Think of a Power Distribution Center (PDC) as the heart of an industrial operation's electrical system. It’s a complete, factory-built assembly designed to take the high-voltage power coming into your facility and safely tame it, transforming and directing it to all the machinery that keeps your plant running.

In short, a PDC gives you a single, protected, and manageable control point for your entire operation’s power needs.

The Core Role of a Power Distribution Center

Picture a complex manufacturing plant. You’ve got dozens—maybe hundreds—of motors, pumps, conveyors, and sophisticated control systems. Without a PDC, trying to power everything would be a nightmare. You’d have a chaotic web of individual connections, each with its own safety risks and maintenance headaches.

This is exactly the problem a Power Distribution Center solves, and it does it with an elegant simplicity.

A PDC taps into a single, high-voltage feed from the utility and acts like a highly sophisticated traffic controller for that electricity. Safely tucked inside its rugged enclosure, transformers step the voltage down to usable levels for your equipment. From there, switchgear and circuit breakers safely route that power out to various loads, simplifying the entire electrical architecture of a plant or equipment skid.

Let's break down the essential jobs a PDC handles.

Core Functions of a Power Distribution Center

Here's a quick look at the primary roles a PDC plays and why they matter for day-to-day operations.

| Function | Description | Impact on Operations |

|---|---|---|

| Voltage Transformation | Steps down high-voltage utility power (e.g., 13.8kV) to lower, usable voltages (e.g., 480V) for machinery. | Eliminates the need for multiple, separate transformers scattered across the plant, simplifying infrastructure and maintenance. |

| Centralized Distribution | Provides a single, organized hub for routing power to all downstream equipment, from motors to control panels. | Prevents hazardous "spaghetti wiring" and creates a logical, easy-to-trace power map of the facility. |

| Overcurrent Protection | Uses circuit breakers and fuses to instantly interrupt power during faults like short circuits or overloads. | Protects expensive equipment from catastrophic damage and prevents small issues from cascading into facility-wide blackouts. |

| Safety and Isolation | Consolidates disconnects into one location, allowing technicians to safely de-energize equipment for maintenance. | Drastically improves worker safety, simplifies Lockout/Tagout (LOTO) procedures, and reduces the time needed for repairs. |

Ultimately, a PDC brings order, safety, and reliability to what would otherwise be a dangerously complex system.

Centralizing Power Management

The most obvious win you get from a PDC is centralization. Instead of hunting down dozens of disconnects spread across a massive facility, your team has a single source of truth for power. This alone makes troubleshooting, routine checks, and overall power management worlds easier.

This centralized approach brings a few key advantages:

- Simplified Lockout/Tagout: When it's time for maintenance, having a single main point of disconnection makes safety procedures faster and far more reliable.

- Streamlined Monitoring: Centralized metering gives plant managers a bird's-eye view of energy consumption for the entire operation, all from one dashboard.

- Organized Distribution: It enforces a logical and orderly way to route power, getting rid of the tangled, hazardous wiring that plagues older or poorly planned facilities.

By bringing everything together, a PDC creates a more organized, safer, and predictable electrical environment. This structure is the foundation for preventing overloads and slashing unplanned downtime.

Protecting People and Equipment

Beyond just keeping things tidy, a Power Distribution Center’s most critical job is protection. It stands as a formidable guardian against the electrical faults that can destroy expensive machinery and, more importantly, endanger your people. It's designed to isolate problems at the source before they can ripple through the entire system.

A fault in one area shouldn’t shut down your entire operation, and a well-designed PDC ensures it won’t.

A well-designed power distribution center is the bedrock of operational uptime. By isolating faults and protecting equipment, it directly translates into improved reliability, increased production, and a stronger bottom line.

This protective role means the PDC has to work in harmony with all the downstream equipment it feeds. For instance, a PDC supplies the main power to other critical components, and you can learn more about how a Motor Control Center fits into this system.

At the end of the day, this integrated approach ensures that every single component—from the main incoming line to the final motor—is protected. That robust, end-to-end protection is the backbone of any reliable and profitable industrial operation.

What's Inside a Power Distribution Center?

