At its core, a motor variable speed controller is a device that fine-tunes the speed and torque of an electric motor by adjusting the electrical power feeding it. You can think of it like a dimmer switch for a light bulb, but instead of adjusting brightness, it gives you precise control over your motor's performance. It’s the difference between a simple on/off switch and a system that can run at the exact speed a job requires.

What Is a Motor Variable Speed Controller and Why You Need One

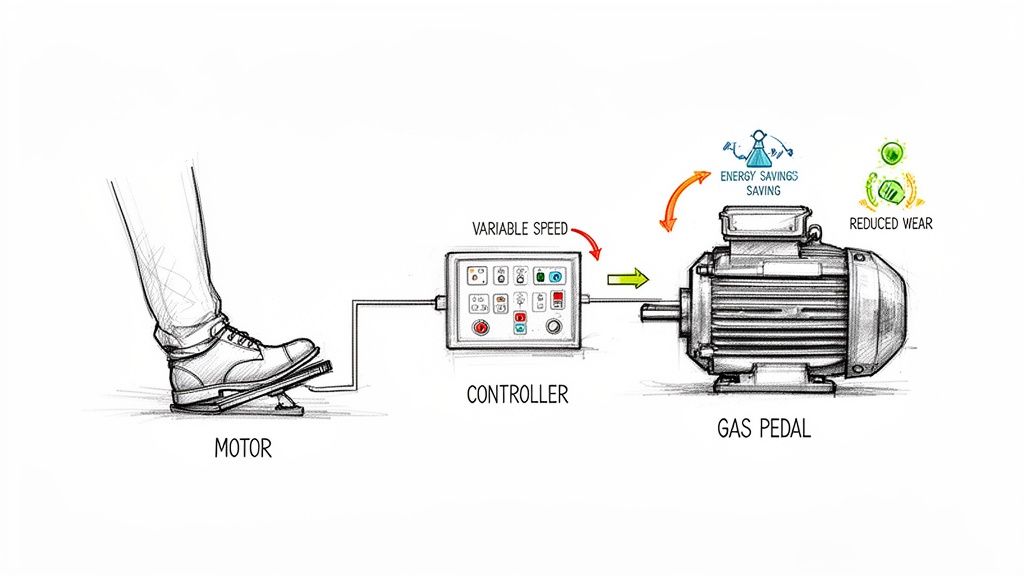

Imagine trying to drive a car that only has two modes: full throttle and park. That's essentially how many industrial motors run without a controller. They're either all on or all off, which is a brutally inefficient and mechanically jarring way to operate. This works for the simplest tasks, but it's incredibly wasteful for applications where the load changes, like a conveyor belt that needs to speed up or a fan that must adjust airflow.

The motor variable speed controller acts as the "gas pedal" for your machinery. It solves the fundamental problem of using a fixed-speed motor for a variable-demand job. Instead of running a motor at 100% and then using a mechanical brake—like a damper or valve—to choke the output, the controller tells the motor itself to slow down. This elegantly matches the motor's work to the system's real-time needs.

The Strategic Value of Precision Motor Control

It's a mistake to see these controllers as just another component. They are a strategic investment that sends a ripple effect of improvements across your entire operation. The initial cost is almost always dwarfed by the long-term returns in energy savings and equipment health.

The most obvious win is a massive reduction in energy consumption. In many industrial settings, motors are the single biggest electricity hogs. By matching motor speed to the actual load, especially in common pump and fan applications, facilities can cut their energy use by as much as 50%.

By enabling motors to operate only as fast as necessary, a motor variable speed controller eliminates wasted energy, reduces mechanical wear, and provides the fine-tuned process control essential for modern industrial automation.

But the benefits go far beyond the power bill. These controllers bring a few other game-changing advantages to the table:

- Extended Equipment Lifespan: The controller enables a "soft start," gently ramping up the motor's speed instead of slamming it on. This completely avoids the violent mechanical shock and huge electrical inrush current—which can spike to over 600% of the motor's rating—that comes with a direct-on-line start. The result is significantly less wear and tear on belts, gears, couplings, and the motor itself.

