, a VFD can slash energy bills. By matching motor speed to the actual demand, the savings are huge. Slowing a fan by just 20% can cut its energy use by nearly 50%.

- Advanced Functionality: VFDs handle reversing, dynamic braking, and provide a ton of diagnostic feedback, making them the most versatile and powerful motor control solution out there.

While they cost more upfront, the gains in process control and energy efficiency often deliver a quick return on that investment, making them the gold standard for motor control.

Comparison of Motor Starter Technologies

To make the choice clearer, it helps to see these technologies compared side-by-side. Each has a distinct role, and what’s best really depends on the application's demands for control, protection, and efficiency.

| Feature | Across-the-Line Starter | Soft Starter | Variable Frequency Drive (VFD) |

|---|---|---|---|

| Starting Method | Full voltage, instantaneous | Gradual voltage ramp-up | Full control of both frequency and voltage |

| Starting Current | Very high (6-8x full load amps) | Reduced (1.5-4x full load amps) | Fully adjustable, typically limited to 1.5x full load amps |

| Mechanical Stress | High | Low | Very low |

| Speed Control | None | None (only controls start/stop) | Full and precise speed control during operation |

| Energy Savings | None | Minimal (only during startup) | Significant, especially on variable-torque loads (fans, pumps) |

| Complexity & Cost | Low cost, simple | Moderate cost and complexity | Highest cost and complexity |

| Best For | Small motors (<10 HP), applications where high torque is needed instantly | Conveyors, pumps, fans, and any application where a smooth start is critical | Applications requiring precise speed control, and maximum energy efficiency |

Ultimately, the journey from a simple ATL starter to a sophisticated VFD reflects the evolution of industrial control. Knowing where your application fits on this spectrum is the first step toward a more reliable and efficient operation.

How to Correctly Select and Size a Motor Starter

Choosing the right motor starter isn’t about guesswork. It’s a methodical process, and getting it wrong can be costly. A mismatched starter is a direct path to nuisance tripping, premature equipment failure, and some serious safety hazards.

Think of it like picking a circuit breaker for your house. Too small, and it trips all the time. Too big, and it fails to protect your wiring from a potential fire. The same logic applies here, just with much higher stakes in an industrial setting.

The whole process starts with one single source of truth: the motor’s nameplate. That little metal plate has every critical piece of data you need to make the right call.

Decoding the Motor Nameplate

Your journey to finding the perfect starter begins by grabbing three key details right off the motor you’re working with. These are the non-negotiables that will steer every decision you make from here on out.

- Horsepower (HP): This is the classic measure of a motor's power. Most starter selection charts are organized by horsepower, making it your first point of reference.

- Full Load Amps (FLA): This number tells you the maximum current the motor will draw when it's working at its rated load. The overload relay inside the starter has to be set based on this value for proper protection.

- Service Factor (SF): Usually a number like 1.15 or 1.25, the service factor tells you how much of an overload the motor can handle for short bursts without being damaged. For example, a 10 HP motor with a 1.15 SF can safely run at 11.5 HP for a limited time. This is absolutely critical for sizing your overload protection correctly.

Without these three values, you’re basically flying blind.

Navigating Sizing Standards

Once you have your motor data, it's time to match it to a starter using one of the industry's sizing systems. In North America, the standard to know is from the National Electrical Manufacturers Association (NEMA). NEMA starters are the tanks of the industry—robust, heavy-duty, and built around a simple sizing chart.

NEMA sizes are designated by numbers (like NEMA Size 0, Size 1, or Size 2), and each one corresponds to a specific horsepower rating at different voltages. For example, a NEMA Size 1 starter is a solid choice for a 10 HP motor running on 480V. It's a straightforward system that makes selection pretty easy. You can use a detailed NEMA motor starter sizing chart to break down the ratings by voltage and motor size.

Properly selecting and sizing a motor starter is a critical step in mitigating potential electrical and mechanical hazards, forming a key part of any comprehensive risk assessment process. Understanding these standards is fundamental to building a safe and compliant system. For a broader look at this topic, you can review guidelines on conducting a thorough risk assessment process.

The other major player is the International Electrotechnical Commission (IEC). IEC starters are generally more compact and budget-friendly, and they offer more specific sizing options. The trade-off? They’re less forgiving of overloads compared to their NEMA cousins, so you need to be much more precise with your selection.

Choosing the Right Enclosure

The final piece of the puzzle is the enclosure. You have to shield the starter’s guts from its operating environment to keep it running safely and for a long time. NEMA has a clear rating system for enclosures that tells you exactly what kind of protection you're getting.

Here are a few of the most common ones you'll run into:

- NEMA 1: This is your basic, general-purpose indoor enclosure for clean, dry locations. It keeps fingers out but won't do much against dust or water.

- NEMA 3R: Built for the outdoors, this enclosure protects against rain, sleet, and snow.

