At its core, a disconnect switch is a straightforward, manually operated device designed for one critical purpose: to completely and visibly cut off a circuit from its power source. Think of it as an electrical safety switch. Its entire job is to create a physical "air gap," a clear, undeniable break in the circuit that guarantees electricity cannot flow past it. This makes it an absolute necessity for safe maintenance, repairs, or emergency shutdowns.

The Core Function of a Disconnect Switch

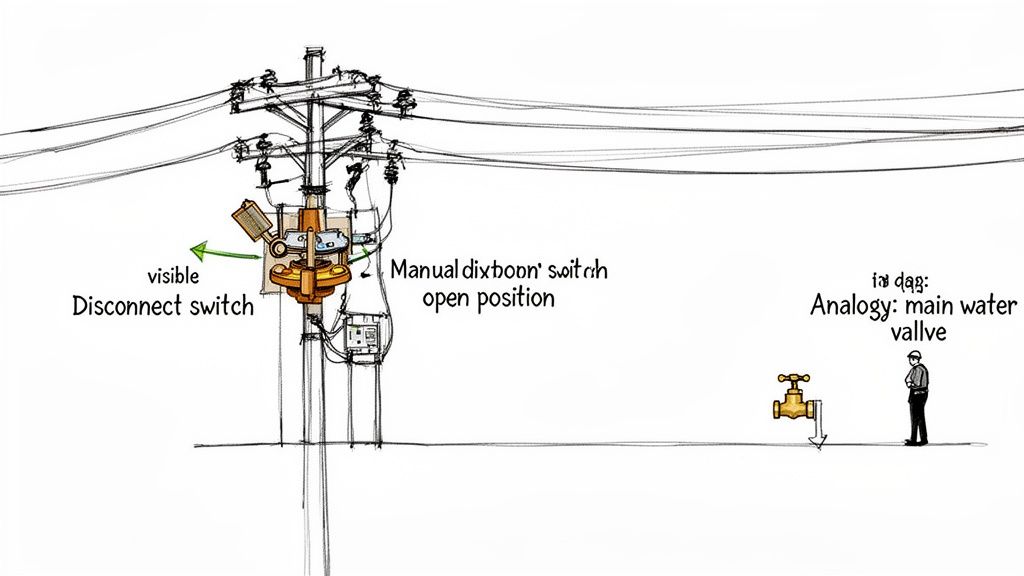

The best way to understand a disconnect switch is to think of it as the main water valve for your house.

When a plumber needs to fix a leaky pipe, they don't just turn off the faucet under the sink. They go straight to the main shutoff valve, closing it to ensure not a single drop of water can reach their work area. A disconnect switch provides that same level of absolute certainty for electricity.

This function isn't just about convenience; it's a cornerstone of electrical safety on the job. The ability to physically lock the switch in the "off" position is the foundation of the Occupational Safety and Health Administration's (OSHA) lockout/tagout (LOTO) procedures. This protocol is what stands between a technician and a machine that could accidentally be re-energized while they're working on it.

Why Visual Isolation Matters

You'll almost always find a disconnect switch installed "within sight" of the equipment it protects, and that’s by design. Unlike a circuit breaker that might be hidden away inside a panel down the hall, the disconnect switch gives a technician an immediate, visual confirmation that the circuit is dead.

That physical separation of contacts is the ultimate safeguard against electrical shock. There's no ambiguity.

A disconnect switch is a critical safety device in electrical systems, designed to physically isolate power circuits during maintenance, emergencies, or repairs, preventing accidents and ensuring worker safety in industrial settings.

Let's quickly summarize the key points in a table.

Disconnect Switch at a Glance

| Key Aspect | Description |

|---|---|

| Primary Function | To safely and visibly isolate a circuit from its power source. |

| Mechanism | Creates a physical "air gap" in the circuit, preventing electrical flow. |

| Core Benefit | Ensures worker safety during maintenance and repairs. |

| Key Application | A critical component of Lockout/Tagout (LOTO) safety procedures. |

| Typical Installation | Placed "in-sight" of the equipment it controls for visual verification. |

This at-a-glance view highlights just how fundamental these devices are in any robust electrical system.

Indispensable in Industrial Settings

For any company involved with motor control centers and UL-listed panels, disconnect switches are non-negotiable. They are essential for building reliable and code-compliant power distribution systems in manufacturing plants, automation projects, and beyond.