- Enhanced Process Control: From bottling lines to chemical mixing, countless industrial processes demand exact speeds to get the product right. A controller delivers the precision needed to hold tight tolerances, reduce waste, and ensure every batch is consistent.

- Improved System Reliability: By cutting down on mechanical stress and preventing motors from overheating, these controllers make the entire system more stable and dependable. That means fewer surprise breakdowns and less costly downtime.

Moving Beyond Mechanical Inefficiency

The old way of controlling motor-driven systems was purely mechanical and, frankly, crude. To reduce flow in a pumping system, an operator would have to physically close a valve partway, forcing the pump's motor to work against that restriction while still spinning at full speed.

Think about that for a second. It’s the exact same logic as flooring the accelerator in your car while simultaneously riding the brake to manage your speed. It's incredibly wasteful and puts a ton of unnecessary strain on every single component.

A motor variable speed controller provides a far more intelligent and direct path to control. By adjusting the motor's electrical input, it addresses the power at the source, making the whole operation more responsive and efficient. This move away from mechanical restriction and toward smart electrical regulation is a cornerstone of modern industrial performance.

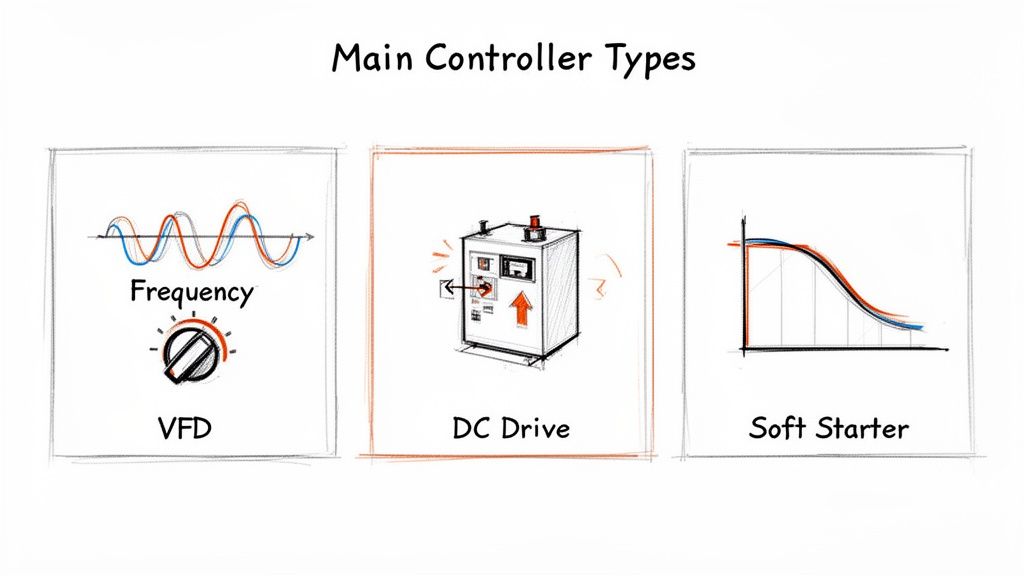

Exploring the Main Types of Motor Speed Controllers

When it comes to motor control, one size definitely does not fit all. Picking the right technology is critical for performance, efficiency, and the longevity of your equipment. Think of it like a mechanic's toolbox—you need the right tool for the job, and you wouldn't use a sledgehammer where a precision screwdriver is needed.

The world of motor control is dominated by three main players. Understanding what makes each one tick is the first step to making a smart choice for your application, whether you're running a simple conveyor or a complex, automated production line.

The Workhorse: AC Variable Frequency Drives (VFDs)

The Variable Frequency Drive (VFD) is, without a doubt, the champion of modern motor control. It's the most versatile and common solution out there, especially for the three-phase AC induction motors that are the backbone of most industrial machinery. A VFD gives you total command over a motor’s speed, from a dead stop all the way to full throttle.

