When you're trying to pick the right starter for a motor, a NEMA motor starter sizing chart is your best friend. It gives you a direct, standardized way to match a starter to your motor's horsepower (HP) and voltage. No guesswork, no crossed fingers—just a clear path to selecting the right equipment.

For example, if you have a 10 HP motor running at 460V, the chart will point you directly to a NEMA Size 1 starter. This kind of straightforward guidance is what makes the NEMA system so reliable for ensuring safe and dependable operation.

Why a NEMA Sizing Chart Is Essential

Choosing the right motor starter isn't a minor detail; it's a critical decision that impacts equipment longevity, uptime, and even facility safety. A starter that's too small is a recipe for disaster, leading to premature failure, frustrating downtime, and serious electrical hazards.

A NEMA sizing chart cuts through the complexity. It gives engineers, technicians, and system designers a trusted reference built on decades of industry experience. Think of it as the foundation for maintaining the integrity and performance of your entire system. The goal is simple: make sure the starter can handle not just the motor's continuous running current, but also the massive inrush current it draws on startup. NEMA standards are famously robust, with built-in safety margins designed for the tough conditions common in North American industrial plants.

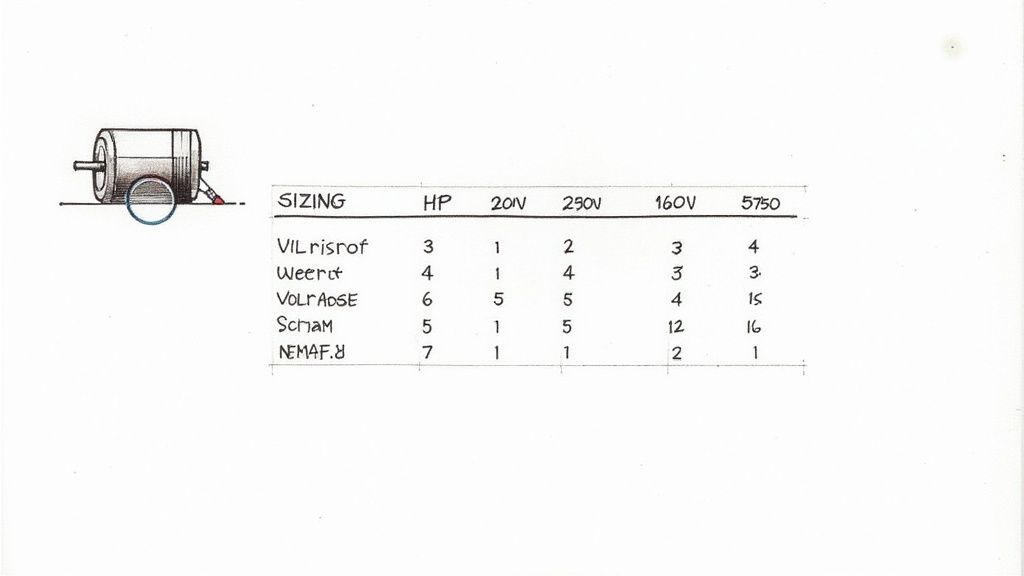

NEMA Starter Size vs Motor HP and Voltage (Three-Phase)

This table is your go-to reference for quickly finding the correct NEMA starter size. Just find your motor's horsepower and operating voltage to identify the corresponding NEMA size you'll need.

| NEMA Size | Continuous Amp Rating | Max HP at 200V | Max HP at 230V | Max HP at 460V / 575V |

|---|---|---|---|---|

| 00 | 9A | 1.5 HP | 1.5 HP | 2 HP |

| 0 | 18A | 3 HP | 3 HP | 5 HP |

| 1 | 27A | 7.5 HP | 7.5 HP | 10 HP |

| 2 | 45A | 10 HP | 15 HP | 25 HP |

| 3 | 90A | 25 HP | 30 HP | 50 HP |

| 4 | 135A | 40 HP | 50 HP | 100 HP |

| 5 | 270A | 75 HP | 100 HP | 200 HP |

| 6 | 540A | 150 HP | 200 HP | 400 HP |

| 7 | 810A | – | 300 HP | 600 HP |

| 8 | 1215A | – | 450 HP | 900 HP |

| 9 | 2250A | – | 800 HP | 1600 HP |

As you can see, the NEMA system covers an incredible range, from fractional horsepower motors all the way up to massive industrial drivers. This standardized approach simplifies everything from design to maintenance.

