So, what exactly is a Variable Speed Drive (VSD)?

Think of a VSD as the brains behind your motor's brawn. Instead of a basic on/off switch that slams equipment into action at full throttle, a VSD is more like a sophisticated dimmer switch or a gas pedal. It gives you the power to tell a motor exactly how fast to run and with how much force. This fine-tuned control is the secret to unlocking massive gains in efficiency and equipment longevity.

Understanding Variable Speed Drives

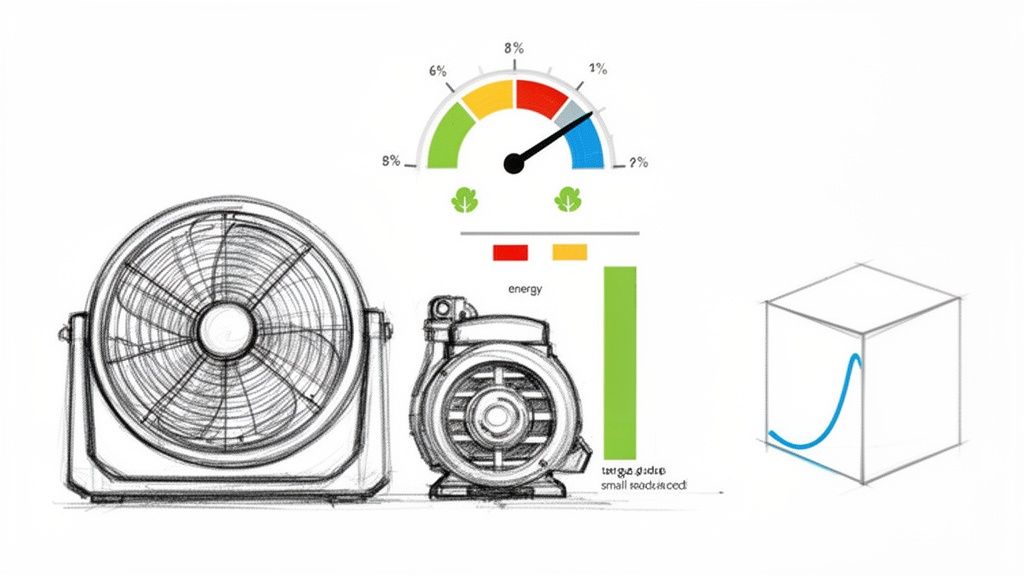

At its core, a VSD manages the power flowing into an electric motor to precisely regulate its rotational speed. The reality is, most industrial applications—pumps, fans, conveyors, you name it—don't need to run at 100% capacity all the time. Running them full-out when it isn't necessary is like flooring the accelerator in your car just to ride the brake. It's incredibly wasteful and puts a ton of unnecessary strain on the entire system.

A VSD neatly solves this problem by adjusting the electrical frequency and voltage supplied to the motor. This allows the motor to ramp up smoothly, run at the exact speed the job requires, and then gently ramp back down. It turns a simple, fixed-speed motor into a smart, adaptable, and highly efficient machine.

The Power of Precise Control

Picture a municipal water pump system. Without a VSD, the pumps would constantly cycle on and off with jarring force to maintain pressure, causing huge electrical surges and mechanical shockwaves through the pipes and valves. It’s brutal on the equipment.

Now, add a VSD. The pumps can run continuously at a much lower, more consistent speed, perfectly matching the real-time water demand. No more violent stops and starts.

This level of control delivers some serious advantages:

- Energy Efficiency: This is the big one. By running motors only as fast as they need to, VSDs can slash electricity consumption. For common pump and fan applications, just a 20% speed reduction can lead to energy savings of nearly 50%.

- Reduced Mechanical Stress: A VSD gives you a "soft start," eliminating the violent jolt of an across-the-line start. This gradual acceleration is much easier on belts, gears, and couplings, which means they last longer and fail less often.

- Improved Process Management: VSDs let operators dial in their processes with incredible accuracy. The result is better product quality, less wasted material, and far more consistent output day in and day out.

A VSD bridges the gap between raw power and intelligent application. It ensures that a motor uses only the energy it needs, for as long as it's needed, transforming a brute-force tool into a precise instrument of control.

To put it simply, a VSD gives you the control you need to run a smarter, more efficient operation. Here's a quick breakdown of what they do and why it matters.