How does it work its magic? A VFD performs a clever bit of electrical gymnastics. It takes the standard, fixed-frequency AC power from the wall (usually 60 Hz in North America), converts it into DC power, and then uses powerful transistors to chop that DC power back into a brand new, synthetic AC waveform. The kicker is that it can create this new waveform at any frequency you command.

The core principle is beautifully simple: an AC motor's speed is directly tied to the frequency of the power you feed it. By precisely dialing that frequency up or down, a VFD lets you run the motor at the exact speed your process needs.

This level of control is non-negotiable for applications that demand constant adjustment, like a pump maintaining steady pressure in a system or a fan modulating airflow for climate control. For a deeper dive, check out our comprehensive guide to AC motor variable speed.

Specialized Control With DC Drives

While AC motors run the show these days, don't count DC motors out just yet. They still have a firm foothold in niche applications where high starting torque and rock-solid speed control at very low RPMs are must-haves. That’s where the DC drive steps in.

DC drives operate on a different principle because they’re controlling a different beast. They regulate motor speed by simply adjusting the DC voltage sent to the motor's armature. More voltage means more speed, less voltage means less speed. It's a direct, responsive, and beautifully straightforward method of control.

You’ll still find DC drives hard at work in:

- Legacy Equipment: A ton of older, tried-and-true industrial machines were designed around the rugged performance of DC motors.

- Heavy-Duty Machinery: Think cranes, hoists, and extruders that need massive torque right from the get-go.

- Precision Applications: The simple, direct control loop makes them a solid choice for certain high-precision tasks.

The Limited (But Important) Role of Soft Starters

A soft starter is often lumped in with VFDs and DC drives, but it’s crucial to understand it’s in a different category. A soft starter is not a speed controller. Its one and only job is to manage how a motor starts and stops.

When a big AC motor fires up directly across the line, it causes a huge electrical surge—often 6 to 8 times its normal running current—and a violent mechanical jolt. A soft starter acts like a shock absorber. It gently ramps up the voltage for a smooth, controlled start, then typically gets out of the way and lets the motor run directly off the line.

While it can't change the speed during operation, that gentle startup is invaluable. It drastically reduces mechanical and electrical stress, and it's not uncommon for a soft starter to extend a motor's life by 20-30%. This is why maintenance managers love them.

This focus on efficiency and equipment protection is driving major growth, especially in emerging markets. The electric vehicle motor controller market alone is projected to explode from $9.675 billion in 2025 to a staggering $47.04 billion by 2035.

VFD vs DC Drive vs Soft Starter At a Glance

So, how do you choose? It all boils down to what your application demands. A quick side-by-side comparison can make the decision crystal clear.

| Controller Type | Primary Function | Best For | Key Benefit |

|---|---|---|---|

| AC VFD | Full-range speed control of AC motors by varying frequency and voltage. | Pumps, fans, conveyors, and any application requiring precise, continuous speed adjustments. | Maximum energy savings and complete process control. |

| DC Drive | Full-range speed control of DC motors by varying DC voltage. | Legacy systems, cranes, hoists, and applications needing high torque at low speeds. | Excellent torque control and responsive speed regulation. |

| Soft Starter | Controls only the start/stop acceleration and deceleration of an AC motor. | High-inertia loads like large fans, pumps, and compressors where speed control isn't needed. | Reduces mechanical stress and electrical inrush current, extending equipment life. |

Ultimately, the VFD offers the most complete control, the DC drive excels in high-torque niches, and the soft starter is the specialist for protecting your equipment during startup. Matching the technology to the task is the key to a reliable and efficient system.

So, What's In It For You? Unlocking the Real-World Payoff

Enough with the technical jargon. Let's get down to brass tacks and answer the one question every plant manager or OEM really cares about: What will this do for my bottom line?

Putting a motor variable speed controller on your line isn't just swapping out a piece of hardware. It's a strategic play that starts a chain reaction of benefits, tackling some of the most stubborn headaches in any industrial facility—from runaway energy bills to equipment that dies way too soon.

