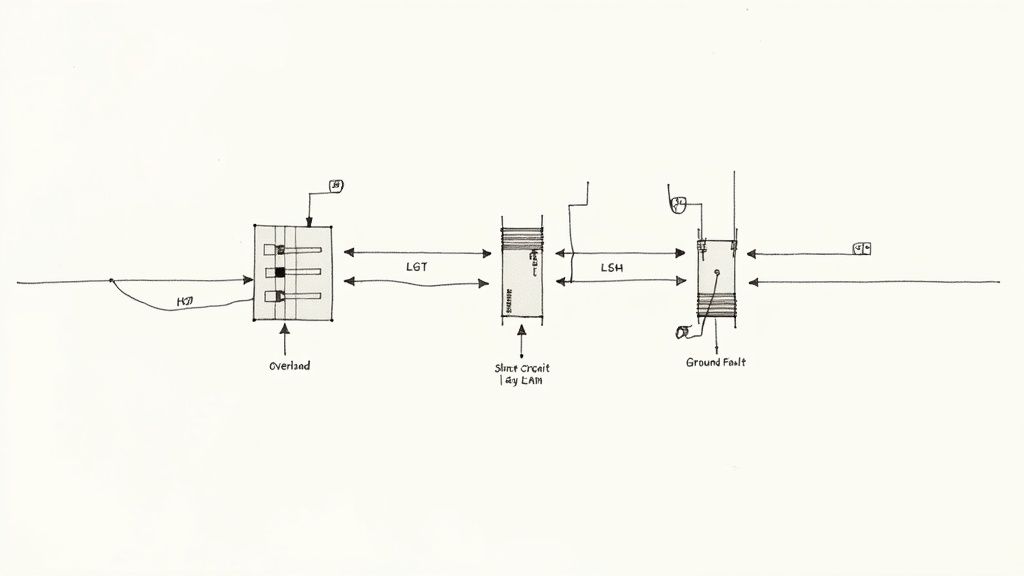

A circuit breaker only has one job: to protect you and your equipment. When it trips, it's not being a nuisance—it's doing its job perfectly. Think of it as an automatic emergency stop for your electrical wiring. It's an alert that something is wrong, and it almost always comes down to one of three issues: an overloaded circuit, a short circuit, or a ground fault.

Each of these represents a different kind of electrical danger, and understanding the difference is the first step in troubleshooting.

The Three Main Culprits Behind a Tripped Breaker

When a breaker trips, it's sending you a clear signal. Your job is to figure out what that signal means. Is it a simple case of too many machines on one line, or is it a symptom of a much more dangerous fault in the wiring? Let's break down the big three.

Circuit Overloads

The most common and thankfully least dangerous reason for a trip is a simple overload. This happens when you try to pull more power through a circuit than it was ever designed to handle.

Think of it like a small country road. It's perfectly fine for a few cars, but when rush hour hits and everyone tries to use it as a shortcut, you get a massive traffic jam. A circuit is the same way. If you plug too many high-draw machines into a single circuit and turn them all on, the demand for amperage exceeds what the wiring can safely carry. The breaker senses this slow build-up of heat and trips to prevent the wires from melting.

This is an incredibly common scenario. In fact, one industry survey found that tripped breakers and fuses were involved in 54% of all electrical service calls. A huge chunk of those were simple overloads.

Short Circuits

Now we're getting into more dangerous territory. A short circuit is exactly what it sounds like: the electricity finds a "shortcut" it's not supposed to take. This happens when a hot wire carrying current comes into direct contact with a neutral wire.

Instead of flowing through a machine and doing useful work, the electricity bypasses it entirely. This creates a massive, uncontrolled surge of current—hundreds or even thousands of amps in an instant. That kind of power surge can vaporize wires, create arcs, and ignite a fire in a split second. The breaker's job is to detect this violent rush and snap off in milliseconds to stop a disaster before it starts.

Ground Faults

A ground fault is a very specific, and very dangerous, type of short circuit. It happens when a hot wire touches a grounded part of the system—like a metal equipment chassis, a conduit, or a metal outlet box.