They act as the first line of defense, providing a secure way to isolate everything from a single motor to an entire production line. To get a better sense of what's driving the demand for these devices, you can explore detailed industry reports on the market.

A Look at the Main Types of Disconnect Switches

Not all disconnect switches are built the same; picking the right one is all about the job at hand. If you want to guarantee safety and keep your equipment running smoothly, you need to know the basic types. The biggest fork in the road is whether the switch provides its own overcurrent protection.

This single difference splits them into two major camps: fused and non-fused.

Fused vs. Non-Fused Switches

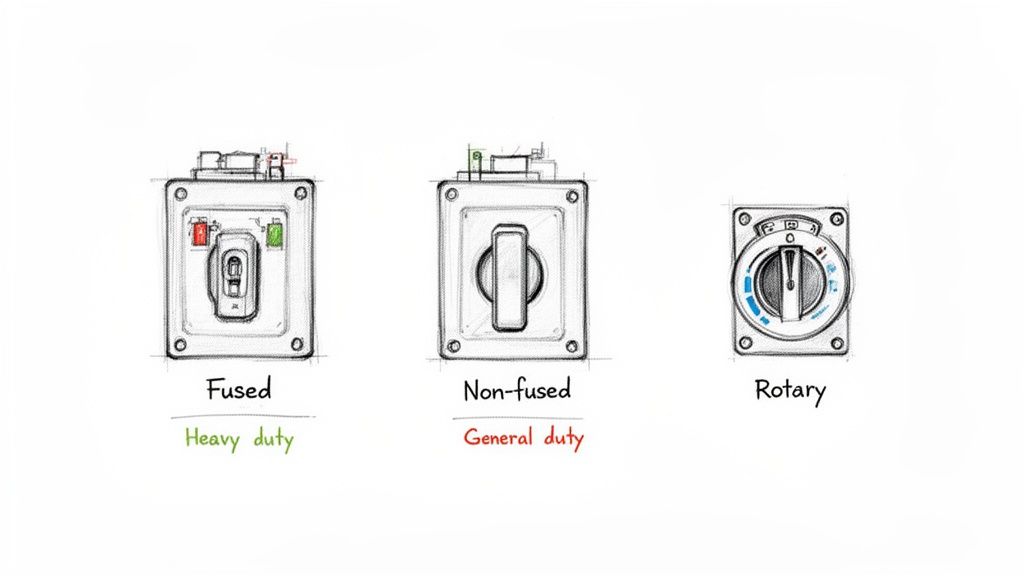

Think of a fused disconnect switch as a device wearing two hats. It’s both a manual "off" switch and a bodyguard for your circuit. Inside, it holds fuses that will blow and cut the power automatically if the current spikes to a dangerous level, saving an expensive motor or piece of machinery from getting fried.

A non-fused disconnect switch, on the other hand, has just one job: to isolate power. It's a purist. It offers zero overcurrent protection on its own, so it's only used in circuits where a circuit breaker or another device upstream is already handling that responsibility.

In a nutshell, fused switches give you isolation and overcurrent protection in one box, which is why they’re the go-to for motor circuits. Non-fused switches are strictly for cutting power, relying on a separate breaker to do the protecting.

It’s no surprise that fused switches dominate industrial settings. The low-voltage disconnect switch market, which is the backbone of motor control, was valued at $3.2 billion in 2023. The fused industrial slice of that pie is expected to hit $4.6 billion in 2024, which tells you just how critical that built-in protection is for machinery. You can dig into more of the numbers by reviewing these detailed industry findings.

Common Designs and Duty Ratings

Beyond just fused or non-fused, you’ll run into different designs built for specific loads and environments. They’re often separated by a "duty rating," which is just a fancy way of saying how tough they are.

Here are a few of the workhorses you’ll find out in the field:

-

Heavy-Duty Safety Switches

These are the tanks of the disconnect world. Built for the grind of industrial applications, they’re designed for frequent use and can safely handle the high fault currents you see with big motor circuits and heavy machinery. -

General-Duty Safety Switches

Just like the name says, these are for lighter commercial or even residential jobs where the switch won't be thrown every day. They're a more budget-friendly option for things like service entrances or light-duty branch circuits where you don't need an industrial-grade build. -

Rotary Disconnect Switches

These guys are compact, versatile, and often found mounted right on a control panel or machine. A simple turn of the handle opens or closes the contacts. They are perfect for providing a local shut-off right where you need it, especially when space is tight. Panel builders love them for their small footprint and modular design.