The first thing you'll notice, and the one that gets the CFO's attention, is the dramatic drop in your power consumption. For most plants, motors are the hungriest things on the grid, often running full-tilt boogie whether they need to or not. It's like flooring the gas pedal in your car and using the brakes to control your speed. You'd never do it, but that's exactly how countless systems operate every single day.

Slashing Energy Costs by Working Smarter, Not Harder

A motor variable speed controller puts an end to that madness. Instead of cranking a pump to 100% and then choking it with a valve to cut back the flow, the controller just tells the motor to slow down. It’s simple, elegant, and the impact is huge, especially for anything that moves air or liquid, like pumps and fans.

This shift to smarter motor control is a big deal. The global market for Variable Frequency Drives (VFDs) is on track to hit $31.3 billion by 2025, which tells you just how essential they've become. While a standard fixed-speed motor hemorrhages energy when it's not running at full load, a VFD dials in the perfect voltage and frequency for the job at hand. This can cut electricity use by up to 50% in pump and fan systems—which, by the way, make up a mind-blowing 65% of all industrial motor applications. You can get more insights on this market trend and what’s behind it.

A variable speed controller matches the motor's muscle to the actual work needed. This simple change can turn one of your biggest operating expenses into a major source of savings, often paying for itself in less than two years.

For centrifugal loads, this relationship is governed by what we call the Affinity Laws, which creates an almost magical savings curve. A small drop in speed leads to a massive drop in power consumption. For instance, slowing a fan down by just 20% can slash its energy use by nearly half.

Making Your Equipment Last Longer

Beyond the energy savings, these controllers are like a spa day for your machinery. The single most violent event in a motor’s life is the "direct-on-line" start. It gets hit with a tidal wave of current and a mechanical jolt that rattles everything downstream. This constant shock therapy hammers the motor windings, bearings, belts, gears, and couplings.

A motor controller completely changes the game with a "soft start." It eases the motor up to speed gently, eliminating that electrical and mechanical shock. This smooth ramp-up and ramp-down drastically cuts wear and tear, meaning your equipment lasts longer and you spend a lot less time dealing with expensive, unplanned breakdowns.

Nailing Your Process Control and Product Quality

In so many processes, precision is everything. Whether you're mixing chemicals, extruding plastic film, or managing tension on a winder, your product quality lives or dies by your ability to hold exact speeds and torques. A variable speed controller gives you that fine-grained command to hit your targets, every single time.

This level of control gives you a few key wins:

- Rock-Solid Consistency: Every batch gets made under the exact same conditions. No more variations, just better quality.

- On-the-Fly Flexibility: Operators can tweak line speeds for different products or materials with the push of a button—no wrenches required.

- Less Waste: By getting rid of sudden jerks and keeping things smooth, controllers mean less damaged product, fewer spills, and a smaller scrap pile.

And as a final bonus, by slowing motors down, these controllers make the plant a much quieter place to work. The reduction in mechanical noise from fans, pumps, and conveyors is often significant, lowering the racket and creating a safer, more comfortable environment for your team.

How to Select and Size the Right Controller for Your Application

Picking the right motor variable speed controller is far more than just grabbing a part off the shelf—it's a critical engineering decision. The wrong choice can spell disaster in the form of poor performance, chronic overheating, catastrophic equipment failure, and costly downtime.

Getting this right the first time is the only way to guarantee your system runs safely, efficiently, and reliably for its entire service life. It’s a process that goes way beyond matching horsepower. You have to dig into the motor's specs, understand the unique demands of the job it's doing, and consider the environment it will live in.

Matching the Controller to the Motor

First things first: the controller and the motor have to be a perfect electrical match. Think of it like pairing an engine with the right transmission—get it wrong, and you’ll have problems from the moment you turn the key. The best place to start is by grabbing the data right off the motor's nameplate.

- Voltage: The controller’s input and output voltage ratings absolutely must match your facility's power and the motor's operating voltage. A mismatch here is a quick way to destroy one or both components.