This creates a new, unintended path for the electricity to flow to the ground. If that path happens to be through a person touching that piece of equipment, the results can be fatal. This is precisely why specialized breakers and outlets (GFCIs) exist, especially in damp locations. To get a better handle on the specifics, you can learn more about how ground fault protection works and why it's so critical.

Key Takeaway: A tripped breaker isn't the problem; it's the solution to a problem. Each trip is a successful safety event, stopping potential equipment damage, electrical shock, or fire in its tracks.

To help you get a quick read on the situation next time a breaker trips, here’s a simple table summarizing what to look for.

Quick Guide to Common Breaker Trip Causes

This quick reference can help you make a preliminary diagnosis based on what you see and hear when a circuit goes down.

| Cause | What It Looks Like | Immediate Risk Level |

|---|---|---|

| Circuit Overload | Breaker trips after a high-power device is turned on; often occurs with multiple appliances running. | Low to Moderate |

| Short Circuit | Breaker trips instantly with a loud pop; may be accompanied by a burning smell or sparks. | High |

| Ground Fault | Breaker or GFCI outlet trips immediately, especially in damp areas like kitchens or bathrooms. | High |

Remember, while an overload is often something you can fix yourself by managing your equipment, shorts and ground faults are clear signs of a serious wiring problem that needs a professional electrician's attention.

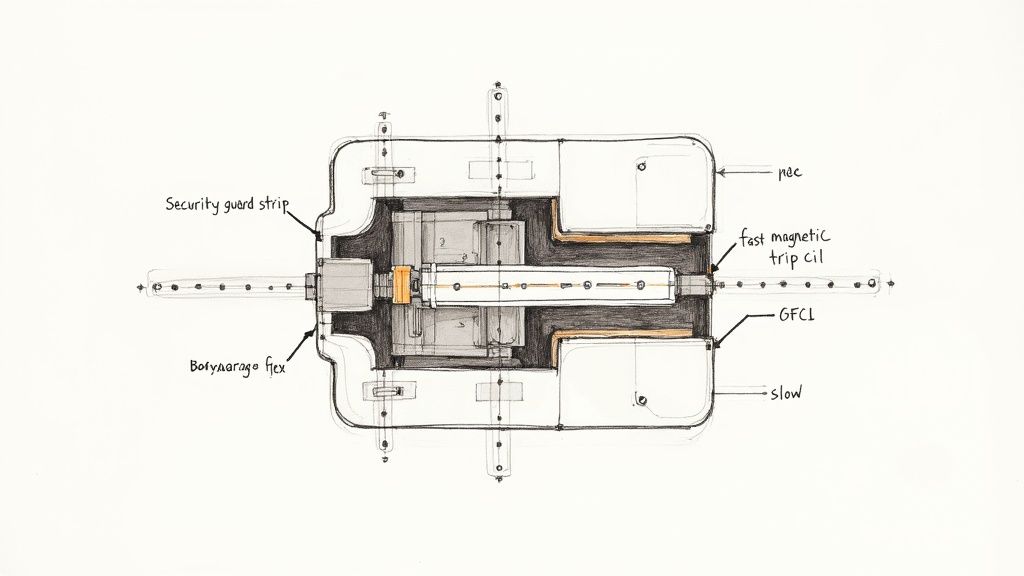

How a Breaker Protects Your Electrical System

A circuit breaker is much more than a simple on/off switch. Tucked inside that plastic casing is a smart safety device, engineered to spot different kinds of electrical trouble and shut things down in a heartbeat. To really understand what causes a breaker to trip, you have to look at what's going on inside.

At its heart, a standard breaker has two distinct jobs, each designed to stop a specific type of electrical fault. It’s like having two security guards on duty: one is patient and watches for slow-building problems, while the other is a lightning-fast bodyguard for sudden emergencies.

The Patient Guard: Thermal Protection

The first line of defense is thermal protection, and its job is to stop circuit overloads. The key component here is a bimetallic strip—a small piece of metal made from two different alloys fused together. As electricity flows through the circuit, this strip gets warm.

If the current gets a little too high, say from running a high-draw packaging machine and a heat sealer on the same line, the strip heats up slowly. As it does, one of the metals expands faster than the other, causing the strip to bend. If it bends far enough, it physically releases the switch mechanism, tripping the breaker. This slow, deliberate response is perfect for preventing wires from dangerously overheating during a sustained overload.