- NEMA 4X: When you need serious protection, this is it. It’s watertight, dust-tight, and corrosion-resistant, making it the go-to for washdown areas in food plants or salty marine air.

- NEMA 12: Designed for indoor industrial environments, it protects against things like circulating dust, falling dirt, and non-corrosive drips.

By carefully matching your motor data, the right sizing standard, and the correct enclosure, you can be confident your motor starter will perform safely and reliably for years.

Wiring Fundamentals and Real-World Applications

Knowing the parts of a motor starter is one thing, but seeing how they come together in the real world is where it all starts to make sense. A motor starter isn't just some box of electrical parts; it's the heart of countless machines, from the pump filling a city's water tower to the conveyor zipping packages across a warehouse floor.

The starter you choose has a direct impact on the machine's performance, how long it lasts, and how safe it is to operate. Every application throws a different curveball, and you need the right kind of control to knock it out of the park.

Where You'll Find Motor Starters

Different machines have wildly different needs. A sudden, high-torque start might be exactly what a rock crusher needs, but it would be catastrophic for a delicate pumping system. This is why you can't just pick any starter off the shelf.

Here are a few common places you'll see them and why a specific type gets the job:

- Pumps: A soft starter is the go-to choice here. Slamming a pump on at full speed can cause "water hammer"—a destructive pressure spike that rattles pipes and can cause serious damage. A soft starter gently ramps up the motor, avoiding that mechanical shock and making the whole plumbing system last longer.

- Fans and Blowers: For a simple exhaust fan, a basic across-the-line starter usually does the trick. But if you need to vary the airflow, a VFD is the way to go. It gives you pinpoint speed control and can lead to massive energy savings.

- Conveyors: Just like with pumps, conveyors love a smooth start. A soft starter prevents products from lurching forward, falling over, or getting damaged. It gets the belt moving with a gentle, controlled acceleration.

- Compressors: These often need a huge kick of torque to get going against the pressure already in the system. In these situations, a direct-on-line (DOL) starter delivers that instant jolt of power to get the compressor up and running fast.

Cracking the Code on the Wiring

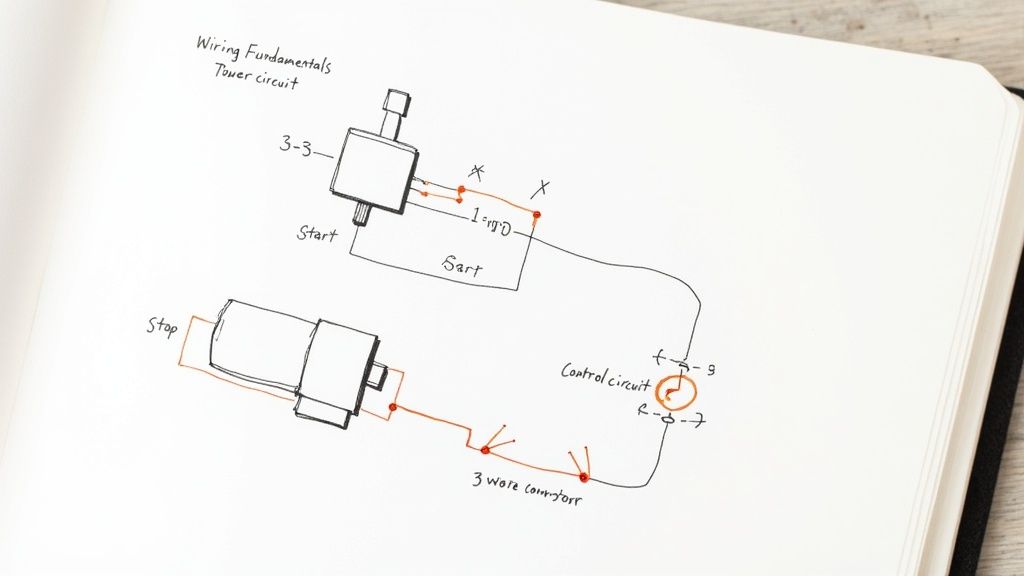

At first glance, the wiring inside a starter can look like a bowl of spaghetti. But it’s all built on a brilliantly simple idea: keep the high-power "muscle" separate from the low-power "brains." Every starter has two circuits that work in tandem.

1. The Power Circuit: This is the heavy-hitter. We're talking thick, heavy-gauge wires carrying the full motor current—often 480 volts or more. This circuit runs from the main power source, through the beefy contacts in the contactor, and straight to the motor. It’s the part that does all the real work.

2. The Control Circuit: This is the smart, low-voltage side of the operation. It typically runs on a much safer voltage like 120V AC or 24V DC. This circuit includes the pushbuttons, the coil for the contactor, and the overload relay contacts. Its only job is to tell the power circuit when to turn on and off.

