Medium-Voltage (MV) circuit breakers are the silent workhorses of any serious industrial power system. Their job is simple but absolutely critical: protect incredibly expensive equipment and prevent catastrophic downtime when things go wrong.

Think of them as the ultimate high-speed, automated safety valve for your entire electrical network. When a fault occurs, their one and only mission is to detect it and shut it down—instantly.

The Unsung Heroes of Industrial Power Systems

In any plant, power is the lifeblood. But when a fault happens—maybe a frayed cable shorts to ground or a major piece of equipment fails internally—the surge of electrical energy is enormous. Without a protective device in the way, that surge can vaporize multi-million-dollar assets in a literal flash, cause facility-wide damage, and put your team in serious danger.

This is where MV circuit breakers step in.

They operate in the medium-voltage range, typically from 1kV to 38kV, which is the sweet spot for most manufacturing plants, data centers, and utility distribution systems. They’re engineered to handle the serious power levels found in these environments, standing guard to ensure power flows smoothly day-to-day but acting decisively the second a problem arises.

Why Are MV Circuit Breakers So Important?

Unlike a simple fuse, which is a one-and-done device, a circuit breaker is a reusable, intelligent switch. After a fault is cleared, you can reset it (often remotely) and get operations back online fast. That ability is everything when downtime is measured in thousands of dollars per minute.

For us engineers, integrators, and packagers, knowing these devices inside and out is non-negotiable. It's the foundation of designing a power system that's not just functional, but also safe and resilient.

A properly selected and maintained MV circuit breaker is essential for:

- Asset Protection: It’s the last line of defense for your big-ticket items—large motors, generators, and transformers—from destructive overcurrents.

- Personnel Safety: By isolating faults in milliseconds, breakers drastically reduce the risk of an arc flash, which can cause life-threatening injuries.

- Operational Continuity: A well-designed system ensures only the breaker closest to the fault trips. This isolates the problem locally instead of causing a plant-wide blackout.

- System Reliability: They are the cornerstone of any modern electrical grid, whether you're running a traditional factory or integrating renewables like solar and wind.

The Modern Imperative

Let's be honest, the stakes are only getting higher. As industrial processes become more automated and reliant on sensitive electronics, the cost of an unplanned outage is astronomical. At the same time, the grid itself is evolving, with distributed energy resources adding new layers of complexity.

Mastering MV circuit breaker technology isn't just a technical skill anymore—it’s a strategic necessity for keeping any industrial operation competitive and safe. To get a bird's-eye view of how these devices fit into the broader protection landscape, check out this excellent overview on Circuit Breakers. From there, we’ll dive deep into the MV-specific applications that are critical to your work.

