When it comes to high-stakes automation, brushless servo motors are the MVPs. These aren't your run-of-the-mill motors; they're complete, intelligent systems built for jobs where precision, speed, and absolute reliability are the only options. Think of them as the elite athletes of the factory floor.

Why Brushless Servos are the Standard in Modern Automation

If you've ever tried to paint a detailed picture with a thick, clumsy brush, you know the frustration. You can get the general shape, but the fine, critical details are lost. That’s the difference between a standard motor and a brushless servo. The former is great for simple, brute-force tasks, but the latter is the fine-tipped tool that makes modern automation possible.

They are the unseen force guiding a CNC machine with microscopic accuracy, the lightning-fast reflexes of a pick-and-place robot, and the steady hand ensuring every package is sealed perfectly. The move toward servos isn't just a fleeting trend. It’s a direct answer to the relentless demand for higher throughput, perfect quality, and machines that just don't quit. And driving this performance is the cutting edge of digital servo motors and drives.

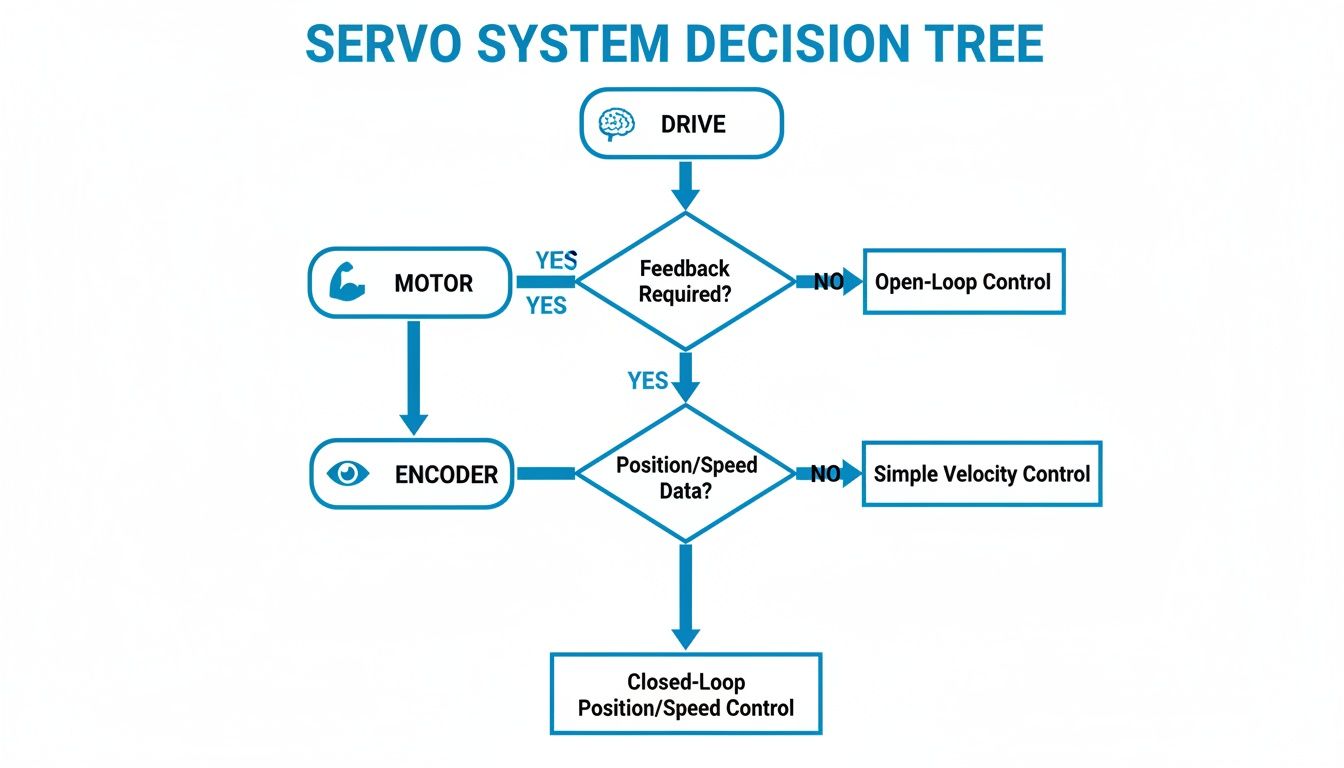

The Three Pillars of Precision

A brushless servo system is really a team of three components working in lock-step to achieve perfect motion.

