The real difference boils down to one simple idea: a Motor Control Center (MCC) is a specialized hub designed to centrally control and protect motors, while switchgear is built for the broad-scale distribution, protection, and isolation of an entire electrical system.

Think of it like this: an MCC is the tactical command center for a factory's machinery, while switchgear is the main power grid control station for the whole building.

Understanding The Core Distinction Between MCCs And Switchgear

At its heart, the motor control center vs. switchgear discussion is about specialization versus generalization. While both manage electrical power, their primary jobs, design philosophies, and common applications couldn't be more different.

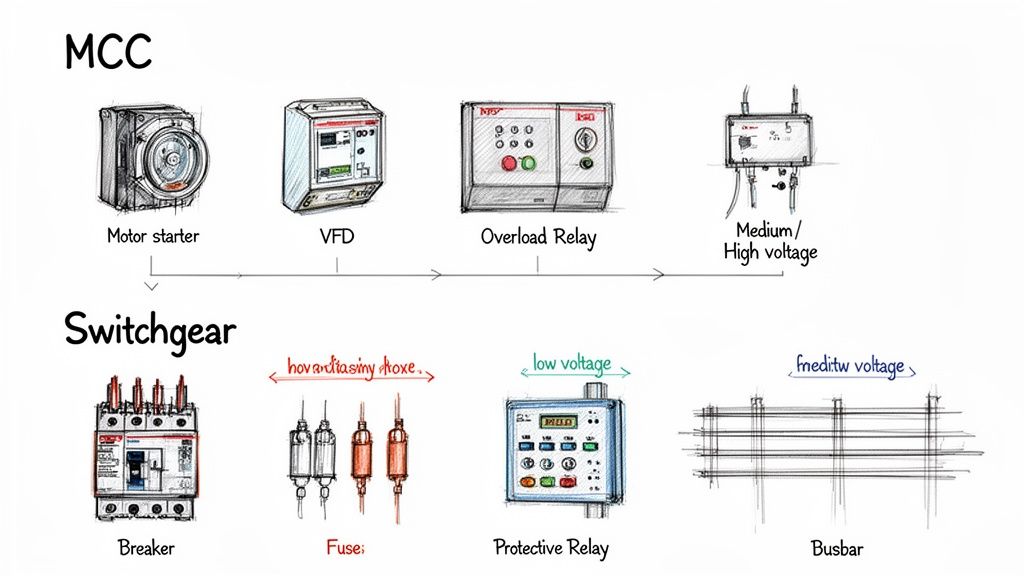

An MCC’s role is incredibly specific. It’s designed to group motor starters, variable frequency drives (VFDs), and their associated protective devices into a single, coordinated assembly. This centralization makes life a lot easier when you're trying to operate and maintain dozens of motors spread across a huge facility.

Switchgear, on the other hand, acts as the primary guardian of an electrical system. Its job is to take high-power feeds from a utility or generator and safely distribute that power to everything downstream—transformers, panelboards, and even the MCCs themselves. It’s engineered from the ground up to handle massive fault currents and provide critical system-wide isolation for safety and maintenance.

Defining The Functional Roles

A Motor Control Center is the operational hub for industrial processes. Its modular design, with individual "buckets" or removable units for each motor, is a lifesaver. It allows for quick troubleshooting and replacement, which drastically minimizes costly downtime. If you want to get into the nitty-gritty of their design, we've got a detailed guide that answers the common question: what is a motor control center?

Switchgear is built for pure robustness and protection. Inside, you’ll find large circuit breakers and heavy-duty protective relays designed to interrupt enormous electrical currents during a fault. This prevents catastrophic damage to your entire infrastructure. The construction is heavily focused on containing dangerous arc flash events and keeping personnel safe.

The simplest way to frame the difference is by scope: An MCC controls what the power does (run a motor), while switchgear manages where the power goes (distribution and protection).

At a Glance MCC Vs Switchgear

To cut through the noise, this table gives you a quick, high-level look at the fundamental distinctions between these two critical pieces of equipment.

| Attribute | Motor Control Center (MCC) | Switchgear |

|---|---|---|

| Primary Function | To centralize motor control, starting, and local protection in one location. | To distribute, protect, and isolate main electrical circuits and feeders. |

| Typical Voltage | Primarily Low Voltage (LV), typically 480V or 600V. | Low Voltage (LV), Medium Voltage (MV), and High Voltage (HV). |

| Main Components | Combination starters, VFDs, soft starters, overload relays, and small breakers. | Large power circuit breakers, fuses, protective relays, and busbars. |

| Key Application | Industrial plants with many motors (e.g., manufacturing, water treatment). | Utility substations, data centers, commercial buildings, and main service entrances. |

As you can see, while they might look similar from a distance, their jobs on the plant floor are worlds apart.