Key Benefits of Using a Standard Chart

Sticking to the NEMA charts when selecting a starter brings some serious advantages that go well beyond just getting the right part number.

- Enhanced Safety: This is the big one. Proper sizing prevents overloading, a primary culprit behind motor burnout and electrical fires.

- Improved Reliability: It guarantees the starter's contacts and coils are beefy enough for the job, which translates directly to a longer service life and less unexpected downtime.

- Streamlined Specification: Using a universal standard makes the design and procurement process much simpler, ensuring consistency across different projects and facilities.

- Code Compliance: Following NEMA guidelines helps ensure your installations are up to snuff with the National Electrical Code (NEC) and other local regulations.

At the end of the day, these charts are all about matching horsepower and voltage to a specific starter size. Take a 50 HP motor at 460 volts—that lines up perfectly with a NEMA Size 3, which is rated for 90 amps of continuous current. This classification system runs from Size 00 for tiny 2 HP motors all the way up to Size 9 for enormous 900 HP units.

It's true that NEMA starters are often physically larger than their IEC counterparts, sometimes nearly double the size. But that extra bulk comes with a huge upside: durability. They are built like tanks and often rated for millions of operations, making them a fixture in demanding environments. You can learn more about how to properly size a motor starter for maximum efficiency and safety.

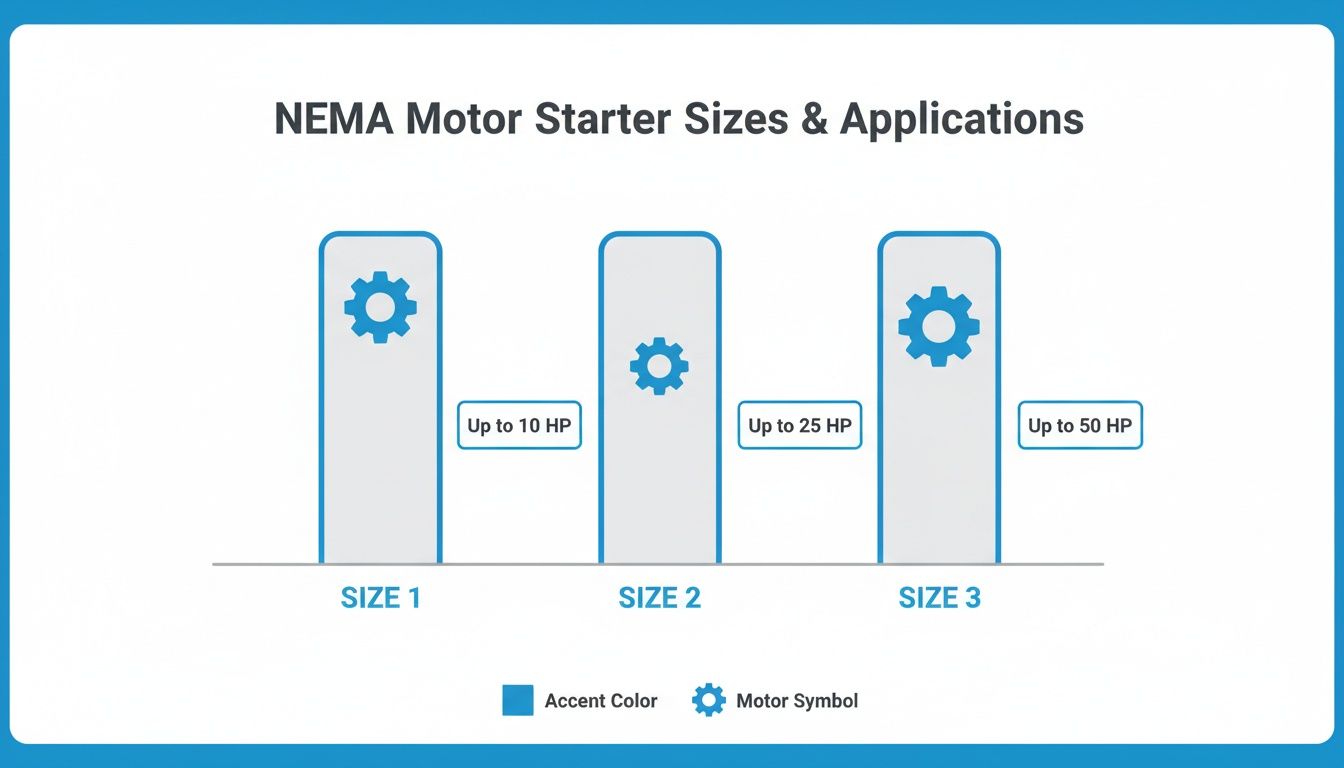

This chart shows some of the most common applications for NEMA starter sizes you'll encounter in the field.

It’s a great visual reminder of how each NEMA size is engineered to handle a specific horsepower range, making your selection process predictable and reliable.

Understanding Core NEMA Starter Principles

Before you even glance at a NEMA motor starter sizing chart, it pays to understand the philosophy behind their design. The National Electrical Manufacturers Association (NEMA) sets the standards for most electrical gear made and used in North America, and their whole approach is built around safety, reliability, and interoperability. NEMA standards are all about durability and generous safety factors, which is why their starters are famous for being absolute tanks built to survive harsh industrial environments.