To really get what a power distribution center does, you have to look under the hood. It’s way more than just a big metal box. A PDC is a highly engineered system where every single component has a job to do. I like to think of it like a city's power grid in miniature—it has a main power plant, substations, and local circuit protection, all working in concert to get electricity where it needs to go safely and reliably.

Let's trace the path of power, starting from where the high-voltage feed comes into the enclosure. This journey shows exactly how raw, untamed utility power is stepped down, routed, and safeguarded before it ever gets to your critical equipment.

This diagram neatly sums up the three primary functions of a PDC.

As you can see, the real value of a PDC is its ability to centralize control, protect your assets, and manage the entire electrical flow from one strategic point.

The Main Disconnect and Transformer

The whole process starts at the main incoming disconnect or circuit breaker. This is the big red button for the entire PDC, letting technicians kill the power to the whole system for safe maintenance or emergency shutdowns. It’s your first line of defense and the master switch for everything downstream.

Right after the disconnect, you'll find the transformer, which is the real workhorse of the system. Industrial plants often get fed with some serious high-voltage power (like 13,800 volts), which would fry most equipment instantly. The transformer’s job is to "step down" this voltage to something usable, which is typically 480/277V in most industrial settings.

You can think of the transformer like a pressure regulator in a high-pressure water main. It takes immense, unusable force and dials it back to a safe and manageable level for all the smaller pipes and faucets. Without it, your motors, drives, and control panels wouldn't stand a chance.

Switchgear and Busbars: The Power Highways

Once the voltage is at a usable level, that power has to get distributed. That’s where switchgear and busbars come in. If the transformer is the pressure regulator, then busbars are the massive, multi-lane superhighways that carry the electrical current throughout the PDC.

These thick, solid bars of copper or aluminum are much better at handling heavy current loads than conventional wiring could ever be.

The design of the busbar system is fundamental to the PDC's capacity and reliability. Proper sizing and bracing of these "electrical highways" directly determine the unit's short-circuit current rating (SCCR), a critical safety metric.

Bolted onto these busbars is the switchgear—an assembly of circuit breakers and switches that act like on-ramps and off-ramps on our power highway. They safely channel electricity from the main busbars out to smaller feeder circuits, which then go on to power individual machines, control panels, or motor control centers.

Circuit Breakers and Metering Devices

Every one of those feeder circuits has its own circuit breaker for protection. These are the smart, fast-acting safety guards of the PDC. Their one and only job is to watch the current flowing through them and, if they detect an overload or a dead short, to trip instantly and cut the power.

This is what stops a single malfunctioning motor from tripping the main breaker and shutting down your entire plant. Depending on the application, you'll see different kinds of breakers, from basic thermal-magnetic ones to sophisticated electronic trip units that give you incredibly precise control and feedback.

Finally, we have the metering devices, which are basically the PDC's dashboard. These instruments give you a real-time look at critical data, including:

- Voltage and Current: Are your power levels stable and within spec?

- Power Factor: How efficiently is your facility using electricity?

- Energy Consumption (kWh): Where is your power going, and how much is it costing you?

This information isn't just nice to have anymore; it's absolutely essential for smart maintenance and operational efficiency. By keeping an eye on these numbers, engineers can spot problems like voltage sags or harmonic distortion long before they cause a catastrophic failure. This turns the PDC from a passive electrical box into an active, manageable asset that helps keep your facility running smoothly.