VSD At a Glance: Core Functions and Benefits

| Core Function | Primary Benefit |

|---|---|

| Speed & Torque Regulation | Matches motor output directly to process demand. |

| Soft Starting/Stopping | Eliminates electrical inrush and mechanical shock. |

| Variable Frequency Control | Unlocks significant energy savings, especially in pump and fan systems. |

| Process Optimization | Enables precise adjustments for better quality and consistency. |

Ultimately, integrating a VSD is about more than just saving a few dollars on your utility bill; it's about extending the life of your critical machinery and gaining a whole new level of control over your entire process.

How VSDs Actually Control a Motor

So, how does a VSD pull this off? The gas pedal analogy is great for the what, but the how is where the real engineering magic lies. To really get it, you have to look under the hood at the most common type of drive, the Variable Frequency Drive (VFD).

Think of a VFD as a sophisticated power converter. Its one job is to take the raw, fixed utility power coming into your facility and completely reshape it into a custom-made power signal that gives the motor precise instructions. This all happens in three quick stages.

Stage 1: The Rectifier

First things first, the drive has to deal with the incoming alternating current (AC) power from the grid. This power is a sine wave, constantly oscillating, which isn't a stable foundation for building a new, variable signal. The drive needs a clean slate.

That’s the job of the rectifier. It takes that incoming AC and converts it to direct current (DC). It does this using a set of diodes that act like one-way gates for electricity, forcing the oscillating current to flow in a single direction. The result is a pulsating DC voltage.

This step is critical. Without converting to DC first, the drive would be stuck with the grid's fixed frequency.

Stage 2: The DC Bus

That pulsating DC from the rectifier isn't quite ready for primetime—it still has ripples from the original AC waveform. The next component, the DC Bus (or DC link), cleans up the signal.

The DC Bus uses large capacitors, which essentially act as small, fast-charging batteries. They soak up the peaks of the pulsating DC and fill in the valleys, smoothing everything out into a stable, high-voltage DC supply.

The result is a stable, high-voltage DC supply. This clean DC power is now ready to be shaped and molded by the final, most critical stage of the process, allowing for ultimate control.

This intermediate step is what makes VFDs so flexible. By creating its own DC power source, the drive completely decouples the motor from the grid, giving it total freedom to build a brand-new AC signal from scratch.

Stage 3: The Inverter

This is where the real control happens. The inverter takes that clean, stable DC voltage from the bus and uses it to construct a new, synthetic AC power signal to send to the motor.

It accomplishes this with a series of incredibly fast electronic switches called Insulated-Gate Bipolar Transistors (IGBTs). These IGBTs chop up the DC voltage into a series of precisely timed pulses, a technique known as Pulse Width Modulation (PWM).

By controlling the width and frequency of these pulses, the inverter can perfectly simulate an AC sine wave at any voltage and frequency it needs.

- To run the motor slower, the inverter creates a lower-frequency waveform.

- To run it faster, it simply generates a higher frequency.

This PWM output is what gives the VFD its amazing precision, allowing motor speed to be dialed in perfectly for the application. To see how these components work together in more detail, you can explore some variable frequency drive basics.

The Business Case for Using Variable Speed Drives

Sure, the tech behind variable speed drives is interesting, but for any plant manager or CFO, the real question is much simpler: what’s the ROI? When you look past the spec sheets, VSDs make a powerful business case built on real-world financial gains, stabler operations, and better product quality. The benefits ripple out far beyond simple motor control, touching the entire lifecycle of your equipment.

The benefit everyone talks about first is the dramatic drop in energy consumption. Electric motors are the workhorses of industry, but they’re also responsible for a huge slice of industrial electricity bills. Many of these motors, especially those on pumps and fans, operate under a set of rules known as the Affinity Laws.

Unlocking Exponential Energy Savings

The Affinity Laws lay out the relationship between the speed of a centrifugal pump or fan and the power it draws. The key takeaway is that this relationship isn't linear—it's exponential. This means even a tiny reduction in motor speed can trigger a massive drop in energy use.

The Power of the Cube: According to the Affinity Laws, the power a pump or fan needs is proportional to the cube of its speed. This is where the incredible opportunity for savings comes from.

Let's look at a practical example:

- Running a fan at 100% speed takes 100% of its design power. No surprise there.