This is a completely different world from the International Electrotechnical Commission (IEC) standards you see more often globally. IEC starters are generally smaller and more tailored to a specific job, meaning you have to nail the selection based on the exact duty cycle and load. NEMA’s way of thinking is to build a heavy-duty, field-serviceable starter that can take a beating from voltage swings and massive inrush currents without breaking a sweat.

Decoding Key Motor Nameplate Data

To pick the right starter, you first have to know how to read the motor’s nameplate. These ratings are what drive your starter sizing and, just as importantly, your overload protection settings.

- Full Load Amps (FLA): This is the current your motor pulls when it's running at its rated horsepower. It’s the number one value you'll use for choosing the starter’s overload relay heater elements, which are there to protect the motor from cooking itself.

- Service Factor (SF): Think of the Service Factor as a built-in "overload" capacity. It’s a multiplier that tells you how much extra load a motor can handle for short bursts without being damaged. For example, a motor with a 1.15 SF can safely operate at 115% of its rated horsepower. This is a crucial piece of the puzzle for calculating the max current for your overload relay.

- Locked Rotor Amps (LRA): Also called inrush current, LRA is that massive surge of current a motor draws in the instant it starts up. We’re talking a huge spike, often 6 to 8 times the normal FLA. NEMA starters are specifically designed to handle this initial punch.

NEMA vs. IEC: A Practical Comparison

The choice between NEMA and IEC really boils down to the job at hand and where in the world you are. For the kind of heavy-duty work common in North American plants, NEMA starters are the default choice. Their rugged build and ease of service are what keep facilities running.

A huge real-world advantage of NEMA is its standardized sizing. You can often swap heater elements between different brands. This makes maintenance a lot simpler and means you don't have to stock a mountain of brand-specific spare parts—a massive plus for any large industrial site.

On the flip side, IEC starters get the nod for their compact size and lower initial cost, making them a good fit for OEM equipment or lighter-duty applications. But, they demand much more precise engineering for every single use case. For most industrial jobs in North America, the sheer durability and reliability of the NEMA system deliver better long-term value and, frankly, more peace of mind.