How Different MV Circuit Breakers Work

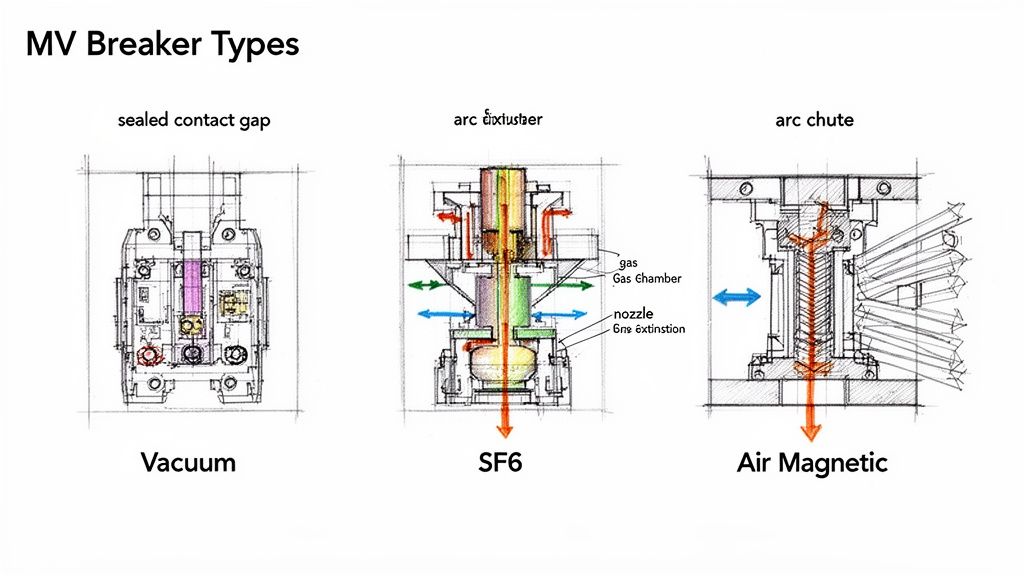

To really get a handle on MV circuit breakers, you have to think about what they’re up against. A fault current isn't just a big number; it's a violent event. It creates an electrical arc—a bolt of plasma hotter than the sun's surface—that desperately wants to keep flowing. The breaker's entire job is to extinguish that arc, and do it in a blink of an eye. The how is what separates the different technologies.

When the breaker's contacts pull apart to stop the current, voltage leaps across the gap, forming that arc. If you just let it sit there, it would melt everything in its path. So, each type of breaker uses a unique medium and a clever bit of physics to de-ionize the plasma, cool the arc, and kill the fault for good.

Vacuum Circuit Breakers (VCBs)

The modern workhorse in the MV world is the vacuum circuit breaker, or VCB. Its design is brilliant in its simplicity. The main contacts are sealed inside a ceramic bottle, called a vacuum interrupter, where nearly all the air has been pumped out.

Think about it like this: a fire can't burn without oxygen. An electrical arc is the same—it needs a medium, like air, to sustain itself. By putting the contacts in a near-perfect vacuum, you’ve essentially starved the arc of its fuel.

When the contacts separate, the only thing that can form an arc is a tiny bit of vaporized metal from the contacts themselves. With almost no gas molecules to ionize, the arc is incredibly easy to extinguish the very next time the AC waveform hits a "current zero." The vacuum's incredible insulating strength then prevents the arc from ever re-igniting.

This simple, elegant mechanism is the VCB’s superpower. It results in an exceptionally long life, almost no maintenance, and quiet, self-contained operation, making it the go-to choice for modern indoor switchgear.

SF6 Circuit Breakers

For years, Sulfur Hexafluoride (SF6) was the king of high-performance arc quenching. These breakers use SF6 gas to smother the arc. It's an electronegative gas, which is a fancy way of saying its molecules are absolute magnets for free electrons.

As the contacts part, a high-pressure blast of SF6 gas floods the arc. The gas molecules immediately soak up the free electrons that keep the arc alive, effectively choking it out. This cools the plasma channel and rapidly restores the insulation between the contacts.

While SF6 is an amazing insulator, it has a serious environmental downside. It’s a greenhouse gas with a global warming potential over 24,000 times that of CO2. Because of this, regulations are tightening, and the industry is shifting hard toward SF6-free alternatives. Still, its performance in high-voltage gear means you’ll see it in the field for years to come.

Air Magnetic Circuit Breakers

This is one of the old-school technologies, but it's a tough and reliable one. Air magnetic breakers interrupt the current right in the open air, but they have a trick up their sleeve. They use powerful magnetic fields to physically move and stretch the arc to death.

Imagine trying to blow out a huge, stubborn candle. Instead of just blowing harder, you could force the flame into a maze of plates that pull it apart and cool it down. That's exactly what these breakers do.

- Magnetic Blowout Coils: The massive fault current is routed through coils that generate a powerful magnetic field.

- Arc Movement: This field pushes the arc upwards and away from the contacts, like a magnet repelling another.

- Arc Chute: The arc is driven into a chamber filled with insulating plates, called an arc chute. This stretches it out, making it longer, thinner, and cooler until it simply can't sustain itself anymore and flickers out.

These breakers are big, loud, and need a lot of maintenance, so you won’t find them in many new installations. But they were built to last, and plenty are still in service in older industrial plants.

Comparing Key MV Breaker Technologies

Choosing the right MV circuit breaker is all about matching the technology to the job. Every design comes with its own set of trade-offs, and what's perfect for a utility substation might be all wrong for a data center.