- But reduce that speed by just 20% (down to 80%), and the power consumption plummets to roughly 51%.

- Slow it all the way down to 50% speed, and it sips power at a mere 12.5% of the original demand.

This powerful principle is precisely why VSDs are a game-changer for any application with variable demand. With around 300 million motors spinning away globally, a drive's ability to cut speed by just 20% can slash energy use by nearly 50% in common pump and fan scenarios. For a closer look at the math, check out our guide on calculating VFD energy savings.

This is one of the most effective ways to lower the energy footprint of industrial motor fleets worldwide. You can see how big the opportunity is by looking at the growth of the global variable speed drive market.

Extending Equipment Lifespan Through Soft Starting

Beyond the savings on your utility bill, VSDs act as a kind of mechanical insurance policy for your equipment. A motor started "across-the-line" (without a drive) gets hit with an instantaneous jolt of electricity, forcing it to lurch from zero to full speed in a split second. This is incredibly violent for the entire mechanical system.

That initial electrical inrush can be 600% or more of the motor's normal running current, and the mechanical shock is just as bad. It's like taking a sledgehammer to your machinery every single time you turn it on. All that stress leads to premature wear on critical components.

A VSD changes this completely by giving the motor a "soft start." It gently ramps up the voltage and frequency, allowing the motor to accelerate smoothly.

The benefits of a VSD-driven soft start are immediate:

- Reduced Stress on Couplings: It prevents the sudden, jarring torque that damages or knocks couplings out of alignment.

- Longer Bearing Life: It gets rid of the shock loading that is a primary cause of bearing failure in motors and the equipment they drive.

- Less Wear on Belts and Gears: A smooth startup stops belts from slipping and eases the strain on gearbox components.

By taking that mechanical shock out of the equation, a VSD can dramatically extend the life of your motors, pumps, fans, and conveyors. That means fewer breakdowns and lower maintenance costs over the long haul.

Gaining Unprecedented Process Control

Finally, the incredible precision a VSD offers translates directly into better product quality and more consistent operations. In countless industrial processes, "full speed" isn't the optimal speed. Being able to fine-tune a motor's output gives you a level of accuracy that’s simply impossible with a basic on/off switch.

Think about a bottling line conveyor. If it runs too fast, bottles tip over, causing spills, cleanup delays, and wasted product. Too slow, and it creates a bottleneck that gums up the whole production line.

With a VSD, operators can dial in the exact speed to perfectly match the filler's output, creating a smooth, uninterrupted flow. This same idea applies everywhere, from managing pump pressure in a chemical mixing tank to controlling fan speed in a drying oven. This level of control cuts down on waste, improves consistency, and ultimately, boosts your bottom line.

Choosing the Right Motor Control Solution

Sure, a variable speed drive can do amazing things, but that doesn't mean every motor in your plant needs one. It's a classic engineering trade-off: balancing performance, complexity, and of course, cost. Over-engineering a simple application with a full-blown VSD is just as wasteful as letting a high-demand process limp along without one.

The real key is matching the technology to the job at hand. For the vast majority of industrial motors, the choice boils down to three common methods: the simple Across-the-Line Starter, the more refined Soft Starter, and the powerhouse Variable Speed Drive. Knowing where each one shines is the first step to making a smart, cost-effective decision for your operation.

The Three Tiers of Motor Control

Let's break down how these solutions stack up. Think of it like choosing a vehicle for a job. You wouldn't use a Formula 1 car for a quick trip to the hardware store, and you definitely wouldn't enter a delivery van in the Monaco Grand Prix. It’s the same logic with motor controls.

1. Across-the-Line (ATL) Starters

This is the most straightforward option out there—basically, a heavy-duty on/off switch. When you hit "start," it connects the motor directly to the full line voltage. It's cheap, tough, and dead simple for applications where the motor just needs to run at one constant speed and the mechanical shock of a sudden, hard start isn't a dealbreaker.

2. Soft Starters

A soft starter is a big step up, designed to solve one specific problem: the brutal mechanical and electrical jolt of an ATL start. It works by gradually ramping up the voltage to the motor, allowing it to accelerate smoothly and under control. Once the motor hits full speed, the soft starter is usually bypassed, letting the motor run directly off the line. It's the perfect middle ground for reducing stress on equipment like pumps or conveyors where you don't need to adjust the speed once it's running.