- The Motor: This is the muscle. Its brushless design means there are no physical brushes to wear down, which translates to a much longer, maintenance-free operational life.

- The Encoder: This is the system's eyes and ears. It constantly watches the motor’s exact position and speed, feeding that information back in real-time.

- The Drive: This is the brain. It takes the feedback from the encoder and instantly sends finely-tuned electrical pulses to the motor, ensuring it never strays from its programmed path.

This constant communication—the feedback loop—is what truly sets a servo apart. The drive is always making tiny, on-the-fly corrections to nail the target position and speed. It's a non-stop process of measure, compare, and correct that guarantees incredible accuracy. This is especially critical in demanding applications, and it's a world away from simpler motor technologies, as we explore in our guide on direct drive motors.

This push for smarter automation is driving huge market growth. The global brushless DC motor market—the heart of these servo systems—was valued at USD 24.01 billion in 2025. It’s projected to nearly double to USD 47.85 billion by 2034. Why? Because eliminating mechanical wear and delivering torque efficiencies that top 90% gives companies a massive competitive edge.

How Brushless Servo Motors Achieve Flawless Control

To really get what makes a brushless servo motor so precise, you can't just think of it as a single component. It's more like a highly coordinated team of specialists working together. This team has three core members, each with a critical job: the motor brings the muscle, the encoder provides the sensory feedback, and the drive is the brain making all the decisions.

Working in perfect sync, they form a closed-loop system that’s constantly checking and correcting itself. This is what allows a servo to execute commands with such incredible accuracy. It's the key difference between a servo and a standard motor. A basic motor gets power and just spins; a brushless servo system is in a constant feedback loop, making thousands of micro-adjustments every second to hit its mark perfectly, every time.

The Powerhouse: The Brushless DC Motor

The motor itself is the brawn of the operation. The genius is in its simplicity—it gets rid of the physical brushes that are the number one point of failure in traditional DC motors. Instead of mechanical brushes making contact to transfer power, it has a permanent magnet rotor spinning inside a stator field with electromagnetic coils.

This "brushless" design means zero friction, no sparking, and no parts to grind down over time. The payoff? You get a motor that runs cooler, is far more efficient (often >90% efficiency), and lasts significantly longer. It's a clean, direct conversion of electricity into pure rotational force.

For anyone in maintenance or plant engineering, this is a huge win. No brushes means fewer PMs on the schedule, far less unexpected downtime, and a lower total cost of ownership over the life of the machine. The thinking is simple: no brushes, no problems.

The Senses: The High-Resolution Encoder

If the motor is the muscle, the encoder is the system’s incredibly precise sense of touch and position. This little device is bolted right onto the motor shaft and acts as a vigilant spotter, constantly tracking the shaft's exact angle, speed, and direction.

Think of it like trying to drive a car with a blindfold on. You can hit the gas, but you have no clue where you are, how fast you're going, or if you're even pointed in the right direction. The encoder is what takes the blindfold off. It sends a constant stream of high-resolution data back to the servo drive, reporting exactly what the motor is doing at any given millisecond.

The Brain: The Intelligent Servo Drive

The servo drive, sometimes called an amplifier, is the sophisticated brain running the whole show. It's constantly running a high-speed calculation to make sure the motion is perfect. The process is straightforward:

- Get the Command: The drive receives a target from a PLC or motion controller, something like, "Move to position 1,250 at 300 RPM."

- Check the Feedback: It immediately looks at the real-time data streaming in from the encoder to see the motor's actual position and speed.

- Correct the Error: The drive instantly calculates the difference—the "error"—between where it should be and where it is. It then sends a precisely adjusted electrical current to the motor's coils to wipe out that error.

This entire sequence happens thousands of times a second. It's this principle, closed-loop control, that allows the system to instantly compensate for changing loads, vibrations, or any other real-world disturbances. The drive's ability to intelligently manage power through electronic commutation ensures the motor is always exactly where it needs to be, doing its job with robotic perfection.

Choosing The Right Motor For Your Application

Picking the right motor technology is one of the most critical calls you'll make in any automation project. This isn't just about grabbing something with enough horsepower; it’s about matching the tool to the specific job at hand. Get it wrong, and you're staring down the barrel of poor performance, unexpected downtime, and costs that spiral out of control.