To make sense of it all, here's a quick comparison of the main players.

| Technology Type | Arc Quenching Medium | Key Advantages | Common Applications | Maintenance Needs |

|---|---|---|---|---|

| Vacuum (VCB) | High Vacuum | Long life, low maintenance, quiet operation, environmentally friendly. | Industrial plants, data centers, commercial buildings, renewable energy. | Very Low |

| SF6 Gas | Sulfur Hexafluoride Gas | Excellent insulating and arc-quenching properties, compact design. | Utility substations, high-voltage applications, GIS (Gas Insulated Switchgear). | Moderate |

| Air Magnetic | Ambient Air | Robust and simple design, no specialized gas handling required. | Older industrial facilities, traction systems, power generation plants. | High |

This breakdown shows why there isn't a single "best" breaker—it's about the right tool for the right application.

This diversity is why MV circuit breakers are such a huge part of the market, holding a dominant 45.53% share of the entire circuit breaker industry. They are the backbone of our industrial and utility grids. The clear trend, as noted by researchers at Fortune Business Insights, is toward the eco-friendly and low-maintenance profile of VCBs, which have become the top choice for new projects.

For most modern medium-voltage jobs, the vacuum circuit breaker is tough to beat on reliability, safety, and total cost of ownership. If you want to get into the nitty-gritty, check out our deep dive into how a vacuum circuit breaker works.