This separation is a core principle of industrial safety and design. It lets an operator safely control a massive, high-horsepower motor with a simple, low-energy pushbutton.

The Simple Genius of 3-Wire Control

One of the most common and vital wiring schemes you'll encounter is called 3-wire control. This setup uses a momentary "start" button and a momentary "stop" button to run the motor, but it has a crucial safety feature built right in: it prevents a machine from restarting by itself after a power outage.

Key Takeaway: With 3-wire control, if the power goes out while a machine is running, it will not automatically fire back up when the power returns. An operator has to physically walk over and press the "start" button again, ensuring the machine only runs when someone is present and ready for it.

This elegant, simple logic is a cornerstone of machine safety in just about every factory and plant. To see how these ideas play out in practice, you can dive into our guide on a three-phase motor wiring diagram. It’s the next step in bridging the gap between knowing what a motor starter is and understanding how to put one to work safely and effectively.

Your Top Motor Starter Questions, Answered

Even after getting the basics down, you're bound to run into specific questions when you're in the thick of a project. Whether you're selecting, installing, or troubleshooting a motor starter, a few common queries always pop up.

This section is a quick-hitter guide for engineers and techs on the floor. We'll cut through the noise and give you direct answers on the differences between similar components, using advanced starters, and what to do when a starter trips. Think of it as a cheat sheet to build on what you already know.

What’s the Real Difference Between a Contactor and a Motor Starter?

This is easily the most common point of confusion, but the distinction is dead simple and absolutely critical for safety. The easiest way to think about it is that a motor starter is a complete system, and a contactor is just one piece of that system.

A contactor is nothing more than a beefed-up switch. Its only job is to open and close a circuit to connect or disconnect the motor from its power source. It gives you control, but it offers zero protection against overcurrents that can fry a motor in seconds.

A motor starter, on the other hand, bundles that same contactor with an overload relay. That overload relay is the brains of the outfit, constantly watching the current flowing to the motor. If it senses a dangerous overload, it trips and signals the contactor to cut the power.

In short: Every motor starter has a contactor inside, but a contactor alone is not a motor starter. A contactor is for control; a motor starter is for control and protection.

Can I Just Use a VFD as a Motor Starter?

Absolutely. In fact, a Variable Frequency Drive (VFD) is the most sophisticated and capable motor starter you can get. It handles all the core functions—starting, stopping, and built-in overload protection—but it does so much more.

While a basic starter just provides on/off control (and a soft starter just manages the voltage ramp-up), a VFD gives you total command over the motor's speed, torque, and even its direction while it's running. It works by fundamentally changing the frequency of the power it sends to the motor.

A VFD is the ultimate soft start, but its real power is unlocked in applications where you need variable speed for process control or massive energy savings. For example, using a VFD to slow down a fan or pump to match real-time demand can slash electricity use by 30-50% or more.

My Motor Starter Tripped. How Do I Reset It?

Hold on. Before you even think about hitting that reset button, remember this: an overload trip isn't a failure. It's the starter doing its job perfectly, saving your expensive motor from burning up. The first step is always to figure out why it tripped.

Look for common culprits like:

- A Mechanical Jam: Is the equipment connected to the motor physically stuck or blocked?

- Bad Bearings: Worn-out bearings in the motor or the load can create huge amounts of friction.

- Voltage Imbalance: Unstable power from the utility can force the motor to draw excess current.

- Sustained Overload: Is the motor simply being asked to do more work than its nameplate rating allows?

Once you've found and fixed the root problem, resetting is usually straightforward. Most overload relays have a prominent reset button, often colored blue or red.

A quick tip: for thermal overloads, you might need to wait a few minutes for the internal bimetallic strip to cool down before it will reset. It's also smart to set the device to "manual reset." This prevents the machine from unexpectedly restarting on its own after an overload, which is a major safety hazard for anyone working on the line.

What Does the “NEMA Size” on a Starter Actually Mean?

NEMA, the National Electrical Manufacturers Association, created a standardized sizing system that’s the go-to standard in North America. This system sorts starters into different "sizes" based on the current and horsepower they can handle at different voltages.

These sizes are numbered, starting from NEMA Size 00 for tiny motors all the way up to NEMA Size 9 for giant industrial equipment. Each size has a maximum horsepower rating. For instance, a NEMA Size 1 starter is generally rated for a 10 HP motor running on 480V.

The biggest advantage of the NEMA system is its sheer toughness and interchangeability. A NEMA Size 1 starter from one brand is built to the same heavy-duty standard as one from another. This makes selection easier and guarantees you're getting a durable workhorse built for demanding environments.

At E & I Sales, we live and breathe motor control. We help engineers and project managers spec the right solutions, from off-the-shelf starters to fully engineered and integrated UL-listed control panels. Our team has the expertise to make sure your systems are safe, efficient, and built to last.

Check out our custom control panel and system integration services to see how we can tackle your next project.