Think about it this way. A high-speed CNC machine needs to carve intricate patterns into metal with absolute, flawless precision. A desktop 3D printer has to build a prototype layer by layer with dead-on, repeatable steps. And a simple conveyor belt? It just needs to shuttle boxes from point A to point B, no questions asked. Each task demands a totally different flavor of motion control.

This is exactly where the lines between brushless servo motors, stepper motors, and brushed DC motors are drawn. While they all spin, they do so with wildly different levels of precision, speed, and intelligence. The CNC machine is a no-brainer for a brushless servo, with its continuous feedback loop and dynamic response. The printer is a perfect fit for the cost-effective repeatability of a stepper. And that conveyor? The bare-bones simplicity of a brushed DC motor is all it needs.

Head-to-Head Motor Comparison

To make a smart decision, you have to look at how these technologies stack up across the metrics that really matter on the factory floor. We're talking about more than just speed and accuracy. You have to consider the long-game factors like maintenance, operational lifespan, and the total cost of ownership. Each motor type has a unique profile of strengths and weaknesses.

For example, a stepper motor is a fantastic, budget-friendly choice for applications that need high torque at low speeds and solid holding power, like a simple positioning stage. But its performance nosedives at higher speeds, and since it runs open-loop (without feedback), it can lose its position if you overload it. That makes it a non-starter for dynamic, high-speed jobs where a brushless servo truly shines.

The flowchart below gives you a great high-level view of how the pieces of a servo system fit together, starting with the brains of the operation—the intelligent drive.

As you can see, the drive acts as the brain, commanding the motor (the muscle) based on a constant stream of information from the encoder (the senses). This closed-loop system is the very definition of servo performance.

Evaluating Key Industrial Criteria

When you're writing a spec for a motor, you have to look past the initial price tag and think about the full lifecycle. A brushless servo system might cost more upfront, but its incredible efficiency, practically zero maintenance, and long operational life often lead to a much lower total cost of ownership. This is especially true in demanding, 24/7 operations.

The real art is balancing what you need with what you can afford. A stepper motor might look like a bargain, but the cost of a single missed step in a critical process can easily wipe out any initial savings. A brushless servo is basically performance insurance against those kinds of expensive mistakes.

To really nail this down, let’s get into a detailed comparison and see how these three motor types measure up in the real world. A better grasp of these differences will make it crystal clear why brushless servo motors are the go-to solution for so many modern automation challenges. And if you need to get into the nitty-gritty of the forces involved, you can learn more about how to complete a torque calculation for a motor in our other guide.

Motor Technology Comparison for Industrial Applications

This table breaks down the core differences between brushless servo, stepper, and brushed DC motors. Pay close attention to how factors like lifespan and efficiency impact the long-term value beyond the initial purchase price.

| Attribute | Brushless Servo Motor | Stepper Motor | Brushed DC Motor |

|---|---|---|---|

| Precision | Very High. Closed-loop feedback ensures accuracy to fractions of a degree. | High. Good for repeatable steps but can lose position under unexpected load. | Low. Lacks inherent position control; requires external sensors. |

| Speed Range | Very Wide. Maintains high torque across a broad RPM range. | Low to Medium. Torque drops significantly as speed increases. | Wide. Speed is directly proportional to voltage, but control is basic. |

| Efficiency | Excellent (>90%). Brushless design minimizes energy loss. | Low to Medium. Draws full current constantly, even when stationary. | Moderate (75-80%). Energy is lost to heat and friction from brushes. |

| Lifespan | Very Long (20,000+ hours). No brushes to wear out; bearings are the limit. | Long. No brushes, but susceptible to bearing wear. | Limited (1,000-5,000 hours). Brush and commutator wear are primary failure points. |

| Maintenance | Minimal. No brushes to inspect or replace. | Minimal. Simple mechanical design requires little upkeep. | Regular. Requires inspection and replacement of worn brushes. |

| Cost | High. Includes motor, encoder, and intelligent drive. | Low. Simple motor and driver combination is very cost-effective. | Very Low. The simplest and cheapest motor technology to implement. |

Ultimately, the data speaks for itself. For applications demanding high precision, dynamic performance, and long-term reliability, the brushless servo motor stands in a class of its own.

Mastering Torque, Speed, and Efficiency

This is where the rubber meets the road. Performance is what truly sets brushless servo motor technology apart from everything else. While other motors can spin a shaft, a brushless servo delivers precisely controlled power, speed, and force, making it the go-to for applications where every millisecond and micron is non-negotiable.

