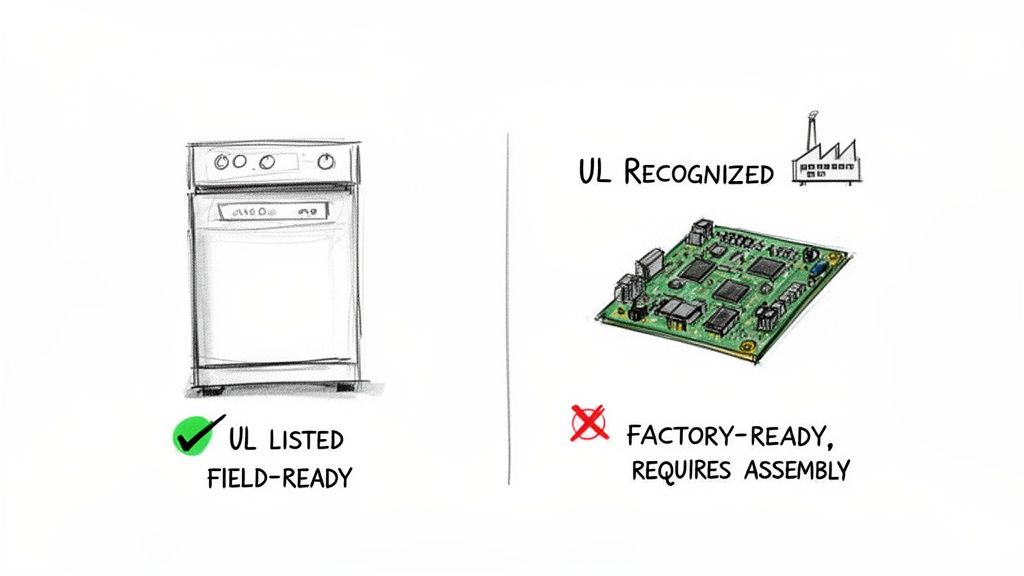

The most crucial thing to grasp when talking about UL Listed vs UL Recognized is where the product is headed. Is it a finished product ready for an electrician to install in the field, or is it a component destined for a factory assembly line?

That's the fundamental split: UL Listed applies to standalone products, while UL Recognized is for components that get installed inside a larger piece of equipment. One is the final product; the other is a part of the whole.

Understanding The Core Difference

Let’s break it down with a simple analogy. Think of a UL Listed control panel as a brand-new car you buy from a dealership. It's fully assembled, it's been crash-tested, and it's ready to be driven off the lot. The entire vehicle has been evaluated as a single, functional unit for safety and performance.

A UL Recognized component, on the other hand, is like a high-performance engine. That engine has been individually tested and proven to meet certain standards under specific conditions. But you can't just put the engine on the road. It needs to be correctly installed in a car (the final assembly) by professionals in a factory, where its interaction with the brakes, chassis, and electronics will be evaluated.

This dual-track system was a smart move by UL. It allows manufacturers to source pre-certified components without having to re-test every single switch and power supply from scratch. This makes the path to getting a complex machine—like a packaging line or a control panel—UL Listed much more efficient. You can find more historical context on this system at triadmagnetics.com.

Key Differences UL Listed vs UL Recognized at a Glance

When you're designing a machine or specifying parts, knowing the difference isn't just academic—it has real-world consequences for cost, compliance, and field acceptance. This table boils down the essential distinctions you need to know.

| Attribute | UL Listed | UL Recognized |

|---|---|---|

| Product Type | Standalone, complete end-products (e.g., control panels, motors, appliances). | Components or parts for factory installation (e.g., relays, power supplies, circuit boards). |

| Application Scope | Meant for field installation and direct use by end-users. | Intended for use within a larger UL Listed assembly or system. |

| Evaluation Focus | Comprehensive safety and performance testing of the entire product. | Focused testing of a component under specific, limited conditions. |

| Marking | Circular "UL" mark, often with the word "LISTED." | Backward "UR" or "RU" mark, signifying a Recognized Component. |

| Field Acceptance | Accepted by Authorities Having Jurisdiction (AHJs) and inspectors. | Not accepted as a standalone product in the field; requires evaluation in the final assembly. |

Ultimately, choosing between specifying Listed or Recognized components comes down to your final goal. Are you building a system from the ground up, or are you installing a finished piece of equipment? The answer will guide you to the correct UL mark every time.