- Horsepower (HP) or Kilowatts (kW): The controller has to be rated to handle the motor's horsepower. You can always use a bigger controller on a smaller motor, but you can never, ever safely use an undersized controller.

- Full-Load Amps (FLA): This is the number that truly matters. The FLA rating tells you the current the motor draws when it's working its hardest. Your controller's continuous current rating must be equal to or greater than the motor's FLA. No exceptions.

Always trust the Full-Load Amp (FLA) rating over horsepower when sizing a controller. Amps are the true measure of the work getting done, and it’s a much more accurate yardstick, especially with today's high-efficiency motors.

Understanding Your Application's Torque Needs

Once the electrical basics are covered, you need to think about the kind of work the motor is actually doing. Different jobs put wildly different demands on a motor, and it all comes down to torque. This is a crucial distinction that directly steers you toward the right controller.

We generally break applications into two camps:

- Variable Torque: For these jobs, the torque needed changes as the speed changes. Think of fans, centrifugal pumps, and blowers. The faster they spin, the more torque they need to move more air or liquid. These loads are the perfect candidates for VFDs and offer the biggest opportunities for energy savings.

- Constant Torque: Here, the application demands the motor's full rated torque no matter how fast or slow it's running. Conveyors, positive displacement pumps, extruders, and hoists are classic examples. They need consistent muscle to move heavy loads, even when just creeping along.

Knowing which camp your application falls into is non-negotiable. Controllers are often rated differently for variable and constant torque jobs, with constant torque applications demanding a beefier—and usually more expensive—unit. If you want to get into the weeds, you can learn more about how to perform a torque calculation for motor selection.

Don't Forget the Environment and Enclosure

Where is this controller going to live? A clean, air-conditioned electrical room is a world away from a dusty factory floor or an outdoor installation exposed to rain and snow. This is where NEMA (National Electrical Manufacturers Association) enclosure ratings are your best friend.

The enclosure is the controller's armor, protecting its sensitive electronics from dust, dirt, water, and corrosive chemicals.

- NEMA 1: Your standard indoor enclosure for clean, dry locations.

- NEMA 12: Steps it up to protect against dripping liquids and airborne dust.

- NEMA 4/4X: Built tough for washdown environments, protecting against hose-directed water. The "X" in 4X means it also resists corrosion.

Choosing the right enclosure isn't optional—it's a fundamental requirement for safety and reliability.

This flowchart helps connect the dots, showing how your main goal—whether it's saving money, making equipment last longer, or improving your process—links directly to the benefits a controller can deliver.

As you can see, a single investment in the right controller pays dividends in multiple ways, aligning perfectly with your key operational goals.