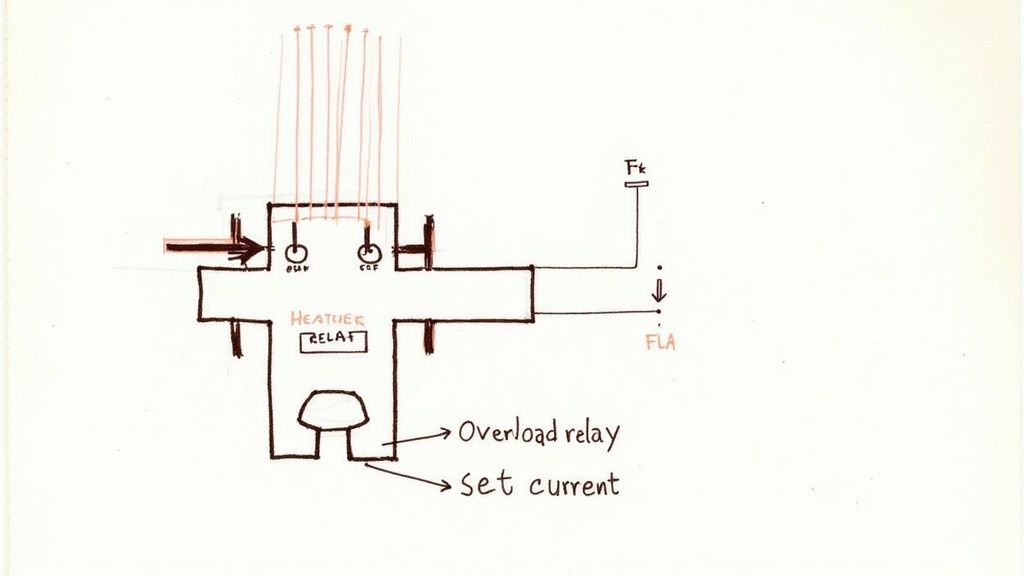

How to Select Overload Relays and Heater Elements

Picking the right NEMA starter size from a chart is a solid first step, but it's the overload relay and its heater elements that are the real heroes of motor protection. While the starter's contactor is busy handling the on/off switching, the overload relay acts as the motor’s dedicated bodyguard, standing watch against the damaging heat of overcurrent conditions.

So how does it work? An overload relay constantly monitors the current being pulled by the motor. If that current creeps above a safe level for too long, a heater element inside the relay gets hot and trips a mechanism. This action opens the starter's control circuit, shutting down the motor long before its windings can overheat and burn out. It's a simple, rugged, and essential process for preventing costly failures.

Calculating Maximum Allowable Amperage

Before you can pick the right heater, you need to know the motor's absolute maximum current limit. This isn't just the Full Load Amps (FLA) you see on the nameplate; you also have to factor in the motor’s built-in safety margin, known as the Service Factor (SF).

The formula is refreshingly simple:

Maximum Allowable Amps = Motor FLA x Service Factor (SF)

Let's say you have a motor with an FLA of 25 amps and a Service Factor of 1.15. The maximum current it can safely handle continuously is 28.75 amps (25 x 1.15). That number is your target. For motors with a 1.0 SF, your max amps are simply equal to the FLA. For a deeper dive, our comprehensive guide offers more on the fundamentals of the protection of motors.

Pro Tip: Always, always use the actual motor nameplate FLA for this calculation. Don't grab a generic value from a chart. Different motor designs can have slight variations in current draw, and getting this number right is the key to avoiding nuisance trips or, even worse, failing to protect your motor when it counts.

Using Manufacturer Tables to Find the Right Heater

With your maximum allowable amperage calculated, it's time to turn to the manufacturer's heater selection table. You'll find this in the documentation that comes with the motor starter. These tables are unique to each brand and model of overload relay—you absolutely cannot mix and match parts from different manufacturers.

Using the table is easy. Just find the amperage range that your calculated value falls into. The table will point you directly to the exact part number for the heater element you need. This careful matching ensures the overload relay will trip at precisely the right time, protecting your expensive motor without causing unnecessary shutdowns from harmless, temporary current spikes.

This precise sizing process is a cornerstone of the global motor starter market, which was valued at USD 7.4 billion in 2024 and continues to expand. In fact, proper sizing using a NEMA motor starter sizing chart and correct overload selection helps prevent up to 20% of industrial fires that are sparked by motor overloads. You can discover more insights about the motor starter market growth on Research Nester.

Sizing Adjustments for Special Operating Conditions

The standard NEMA motor starter sizing charts you see are based on pretty ideal conditions—think of a clean, climate-controlled facility operating at sea level. Specifically, they assume an ambient temperature no higher than 40°C (104°F) and an altitude below 3,300 feet (1,000 meters).

But let's be real, the world of industrial machinery is often much tougher than that. When your equipment operates in hotter, higher, or more demanding environments, you have to account for it in your selection. If you don't, you're just asking for nuisance trips and premature failures.