Inside The UL Certification and Testing Process

The line between UL Listed and UL Recognized isn't just a label on a product; it’s the result of two completely different testing philosophies. If you’re an engineer or designer, getting this right is critical, as it determines exactly how a product or component can be integrated into a system safely and by the book. The journey to each mark evaluates different things, leading to very different outcomes.

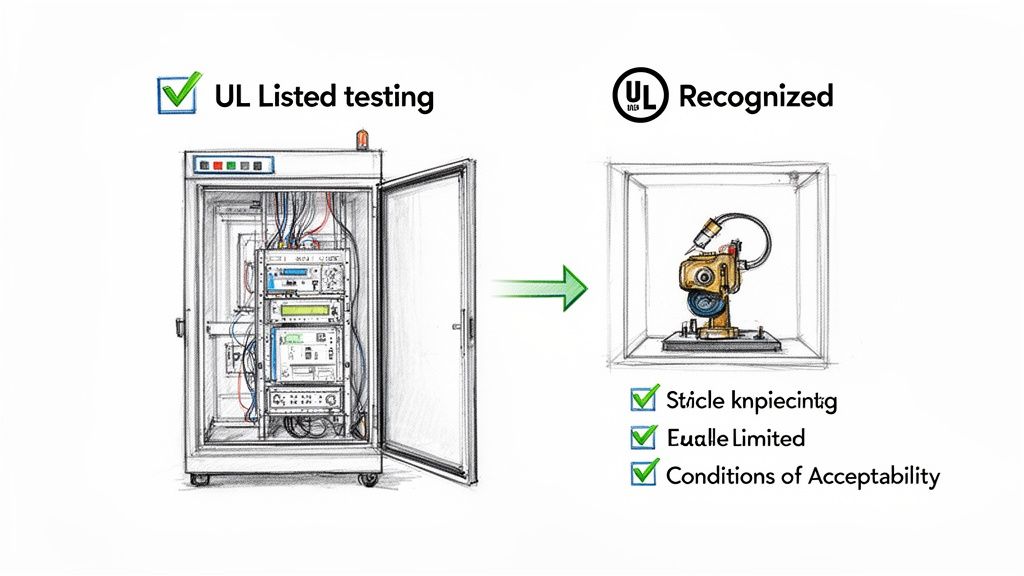

A UL Listed product gets the full, top-to-bottom evaluation. UL’s engineers test the complete, standalone unit exactly as it would be installed and used in the field. The whole point is to ensure the product is free from any reasonably foreseeable risk of fire, electric shock, or other hazards you might encounter in its final environment.

The process for a UL Recognized component, on the other hand, is much more surgical. It certifies a part, not a finished product. The tests are tailored specifically to that component's job inside a bigger piece of equipment, and its certification is only valid when used under a very precise set of rules.

The Scope of UL Listed Testing

When a product like an industrial control panel goes in for a UL Listing, it's put through a gauntlet of tests that check its overall safety and durability as a complete system. This goes way beyond just making sure the internal wiring is correct; it's a comprehensive audit of the entire assembly.

Key testing areas for UL Listed products include:

- Construction Integrity: UL experts examine the physical enclosure for sturdiness, corrosion resistance, and its ability to shield live parts from accidental contact.

- Electrical Safety: This is a deep dive into proper grounding, insulation, and the securement of live parts. They also verify that all electrical clearances meet strict standards.

- Performance Under Stress: The product gets hit with normal and fault conditions—think power surges or short circuits—to ensure it fails safely without starting a fire or creating a shock hazard.

- Environmental Durability: Depending on where the product is meant to be used, it might face tests for resistance to dust, water ingress (like a high-pressure hosedown), and even ice formation.

The entire philosophy behind a UL Listing is to validate a product's safety as a whole, right in its final, intended application. It answers one simple question: "Is this entire device safe for an electrician to install and for an operator to use in the real world?"

This exhaustive approach is exactly why getting a UL Listing is a more rigorous, time-consuming, and expensive journey. It certifies the product for field installation, giving Authorities Having Jurisdiction (AHJs) the green light they need to approve its use on-site.

The Nuances of UL Recognized Evaluation

In sharp contrast, the evaluation for a UL Recognized component is highly specific and deliberately limited. Think of a power supply or a circuit board that’s designed to live inside a larger machine. UL doesn’t test it as a standalone item because it was never meant to be one.