Choosing between them means looking at what the circuit needs—everything from the electrical load and environmental conditions to the specific safety codes you have to follow.

How Disconnects Differ From Breakers and Contactors

It’s easy to get electrical components mixed up, especially when they all seem to "switch" power in one way or another. One of the most common points of confusion is the difference between a disconnect switch, a circuit breaker, and a contactor.

While they all sit in a circuit and control the flow of electricity, their core jobs are fundamentally different. Trying to substitute one for another is a recipe for an unsafe, unreliable system.

An Everyday Analogy: Your Home's Plumbing

Let's think about it in terms of the water flowing into your house. It's a surprisingly good parallel.

- A contactor is like your kitchen faucet. You turn it on and off constantly throughout the day for a specific task. It’s designed for frequent, routine operation.

- A circuit breaker is the emergency flood-stop valve in your basement. It sits there, doing nothing, until a pipe bursts. When it detects that sudden, dangerous rush of water, it snaps shut automatically to prevent a catastrophe.

- The disconnect switch is the main water shutoff valve out by the street. A utility worker has to come out, turn it with a special tool, and lock it in the "off" position to guarantee no water can enter the house during major repairs. It’s a deliberate, manual safety action.

Unpacking the Core Functional Differences

The real distinction boils down to manual vs. automatic and safety vs. operational control.

A disconnect switch is a purely manual device, built for one thing: absolute safety isolation. When you throw that handle, you are physically creating a visible air gap in the circuit. There’s no ambiguity. It’s a guarantee that the circuit is de-energized so someone can safely perform maintenance. Its purpose is entirely focused on protecting people.

A circuit breaker, on the other hand, is an automatic safety device. It’s always on watch, monitoring the circuit for overloads and short circuits. The moment it detects a dangerous fault condition, it "trips" on its own to cut the power and protect the equipment from burning up. While you can often operate a breaker manually, its primary job is automatic protection.

Contactors play a completely different role. They are electrically operated switches, designed to be turned on and off frequently by a remote signal. A small control voltage energizes a coil, which pulls the main contacts closed to power up a motor or heater. They're all about operational convenience, not providing a positive, lockable point of isolation for safety.

The key takeaway is simple: Disconnects are for manual safety isolation, breakers are for automatic equipment protection, and contactors are for operational remote control. Each plays a distinct and non-interchangeable role.

To make this crystal clear, let's put them head-to-head.

Disconnect Switch vs Circuit Breaker vs Contactor

This table breaks down the essential differences at a glance, highlighting why you need the right component for the right job.

| Component | Primary Function | Operation | Typical Application |

|---|---|---|---|

| Disconnect Switch | Safety Isolation | Manual (handle-operated) | De-energizing equipment for Lockout/Tagout (LOTO) |

| Circuit Breaker | Overcurrent Protection | Automatic (trips on fault) | Protecting circuits from overloads and short circuits |

| Contactor | Operational Control | Remote (electrically controlled) | Frequently starting and stopping motors |

Understanding these distinct roles is the cornerstone of designing safe and compliant electrical systems. While a device like an ABB circuit breaker is a critical protective device, it simply cannot provide the same guaranteed, visible, and lockable isolation that a true disconnect switch offers. Using the right tool for the job isn't just a best practice—it's essential for a safe and reliable installation.

Where You'll Find Disconnect Switches in the Real World

Let's move from the textbook definitions to the factory floor. Disconnect switches aren't just a good idea; they're the non-negotiable heroes of nearly every industrial setting, crucial for both safety and keeping operations running smoothly.