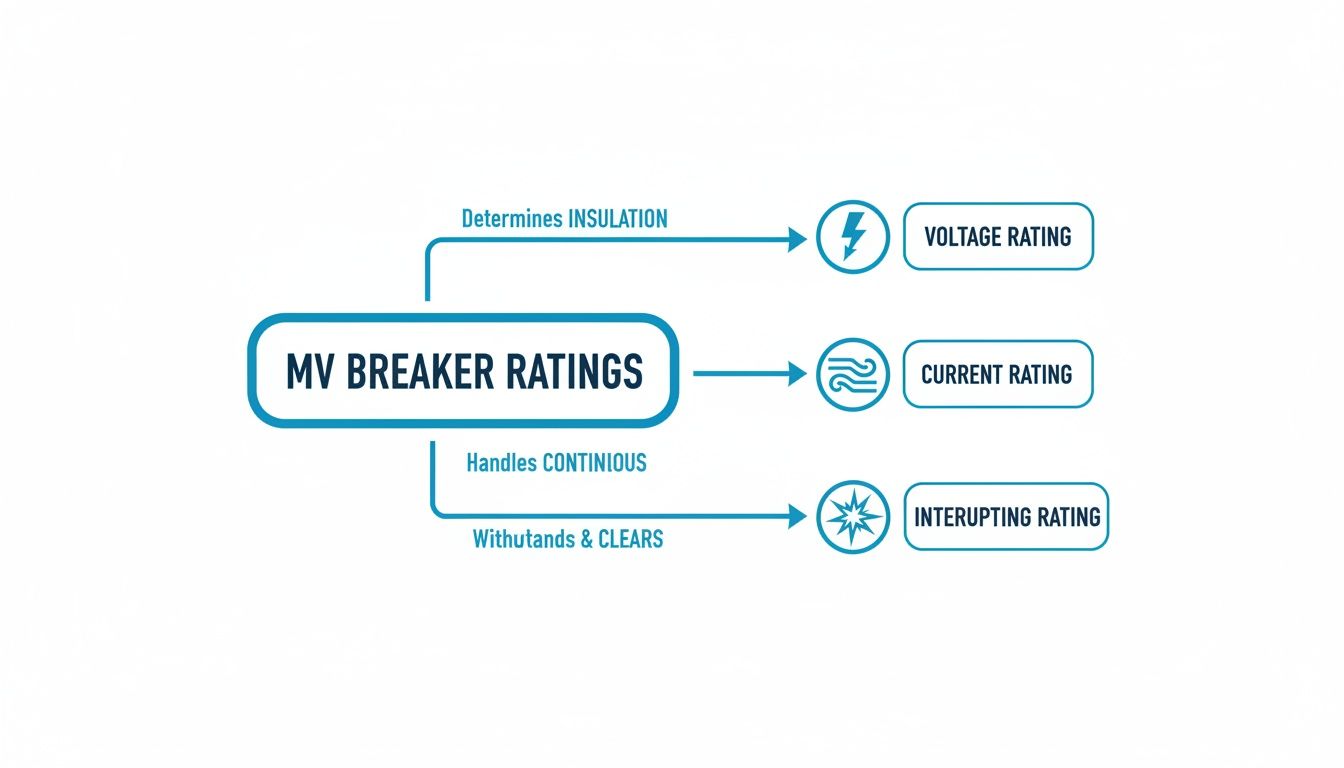

Decoding Critical Ratings and Specifications

Reading the data sheet for an MV circuit breaker can feel like drinking from a firehose. But if you know what to look for, a handful of key numbers tell you everything you need to know about its performance and, more importantly, its safety limits.

These ratings aren't just suggestions; they are the hard-and-fast rules that define the breaker's ability to protect your system. Getting them wrong is a fast track to fried equipment or something much, much worse. Think of these specs as the breaker's DNA—they dictate where it can live, how much load it can carry, and how it will behave when things go sideways.

Voltage Class and Continuous Current

Let's start with the basics. The two most fundamental ratings are the breaker's voltage class and its continuous current. These define its day-to-day operating parameters.

Voltage Class (kV): This is the maximum system voltage the breaker is designed to handle. A 15kV breaker, for instance, is perfectly at home on a 13.8kV system. Its internal insulation and arc-quenching guts are built to handle that level of electrical pressure.

Continuous Current (A): This tells you how much current the breaker can carry, 24/7, without breaking a sweat or overheating. A breaker rated for 1200A can handle that load all day, every day. This value comes down to the physical size and material of its internal conductors.

Matching these two ratings to your system is the first critical filter in your selection process. An undersized current rating means overheating and a shortened lifespan. The wrong voltage class? That's a major safety hazard, full stop. For a deeper look into the calculations, check out our guide on proper circuit breaker sizing.

The Most Important Rating: Interrupting Capacity

Voltage and continuous current are about normal operations. The interrupting rating is about surviving the absolute worst-case scenario. This number, measured in kiloamperes (kA), defines the maximum fault current the breaker can safely extinguish without blowing itself to pieces.

Imagine a dam holding back a river. Its height and width are like the voltage and continuous current ratings—they manage the everyday flow. But the dam's ability to withstand a historic, once-in-a-century flood? That's its interrupting rating.

If a fault unleashes more current than the breaker's interrupting rating, the result is violent and immediate. The immense magnetic forces and arc energy can literally tear the breaker apart, creating a devastating arc flash, spraying molten metal, and starting fires. This is why you can never, ever install a breaker with an interrupting rating lower than the system's available fault current.

Critical Takeaway: A breaker's interrupting rating isn't a performance metric; it's a safety-critical limit. Under-specifying this value doesn't just put the breaker at risk—it jeopardizes the entire switchgear lineup and the lives of anyone nearby.

Understanding Withstand and Operating Duty

Beyond the headline numbers, a few other specs give you crucial insight into how an MV circuit breaker will actually perform in a coordinated system.

Short-Time Withstand Current (kA): This is the amount of fault current a breaker can endure for a very brief, specific time (usually 1-3 seconds) without tripping. Why is this important? It’s all about coordination. This allows a downstream breaker closer to the fault to do its job first, isolating the problem without causing a wider outage. The breaker has to be mechanically tough enough to hold itself together against incredible magnetic forces during this window.

Making Capacity (kA peak): When a breaker closes into an existing fault, the initial current spike can be more than double the sustained fault current. Making capacity specifies the absolute peak current the breaker can safely close against without its contacts welding shut or being blown open.

Operating Duty Cycle: This tells you the sequence of open-and-close operations a breaker can perform in quick succession before it needs a rest. A standard duty cycle might look like O – 0.3s – CO – 15s – CO. This means it can Open, wait 0.3 seconds, do a Close-Open, wait 15 seconds, and then do one more Close-Open. This sequence ensures the arc-quenching medium has enough time to recover between interruptions.