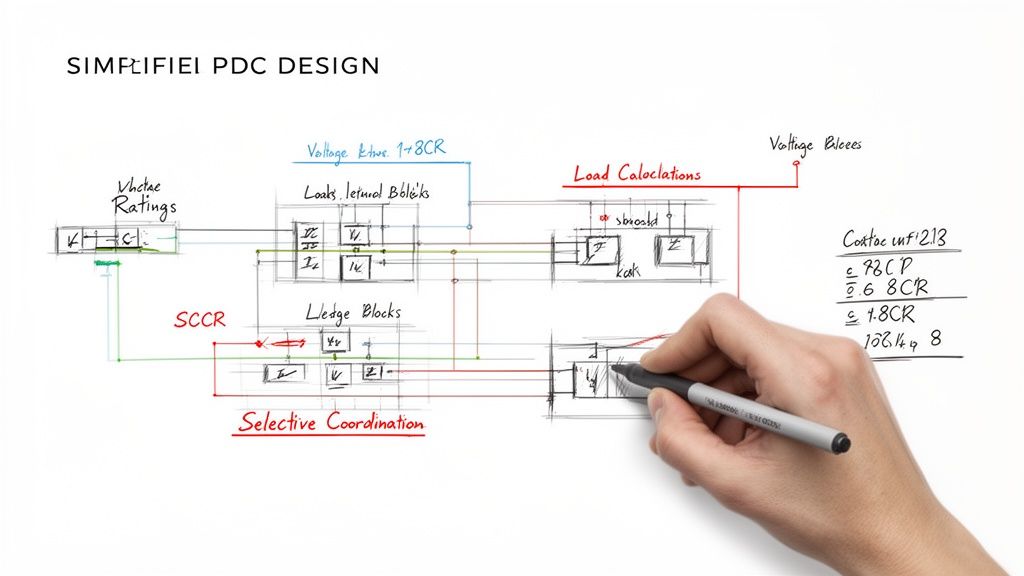

How to Design and Specify Your Power Distribution Center

Putting together a power distribution center is so much more than just connecting a few wires. It's about engineering the electrical backbone for an entire operation—one that’s safe, efficient, and built to last. When you get the specs right from the start, you sidestep costly mistakes, slash potential downtime, and build a system that can handle not just today's needs, but tomorrow's growth, too.

It all comes down to a methodical approach. You have to start with the most basic question: how much power does all your equipment actually need? From that single point, every other decision—from voltage ratings to grounding schemes—falls into place to create a truly reliable system.

Nailing Down Load Requirements and Voltage Ratings

Your first move is always a detailed load calculation. This means listing out every single piece of equipment that will pull power from the PDC—motors, heaters, control panels, lights, you name it—and adding up their power demands. It's absolutely critical to account for both the constant, steady loads and the big, power-hungry machines that only kick on intermittently.

One of the most common trip-ups we see is underestimating future needs. A solid rule of thumb is to build in a 20-25% capacity buffer on top of your total calculated load. That extra headroom gives you the flexibility to add more equipment later without having to rip and replace the entire PDC.

With a clear picture of your load, you can pin down the right voltage ratings. This is usually dictated by the incoming utility service and the demands of your biggest motors or machines. A very common setup in industrial plants is stepping down a medium-voltage feed (say, 13.8kV) to a much more usable 480V for the three-phase motor loads on the floor.

Understanding Short-Circuit Current Ratings (SCCR)

Once you've got the basic load and voltage sorted, the conversation has to turn to a critical safety metric: the Short-Circuit Current Rating (SCCR). In simple terms, SCCR is the maximum amount of fault current a component can handle without failing catastrophically—as in, exploding or catching fire.

Think of it as the system's ability to withstand an electrical hurricane. A low SCCR is like building a house that can't handle high winds. When a fault hits, the results are disastrous.

The SCCR of your entire power distribution center is only as strong as its weakest link. Every single component—from the main breaker down to the smallest terminal block—must be rated to handle the available fault current at its specific location.

Figuring out the available fault current from the utility transformer isn't just a good idea; it's a non-negotiable step. That number determines the minimum SCCR you need for your main protection device and has a domino effect on the ratings for everything downstream, creating a fully coordinated and safe system.

The Critical Role of Selective Coordination

Selective coordination is a smart design strategy that can make a world of difference in your plant's reliability. Imagine this: in a system without coordination, a short circuit on a tiny branch circuit—like a single motor—could trip the main breaker and shut down the entire facility. That’s a massive, costly headache.

Selective coordination is the fix. It ensures that only the breaker closest to the fault is the one that opens. So, if that one pump motor fails, its dedicated breaker trips, but the rest of the plant keeps humming along without interruption.

You achieve this by carefully choosing breakers with specific trip curves and time-delay settings. The breaker downstream is always set to react faster than the one upstream, creating a clear and precise protective hierarchy. This isn't just a "nice-to-have" feature; it's often a code requirement for critical infrastructure like emergency and life-safety circuits.