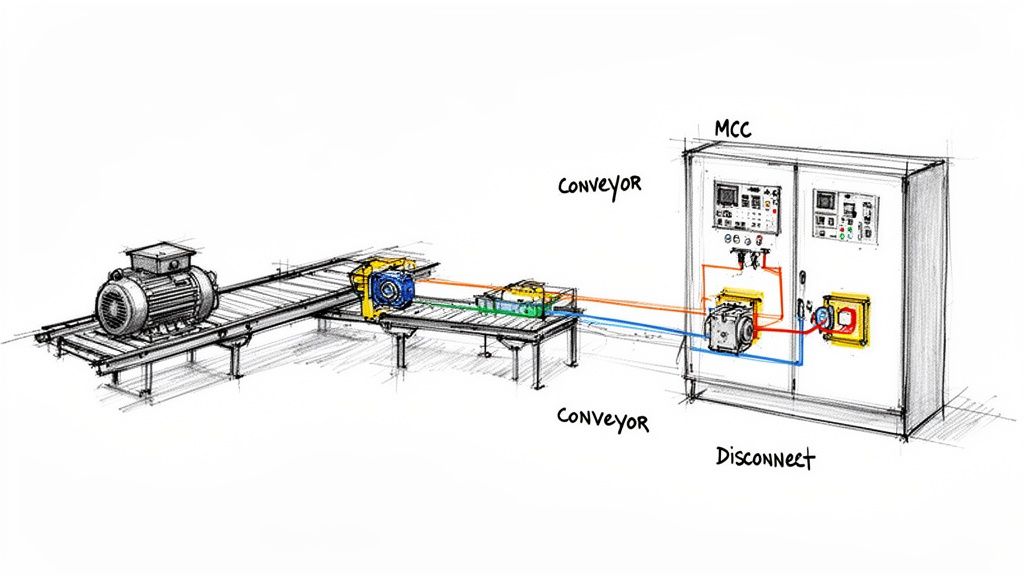

Picture a massive manufacturing plant with conveyor belts, pumps, and mixers all humming along, powered by hundreds of electric motors. What happens when one motor on a critical production line needs a new bearing? You can't just shut down the entire facility. That would be a logistical and financial nightmare.

This is exactly where the disconnect switch proves its worth.

By placing a disconnect right at the motor, a technician can walk up, throw the handle, and completely isolate that single piece of equipment. This local cutoff point guarantees the machine is de-energized, making it safe for repairs while the rest of the plant keeps on producing.

Critical Roles Across the Plant

Once you know what to look for, you'll start seeing disconnect switches everywhere in a factory. Their presence is the sign of a thoughtfully designed and safe electrical system.

Here are some of the most common spots you'll find them:

- Motor Control Centers (MCCs): These are the command centers for a plant's motors. Each motor "bucket" or unit inside the MCC gets its own disconnect, letting you safely work on one motor circuit without affecting the others.

- Main Machinery Power: Every major piece of equipment—from a CNC mill to a giant hydraulic press—needs a main disconnect. This is the master "off" switch for the whole machine, absolutely essential for setup, maintenance, or hitting the brakes in an emergency.

- HVAC and Pumping Systems: Think about the powerful systems running large commercial chillers, air handlers, and water pumps. Electrical code often requires a disconnect to be installed "within sight" of this equipment so a technician can kill the power right before putting their hands on it.

- UL-Listed Control Panels: For a custom control panel to earn a UL 508A listing, it has to provide a way to cut all incoming power. A flange-mounted disconnect handle right on the enclosure door is the industry standard for meeting this requirement safely and effectively.

The market data really drives this point home. The industrial sector accounted for a staggering 43.71% of all disconnect switch sales in 2023. Why? Because industries like manufacturing and power generation rely on them to prevent downtime, which can easily cost millions. You can dig into the numbers in this disconnect switch market trends report.

At the end of the day, in any industrial environment, the disconnect switch is the physical barrier between high-voltage power and a human being. Its simple, tough design provides the clear, visible, and lockable power isolation that stops catastrophic accidents and costly shutdowns before they can happen.

Navigating Key Codes and Safety Standards

In the world of industrial power, a disconnect switch isn't just a good idea—it's a hard requirement, baked into the safety codes that govern everything we do. These standards are the rulebook, transforming a simple piece of hardware into a non-negotiable device that protects both people and equipment.

It all starts with the National Electrical Code (NEC). If you're dealing with motors, you live in Article 430. One of its most critical mandates is the "within sight" rule, which demands that a disconnect must be visible and located no more than 50 feet from the equipment it serves. This isn't arbitrary; it's a practical safeguard that prevents a technician from working on a machine while someone unknowingly re-energizes the circuit from down the hall.

Connecting Hardware to Human Safety

While the NEC lays out the rules for the hardware, the National Fire Protection Association (NFPA) focuses on keeping people safe around it.

That's where NFPA 70E, the Standard for Electrical Safety in the Workplace, comes in. This is the playbook for safe work practices, and it’s the reason we have procedures like Lockout/Tagout (LOTO). A disconnect switch is the linchpin of any LOTO procedure, providing that essential, lockable point of isolation that NFPA 70E requires before a single tool is lifted.

Think of it this way: The NEC tells you how and where to install the disconnect. NFPA 70E tells you why and how to use it to make sure everyone goes home safe.