Derating for High Ambient Temperatures

Heat is the enemy of electrical components. When a starter is stuck in a hot environment, it can't dissipate its own operational heat effectively. This buildup can fool the overload relay into tripping or, worse, cook the starter's internal components.

The rule of thumb is to derate the starter's current-carrying capacity by about 8-10% for every 10°C you go above that standard 40°C mark. This almost always means you'll need to jump up a NEMA size.

- Real-World Example: Imagine a motor needs a NEMA Size 1 starter, which is rated for 27A. But, it's operating in a scorching 50°C boiler room. That extra heat drops its effective capacity down to around 24A, which isn't enough. The right move is to step up to a NEMA Size 2 and then pick the correct heater element based on the motor's actual FLA.

Factoring in High Altitude Operation

Working at high altitudes introduces a similar problem, but for a different reason. The air is thinner, which means it’s much less effective at carrying heat away from the motor and the starter through convection.

Again, you'll need to derate. While it's always best to check the manufacturer's specific data sheets, a solid guideline is to go up one NEMA size for every 2,000-foot increase in elevation above the 3,300-foot baseline.

Don't forget that high altitude can also worsen voltage drop, especially over long cable runs. This adds even more stress to your system. Knowing your voltage drop calculation formulas is critical to ensure the entire system is specified correctly for the environment.

Adjusting for Severe Duty Cycles

Some applications are just brutal on starters. We're talking about frequent starting and stopping, jogging, or "plugging"—where you reverse a motor's direction before it has fully stopped. Each of these actions generates a massive amount of heat from the repeated inrush current.

For these kinds of severe-duty applications, the standard charts go right out the window. It’s common practice to select a starter that is at least one, and sometimes two, sizes larger than what the nameplate horsepower calls for. This gives you the extra thermal mass and more robust contacts needed to survive the abuse without welding themselves shut.

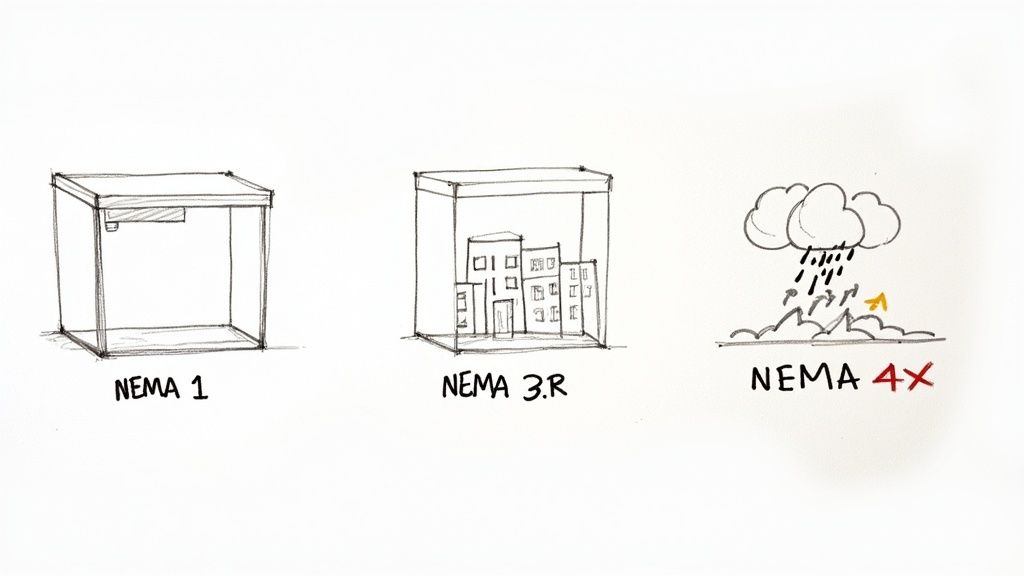

Selecting the Right NEMA Enclosure for Your Environment

Sizing a motor starter is only half the battle; protecting it is just as important. The enclosure is your starter's only line of defense against its operating environment, shielding it from everything from dust and moisture to corrosive chemicals and accidental contact. Skimp on the enclosure, and you’re setting yourself up for premature failure, electrical hazards, and expensive downtime.

The NEMA enclosure rating system is a standardized way to define the level of protection an enclosure provides. This system makes it straightforward to match an enclosure to the specific hazards in your facility, whether that's a clean, dry storeroom or a high-pressure washdown area in a food processing plant.