Navigating Global Standards and Protection Coordination

Picking the right MV circuit breaker goes way beyond just matching the basic ratings on a spec sheet. You have to make sure the device speaks the right engineering language for where it's being installed. A breaker’s real-world reliability hinges on two things: following globally recognized standards and being smart enough to trip exactly when—and only when—it’s supposed to.

If you're an OEM or integrator shipping equipment across borders, you’ll constantly run into the two dominant standards bodies: ANSI/IEEE (American National Standards Institute / Institute of Electrical and Electronics Engineers) and IEC (International Electrotechnical Commission). They each have their own philosophy, testing methods, and lingo, which can lead to major headaches if you're not ready for it.

ANSI/IEEE vs. IEC Standards

Think of these standards as two different dialects of the same engineering language. ANSI/IEEE is the go-to in North America, while IEC pretty much runs the show in Europe, Asia, and most other parts of the world. And the differences aren't just for academics—they have a real impact on a breaker's physical design, its ratings, and how it fits into a switchgear assembly.

A perfect example is how they handle interrupting ratings. ANSI often specifies breakers using a symmetrical current value. IEC, on the other hand, uses a mix of symmetrical and asymmetrical values. This subtle difference means you can’t just do a simple, one-to-one comparison between two data sheets. It's an apples-to-oranges situation that can easily trip you up.

In Europe, for instance, sticking to IEC and national standards is absolutely mandatory. That market is on track to hit USD 5.01 billion by 2026, with Germany alone making up USD 1.34 billion of that. This growth is fueled by the massive, interconnected ENTSO-E grid that links over 35 countries, all demanding compliant, reliable circuit protection. For EPC firms, this means every MV breaker has to meet strict local codes while also playing nice with the larger grid.

The Art of Protection Coordination

Standards get you in the door, but true system reliability is born from protection coordination. This is the art and science of making sure the right breaker trips at the right time. The goal is straightforward: isolate a fault as close to its source as possible. You want to prevent a small, localized issue from cascading into a plant-wide blackout.

Picture this: a short circuit happens in a single motor control center. The ideal scenario is that the breaker feeding that specific MCC trips instantly. But if the main plant breaker trips instead? The whole facility goes dark. A minor hiccup just turned into a massive production loss.

Engineers pull this off by programming the protective relays that act as the brains for the breakers. They use Time-Current Curves (TCCs) to map out exactly how each breaker will respond to different levels of overcurrent.

A TCC is basically a breaker's response profile. It plots how long the breaker will wait before tripping at any given current. By carefully layering these curves, engineers create a protective hierarchy, ensuring the device closest to the fault ("downstream") always acts first.

This diagram gives a great high-level look at the core ratings that get programmed and coordinated within a protection scheme.

As you can see, the voltage, continuous current, and interrupting capacity are all distinct but interconnected ratings that define what a breaker can safely handle.

Advanced Coordination Techniques

For more critical or complex systems, engineers have a few more tricks up their sleeve to cut down response times and keep disruptions to a minimum. One of the most effective is Zone Selective Interlocking (ZSI).

With ZSI, the breakers actually talk to each other. When a downstream breaker sees a fault, it sends a "hold off" signal to the upstream breaker, telling it to wait. If that downstream breaker can't clear the fault fast enough, then the upstream one trips as a backup. It's a smart, communicative approach that you can learn more about in our guide to how zone selective interlocking boosts system reliability.

Getting Installation and Maintenance Right

You can specify the most advanced MV circuit breaker on the market, but its real-world performance boils down to two things: how well it was installed and how well it's been maintained. A sloppy installation or years of neglect can turn a critical protective device into your system's weakest link. For the folks in the field and on the plant floor, getting this right isn't just about reliability—it's about safety.

Think of it this way: a proper installation lays the foundation for decades of service. Any shortcuts taken here will absolutely come back to haunt you later.

Nailing the Initial Installation

The path to a long, reliable service life starts the second that breaker hits your loading dock. This isn't just about wrestling it into a cubicle; it's a careful, methodical process where every detail counts.