The Role of UL Certification

For anyone building control panels, Underwriters Laboratories (UL) standards are gospel. UL provides that critical third-party stamp of approval, verifying that components and entire assemblies meet rigorous safety and performance benchmarks.

Two standards are absolutely essential here:

- UL 98 (Enclosed and Dead-Front Switches): This is the standard for the disconnect switch itself. It gets put through its paces to ensure it can reliably interrupt current and handle nasty fault conditions without failing.

- UL 508A (Industrial Control Panels): This one applies to the whole finished product—the control panel. To earn that coveted UL 508A listing, the panel must have a certified main disconnecting means. That makes a UL 98-rated switch a foundational building block for any compliant panel.

To get a better handle on how these certifications work together, you can learn more about the differences between UL Listed and UL Recognized components in our detailed guide. At the end of the day, following these standards isn't just about checking boxes. It’s about building a rock-solid foundation of safety and reliability into every single system you design.

Choosing and Maintaining Your Disconnect Switch

Picking the right disconnect switch goes way beyond just matching the voltage and amperage on the label. Get this choice right, and you’re setting your system up for safety, reliability, and code compliance. Get it wrong—say, by undersizing the switch or picking the wrong enclosure—and you're looking at premature failure, serious safety hazards, and downtime that'll hit your bottom line hard.

You have to look at the whole picture. It's like choosing tires for a truck. You wouldn’t slap standard highway tires on a rig that's heading off-road, right? The same logic applies here. A general-duty switch just won't survive in a harsh industrial environment that demands a heavy-duty model.

Your Essential Selection Checklist

Before you even think about purchasing a disconnect switch, run through this checklist. Nailing these details from the get-go will save you from massive headaches later.