Matching NEMA Ratings to Common Industrial Settings

Different environments obviously call for different levels of protection. A NEMA 1 enclosure, for instance, is perfect for general-purpose indoor use where the main goal is simply to keep fingers away from live parts. It handles a bit of falling dirt but offers zero protection against liquids.

On the other hand, outdoor installations or indoor areas that get wet need something much more robust. A NEMA 3R enclosure is a common choice for outdoor equipment because it's built to keep out rain, sleet, and snow. For the toughest jobs involving corrosive agents or frequent hose-downs, you'll need a NEMA 4X enclosure, usually made from stainless steel or fiberglass. If you want a full rundown, you can explore the various types of electrical boxes available.

The market for enclosed motor starters tells the story of how critical this is. Valued at USD 1.87 billion in 2024, it's expected to hit USD 2.62 billion by 2032, largely because North American industries rely on them to protect their equipment. In fact, real-world data shows that using the correct NEMA-rated enclosure can slash failure rates by up to 40% in dirty or wet conditions compared to using an open-type starter. You can read more about the growth in the enclosed motor starter market at Data Bridge Market Research.

Common NEMA Enclosure Types and Applications

This quick-reference table breaks down the most common NEMA enclosure types to help you make the right call on the spot. Use this chart alongside your NEMA motor starter sizing chart to ensure you've covered both the electrical specs and the physical protection for a solid, reliable installation.

| NEMA Rating | Protection Against | Typical Application |

|---|---|---|

| NEMA 1 | Falling dirt, accidental contact | Clean, dry indoor environments like control rooms or warehouses. |

| NEMA 3R | Rain, sleet, snow, external ice formation | Outdoor electrical panels, irrigation pumps, and lighting controls. |

| NEMA 4X | Windblown dust, rain, splashing/hose-directed water, corrosion | Food and beverage plants, wastewater treatment facilities, marine settings. |

| NEMA 12 | Circulating dust, falling dirt, dripping non-corrosive liquids | Indoor manufacturing plants, machining areas, and assembly lines. |

Remember, the "X" in a NEMA 4X rating is what signifies its corrosion resistance. This is a non-negotiable feature in places with chemical fumes, high humidity, or salt spray, as it stops the rust and degradation that would otherwise compromise the enclosure over time.

Common Sizing Mistakes and How to Avoid Them

Even with a solid NEMA motor starter sizing chart in hand, simple mistakes can cause a world of hurt—think nuisance tripping, fried equipment, and expensive downtime. Knowing what to watch for is the first step to getting the installation right the first time. Trust me, a few extra minutes during selection will save you hours of headaches later on.

One of the most common slip-ups I see is ignoring the motor's Service Factor (SF). A technician will grab the Full Load Amps (FLA) off the nameplate and size the overload heater based on that number alone. They completely forget that an SF of 1.15 means the motor is built to safely handle 15% more current. This oversight almost always leads to picking a heater that’s too small, causing the starter to trip when the motor is just doing its job.

Overlooking Environmental Factors

Another critical error is failing to consider the environment where the starter will live. Those standard sizing charts all assume a nice, comfortable ambient temperature—usually no more than 40°C (104°F). But what happens when you mount that starter in a blistering hot boiler room or inside an enclosure baking in the sun?

Its ability to get rid of heat plummets. This excess heat fools the overload relay into tripping, even when the motor's current is perfectly fine. The fix is to derate the starter by going up one NEMA size. This gives it the extra thermal capacity it needs to run reliably without false trips.

Troubleshooting Common Symptoms of Improper Sizing

If you know what to look for, the symptoms of an incorrectly sized starter are pretty easy to spot. These issues are almost always preventable by carefully using a NEMA motor starter sizing chart and thinking through all the variables of the application.

Here are a few tell-tale signs I’ve seen out in the field:

- Nuisance Tripping: The overload just keeps kicking out for no apparent reason. More often than not, it's because the heater element is too small—either the Service Factor was ignored or no one accounted for high ambient temperatures.

- Contactor Chattering: That loud, angry buzzing from the starter could be low control voltage, but it's also a classic sign that the contactor is undersized for the motor's inrush current. The contacts are literally bouncing because they can't handle the load.