- Handle With Care and Inspect Everything: MV breakers are built tough, but they're not invincible. A drop or a hard jolt can damage sensitive internal components. Before you even think about installation, give it a thorough visual once-over. Look for cracked insulators, bent framing, or any other signs of shipping damage.

- Mounting and Alignment: Make sure the switchgear cell is spotless—no dust, debris, or forgotten hardware. As you rack the breaker in, feel for a smooth, positive engagement. You need to be certain the primary stabs and secondary control contacts are perfectly aligned. Even slight misalignment can cause a poor connection that leads to overheating or, worse, a failure of the trip circuit.

- The Criticality of Torque: This is where so many installations go wrong. Loose connections create high resistance, which generates heat and can lead to a catastrophic thermal failure. On the flip side, cranking down too hard can strip threads or damage the conductor. Always, always use a calibrated torque wrench and follow the manufacturer's specs to the letter for every single power and control connection.

It’s no exaggeration—one industry study found that improper torqueing was the root cause of over 75% of electrical connection failures. It's a simple mechanical step with massive implications for the safety and integrity of the entire system.

Setting a Rhythm for Preventive Maintenance

Once that breaker is commissioned, you can't just forget about it. A proactive, preventive maintenance (PM) strategy is non-negotiable if you expect it to work when you need it most. This means moving away from a "run-to-failure" mindset and actively hunting for problems before they escalate.

A solid PM program is a mix of simple annual checks and more in-depth testing every few years.

- Routine Visual and Mechanical Checks (Annually): With the gear de-energized, open the cubicle and look for tell-tale signs of trouble: dust buildup, corrosion, discoloration from heat, or any hint of moisture. Manually operate the breaker (charge, close, trip) to confirm the mechanism moves freely and doesn't sound "clunky" or strained.

- Insulation Resistance Testing ("Meggering"): This classic test is your best friend for verifying the health of the breaker's insulation. By applying a high DC voltage and measuring the resistance to ground, you can spot contamination or moisture ingress long before it leads to a flashover.

- Contact Resistance Measurement: You need a clean, low-resistance path through the main contacts when the breaker is closed. Using a digital low-resistance ohmmeter (DLRO) to push a high current through the contacts gives you a precise micro-ohm reading. If you see this number trending upward over the years, it’s a clear sign of contact wear or surface contamination.

- Mechanism Lubrication: The grease packed into the operating mechanism from the factory doesn't last forever. It can dry out, harden, or get contaminated with dirt. Follow the OEM's guide for cleaning and re-lubricating the key pivot points and sliding surfaces to prevent a sluggish or failed mechanical operation.

By sticking to these fundamentals for installation and maintenance, you can dramatically extend the life of your MV circuit breakers and ensure they're ready to do their job—protecting your people and your equipment—when that fault finally happens.

Your Essential Procurement Checklist

Choosing the right MV circuit breaker is one of those high-stakes decisions that defines a project’s safety, reliability, and frankly, your bottom line. Get the specs wrong, and you’re looking at costly change orders, dangerous equipment failures, or weeks of unexpected downtime.

Think of this checklist as your pre-flight inspection. It’s a framework to systematically walk through every critical detail before you even think about issuing a purchase order. It’s about moving from a set of requirements to a confident, well-documented decision that gets you the exact equipment your system demands.

Technical and Application Specifications

First things first: you have to nail down the non-negotiable technicals. These are dictated by your electrical system and the environment it lives in. Getting these right is absolutely fundamental.

- Voltage Class (kV): What’s the nominal system voltage? Make sure the breaker's rated maximum voltage is a step above that. For a 13.8kV system, you need a 15kV class breaker. No exceptions.

- Continuous Current (A): How much full-load current will this breaker see day in and day out without breaking a sweat? Always factor in a healthy margin for future load growth—you’ll thank yourself later.

- Interrupting Rating (kA): What’s the absolute worst-case short-circuit current available at the breaker's location? This is a safety-critical number. Understating it is not an option.

- Operating Environment: Is this breaker living indoors in a climate-controlled E-house, or is it getting blasted by the elements outdoors? You need to specify the right NEMA or IP rating for the job.

- Special Conditions: Don’t forget the curveballs. Are you dealing with high altitudes (which messes with cooling and insulation), corrosive salt spray, or extreme desert heat? These conditions demand special consideration.