3. Variable Speed Drives (VSDs)

The VSD is the most advanced of the bunch. Just like a soft starter, it delivers a smooth start, but that's where the comparison ends. A VSD gives you continuous, precise control over the motor's speed throughout its entire operation, not just at startup. This is the go-to solution for applications with changing loads, like pumps and fans, where matching motor speed to real-time demand can unlock massive energy savings and give you unparalleled process control.

To make this even clearer, let's put these three side-by-side.

Comparison: VSD vs. Soft Starter vs. Across-the-Line Starter

Choosing the right motor starter is a critical decision. Each type offers a different level of control, cost, and complexity, tailored to specific operational needs. This table breaks down the core differences to help you see which one fits your application.

| Feature | Across-the-Line Starter | Soft Starter | Variable Speed Drive (VSD) |

|---|---|---|---|

| Primary Function | Basic on/off control | Smooth motor acceleration/deceleration | Continuous speed and torque control |

| Speed Control | None (runs at fixed speed) | None during operation (only at start/stop) | Full range, continuous speed control |

| Startup Current | Very high (600-800% of full load) | Reduced (150-400% of full load) | Limited and controlled (typically <150%) |

| Mechanical Stress | High (sudden torque) | Low (gradual ramp-up) | Very low (fully controlled) |

| Energy Savings | None | Minimal (only at startup) | Significant (especially on variable-torque loads) |

| Best For | Simple, constant-speed applications like mixers or saws where startup shock is acceptable. | Applications needing to reduce mechanical stress on startup, like conveyor belts or centrifugal pumps that run at a single speed. | Applications with variable loads or requiring precise process control, like HVAC fans, pumps, and extruders. |

| Complexity & Cost | Low | Medium | High |

Ultimately, the best choice depends entirely on the job the motor is doing. For a simple "run-or-don't-run" task, an ATL starter is perfectly fine. But when you need to protect your equipment or manage your energy bill, you need to look at soft starters and VSDs.

When Is a Soft Starter Enough?

This is a common fork in the road for many engineers: do I really need the VSD, or can I get by with a soft starter? While both give you a gentle startup, their core purpose is completely different. A soft starter is a one-trick pony—a very good one—but its job is over the second the motor gets up to speed.

You should lean towards a soft starter when:

- Your main goal is to reduce mechanical stress on startup and shutdown.

- The motor only needs to run at a constant, full speed during operation.

- You need to limit the massive inrush current from an ATL start to stop lights from dimming or breakers from tripping.

- The application simply does not require variable speed for process control.

A classic example is a long, heavily loaded conveyor belt. Slamming it with full power would jerk the belt, potentially spilling product or damaging the gearbox. A soft starter ensures a smooth, gentle ramp-up to its single operating speed, protecting the equipment without the extra cost and setup of a VSD.

When Do You Need a Full VSD?

The decision to specify a VSD really boils down to one question: do you need continuous speed control? If you can make your process better, more efficient, or more precise by adjusting the motor's speed while it's running, then a VSD is the right tool. It’s not just a starter; it’s a process optimization machine.

A soft starter is like a ramp onto the highway—it gets you up to speed safely. A VSD, on the other hand, is the entire cruise control system, constantly adjusting your speed to match traffic for peak efficiency and performance.

You absolutely need a VSD when:

- The application has variable loads, like HVAC fans or centrifugal pumps.

- Energy savings are a major priority, especially where you can leverage the Affinity Laws.

- Your process demands precise speed regulation to maintain product quality.

- You need to run the motor at several distinct speeds for different parts of a machine cycle.

Think about the HVAC system in a large building. You don't need the fans blasting at 100% on a mild spring day. A VSD lets the system slow those fans way down, keeping everyone comfortable while slashing the electricity bill. A soft starter just can’t do that—it lacks the ongoing speed adjustment needed to capture those savings.

By clearly defining what your motor needs to do from start to finish, you can confidently choose the control solution that gives you the right performance at the right price.

Just picking out the right variable speed drive is only half the battle. A truly successful project comes down to what happens next—the integration. This is where the drive, the motor, and your actual application have to learn to work together, and it's where careful planning pays off big time.