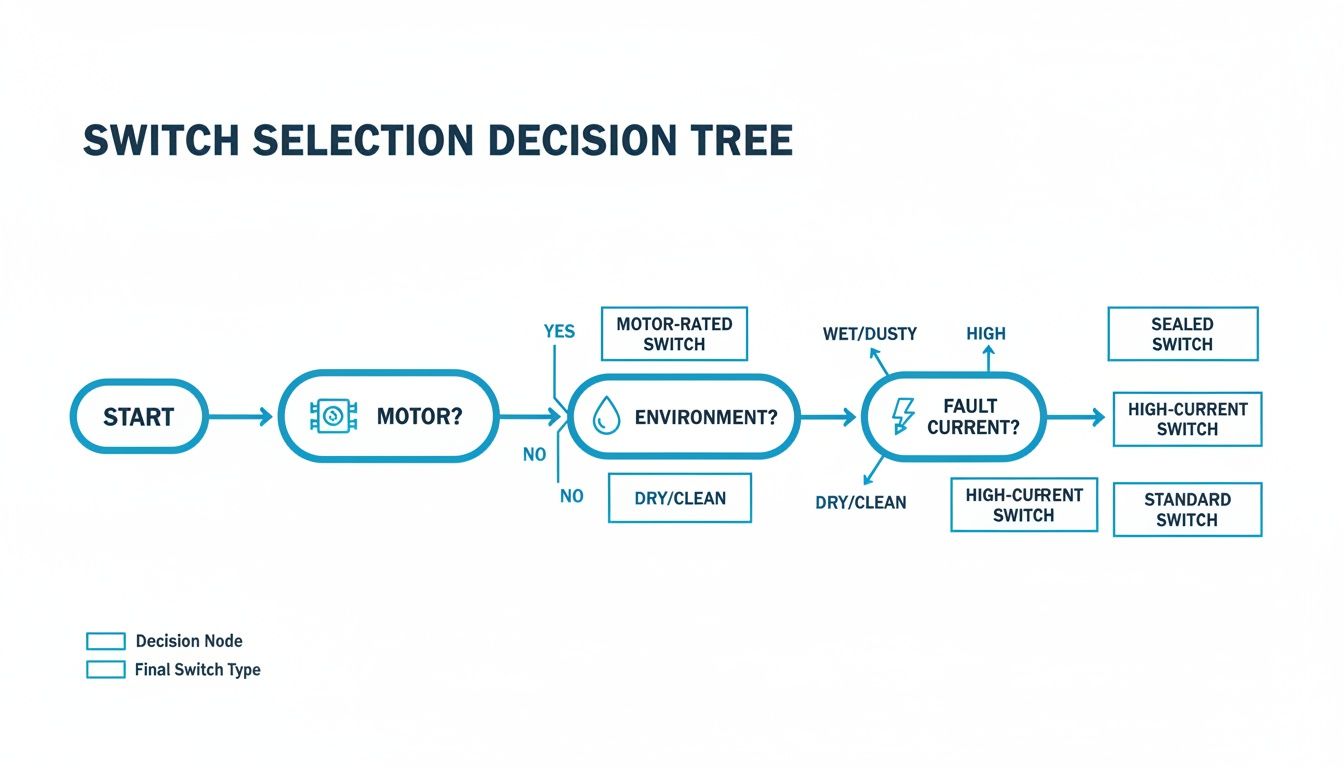

- Horsepower (HP) Rating: This is non-negotiable if the switch is for a motor. Motors pull a massive amount of current when they first start up, and the switch absolutely must be rated to handle that specific motor load.

- Enclosure Type: The environment is everything. Is it a corrosive or washdown area? You'll need a NEMA 4X enclosure. Just a dusty indoor spot? A NEMA 12 might do the job just fine.

- Fault Current Rating: The Short Circuit Current Rating (SCCR) has to be high enough to handle the worst-case scenario. It must safely withstand the maximum potential fault current at that point in the system, preventing a catastrophic explosion during a short circuit.

- Fused vs. Non-Fused: Do you need the switch itself to provide overcurrent protection (fused)? Or is there already a breaker or fuse upstream handling that job (non-fused)?

Choosing the right disconnect switch is a foundational step in building a safe electrical system. Overlooking a detail like the enclosure type or fault current rating doesn’t just risk the switch; it risks the equipment it protects and the personnel who operate it.

Best Practices for Long-Term Maintenance

Once it's installed, a disconnect switch isn't a "set it and forget it" device. It needs regular attention to stay reliable and safe throughout its service life. Neglecting maintenance is a common—and dangerous—mistake. The good news is that proactive care is pretty simple.

A solid maintenance plan is your best tool. If you're looking for a great starting point, check out the principles for maintaining motor control centers, as many of them apply directly to the disconnects inside.

Here are the key tasks to stay on top of:

- Regular Inspections: Do a visual walk-through. Look for tell-tale signs of overheating, like discolored terminals or melted insulation. Check for any hint of corrosion or moisture getting inside the enclosure.

- Connection Tightness: Things loosen up over time thanks to vibration and the constant heating and cooling of electrical cycles. Get a torque wrench out periodically and make sure all terminal lugs are tightened to the manufacturer's specs.

- Mechanical Operation: During a planned outage, throw the handle. Operate the switch a few times to make sure the mechanism moves freely. You don't want to find out it's seized up from years of inactivity during an emergency.

Answering Your Top Questions About Disconnect Switches

Even after getting the basics down, a few common questions always seem to pop up on the plant floor. Let's clear up a couple of the most frequent points of confusion to sharpen your understanding and help you make safer, smarter decisions.

Can a Circuit Breaker Double as a Disconnect Switch?

Sometimes, yes—but it's a qualified "yes." The National Electrical Code (NEC) does allow a circuit breaker to serve as a disconnecting means, provided it has the right ratings for the job. Critically, it must have a way to be locked out in the "off" position to comply with LOTO procedures.

Even so, many seasoned electricians and safety professionals will tell you they prefer a dedicated, standalone disconnect switch. Why? Because a traditional disconnect gives you that unmistakable visual confirmation—a physical air gap between the contacts—that the circuit is truly dead. It’s an extra layer of assurance you just can't argue with.

What Does the NEC Mean by "Within Sight of the Motor"?

This is a huge one, and it's a safety rule you can't afford to get wrong. The NEC defines "in sight from" as being visible and located no more than 50 feet away from the equipment it controls, like a motor.

The reasoning here is brilliantly simple and life-saving. It's designed to stop one person from accidentally re-energizing a machine while another technician, hidden from view, is working on it. This rule ensures the person performing the maintenance has direct, immediate control over the power source.

This decision tree gives you a great visual for the thought process behind choosing the right switch, walking through the key questions about the application, environment, and potential fault current.

As the guide shows, the single most important step is always matching the switch to its specific job.

Designing a safe, compliant, and rock-solid electrical system takes more than just buying components off a shelf—it demands a partner with deep experience in the field. At E & I Sales, we live and breathe this stuff, specializing in engineering UL-listed control panels and integrating motor controls built for the toughest industrial environments. Find out how our expertise can power your next project at https://eandisales.com.