Grounding Strategies and Metering Integration

Proper grounding is the bedrock of electrical safety. Period. It gives fault currents a safe, low-resistance path back to the source, which lets breakers do their job and trip quickly. This prevents dangerous voltages from energizing equipment frames and enclosures where people could touch them. The grounding scheme you choose, like a solidly grounded wye system, is a critical design call that impacts both personnel safety and equipment protection.

Beyond just safety, today's PDCs are becoming much smarter. By integrating advanced metering, they transform from passive power hubs into active energy management tools. Smart meters and power quality monitors can give you real-time data on things like:

- Energy Consumption (kWh): Pinpoint where your energy is going and find opportunities to be more efficient.

- Voltage Sags and Swells: Catch power quality problems that can wreak havoc on sensitive electronics.

- Harmonic Distortion: Identify "dirty power" from equipment like VFDs that causes overheating and premature failure.

This level of insight turns the PDC into an information hub, paving the way for predictive maintenance and lower operating costs. It's a key principle behind modern industrial control panel design and total system integration.

The demand for these smarter, more resilient components is exploding. The global power distribution component market is forecast to more than double from USD 309.6 billion in 2025 to a staggering USD 644.0 billion by 2035. It’s a clear signal of the massive shift toward industrial electrification and grid modernization. You can dig deeper into the factors driving this growth in the power distribution market.

To help you get started, we've put together a checklist of the essential design factors you need to consider.

PDC Design and Specification Checklist

Thinking through these factors methodically will help ensure your power distribution center is safe, reliable, and perfectly matched to your operational needs.

| Design Factor | Key Consideration | Why It Matters |

|---|---|---|

| Load Calculation | Sum of all connected equipment loads + 20-25% future capacity. | Prevents undersizing, which leads to overloads and costly future upgrades. |

| Voltage Rating | Match incoming utility service and major equipment requirements (e.g., 480V, 4160V). | Ensures compatibility and efficient power delivery to all loads. |

| SCCR | Available fault current from the utility transformer. | Guarantees the system can safely withstand a short-circuit event without catastrophic failure. |

| Selective Coordination | Breaker trip curves and settings arranged in a hierarchy. | Isolates faults to the smallest possible area, preventing widespread outages and maximizing uptime. |

| Grounding System | Solidly grounded, high-resistance, etc. | Provides a safe path for fault current, protecting personnel and equipment from electric shock. |

| Metering | Energy, power quality, and demand monitoring. | Offers valuable data for energy management, predictive maintenance, and operational efficiency. |

This checklist isn't exhaustive, but it covers the core pillars of a well-engineered PDC. Getting these right is the first step toward a robust and dependable electrical infrastructure.

Of course. Here is the rewritten section, crafted to sound like it was written by an experienced human expert.

Getting the Codes Right and Making Integration Work

Think of codes and standards not as a bureaucratic pain, but as the very bedrock of a safe and reliable power distribution center. Getting this right isn't just about checking a box; it's about building something that will stand up to real-world electrical demands without putting people or equipment at risk.

Skipping this step is a recipe for disaster. You're opening the door to equipment failures, serious safety hazards, and massive financial liability. A properly certified PDC, on the other hand, is your proof—your peace of mind—that the entire system has been put through its paces against the industry’s toughest benchmarks.

UL, NEC, and What They Actually Mean for You

When you're specifying a power distribution center, you'll hear two acronyms constantly: NEC and UL. You have to know what they mean. The National Electrical Code (NEC) is the rulebook for how to safely install electrical systems in the U.S. Underwriters Laboratories (UL) is the independent third party that tests and certifies the equipment itself to prove it meets those safety standards.

It's a simple relationship: the NEC sets the rules of the game, and a UL listing is the seal of approval that says your equipment is ready to play safely.

You'll run into a few key standards over and over:

- UL 508A: This is the go-to standard for Industrial Control Panels. While a PDC is much more than a control panel, its low-voltage control sections often need this certification. It ensures all the components are chosen correctly, wired professionally, and protected from overcurrent.

- UL 891: This one covers Switchboards, which form the backbone of most PDCs. A UL 891 listing tells you the heavy-duty stuff—the busbars, the structural bracing, the main breakers—has been tested to handle its rated voltage and, crucially, survive a massive short-circuit event.