The Fast Bodyguard: Magnetic Protection

The second guard is magnetic protection, and it's built for one thing: reacting instantly to the violent current surge of a short circuit. This system uses a small electromagnet, or solenoid. During normal operation, the current flowing through it is too weak to have any effect.

But during a short circuit, the current can spike to hundreds or even thousands of amps in an instant. This massive surge creates a powerful magnetic field that yanks a metal lever, which immediately trips the breaker. This reaction is almost instantaneous, cutting the power before that massive burst of energy can start a fire or cause an explosion.

A breaker’s dual-action design allows it to distinguish between a minor, temporary overload and a catastrophic short circuit, providing the right level of protection for each threat.

Modern Breakers With Advanced Protection

While thermal and magnetic protection are the bedrock of breaker technology, modern safety codes demand even smarter safeguards in certain environments. This is where specialized devices like GFCIs and AFCIs come into the picture, adding extra layers of intelligence right inside the breaker itself.

Ground Fault Circuit Interrupters (GFCIs)

A GFCI's sole purpose is to prevent electric shock. It does this by constantly measuring the current flowing out on the "hot" wire and comparing it to the current coming back on the "neutral" wire.

- How it Works: In a properly functioning circuit, these two currents should be perfectly balanced. But if electricity finds an alternate path to the ground—like through a person touching a faulty piece of equipment—the returning current will be less than the outgoing current.

- Its Purpose: The GFCI can detect an imbalance as tiny as 4-6 milliamperes and will trip the circuit in a fraction of a second. This is fast enough to prevent a fatal shock, which is why you'll find them mandated in wet or high-risk locations like wash-down areas, kitchens, and outdoor outlets.

Arc Fault Circuit Interrupters (AFCIs)

An AFCI is basically a fire prevention device. It’s designed to listen for the specific electrical "noise" or signature created by a dangerous arc fault—the kind of spark that jumps between loose or damaged wiring.

- How it Works: An arc is an erratic, sputtering connection. It's not the clean, massive surge of a short circuit, so a standard breaker might not even notice it. The AFCI, however, has sophisticated electronics that are trained to recognize the unique waveform of a dangerous arc.

- Its Purpose: Once it detects an arc, the AFCI trips the circuit to stop the intense heat from igniting nearby materials like dust, insulation, or cardboard. These are crucial in areas where frayed cords or damaged in-wall wiring can create a hidden fire hazard.

You can take a closer look at the different types and technical specs of these and other devices in this detailed guide to the miniature circuit breaker.