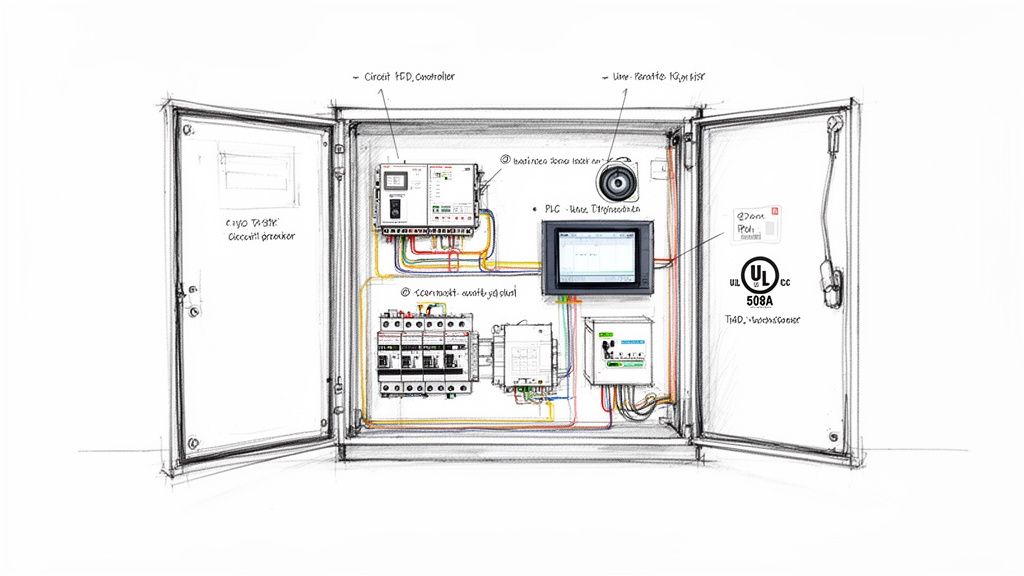

Integrating Controllers into UL-Listed Control Panels

A motor variable speed controller on its own is just one piece of the puzzle. A truly professional setup is a complete, integrated system. Just slapping a drive on the wall and running some wires is a surefire way to run into reliability issues and create serious safety hazards down the road.

That’s why proper integration into a purpose-built, UL-listed control panel is absolutely non-negotiable. It’s the only way to guarantee safety, meet electrical codes, and build a system that’s dependable for the long haul. This is what turns a pile of parts into a cohesive, turnkey solution ready to perform the moment you flip the switch.

More Than Just a Box: Key Panel Components

A professionally built control panel is engineered to house much more than just the controller itself. It brings together all the necessary support hardware—properly sized and wired—to protect both the equipment and the people operating it.

Inside a well-designed panel, you’ll find several critical components working in harmony:

- Circuit Protection: This is your first line of defense. Fuses or circuit breakers are installed "upstream" from the controller to guard against short circuits and overcurrents, preventing a minor issue from turning into a catastrophic failure.

- Disconnect Switch: A lockable main disconnect is a fundamental safety requirement. It allows technicians to completely de-energize the entire panel and follow lock-out/tag-out (LOTO) procedures before touching a single wire.

- Line Reactors: Think of these as shock absorbers for your electrical power. Installed on the input side of the controller, these inductors smooth out the incoming voltage, shielding the sensitive drive electronics from spikes and cleaning up the harmonic distortion sent back to the grid.

- Operator Interface: This could be as simple as a start/stop button and a speed knob or as sophisticated as a full-color Human-Machine Interface (HMI) touchscreen. It’s what gives operators on the floor the local control and monitoring they need.

Why the UL 508A Sticker Matters

When you see a UL 508A mark on a control panel, it’s not just a sticker—it’s a seal of approval that guarantees safety and compliance. This standard is the definitive benchmark for building industrial control panels in North America.

A UL 508A certification is proof that the panel was built by a certified shop using approved components, correct wiring techniques, and proper component spacing, all of which is documented and traceable.

A UL-listed panel buys you peace of mind. It signals to electrical inspectors, insurance companies, and your own safety team that the system has been thoroughly vetted against strict, nationally recognized standards for fire and electrical safety.

Choosing a UL-certified panel makes project commissioning smoother, simplifies regulatory sign-offs, and drastically reduces your liability. It ensures every single component is correctly sized, protected, and documented. For a deeper dive into what this entails, our complete guide to industrial control panel design has all the details.

Plugging Into Your Plant's Automation Brain

In any modern facility, a motor controller rarely acts alone. It needs to talk to the rest of your automation ecosystem, from the Programmable Logic Controllers (PLCs) that run the machine’s logic to the SCADA systems that give you a bird's-eye view of the whole plant.

This communication happens over industrial protocols. Standards like EtherNet/IP and Modbus act as the common language, letting the controller share critical data in real-time. This allows a central system to send speed commands, check the motor’s current draw, and instantly receive diagnostic fault codes.

This tight integration is the bedrock of modern process automation and the hallmark of a system delivered by an experienced partner who knows how to make all the pieces work together flawlessly.

Real-World Applications of Motor Speed Controllers

The real magic of a motor variable speed controller isn't just in the tech specs; it's what they do out in the field. These devices are the quiet workhorses in countless industries, saving massive amounts of energy, fine-tuning processes, and preventing the kind of wear and tear that leads to expensive downtime. You'll find them solving problems everywhere, from city infrastructure to sprawling factory floors.