Instead, the testing hones in on its performance within a controlled, factory setting. The make-or-break detail here is the Conditions of Acceptability. These are critical limitations and requirements that UL attaches to the component's certification file.

These conditions might specify things like:

- Maximum voltage and current ratings.

- Specific enclosure requirements needed for fire or shock protection.

- A required mounting orientation.

- The maximum ambient operating temperature.

A UL Recognized component is only considered certified if the end-product manufacturer follows all of its Conditions of Acceptability to the letter. If an engineer uses a UL Recognized relay but puts it in an enclosure that doesn’t meet the conditions specified in its file, the relay's certification is instantly void for that assembly.

This is the fundamental trade-off. UL Recognition offers a more streamlined and less expensive path for component manufacturers. It lets OEMs build with pre-vetted parts, which simplifies their own final UL Listing process. But—and this is a big but—it puts all the responsibility on the OEM to understand and follow every single one of the component’s limitations. This is why a Recognized mark signals factory-readiness, while a Listed mark confirms field-readiness.

Meeting Regulatory Requirements and Gaining Market Access

Deciding between a UL Listed product and a UL Recognized component is far more than just a technical choice—it's a critical business decision that determines whether you can sell your product, pass inspections, and operate legally. This distinction is the key that unlocks market access, especially in North America where inspectors and regulators hold the final say over what gets installed.

Getting this wrong can lead to crippling delays, rejected projects, and serious legal exposure.

At the heart of the matter is UL's official standing. In the United States, UL is a Nationally Recognized Testing Laboratory (NRTL), a designation granted by the Occupational Safety and Health Administration (OSHA). This isn't just a fancy title; it gives the UL mark real teeth in the eyes of regulators.

The Role of Authorities Having Jurisdiction

On any job site, the ultimate gatekeeper is the Authority Having Jurisdiction (AHJ). This could be a city electrical inspector, a fire marshal, or another code official. Their job is simple: make sure every piece of equipment meets established safety codes, like the National Electrical Code (NEC).

The NEC and local codes are very clear—they often require electrical equipment to be "listed" or "labeled" by a qualified lab. For an AHJ, seeing a UL Listed mark on a product is a green light. It’s a trusted, unambiguous sign that the equipment has been fully tested and is safe to install right out of the box.

A UL Recognized mark tells a completely different story to an inspector. They see it and immediately know the component's safety is conditional. Because it hasn't been evaluated as a complete, standalone system, they will fail it on sight.

That's the difference between a smooth project sign-off and a stop-work order that brings everything to a grinding halt.

Gaining Access to Commercial Markets

The power of the UL Listed mark goes way beyond the job site. It's a non-negotiable commercial requirement. Major distributors, retailers, and industrial suppliers have procurement policies that flat-out demand UL Listing for the products they sell.

It all comes down to liability and risk management. Big players in the market know that UL markings carry different legal and practical weight. They won't touch a product that could put them or their customers at risk. Trying to sell an end-product built with only UL Recognized components is a recipe for commercial failure.

You'll run into some serious business hurdles:

- Limited Sales Channels: Forget about getting stocked by major distributors. Most will refuse to carry a non-Listed product.

- Customer Rejection: Savvy industrial buyers know what to look for. They won't purchase equipment that they know will fail an inspection.

- Insurance and Liability Issues: If an incident like a fire occurs, you can bet the insurance company will scrutinize every component. Using unlisted parts or misapplying Recognized components can lead to denied claims and devastating legal liability.

Navigating the Risks in Control Panel Design

Nowhere are these risks more apparent than in the world of industrial control panels. A control panel is an assembly of countless individual parts, but the finished product must be evaluated as a single, cohesive system to earn a UL Listing under a standard like UL 508A.

You can't just throw a bunch of UL Recognized components into a box and call it a day. That doesn't automatically make the panel compliant.

The panel builder is on the hook for making sure every component is used exactly as its "Conditions of Acceptability" dictate and that the entire design meets the tough construction requirements of UL 508A. For a deeper dive, our guide on industrial control panel design breaks down these critical steps.