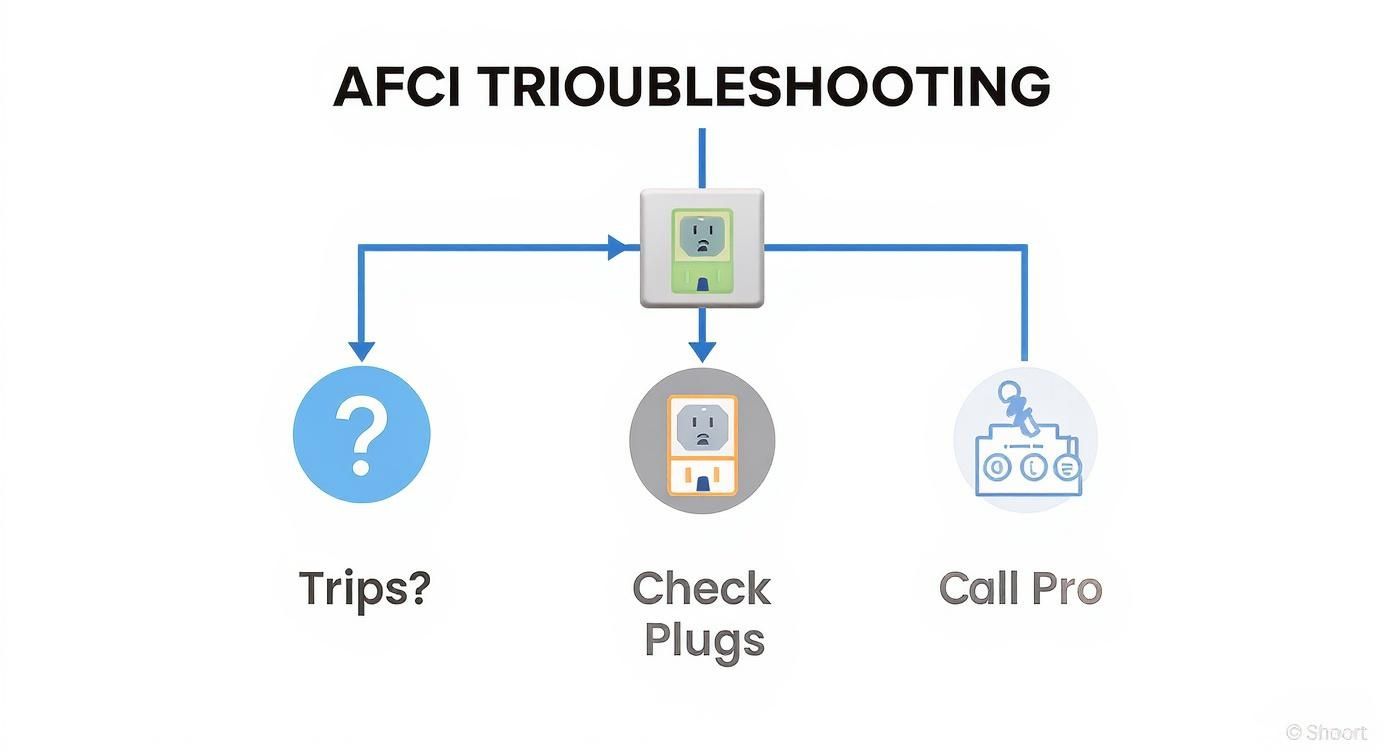

Solving Nuisance Tripping from Arc Fault Breakers

Arc Fault Circuit Interrupters (AFCIs) are fantastic at preventing fires, but their hair-trigger sensitivity can lead to a familiar headache: nuisance tripping. You’re running a piece of equipment, and suddenly, the power cuts out for no clear reason.

What’s going on? An AFCI is built to recognize the distinct electrical "fingerprint" of a dangerous arc—that spark that jumps between loose or damaged wires. The problem is, plenty of perfectly safe devices, from power tools to older motors, create electrical noise that can look a lot like that dangerous signature, tricking the breaker into a false alarm.

What Is Nuisance Tripping?

Nuisance tripping is when an AFCI cuts the power because of something that isn't actually a threat. The breaker isn't broken; it’s just being a little too cautious and misinterpreting the electrical signals it’s seeing.

Think of an AFCI like an overeager security guard. A good one will stop a real intruder, but a hyper-sensitive one might tackle the mailman every morning. The AFCI's job is to tell the difference between the hazardous crackle of a frayed wire and the normal, harmless sparks inside a motor. Sometimes, it gets it wrong.

A few common culprits are notorious for causing these false alarms:

- Brushed Motors: Found in vacuums, power tools, and many older appliances, these motors create tiny, routine sparks as they run.

- Electronic Devices: Things like dimmer switches, fluorescent light ballasts, and even some computers can generate electrical waveforms that an AFCI might flag as suspicious.

- Shared Neutral Wires: In older buildings, it's not uncommon for multiple circuits to share a single neutral wire. This can create tiny imbalances that a sensitive AFCI will interpret as a fault.

Distinguishing a False Alarm from a Real Danger

So, how can you tell if a trip is a minor annoyance or a signal of a real problem? The answer usually lies in the pattern. If the breaker trips once while you're firing up a high-powered tool, it's probably a nuisance. But if you're getting frequent, random trips with no obvious cause, that’s a major red flag.

A persistent AFCI trip is a powerful warning sign. It often points to hidden dangers like stapled wires behind drywall, loose connections in an outlet, or rodent damage to a cable—all of which are significant fire hazards.