Getting this part wrong is a recipe for disaster. We're talking premature motor failures, weird electrical noise messing with other equipment, and the kind of unexpected downtime that ruins a production schedule. Let's walk through the essential checklist to make sure your VSD integration is smooth, reliable, and delivers from day one.

Ensuring Motor and Drive Compatibility

First things first: is your motor actually ready for a VSD? A drive doesn't spit out the same clean, perfect AC power that comes from the utility. Instead, it uses a technique called Pulse Width Modulation (PWM) to create a simulated AC wave, and that high-frequency output can be brutal on standard-issue motors.

Hooking up a VSD to a motor that wasn't built for it can cause a world of hurt:

- Insulation Breakdown: Those rapid-fire voltage spikes from the drive can eat away at the motor's winding insulation, leading to shorts and, eventually, a dead motor.

- Overheating: The harmonics created by the VSD generate extra heat inside the motor, cooking it from the inside out and dramatically shortening its life.

- Bearing Damage: Stray voltages can build up on the motor shaft, creating tiny electrical arcs that pit the bearing races. This "electrical discharge machining" (EDM) is a notorious and premature bearing killer.

This is exactly why you should always pair a VSD with an "inverter-duty" rated motor. These aren't your average motors. They’re built tough, with beefed-up insulation, better cooling designs, and often include shaft grounding rings to handle the unique stresses a drive throws at them.

Managing Electrical Noise and Harmonics

While VSDs are incredible tools, they're also what's known as "non-linear loads." This means they draw power from the grid in quick, sharp pulses instead of a smooth, continuous wave. The side effect of this process is electrical "noise" that gets pushed back into your facility's power system. We call this harmonic distortion.

If you let harmonics run wild, they can cause some serious chaos for other sensitive electronics on the same network. You might see flickering lights, but you could also face much bigger problems, like overheating transformers or circuit breakers that trip for no apparent reason. It’s a major power quality issue that can disrupt your entire operation.

Managing harmonics isn't just a good idea—it's often a requirement. Many utilities have strict rules about how much harmonic distortion you can feed back into their grid.

Thankfully, this is a solvable problem. There are proven solutions designed to clean up that electrical signal and keep your system from interfering with itself or its neighbors. You can learn more by exploring the different types of harmonic filters for VFDs and how they work.

Selecting the Right Enclosure and Cooling

A VSD is a powerful piece of electronics, and just like your computer, it needs protection from the environment and has to stay cool to work properly. Heat is the ultimate enemy of electronics, and a drive generates a fair bit of it—typically losing about 2-3% of the power it handles as waste heat.

Enclosure Ratings are your first line of defense. A simple NEMA 1 enclosure might be fine in a clean, dry electrical room. But that same enclosure would get destroyed in a food processing washdown area or a dusty quarry. You have to match the enclosure to the job (like a NEMA 4X for corrosive areas or NEMA 12 for dusty indoor spots) to keep your drive safe.

Proper cooling and ventilation are equally vital. That enclosure needs a way to get rid of the heat the drive produces. This can be as simple as:

- Giving It Space: Always follow the manufacturer's specs for clearance around the drive to allow for natural airflow.

- Using Fans: Many panels integrate fans and filters to pull in cool ambient air and push out the hot air.

- Adding Air Conditioning: For sealed panels in really hot or dirty places, a dedicated A/C unit is the only way to go.

Skimping on thermal management is one of the fastest ways to get nuisance faults and a drastically shorter lifespan for your VSD. A solid enclosure and cooling plan isn't a luxury; it's a core part of any reliable installation.

Where You'll Find VSDs in the Real World

Variable speed drives are the unsung heroes of the modern world, quietly working behind the scenes in countless places you might not expect. They aren't just for specialized, high-tech factories. Their incredible versatility has made them essential to our infrastructure, manufacturing plants, and even the office buildings we work in.

Once you know what you’re looking for, you’ll start to see their impact everywhere. This isn't a niche trend; it's a massive shift in how industries operate. Projections from Global Market Insights suggest that annual VFD installations will blow past 30 million units worldwide. That’s a huge indicator of the value they deliver. Big players in automotive, oil & gas, and food and beverage are all jumping on board to get a handle on their energy costs and production quality.

From keeping a massive industrial plant running smoothly to managing the climate in a skyscraper, these drives are making our world more efficient.