To see why these systems dominate high-stakes automation, we need to look at three things: torque, speed, and efficiency.

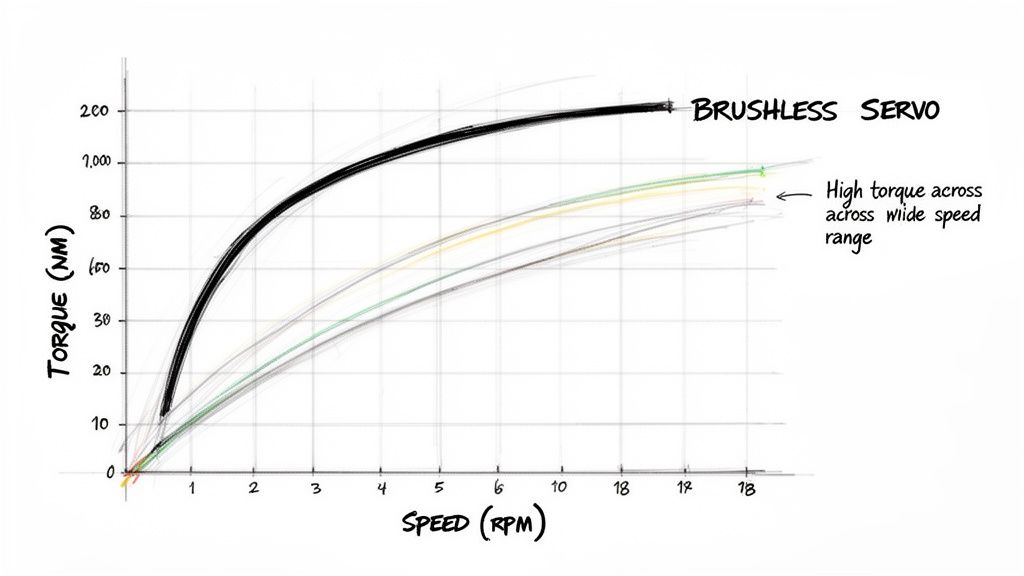

The Torque-Speed Sweet Spot

Think of the relationship between torque and speed as a classic trade-off. With many conventional motors, as you crank up the speed, the available torque (rotational force) just falls off a cliff. It's like a sprinter who bursts out of the blocks but runs out of gas halfway down the track. This can be a massive bottleneck on a production line, forcing you to run machinery slower just to handle heavier parts.

Brushless servos pretty much laugh at this trade-off. They are engineered from the ground up to deliver consistent, high torque across an incredibly wide range of speeds. You can see this clearly on a torque-speed curve; for a brushless servo, it's a long, flat line before it finally starts to taper.

That flat curve is the secret sauce. It means a robotic arm can sling a heavy component around just as forcefully at high speed as it can at a slow crawl. The result? Faster cycle times without ever compromising on power or precision.

Unlocking Serious Energy Efficiency

Efficiency is another area where brushless servo motors are simply in their own league. Since they don't have any physical brushes creating friction, they don't waste energy. It’s an elegant design that converts more electricity directly into useful mechanical work. We’re often talking efficiency ratings of 90% or higher.

That isn't just a number on a spec sheet—it hits the bottom line. A more efficient motor draws less power, which means lower energy bills for the facility, month after month. In an era of rising operational costs and a push for sustainability, that’s a huge win.

The performance gains are substantial. Brushless servos can achieve efficiencies up to 95%, a significant leap over the 75-85% typical for induction motors. This superior efficiency, combined with lifespans exceeding 20,000 hours, makes them an ideal fit for the collaborative robotics sector, where energy-efficiency mandates are driving adoption. Discover more insights about the servo motor market and its growth drivers at Mordor Intelligence.

The Critical Advantage of Running Cool

A direct result of incredible efficiency is fantastic thermal performance. In a motor, wasted energy almost always becomes heat. Since brushless servos waste so little energy, they run significantly cooler than their brushed or even stepper motor cousins.

This cool operation is a game-changer for industrial machinery. Here’s why:

- Longer Component Life: Heat is the mortal enemy of electronics and mechanical parts. A cooler motor means bearings, windings, and encoders last longer, which translates to better reliability and less downtime.

- Tighter Integration: Because they don’t throw off a ton of heat, you can pack brushless servos into tighter spaces without needing bulky fans or complex cooling systems. This is a massive plus in crowded control cabinets or intricate machine designs where every inch counts.