A UL-listed power distribution center isn't just a pile of UL-listed parts. It means the entire assembly has been evaluated as a single, cohesive system. That's the stamp of approval that gives inspectors, insurers, and your own team the confidence that it will perform as designed.

The Integration Headache (And How to Avoid It)

A power distribution center doesn't live on an island. It’s the heart of the plant, feeding power to other critical systems—especially Motor Control Centers (MCCs) and the automation systems run by PLCs. The real trick is getting all these pieces to talk to each other without a fuss.

Too often, the PDC and the MCC are designed in separate vacuums. The result? A messy, inefficient system that's a nightmare to troubleshoot. Communication protocols don't match up, wiring becomes a field-fit puzzle, and the points of failure start multiplying. This approach almost always leads to blown schedules and a lot of finger-pointing during startup.

A fragmented electrical system just creates friction. Real efficiency happens when you treat the PDC, motor control, and automation as one cohesive system, designed from the very beginning to work together.

When you bring the design of the PDC, MCC, and control panels under one roof—often with a single build partner—you get a truly integrated system. This move consolidates all the accountability and guarantees every component communicates flawlessly from day one.

This integrated strategy pays off in big ways:

- Faster Startups: You can run a full Factory Acceptance Test (FAT) on the entire system before it ever leaves the shop floor. This lets you squash integration bugs early, slashing the time you spend commissioning in the field.

- Fewer Failure Points: A unified design gets rid of redundant components and the spaghetti-like wiring between them. The final product is cleaner, simpler, and far more reliable.

- Simpler Controls: When the PDC and MCC are engineered together, things like automation signals and power monitoring can be built right in. This gives operators a single, clear dashboard to see what the entire system is doing.

At the end of the day, a power distribution center that’s been thoughtfully integrated with its downstream loads is more than just a glorified breaker box. It becomes the intelligent, rock-solid core of your entire operation.

Getting Your Power Distribution Center From Purchase Order to Power-On

You can have the best-designed power distribution center on paper, but if you can't get it built and installed correctly, it's all for nothing. The final two hurdles—procurement and installation—are where even the most meticulously planned projects can get tripped up by supply chain nightmares or simple mistakes in the field.

Think of this as your roadmap to get from a purchase order to a fully commissioned system, making sure your project stays on track and on budget right through to startup. The key is understanding the market as it is right now, not as it was a few years ago. Proactive planning, especially for those big-ticket items with long lead times, is no longer optional.

Navigating Procurement in a Wild Market

Let's be blunt: the days of ordering major electrical gear and getting it in a few weeks are long gone. You need a forward-thinking strategy, and that starts with acknowledging the elephant in the room—transformers. They have become a massive bottleneck, with demand completely overwhelming supply and pushing project timelines out by months, sometimes even longer.

The numbers don't lie. The U.S. transformer market is facing a critical shortfall. Projections for 2025 show a 30% supply deficit for large power transformers and a 10% shortfall for distribution transformers. This isn't surprising when you see that demand has skyrocketed since 2019, jumping 116% for power transformers and 41% for their distribution counterparts. This surge is fueled by everything from grid upgrades to widespread industrial electrification. You can dig into the specifics in the full transformer supply report from Wood Mackenzie.

So, how do you protect your project?

- Order Early, Order Now: As soon as your design is locked in, get the purchase orders out for transformers, switchgear, and any other long-lead components. Don't wait.

- Lean on Your Supplier: Partner with a supplier who has deep roots and strong relationships with manufacturers. They'll have a much better handle on realistic lead times.

- Stay Flexible: Be open to alternative manufacturers or components if your first choice is stuck in backorder limbo. As long as the specs and safety ratings line up, flexibility can save your schedule.

Turning procurement from a roadblock into just another step in the plan means getting ahead of it. Working with a trusted control panel builder who lives and breathes these market dynamics is your best defense.