It’s tempting to just reset the breaker and move on, but ignoring these warnings is a gamble. Research from electrical safety experts paints a clear picture. One survey found that in 74% of AFCI service calls, contractors discovered genuine, dangerous arcing conditions. Adding to that, the Consumer Product Safety Commission (CPSC) reported that 85% of electrical fires they investigated occurred in homes over 20 years old, where aging wiring is a prime suspect. To get a deeper technical perspective, you can read this breakdown of high-voltage circuit protection.

Troubleshooting Persistent AFCI Trips

If an AFCI breaker just won't stop tripping, there are a few diagnostic steps you can take. First, unplug everything on the circuit. Reset the breaker. If it stays on, the issue is almost certainly with one of the devices you unplugged. Start plugging them back in one at a time until the breaker trips again. You've found your culprit.

But what if the breaker trips again, even with nothing plugged in? That tells you the fault is in the wiring itself. It could be a loose terminal screw on an outlet, a wire nicked inside a wall, or a bad connection in a junction box. At this stage, the problem is beyond a simple fix and needs a professional. Do not ignore it. An electrician has specialized tools to hunt down the exact location of the arc fault and fix it safely, ensuring your breaker does its job without the constant false alarms.

Diagnosing Breaker Trips in Industrial Settings

When a breaker trips in your house, it’s an annoyance. But when one trips on the plant floor, it can bring a multi-million-dollar production line to a dead stop. The stakes are exponentially higher, and the root cause is rarely as simple as a hairdryer and a microwave on the same circuit.

Industrial environments present their own unique electrical challenges. Heavy-duty equipment like massive motors, compressors, and Variable Frequency Drives (VFDs) don't behave like typical household appliances. For example, the huge inrush current needed to kick-start a large motor can be six to eight times its normal running current. A standard breaker can easily mistake this momentary surge for a dangerous short circuit and trip unnecessarily. On top of that, the high-speed electronic switching inside modern VFDs can create electrical "noise" or harmonics that can confuse more sensitive protective devices. Getting a handle on these industrial-specific behaviors is the first real step toward troubleshooting effectively.

The Real Cost of a Tripped Breaker

A tripped breaker in a manufacturing setting isn't just a matter of flipping a switch. It's a direct blow to the bottom line. Consider a German automotive plant where random breaker trips—sometimes up to eight a day—were causing production losses estimated at a staggering $50,000 per hour.

It's not just about downtime, either. The mechanical stress from constant tripping and resetting drastically shortens a breaker's lifespan. A standard Miniature Circuit Breaker (MCB) is built for about 10,000 mechanical operations, while a heavy-duty Vacuum Circuit Breaker (VCB) might be rated for 30,000. Every nuisance trip pushes that component one step closer to premature failure.

A Methodical Approach to Troubleshooting

When a critical machine goes dark, panic is not a strategy. A scattered, "try-this-try-that" approach will only waste time and could even be dangerous. What you need is a systematic, repeatable process to pinpoint the root cause quickly and safely.

Here is a simple checklist to get you started:

The following table outlines a structured approach for troubleshooting breaker trips in an industrial setting, moving from simple observations to more detailed electrical checks.

Industrial Troubleshooting Checklist

| Diagnostic Step | Action to Take | Potential Finding |

|---|---|---|

| 1. Gather Context | Talk to the machine operator. What was happening right before the trip? (e.g., startup, heavy load, idle). Note any HMI alarms, strange noises, or smells. | Startup trip suggests inrush current issues. Mid-cycle trip points to overload. Alarms can pinpoint the exact fault. |

| 2. Visual Inspection (Power Off) | Perform a proper lockout/tagout. Open the panel and look for obvious signs of trouble: burnt wires, discoloration at terminals, loose connections. | Charred components indicate a short circuit. Discolored terminals signal overheating from a poor connection. |

| 3. Analyze Trip Pattern | Is the trip instant or delayed? Does it happen at the same time every day? Is it random? | Instant trips often mean a direct short or ground fault. Delayed trips suggest a thermal overload. Predictable timing might point to external factors like utility voltage sags. |

| 4. Isolate Components | Disconnect the load (motor) from the circuit. Try to reset the breaker. If it holds, the problem is likely in the motor or its wiring. | If the breaker trips with no load connected, the fault is in the wiring between the breaker and the motor. |