Ultimately, the UL Listed mark is your passport to market entry and regulatory approval. It is the definitive proof that a product is complete, safe, and ready for the real world. Relying only on the Recognized status of its internal parts leaves a dangerous—and expensive—compliance gap that can put your whole operation at risk. And remember, product certifications are just one piece of the puzzle; a full understanding of workplace safety protocols, like the NFPA 70E electrical safety standards, is essential for true compliance.

Making The Right Choice in Procurement and Specification

Getting the sourcing decision wrong between UL Listed and UL Recognized isn't just a small technical slip-up. It's the kind of mistake that blows up project timelines and budgets. For any procurement manager or specifying engineer, knowing when to demand each certification is critical for getting a project from design to final sign-off without a hitch.

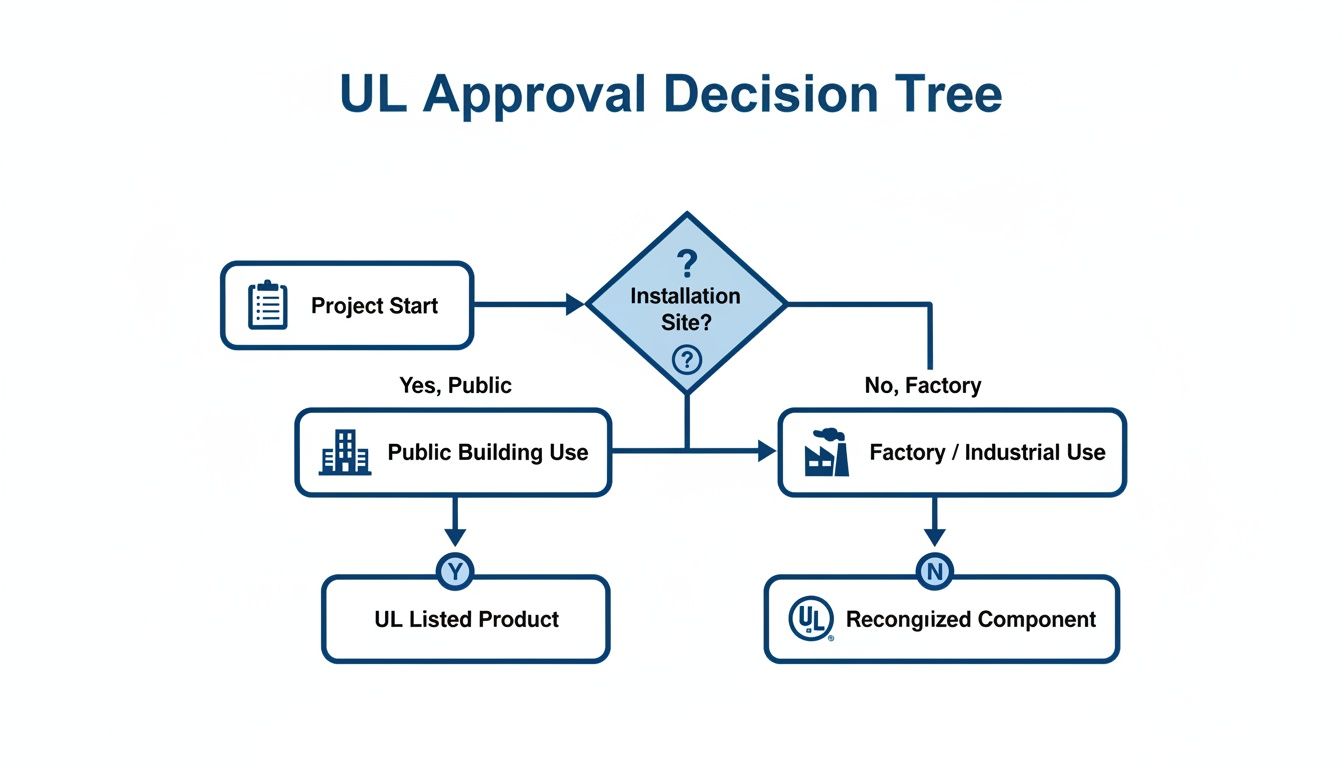

The whole decision really boils down to one simple question: where will this item be installed?

If it's going directly into the field as a standalone piece of equipment, the path is clear—it absolutely must be UL Listed. But if it's just one component being tucked inside a larger assembly in a controlled factory setting, then a UL Recognized part is usually the right—and more cost-effective—call.