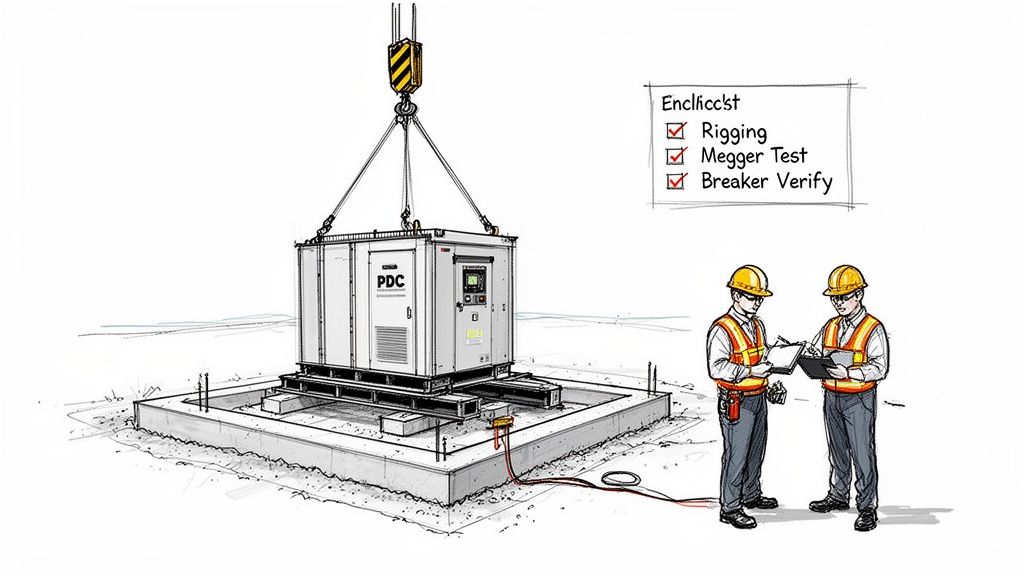

Executing a Flawless Field Installation

Once the PDC arrives on site, the focus pivots to a precise, safe installation. This is much more than just dropping a box on a slab and pulling some cable. It's a methodical process that, when done right, ensures the system will perform reliably for the next 20 or 30 years.

A clean, professional installation is a preview of the system's future reliability. Rushed work, improper rigging, or sloppy wiring just bake in points of failure and create maintenance headaches down the road.

A top-notch installation always follows a clear playbook.

- Site Prep and Rigging: It starts with the foundation. The concrete pad must be perfectly level and engineered to handle the PDC's substantial weight. When the crane arrives, using the designated rigging points is non-negotiable. One wrong move here can damage the enclosure's structural integrity before it's even wired.

- Field Wiring and Terminations: With the PDC set, electricians get to work connecting the main utility feed and all the outgoing circuits. Every single connection needs to be torqued to the manufacturer’s exact specification. Loose terminations are a leading cause of overheating and, in the worst-case scenario, catastrophic failure.

- Commissioning and Go-Live: Before a single volt of operational power flows, a final round of checks is mandatory. Megger testing is used to check the insulation resistance and ensure there are no shorts. Every breaker is functionally tested to confirm it operates correctly. Only after these tests are complete and documented should the system be energized.

Following these steps ensures the PDC you so carefully designed and procured becomes the safe, dependable asset you need, ready to power your operations for years to come.

The Future of Industrial Power Distribution

The industrial electrical landscape is changing, and fast. The days of a stable, predictable power grid that you could simply take for granted are fading. Today, the grid is under more strain than ever, forcing a complete rethink of how a modern power distribution center needs to function.

Tomorrow's PDC isn't just a box of breakers and transformers. It has to be smarter, tougher, and way more adaptable than anything that came before it. This isn't some far-off trend; it's a reality being driven by two massive forces. First, the explosive growth of power-hungry sectors like data centers is creating a traffic jam on the grid. Second, the same digital tech that's changing everything else is unlocking incredible new ways to manage power. Getting ahead of this isn't just a good idea—it's essential for building an industrial operation that can actually survive and thrive.

Grid Strain and the Rise of Smart PDCs

Think about the sheer number of new hyperscale data centers popping up. They are putting a massive new load on the electrical grid, and that directly affects every other industrial user out there. This surge in demand can mess with power quality and cause major delays for anyone trying to get a new service connection.

Here's a stunning number: total grid demand from data centers could nearly triple between 2025 and 2030. Some utilities are seeing new connection requests that add up to tens of gigawatts. This isn't just a data center problem; it puts a squeeze on the available power for everyone. You can dig into the full analysis of how data centers are reshaping grid power demand to see the scale of the issue.