| 5. Measure Load | Use a clamp-on ammeter to measure the current during startup and under normal load. Compare this to the motor’s Full Load Amp (FLA) rating. | A current significantly higher than the FLA rating points to a mechanical issue (e.g., seized bearing, jam) forcing the motor to work harder. |

| 6. Check Insulation | Use a megohmmeter to test the insulation resistance of the motor windings and cabling. | A low resistance reading (megger test failure) indicates failing insulation, which is a common cause of ground faults. |

| 7. Review Drive Faults | If a VFD is involved, access its fault log. The drive records the exact conditions at the moment of the trip. | The fault code (e.g., Overcurrent, Overvoltage, Ground Fault) is an invaluable clue that directs your next steps. |

By following a structured process, you can move from a state of guessing to a data-driven diagnosis, which is the key to solving the problem right the first time.

Expert Tip: Keep a detailed maintenance log for every trip. Note the time, machine status, and any other relevant conditions. Over time, these records can reveal subtle patterns that point directly to the culprit, like a voltage dip that happens every time the big compressor kicks on.

This flowchart shows a simplified diagnostic process for an AFCI, but the core logic—check external factors before blaming the component itself—is a golden rule for troubleshooting any type of breaker.

Advanced Diagnostic Tools and Techniques

When the obvious checks don't solve the puzzle, it's time to bring out the heavy-duty diagnostic tools. This is where condition monitoring and predictive maintenance strategies really shine, helping you find problems before they cause a shutdown.

- Load Measurements: A trusty clamp-on ammeter is your best friend. By measuring the actual current draw during startup and operation and comparing it to the motor's nameplate FLA (Full Load Amp) rating, you can immediately spot an overload. If the amps are too high, it's a clear sign of a mechanical problem making the motor work too hard.

- Insulation Resistance Testing: A megohmmeter, often called a "megger," is the tool for finding failing insulation in motor windings or cables before they fail completely. A low resistance reading means the insulation is breaking down, which will eventually lead to a ground fault or short circuit.

- VFD Parameter Review: If a VFD is running the show, its fault history is a goldmine of information. The drive logs the precise conditions when it tripped, often giving you specific codes for overvoltage, undervoltage, or excessive current. Understanding how variable frequency drives operate is key to properly interpreting these valuable fault codes.

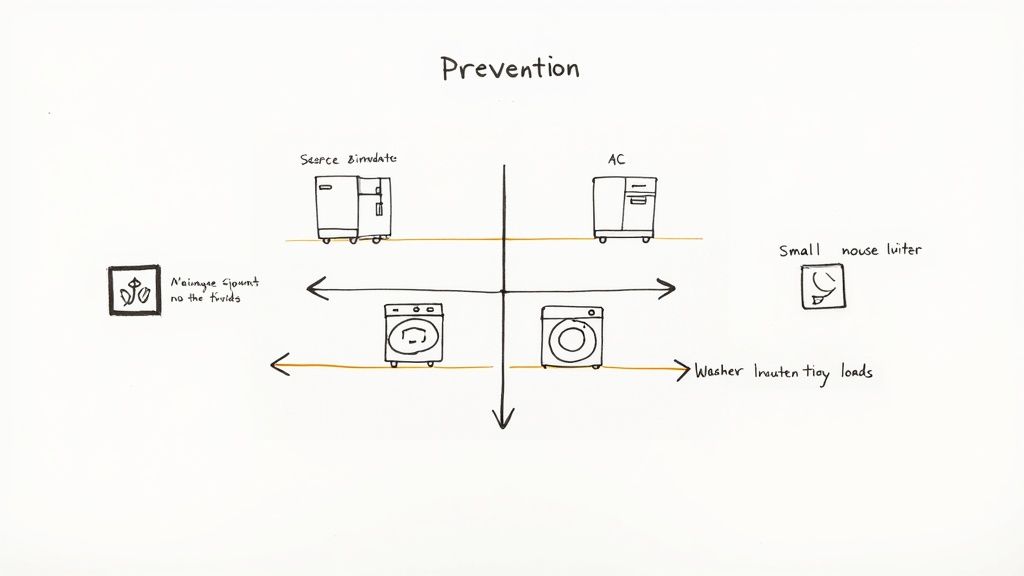

Practical Ways to Prevent Breaker Trips

Once you know why breakers trip, you can move on to the real goal: stopping it from happening in the first place. Being proactive doesn't just save you the headache of downtime; it builds a safer, more reliable electrical system from the ground up.