- Improved Safety: Lower operating temperatures reduce the risk of overheating during demanding, non-stop production cycles. This makes the entire machine safer and more stable.

At the end of the day, the exceptional torque, speed, and efficiency of brushless servo motors aren't just technical specs. They are the engine of modern productivity, giving manufacturers the power to build automated systems that are faster, more reliable, and more cost-effective than ever before.

Integrating Brushless Servos Into Your System

Getting a brushless servo system up and running is about much more than just picking a powerful motor. It’s about building a complete, intelligent motion control ecosystem where every part works in perfect concert.

This whole process demands careful planning, from matching the right components to making sure the final assembly meets critical safety and regulatory standards. One wrong move, and you're looking at poor performance and costly delays.

The absolute foundation of a solid system is the relationship between the motor and its drive. Think of it like a high-performance engine and its transmission—one is basically useless without the other. The servo drive has to be matched perfectly to the motor's voltage, current, and feedback specs to actually get the speed and torque you paid for.

Matching Drives and Encoders for Peak Performance

One of the most common mistakes we see is undersizing the drive. This starves the motor of the power it needs under heavy loads, which means you get sluggish, weak performance right when you need it most. On the flip side, an oversized drive is just a waste of money and can make the setup more complicated than it needs to be. The sweet spot is a drive that can comfortably handle the motor’s continuous and peak current demands without going overboard.

The encoder is just as critical. It’s the system's source of truth, constantly telling the drive where the motor shaft is. Its resolution has a direct impact on your final positioning accuracy. For a high-precision CNC machine, you’ll absolutely need a high-resolution absolute encoder. But for a simple pick-and-place robot, a standard incremental encoder will probably do the trick. The key is matching the feedback device to the precision the job demands.

Crucial Takeaway: A servo system is only as strong as its weakest link. A premium motor paired with a mismatched drive or a cheap, low-resolution encoder is a recipe for disappointment. Getting the components paired correctly is the first and most important step toward flawless motion control.

Integrating Safety and Ensuring UL Compliance

Modern automation isn’t just about speed; it's about safety. Safe Torque Off (STO) is a feature that's pretty much non-negotiable these days. STO is a safety function that tells the drive to cut torque to the motor, bringing it to a safe stop without having to kill power to the entire control panel. Integrating STO correctly is fundamental to building machinery that is both highly productive and safe for the people operating it.

This all ties directly into getting a UL-listed control panel. UL certification is a mark of safety and quality that proves the entire assembly was designed and built to strict standards. Everything from component selection to wire sizing and panel layout matters for compliance. If you're building equipment for industrial settings, you have to build with these best practices in mind. You can dig deeper into this in our overview of electric motor control systems.

For the plant maintenance managers and system integrators out there, these details deliver real results. Brushless designs can cut down on heat by 40% and reduce vibration by 60% compared to their brushed counterparts, making them perfect for complex automation hardware. When you source these components through nationwide partnerships, you can even slash project timelines by 15-20% with a single, streamlined commissioning process.

At the end of the day, successful integration is a holistic process. It takes real expertise in both specifying the right components and designing the system as a whole to create a solution that is powerful, safe, and compliant from the get-go.

Where the Rubber Meets the Road: Real-World Applications and Your Procurement Checklist

The theory is great, but the real magic of brushless servo motors happens when you see them solving tough problems on the factory floor. These systems are the muscle behind modern automation, providing the blend of speed and pinpoint control that today's production demands. From robotics to packaging, their impact is everywhere.

Think about the blistering pace of an automated packaging line. It’s a brushless servo that lets a cartoning machine fold, fill, and seal thousands of boxes an hour without ever crushing the product. That ability to react instantly to different product weights and sizes is what makes it so indispensable.

In advanced manufacturing, they're what give robotic arms their smooth, almost human-like movement. A servo allows a robot to weld a perfect seam, apply a flawless coat of paint, or assemble tiny components with sub-millimeter accuracy. It’s the same story with CNC machines, where brushless servos guide cutting tools with absolute fidelity, carving complex parts out of solid blocks of steel.

Your Procurement Checklist for Brushless Servos

Getting the specs right on a brushless servo system is one of the most critical parts of any automation project. One wrong move here can spiral into poor performance, frustrating downtime, and blown budgets. Before you even think about calling a vendor, use this checklist to nail down your requirements. It forces you to ask the right questions and ensures you’re buying a solution, not just a motor.