The answer to this challenge is making the power distribution center intelligent. A "smart" PDC isn't just a buzzword. It means integrating IoT sensors and real-time analytics to create a system that tells you exactly what's going on with your power.

This is what a smart PDC brings to the table:

- Predictive Analytics: Imagine sensors monitoring the temperature, vibration, and current inside your PDC in real-time. By analyzing this constant stream of data, the system can spot the signs of a failing transformer or breaker weeks before it happens. That turns a catastrophic unplanned outage into a simple scheduled maintenance task.

- Energy Optimization: Smart metering gives you a granular, circuit-by-circuit view of where your energy is going. You can instantly spot inefficient equipment or correct a poor power factor, directly cutting your utility bills.

- Remote Monitoring: Plant managers get a live dashboard on their phone or laptop. They can see the system's status from anywhere, get instant alerts, and make decisions on the spot.

This is a fundamental shift from a reactive to a proactive way of managing power. Instead of waiting for something to break, a smart PDC is constantly working to prevent problems, keeping your operation running at peak uptime and efficiency.

As we look at these technical evolutions, it's also worth remembering the bigger picture of corporate responsibility. Integrating solid ESG strategies for sustainability and responsibility is becoming just as important as the hardware itself.

Modular E-Houses and Turnkey Deployment

Another huge shift is the move away from building electrical rooms from scratch on-site. The old "stick-built" approach is being replaced by the electrical house (e-house)—a self-contained, walk-in metal building that holds the entire power distribution center.

The real magic here is that these e-houses are completely engineered, built, and tested in a controlled factory environment. Once they pass every test, they're shipped to your site as a single, complete unit.

This is a game-changer for project timelines. All the complex wiring, integration, and testing happen off-site, in parallel with your site prep. When the e-house arrives, it's basically a "plug and play" installation. This slashes the need for on-site labor, gets rid of weather delays, and ensures a higher level of quality control. For any industrial operation that needs to get up and running quickly and reliably, this modular approach is the future.

Frequently Asked Questions

When you're in the weeds on a project, a few practical questions about power distribution centers always seem to pop up. Let's tackle some of the most common ones we hear from engineers and project managers out in the field.

Is a PDC the Same as a Switchboard?

Not quite, though it’s easy to see why they get confused. The simplest way to think about it is that a switchboard is a critical component, while a power distribution center (PDC) is the whole integrated package.

A switchboard is really just the guts—an assembly of breakers and busbars that slices up and directs power. A PDC, on the other hand, is a complete, pre-engineered system built in a factory. It arrives on-site with the switchboard already inside, along with the main transformer, disconnects, and often metering equipment, all buttoned up in one tough, self-contained enclosure. It's the turnkey, plug-and-play version.

How Often Does a Power Distribution Center Need Maintenance?

To keep a PDC running reliably for years, you can’t just set it and forget it. A solid maintenance rhythm is key. Here’s a practical schedule we recommend:

- Annual Visual Inspection: Once a year, do a thorough walk-down. You're looking for the obvious signs of trouble—overheating, corrosion, or any physical damage. Get a torque wrench out and verify that critical connections are still tight and make sure everything is clean.

- Infrared (IR) Thermography: This is a non-negotiable, also done annually while the system is under load. An IR scan is the best tool you have for spotting loose connections or failing components that are heating up, long before they decide to fail spectacularly.

Think of infrared scanning as an X-ray for your electrical system. It reveals hidden problems that the naked eye can't see, making it one of the most effective predictive maintenance tools available.

Can You Upgrade an Existing PDC?

Yes, you absolutely can, but you have to do your homework first. Expanding a plant often means needing to add capacity or new circuits to an existing power distribution center. The first step is always a detailed load study to make sure the main transformer and busbars can actually handle the extra demand you plan to throw at them.

If you’ve got enough headroom, a qualified technician can add new feeder breakers without much fuss. But if you find the PDC is already running close to its limit, you'll need to look at either a full replacement or adding a second unit to carry the new load safely.

From initial design to final commissioning, the team at E & I Sales provides the expertise needed to deliver a reliable power distribution center tailored to your exact specifications. Contact us today to discuss your project.