The core principles are the same whether you're in a home workshop or a massive packaging plant. You need to understand your electrical loads, use the right gear for the job, and keep your system in good health.

Balance Your Electrical Loads

By far, the most common culprit behind a tripped breaker is a simple circuit overload. This isn't really an electrical fault so much as a planning problem. Think of each circuit as a single lane on a highway—it has a hard limit on how much traffic it can handle. Try to cram too many power-hungry appliances into that one lane, and you’ll get a jam.

To avoid this, you have to become an electrical traffic controller. Start by mapping out which outlets are on which circuits. An old-school but effective trick is to plug a loud radio into an outlet, then head to your panel and flip breakers one by one until the music stops. Label that breaker, and repeat.

Once you know your layout, you can distribute the load intelligently:

- Separate the Power Hogs: Don't run a microwave and a toaster on the same kitchen circuit at the same time. Same goes for a space heater and a vacuum.

- Give Big Equipment Its Own Lane: Any high-demand machinery, like a central AC unit, a water heater, or an industrial conveyor, should always have its own dedicated circuit. This guarantees it gets the power it needs without fighting other devices for it.

An overloaded circuit is a clear sign that your power demands have outgrown your system's original design. Just spreading out your appliances is a surprisingly effective way to prevent the most frequent kind of breaker trip.

Choose the Correct Breaker for the Job

Not all breakers are created equal. It's a classic mistake to think that any breaker with the right amperage will work. The type of breaker is just as critical, especially when dealing with motors in things like air conditioners or industrial machines. That initial startup requires a massive, split-second surge of power called inrush current.

A standard breaker sees that huge surge and thinks it's a dangerous short circuit, so it trips—even though nothing is wrong. This is where specialized breakers earn their keep.

- HACR-Rated Breakers: Designed specifically for Heating, Air Conditioning, and Refrigeration, these have a built-in time delay. They’re smart enough to ignore that harmless startup surge from a motor, preventing those frustrating nuisance trips.

- High Magnetic Trip Breakers: In heavy-duty industrial settings, you'll see these breakers (often called "D-Curve") used for huge motors and transformers. They are built to withstand extremely high inrush currents without flinching.

Using the wrong type of breaker is a recipe for constant frustration. Making sure the breaker's trip curve matches the load's behavior is how professionals build reliability right into the system.

The Importance of Routine Maintenance

Loose connections are a silent killer in electrical systems. Over time, normal vibrations and the constant cycle of heating and cooling can cause terminal screws on outlets and breakers to work themselves loose. A loose wire creates high resistance, which generates a ton of heat. This can lead to arcing—a serious fire hazard and a common reason what can cause a breaker to trip.

Your best defense is a simple maintenance schedule.

- Annual Panel Inspection: Have a qualified electrician give your panel a yearly check-up. They can torque all the terminal screws to the correct specifications and use a thermal camera to spot "hot spots"—the tell-tale sign of a loose connection before it fails completely.

- Inspect Outlets and Cords: Give your outlets and power cords a quick look-over now and then. Check for any discoloration, scorching, or if an outlet feels warm to the touch. Frayed or damaged cords should be replaced immediately, as they're a direct path to a short circuit.

Catching these little problems early is the key to preventing them from becoming major faults that trip breakers and create serious safety risks.

When to Call in a Professional Electrician

Knowing how to reset a tripped breaker is a handy skill for anyone on the plant floor. But knowing when to leave it alone? That’s far more critical.

Think of a circuit breaker as a safety sentinel. When it trips, it's raising a flag, telling you something is wrong. A one-off trip might just be a momentary overload—no big deal. But when that breaker trips repeatedly, it's not a suggestion anymore. It's a warning that there's a deeper problem you can't just reset away.

Your biggest clue is an immediate re-trip. If you flip the breaker back on and it snaps off again right away—either instantly or within a few seconds—stop. That’s a classic sign of a serious fault, like a short circuit or a dangerous ground fault. Forcing it back on again and again is like putting a brick on the gas pedal of an overheating engine. You’re inviting damage, arcing, and even fire.