Crafting a Compliant Procurement Specification

A vague spec is just asking for trouble. To sidestep any confusion and ensure you get the right parts, your procurement documents have to be crystal clear. Think of a solid specification checklist as your first line of defense against supply chain headaches and non-conforming parts.

Here’s what every single spec sheet should require:

- Define the Certification Type: Be explicit. State "UL Listed" for standalone gear or "UL Recognized" for internal components. Vague terms like "UL Certified" or "UL Approved" are technically meaningless and should never be used.

- Request UL File Numbers: Always require suppliers to provide the specific UL file number for every certified product. That number is your golden ticket to verifying the certification's authenticity and scope.

- Specify the Relevant UL Standard: For something like an industrial control panel, you need to call out the specific standard, like UL 508A. This makes sure the final product is built to the exact safety and construction rules for its job.

When you specify a UL Recognized component, never forget that its certification comes with strings attached. Your design and assembly teams are on the hook for understanding and following its 'Conditions of Acceptability.' If you don't, you've just voided that component's UL status within your final product.

This decision tree gives a nice visual of how the final installation site dictates the procurement path.

As the flowchart shows, any equipment heading out for public or field installation needs a full UL Listing. Components intended for factory integration, on the other hand, can be UL Recognized.

Interpreting Conditions of Acceptability

Sourcing UL Recognized parts doesn't stop once you have the UL file number. The next step is the most important one: digging into the "Conditions of Acceptability." These are the specific rules and limitations UL has defined for that component to ensure it operates safely within a larger system.

These conditions will often spell out details like:

- Electrical Ratings: Maximum voltage, current, and short-circuit current ratings (SCCR).

- Environmental Constraints: Min/max operating temps or required enclosure types.

- Mounting and Spacing: Specific orientations or minimum clearances needed from other components.

Ignoring these conditions is a surefire way to fail the final UL Listing evaluation for your finished assembly. It completely undermines the reason for using a Recognized component to begin with, leading to expensive rework and painful delays. This is a massive point for any control panel builder trying to get a UL 508A Listing on their panel.

Paying close attention to these details ensures every part works for your final system's compliance, not against it. This kind of disciplined approach turns the tricky ul listed vs ul recognized choice into a clear, repeatable process for success.

How To Verify UL Marks and Avoid Counterfeits

Just spotting a UL mark on a product isn't enough to guarantee it’s legitimate. The reality is that counterfeit marks are a persistent headache in the supply chain, creating massive safety risks and liability for everyone involved, from the OEM right down to the plant engineer. A quick visual check is where you start, but real due diligence is digital.

The physical marks themselves offer the first clues. A UL Listed product will almost always have that iconic "UL" inside a circle. On the other hand, a UL Recognized component uses a backward "UR" or "RU" symbol, which is an immediate sign that it's meant for factory installation and isn't a standalone device.

But here’s the problem: counterfeiters have gotten very good at faking these logos. Relying on a label alone is a gamble, especially when you're dealing with something as critical as a miniature circuit breaker, where a failure can have catastrophic results. You have to dig deeper.

The Role of the UL File Number

Every single genuine UL certified product or component has a unique UL File Number. This alphanumeric code is the key to everything—it unlocks the product's entire certification history and scope of use. You'll typically find it printed right on the product label, usually somewhere near the UL mark itself.

Think of this file number as more than just an ID; it's your direct line into UL's official records. Without it, you can't truly verify a thing. If a supplier ever hesitates or can't provide the UL file number for a product they claim is certified, that's a major red flag.

Using the UL Product iQ Database

The definitive tool for verification is the UL Product iQ™ database. This is UL's official online directory of every certified product and component, and it's free for anyone to use. It lets you look up a file number and confirm a product's status in real-time.

The process is straightforward and should be a non-negotiable step for any procurement or quality control team.

- Find the UL File Number: Locate the number on the product's label, its packaging, or in the technical datasheet. For many electrical components, it often starts with the letter "E".

- Go to UL Product iQ: Navigate to the official UL Product iQ website. You'll need to create a free account to get access.

- Enter the File Number: Punch the complete file number into the search field.

- Review the Details: The results will show you the manufacturer's name, the exact UL standard the product was tested against, and—critically—any "Conditions of Acceptability" for UL Recognized components.

If your search for a file number comes up empty, or if the details in the database don't match the product you have in your hands, the UL mark is almost certainly counterfeit or being misused. At that point, reject the product immediately and consider reporting the issue to UL's anti-counterfeiting team.