Optimizing Commercial HVAC Systems

One of the most common places you’ll find a VSD is tucked away with a building's heating, ventilation, and air conditioning (HVAC) system. The huge fans pushing conditioned air through ducts and the pumps circulating hot or chilled water simply don't need to run at 100% speed all the time. That would be a colossal waste of energy.

Instead, a VSD lets the building's automation system fine-tune fan and pump speeds based on what's actually happening—things like the outdoor temperature, how many people are in the building, and the time of day. On a cool spring afternoon, the VSD will automatically slow the fans down, saving a fortune on electricity while keeping everyone comfortable. This kind of smart control is the secret sauce behind today’s energy-efficient buildings.

Precision in Manufacturing and Production

In the world of manufacturing, control is king. VSDs are absolutely critical for dialing in the speed of equipment like conveyor belts, industrial mixers, and extruders, ensuring every product is made to spec and the whole line runs like a well-oiled machine.

Think about a bottling plant. Bottles cruise down a conveyor to get filled. Without a VSD, that conveyor is stuck at one speed, which is almost never the perfect speed for the filler. A mismatch leads to spills, jams, and a whole lot of wasted product and time.

With a VSD, operators can sync the conveyor's speed perfectly with the rest of the line. It sounds simple, but that one change slashes waste, cuts down on frustrating jams, and makes sure every bottle is handled just right.

You see this kind of advanced motor control in the automotive world, too. If you've ever wondered how hybrid cars actually work, you're seeing some of these same variable speed principles in action.

Ensuring Stability in Water Management

Our municipal water and wastewater systems depend on VSDs to keep pressure and flow steady across the entire network. In the old days, pumps would slam on and off to fill a water tower or keep pressure up in the pipes. This caused huge pressure surges and put incredible stress on the whole system.

Today, a VSD can run a pump continuously at the exact speed needed to match the community's water demand in real time.

- In the middle of the night when demand is low, the VSD slows the pump way down.

- As people wake up and demand spikes, the drive smoothly ramps up the pump’s speed to keep the pressure rock solid.

This doesn't just save an enormous amount of electricity; it also dramatically extends the life of expensive pumps, motors, and pipes by getting rid of those violent start-stop cycles.

Common Questions We Hear About VSDs

When you're dealing with motor control, a few practical questions always seem to pop up. We get them all the time from engineers and plant managers trying to get their heads around variable speed drives, so let's clear up some of the most common ones.

Can I Slap a VSD on Any Old Motor?

Not really. While you can connect a drive to most standard AC motors, you shouldn't. For the system to last, you absolutely need an inverter-duty rated motor.

Why? Because these motors are built differently. They're designed to handle the unique electrical stress a VSD puts out. Trying to run a standard motor off a drive is a recipe for trouble down the road.

You'll start seeing problems like:

- Overheating from the high-frequency electrical "noise" created by the drive.

- Fried insulation caused by sharp voltage spikes from the VSD's output.

- Destroyed bearings thanks to stray electrical currents finding their way to ground.

What's the Real Difference Between a VSD and a VFD?

This one trips a lot of people up, but it's pretty simple. Variable Speed Drive (VSD) is the big-picture, catch-all term for any device that can change a motor's speed.

A Variable Frequency Drive (VFD) is just one specific—and by far the most common—type of VSD. It works by changing the frequency of the power going to an AC motor.

Because VFDs are everywhere, you'll hear people use "VSD" and "VFD" like they mean the same thing. And in day-to-day conversation, that's usually fine. Just remember: all VFDs are VSDs, but not every VSD is a VFD.

Seriously, How Much Energy Can a VSD Save?

The savings depend entirely on the job the motor is doing. For equipment like pumps and fans—what we call centrifugal loads—the results are staggering. It all comes down to a set of rules called the Affinity Laws, which show that a tiny drop in speed leads to a massive drop in power consumption.

It sounds crazy, but it's true: slowing a fan down by just 20% can slash its energy use by almost 50%.

Even on constant torque loads like conveyors, the savings are still very real. The drive makes sure the motor only pulls the exact amount of power it needs to move the load, and not a single watt more.

At E & I Sales, our job is to design and build UL-listed control solutions that fit right into your plant. From picking the right motor to getting it commissioned, we have the expertise to make sure your VSD project delivers. See how we can help with your next project at https://eandisales.com.