A solid specification process takes the guesswork out of the equation for both your team and your supplier. It's the foundation for a smooth integration.

Remember, you're not just buying a motor. You're sourcing a complete motion control solution. The more detail you put into your initial requirements, the fewer headaches you'll have during design, build, and commissioning.

Here are the key questions you need to have answers for:

What’s the Load? You need to know the mass, inertia, and any friction the motor has to fight against. Is that load consistent, or does it change mid-cycle?

What’s the Motion Profile? Get specific. Map out the exact speeds, acceleration, and deceleration you need. How far does the load move, and how fast does it need to get there?

How Precise Do You Need to Be? Define the positioning accuracy and repeatability the job requires, down to the micron if necessary. This will point you directly to the right kind of encoder.

What's the Duty Cycle? Is this motor running 24/7, or is it doing short, intermittent bursts of work? This is a huge factor in sizing the motor correctly so it doesn't overheat.

What’s the Environment Like? Take note of the ambient temperature, any moisture or dust (which dictates the IP rating), and whether it will be subjected to shock or vibration.

What Are the Power and Control Needs? What input voltage do you have available? And how does this system need to talk to your main PLC or controller? You'll need to know the right communication protocol, like EtherNet/IP or CANopen.

Walking into a conversation with a supplier armed with these answers means you're in control. You'll get a quote for a brushless servo motor system that will perform exactly as you expect, right out of the box.

Brushless Servo Motor FAQs

When you start digging into the details of brushless servo motors, a few practical questions always seem to pop up. Getting straight answers to these common sticking points can clear up a lot of confusion and make specification and maintenance planning much easier. Here are the quick, no-nonsense answers I give engineers and plant managers every day.

What’s the Main Cause of Failure in Brushless Servo Motors?

This is where brushless motors really shine. Unlike their brushed cousins where brush wear is a constant headache, brushless servos are built like tanks. The most common failures almost never have to do with the motor itself, but with the mechanical parts supporting it.

Bearings are the number one culprit. Usually, it's a simple case of improper lubrication, contamination from the plant environment, or just pushing the motor way past its rated load day in and day out. Other things to watch for include:

- Encoder Failure: These are sensitive electronics. A good jolt from a machine crash, excessive vibration, or electrical noise can knock one out.

- Cable Damage: A frayed or broken cable from poor routing or constant flexing is a classic point of failure that can cause all sorts of intermittent gremlins.

Even with these possibilities, the core motor design is incredibly tough. It’s not uncommon to see them run for well over 20,000 hours in a well-designed system.

Are Brushless Servo Motors More Expensive Than Other Types?

Yes, if you're just looking at the upfront price tag, a full brushless servo system—the motor, encoder, and drive—costs more than a simple stepper or brushed DC motor. But that's not the whole story. You have to think in terms of Total Cost of Ownership (TCO).

The real value of a brushless servo system isn't what you pay for it today, but what it saves you over its entire operational life. That initial cost is an investment in performance and reliability that pays for itself.

Their incredible efficiency means they use less electricity, which adds up on your utility bill. More importantly, the “no-touch” design means you can completely forget about brush inspections and replacements. That’s a huge win for cutting downtime and labor costs. For any demanding application where you can't afford to compromise on precision and speed, a brushless servo delivers performance that other motors just can't touch, making the investment a no-brainer.

Can I Replace a Stepper Motor with a Brushless Servo Motor?

Absolutely. Swapping a stepper for a brushless servo is one of the most common performance upgrades we see, but it's not a simple one-for-one exchange. These two technologies are fundamentally different animals.

A brushless servo demands a closed-loop system. That means you're not just replacing the motor; you have to install the whole package: the servo motor, its high-resolution encoder for feedback, and a dedicated servo drive that can read that feedback and tell the motor what to do. The old stepper motor and its driver have to come out completely.

But the payoff is immediate and significant. You'll get buttery-smooth and quiet operation, much higher speeds without losing torque, pinpoint positional accuracy, and—most importantly—the ability to handle sudden load changes without ever losing its position. That last one is a game-changer if you've ever been frustrated by a stepper stalling out.

For decades, E & I Sales has been the go-to partner for navigating these technical decisions, from picking the right component to integrating a full system. We help OEMs and plant managers design and build automation that just works.

Ready to see what your machine is really capable of? Explore our custom UL control packaging and turnkey integration services at https://eandisales.com.