This simple, data-driven process is the single most powerful tool you have to protect your projects, equipment, and people from the risks of non-compliant parts. It takes the guesswork out of it.

Frequently Asked Questions About UL Certifications

When you're in the trenches designing a system or specifying parts, the distinction between UL Listed and UL Recognized can get a little fuzzy. Let's clear up some of the most common questions that pop up for engineers, procurement managers, and plant operators. Getting these details right is what keeps a project on track and ensures everything is safe and compliant.

Can I Use a UL Recognized Component as a Standalone Product?

Let's make this crystal clear: Absolutely not. A UL Recognized component is, by definition, incomplete. Think of it as a pre-approved ingredient, not the finished meal. Its certification is entirely conditional, meaning it's only valid when used inside a larger system that will eventually get its own full UL Listing.

These parts have only been vetted for a very specific job and haven't gone through the rigorous testing required for a complete device that an electrician would install in the field. An Authority Having Jurisdiction (AHJ)—like your local electrical inspector—would red-flag a field-installed Recognized component in a heartbeat. It simply doesn't meet the electrical code requirements for finished equipment, creating a serious safety hazard and a massive liability risk.

What Are the "Conditions of Acceptability" for a UL Recognized Part?

When UL gives a component its "Recognized" stamp, they issue a report that includes its "Conditions of Acceptability." These aren't suggestions; they are the hard-and-fast rules you must follow when designing that component into your product.

This rulebook is incredibly specific and can cover a wide range of critical parameters.

- Electrical Ratings: This will define the absolute maximum voltage, current, or Short Circuit Current Rating (SCCR) the part can safely handle.

- Thermal Limits: It might specify a maximum ambient operating temperature or mandate the use of a specific heat sink to keep it cool.

- Enclosure Requirements: It will often require a particular type of enclosure to provide the necessary protection against fire or electric shock.

- Mechanical Constraints: You might find details on a required mounting orientation or the minimum spacing needed between it and other components.

The final UL Listing evaluation for your end product will absolutely involve an engineer verifying that you've followed all the Conditions of Acceptability for every single Recognized component you used. If you miss even one, that component's Recognition is void, and your entire product will likely fail its own Listing evaluation. That means expensive redesigns and painful project delays.

Is It Better to Build a Control Panel With All UL Listed Components?

Not really, and honestly, it would usually be impractical and far too expensive. While it's standard practice to use certain UL Listed components like main circuit breakers or power supplies, the real goal is to get a UL Listed final assembly—like a control panel built to the UL 508A standard.

The UL 508A standard was written specifically to guide panel builders on how to correctly and safely use both Listed and Recognized components. Using UL Recognized terminal blocks, relays, contactors, and pilot lights is often much more cost-effective and gives designers the flexibility to create more compact and efficient layouts.

The key takeaway here is that the panel builder must follow the UL 508A standard to the letter and respect every component's unique "Conditions of Acceptability." The focus isn't on the status of every single part inside the box, but on the compliance and Listing of the final, complete panel.

How Do Costs and Timelines Compare for Listed vs. Recognized?

As a general rule, getting a component UL Recognized is significantly cheaper and faster than getting a full product UL Listed. The difference really boils down to the scope of the evaluation.

A Recognition investigation is narrow and focused, looking only at the component itself under a very specific, pre-defined set of conditions. In contrast, a full Listing is a holistic and exhaustive evaluation of the entire end product. That process scrutinizes the enclosure, user interface, overall construction, and performance under all sorts of real-world scenarios, including fault conditions.

This massive difference in testing scope means a full Listing involves more engineering hours, higher lab fees, and a much longer back-and-forth with UL. Based on industry experience, the Recognition process can be 30% to 70% cheaper and might only take a few weeks. A full Listing for a complex piece of equipment, however, can easily take several months from start to finish. This cost-benefit trade-off is exactly why the UL Recognized path exists—it lets component makers provide pre-vetted parts that help OEMs streamline and speed up the Listing process for their own final products.

At E & I Sales, we specialize in navigating these complexities every day. Whether you need expertly engineered UL-listed control panels or premium electric motors for your next project, our team provides the deep product expertise and integration support to ensure your solutions are reliable, code-compliant, and delivered on schedule. Learn how we can help you accelerate your projects and reduce downtime.