- Welded Contacts: This is a bad one. If the starter's contacts are fused together, you know they were nowhere near big enough for the motor's locked-rotor current. That massive inrush on startup basically arc-welded them shut, creating a massive safety hazard.

Here's the bottom line: the contactor is sized to handle the horsepower, but the overload relay is there to protect the motor. Both have to be right. If you upsize a starter for a tough application but forget to match the heater to the motor's specific FLA, you've completely defeated the purpose of the protection.

Frequently Asked Questions About NEMA Starter Sizing

Diving into a NEMA motor starter sizing chart is a great starting point, but the real-world questions often pop up once you're in the field. Getting a handle on the nuances behind these standards is what separates a good installation from a great one—ensuring everything is safe, reliable, and built to last.

Let's tackle some of the most common questions that engineers and technicians run into. Getting these details right builds confidence and helps you sidestep those frustrating pitfalls that can lead to equipment damage or unexpected downtime.

Can I Use a Larger NEMA Starter Than the Chart Recommends?

Absolutely. In fact, it's often a very smart move.

Grabbing a NEMA starter that's one size larger than what the chart calls for is a common and highly recommended practice, especially for tough, severe-duty applications. This strategy, known as "upsizing," gives you a beefy safety margin.

That extra capacity means less wear and tear on the starter's contacts and internal parts, which translates directly to a longer service life. Yes, the initial cost is a bit higher, but it's a small price to pay to prevent premature failures and the massive expense of unscheduled downtime.

There's one critical detail you can't overlook, though: the overload protection must still be sized with precision.

Crucial Point: Even if you upsize the starter's NEMA frame, the overload relay and its heater elements must be selected based on the motor's actual nameplate Full Load Amps (FLA) and Service Factor (SF). This is non-negotiable. It ensures the motor gets the right thermal protection, no matter how big the contactor is.

What Is the Main Difference Between NEMA and IEC Starters?

They both do the same basic job, but NEMA and IEC starters come from completely different design philosophies. Knowing the difference is key to picking the right component for your machinery and where it's headed.

NEMA starters, the standard across North America, are engineered to be absolute workhorses. Think robustness and durability. They are physically bigger, more heavy-duty, and have a modular design that's easy to work with. A huge plus is that parts like overload heaters are often interchangeable between different NEMA-rated brands, which really simplifies maintenance and keeping spares on the shelf.

On the other hand, IEC (International Electrotechnical Commission) starters are the go-to choice in most other parts of the world. They're designed to be compact and application-specific. While they're generally less expensive upfront, they demand a much more precise selection process based on the motor’s exact duty cycle and utilization category (like AC-3 for standard squirrel-cage motors).

- NEMA Approach: A rugged, "one-size-fits-most" philosophy built for durability and with a high tolerance for punishing conditions.

- IEC Approach: A tailored, space-saving, and cost-effective design that needs to be perfectly matched to the specific load.

In short, NEMA gives you a heavy-duty solution built for easy serviceability, while IEC offers a more precise, compact alternative.

How Does a Motor's NEMA Code Letter Affect Starter Sizing?

This is a fantastic question and a common point of confusion. The NEMA Code Letter on a motor's nameplate does not directly impact which NEMA starter size you choose. The starter's contactor is sized purely on the motor's horsepower and voltage, using a standard NEMA motor starter sizing chart.

So, what's the code letter for? It’s all about the upstream short-circuit protective device (SCPD)—the circuit breaker or fuse that sits ahead of the starter.

The NEMA Code Letter tells you the motor's locked-rotor kVA per horsepower, which is a direct indicator of how much inrush current it will pull on startup. A motor with a high code letter, like Code J, will draw a much bigger gulp of current than one with a lower letter, like Code B. Your breaker or fuse must be sized according to NEC Table 430.52 to handle that brief, intense spike without tripping, while still protecting the circuit from a dead short.

The takeaway? The code letter is vital for coordinating your circuit protection, not for picking the starter's NEMA size.

For all your motor control needs, from expert advice to custom UL control packaging, E & I Sales is your trusted partner. We provide premium electric motors and engineered solutions to accelerate your projects and ensure reliability. Explore our comprehensive motor control services at eandisales.com.