Compliance and Integration

Once you have the core specs locked down, you need to think bigger. How does this breaker fit into the rest of your system? This is where you need to put on your system integrator hat.

A well-specified circuit breaker isn't just an isolated component; it's a team player in a larger protection scheme. Its ability to integrate with switchgear, communicate with relays, and comply with regional standards is just as important as its standalone ratings.

The demand for reliable medium voltage gear is exploding, with the market projected to hit USD 11.99 billion by 2030. This growth is fueled by everything from renewable energy tie-ins to massive industrial expansions. For partners like us at E & I Sales who work closely with integrators and packagers, making sure every component plays nice in the sandbox is what we do. You can get more market insights from ResearchAndMarkets.com.

Lifecycle and Commercial Factors

Finally, step back from the upfront price tag and think about the total cost of ownership. This breaker is a long-term asset, probably with a 20- to 30-year lifespan. Thinking about support and parts now will save you a world of hurt down the road.

- Standards Compliance: Does the project spec call for ANSI/IEEE (the standard in North America) or IEC (common everywhere else)? They are not interchangeable.

- Switchgear Compatibility: Is this a brand-new installation or a retrofit into existing gear? For a retrofit, you have to be meticulous. The breaker’s physical dimensions, racking mechanism, and secondary control connections must be a perfect match for the old cubicle.

- Manufacturer Support: What kind of technical backup, documentation, and warranty are you getting? Is there someone you can actually call when you’re in a jam?

- Spare Parts Availability: How quickly can you get your hands on critical spares like trip coils, charging motors, or even a new vacuum interrupter? A long lead time on a simple part can turn a minor issue into days of costly downtime.

Common Questions About MV Circuit Breakers

When you're responsible for critical power assets, you're bound to have some practical questions. Whether you're an engineer or a facility manager, getting straight answers is the first step toward making smart calls on safety, budget, and the long-term health of your MV circuit breakers.

Lifespan and Retrofit Decisions

One of the first questions I always hear is, "How long will this thing actually last?" A modern vacuum circuit breaker is typically built for a service life of 20 to 30 years, or a set number of mechanical operations. But the decision to replace or retrofit isn't just about what the calendar says.

You should seriously start thinking about a retrofit when:

- You're dealing with an old, obsolete model where finding spare parts has become a treasure hunt.

- Your maintenance costs and downtime are creeping up year after year.

- The system has grown, and you need to upgrade the breaker's interrupting capacity to keep up.

- You're looking to add modern safety features like remote racking or better arc flash mitigation.

New Versus Reconditioned Breakers

The classic dilemma: new or reconditioned? This one usually boils down to a trade-off between cost, lead time, and how much risk you're willing to accept. A properly reconditioned unit can be a great, cost-effective fix, especially for a like-for-like replacement in existing switchgear. Plus, you can often get it much faster.

But—and this is a big but—you have to be certain the reconditioning was done by a reputable shop that follows certified processes. A new breaker, on the other hand, gives you the latest tech, a full manufacturer's warranty, and zero operational history to worry about. For critical new installations, it's almost always the right choice.

When it comes to reconditioned gear, traceability is everything. If you don't have complete documentation of the tests performed and the parts that were replaced, you can't have confidence in its ability to protect your system.

Critical Safety Procedures

Finally, let's talk about what matters most: safety. The question "What are the most critical safety procedures for working on MV switchgear?" should be on everyone's mind. There are a few non-negotiables.

- Lockout/Tagout (LOTO): This is ground zero. Always, always verify the equipment is fully de-energized and locked out so it can't be switched back on by mistake.

- Arc Flash Hazard Awareness: You need to know the numbers. Understand the specific incident energy levels and approach boundaries for the gear you're working on.

- Proper PPE: Don't guess. Wear the correct arc-rated personal protective equipment for the calculated hazard level.

At E & I Sales, we field these questions every day, helping engineers and integrators find the right MV protection for their projects. We’ve got the expertise you need to select, install, and maintain your equipment with confidence. Explore our full range of motor control and power distribution solutions at https://eandisales.com.