Red Flags That Demand an Expert

Beyond a breaker that won't stay on, your own senses are your best diagnostic tools. If you notice any of the following signs around your electrical panels, equipment, or outlets, it’s time to call a qualified electrician. Don't try to be a hero.

-

A Burning Smell: If you catch a whiff of burning plastic or an unusual acrid smell (often described as ozone) near a panel or connection point, that's a five-alarm fire in the making. It means wiring insulation is melting from extreme heat.

-

Visible Scorch Marks: See any black or brown discoloration on an outlet, plug, or the breaker itself? That's physical evidence of a serious heat problem or electrical arcing.

-

A Hot Breaker Panel: Go ahead and touch your panel cover (the front, not the inside!). It should feel cool or room temperature. If it's warm or hot to the touch, you've got a problem—likely a loose connection or a failing breaker generating dangerous heat.

-

Buzzing or Hissing Sounds: Your electrical panel should be silent. Any audible buzzing, crackling, or hissing is a cry for help. It usually points to a loose wire arcing or a breaker that's on the verge of failing completely.

Safety Is Not a DIY Project: Messing around inside a live electrical panel is a recipe for disaster. Diagnosing complex wiring faults, tracing short circuits, or replacing a faulty breaker requires specialized knowledge, the right tools, and a deep understanding of safety codes.

Here’s a simple rule of thumb: if you can easily identify the cause of the trip—say, a new motor was just plugged into an already loaded circuit—and removing it solves the problem, you’re probably fine to reset the breaker.

But for anything more mysterious, or anytime you see, smell, or hear one of those red flags, the risk is simply not worth it. A professional electrician has the tools and training to find the root cause safely and ensure the fix is done right and to code.

Diving Deeper: Common Questions About Breaker Trips

Even when you know the difference between an overload and a short circuit, those concepts can feel a bit abstract. Let's tackle some of the most common questions that come up in real-world situations to connect the dots.

Why Does My Breaker Trip When I Use the Microwave?

This is a textbook example of a circuit overload. Microwaves are power-hungry, often pulling between 10 to 15 amps all by themselves.

Now, imagine that microwave is plugged into the same circuit as your toaster oven and coffee maker. When you go to heat up lunch, the combined electrical draw easily surpasses the circuit's 15 or 20-amp rating. The breaker trips to stop the wires from overheating—exactly what it's designed to do. The easiest fix is to move one of the appliances to a different circuit. For a permanent solution, especially in a breakroom, running a dedicated circuit for the microwave is the way to go.

Can a Faulty Appliance Cause a Breaker to Trip?

Without a doubt. A malfunctioning piece of equipment is a prime suspect for both short circuits and ground faults. Over time, internal wiring can wear out, fray, and make contact, causing a massive surge of current and that loud "pop" of a magnetic trip.

Another dangerous scenario is a ground fault, where a hot wire touches the appliance's metal frame. This can cause a standard breaker to trip from the current surge, but it’s precisely the kind of hazard a GFCI is built to detect and stop instantly. To troubleshoot, unplug everything on that circuit. After you reset the breaker, plug each device back in one by one. The one that causes the trip is your problem child.

A breaker trip isn't a failure; it's a success story. It's doing its job. But if it keeps tripping, it’s not nagging—it’s screaming that there's a serious problem that needs your attention. Ignoring it is like hitting snooze on a fire alarm.

Is It Safe to Just Keep Resetting a Tripped Breaker?

Absolutely not. Resetting a breaker that tripped from a temporary overload is one thing, but repeatedly forcing one back on is asking for trouble.

If the breaker trips again immediately, you're dealing with a persistent fault. Each time you force it closed, you're sending a massive surge of current into that fault, which can cook the wiring inside your walls, destroy the breaker itself, and create a very real risk of an electrical fire. If a breaker won't stay on, the only safe move is to leave it off and call a qualified electrician.

At E & I Sales, we provide the robust electrical components and custom control panels designed to prevent trips and enhance safety in demanding industrial environments. Explore our solutions today.