Take HVAC systems and wastewater treatment plants, for instance. The pumps and fans in these places almost never need to run at 100% speed, 100% of the time. By using a controller to dial the motor speed up or down based on actual demand—like adjusting airflow as people move through a building or easing back on pump flow overnight—facilities can rack up some truly impressive energy savings. It's a huge deal in the HVAC world, which is why an HVAC sales representative often works closely with these technologies.

Enhancing Manufacturing and Logistics

In the world of manufacturing and logistics, it's all about precision and uptime. A conveyor system is the perfect example. Firing up a heavily loaded conveyor without a controller is like slamming your foot on the gas pedal. Products get jerked around, things get shifted out of place, and sometimes, stuff just falls right off.

A motor variable speed controller changes the game entirely. It delivers a smooth, controlled acceleration that protects both the products and the conveyor’s mechanical guts. It also gives you the power to perfectly sync up different parts of a production line, which is absolutely essential for keeping the whole operation running like a well-oiled machine.

Being able to fine-tune speed and acceleration isn't just a nice-to-have feature. It’s a core requirement for hitting quality targets and keeping things efficient in any modern automated facility.

Mastering Precision in Chemical Processing

For industries like chemical and plastics manufacturing, consistency is king. The slightest deviation from the recipe can ruin an entire batch. That's where controllers become indispensable for machinery like extruders and mixers.

- Extruders: You need dead-on speed control to maintain the exact pressure and temperature required to produce materials with consistent thickness and quality.

- Mixers: The ability to ramp motor speed up or down gives operators total control over the viscosity and homogeneity of a mixture, guaranteeing every batch is identical.

- Centrifuges: Speed control is what allows for the precise separation of materials based on their density, a foundational process in tons of chemical and biological applications.

In these high-stakes environments, a motor variable speed controller provides the rock-solid torque and speed regulation needed to ensure product consistency, batch after batch. From bustling distribution centers to critical industrial processes, these controllers are the key to unlocking smarter, more efficient, and far more reliable operations.

Getting Your Questions Answered

When you're digging into the world of motor control, a few practical questions always seem to pop up. Let's tackle some of the most common ones we hear from engineers and plant managers out in the field.

Can I Slap a VFD on Just Any Old Motor?

You can, but you probably shouldn't. While a VFD will technically make a standard-duty motor spin, you're asking for trouble. It's always best to pair it with a true inverter-duty motor.

These motors are built differently. They have beefed-up insulation and often a shaft grounding ring designed to handle the punishing, high-frequency voltage pulses a VFD puts out. Using one prevents the kind of slow-burn damage—like fried windings and wrecked bearings—that can take a standard motor out of commission way too soon.

Seriously, How Much Energy Will I Save?

This isn't just marketing fluff; the savings can be massive, especially for certain applications. If you're running variable torque loads like centrifugal pumps or fans, the results are almost unbelievable.

The affinity laws tell the story: slow a fan's speed by just 20%, and you can slash its energy use by nearly 50%. This is where a motor variable speed controller really shines and pays for itself, often much faster than you'd expect.

While every system is unique, we see facilities get a full payback on their controller investment in under two years—sometimes purely from the drop in their electricity bills.

What's the Real Difference Between a VFD and a Soft Starter?

This is a big one, and getting it wrong can be a costly mistake.

Think of it this way: a VFD gives you full-range speed control, like a gas pedal for your motor. You can adjust the speed up and down anytime it's running. A soft starter, on the other hand, is more like a clutch. It only manages the motor's ramp-up and ramp-down to prevent the mechanical shock and electrical surge of a hard start. Once the motor is up to speed, the soft starter's job is done.

At E & I Sales, we don't just sell parts; we engineer complete motor control solutions. Whether you need a single drive or a complex, custom UL-listed control panel, we're the partners you can count on to get it right. If you're ready to select, size, and implement the perfect controller, let's talk.