A Look Inside: Comparing Functional Design and Core Components

To really get the difference between an MCC and switchgear, you have to look past the metal cabinet and get into the guts of the system. Their internal designs and the parts they're built from are engineered for completely different jobs. One is all about granular control over specific machinery; the other is a fortress built for broad power system protection.

Think of an MCC as a densely packed, modular library of motor control units. The whole design is centered on accessibility and standardization for all the equipment it runs. Switchgear, on the other hand, is constructed to be the primary guardian of power distribution. Its design is all about containing faults and interrupting massive amounts of current safely.

Inside the Motor Control Center

The heart of any MCC is the combination starter, which lives inside a removable module that we in the field just call a "bucket." This little self-contained unit is the real workhorse, handling the three essential jobs for a single motor.

Every bucket provides:

- A Disconnect: This is simply the means to safely isolate the motor circuit so a technician can work on it.

- Short-Circuit Protection: A circuit breaker or a set of fuses designed to protect against dangerous high-current faults.

- A Motor Starter: This is typically a contactor that turns the motor on and off, paired with an overload relay that protects the motor itself from burning out.

Modern MCCs have also become the home for Variable Frequency Drives (VFDs) and soft starters. These are more sophisticated controllers that give you precise speed control (VFDs) or reduce the mechanical jolt during motor startup (soft starters). This plug-and-play modularity is the MCC’s biggest advantage—if a unit fails, you just swap it out, keeping downtime to a minimum.

Inside the Switchgear Assembly

Switchgear is built around a completely different core: a massive, heavy-duty busbar system designed to channel and distribute huge amounts of power. Its main components aren’t there to control individual loads; they’re there to protect the main electrical feeders that supply power to everything downstream.

The key players here are:

- Power Circuit Breakers: We're talking about large, incredibly robust devices—often using air, vacuum, or gas insulation—built to interrupt fault currents that can exceed 100,000A without blowing themselves apart.

- Protective Relays: These are the brains of the operation. They constantly monitor the electrical system's vitals—current, voltage, frequency—and tell the circuit breakers to trip the instant they detect a problem like an overcurrent or ground fault.

- Current Transformers (CTs): These instruments are crucial for safety and measurement. They "step down" dangerously high currents to a manageable level that the protective relays can safely read, providing the data needed to make life-saving decisions.

This entire architecture is designed to ensure that a catastrophic fault on one circuit is isolated instantly, preventing a chain reaction that could knock out the entire facility.

While an MCC is designed for operational convenience with its interchangeable buckets, switchgear is designed for absolute system integrity, with fixed, heavily braced components built to withstand extreme electrical and mechanical forces.

A Tale of Two Constructions

The physical build of each system tells you a lot about its job. MCCs usually feature a compartmentalized design, where each motor starter bucket is isolated in its own metal enclosure. This is a huge safety feature, allowing a technician to work on one de-energized unit while the ones next to it are still running.

Switchgear, especially medium and high-voltage gear, takes this a step further with metal-clad construction. This is a much more rigorous standard where all major components—the breakers, the busbars, the controls—are sealed off in their own separate, grounded metal compartments. This design is critical for containing an arc flash, which is a violent and incredibly dangerous explosion of energy that happens during a short circuit.

These specialized roles are reflected in the global market. Motor control centers are a big business, with a market size of about USD 6.5 billion. But the switchgear market is on another level, valued at a massive USD 99.7 billion, underscoring its foundational role in all power infrastructure. Low-voltage MCCs, the kind that handle circuits under 1,000 volts, make up 72.6% of their market, showing just how dominant they are in factories and industrial plants. You can explore more market insights about motor control centers and their applications.

Contrasting Electrical Ratings

The last major point of comparison comes down to their electrical ratings. This is where the motor control center vs switchgear discussion becomes black and white.

MCCs are almost always low-voltage devices, built to run at 480V or 600V. Their ratings are all about the horsepower of the motors they can handle and the continuous current they can supply.

Switchgear, however, covers the entire voltage spectrum:

- Low Voltage (LV) Switchgear: Operates below 1,000V and typically acts as the main power distribution hub for large buildings or plants.

- Medium Voltage (MV) Switchgear: This is your 1kV to 38kV gear, found in utility substations and on large industrial campuses, managing power coming in from the grid.

- High Voltage (HV) Switchgear: Anything above 38kV is considered high voltage, and you'll find this in power generation stations and transmission systems.

At the end of the day, it's rarely an "either/or" choice. In any large facility, they work as a team. The switchgear is the main gatekeeper, receiving utility power and protecting the main distribution lines. Those lines then feed the downstream MCCs, which handle the final, detailed work of controlling every individual motor that keeps the plant running.

Navigating Safety Standards And Code Compliance

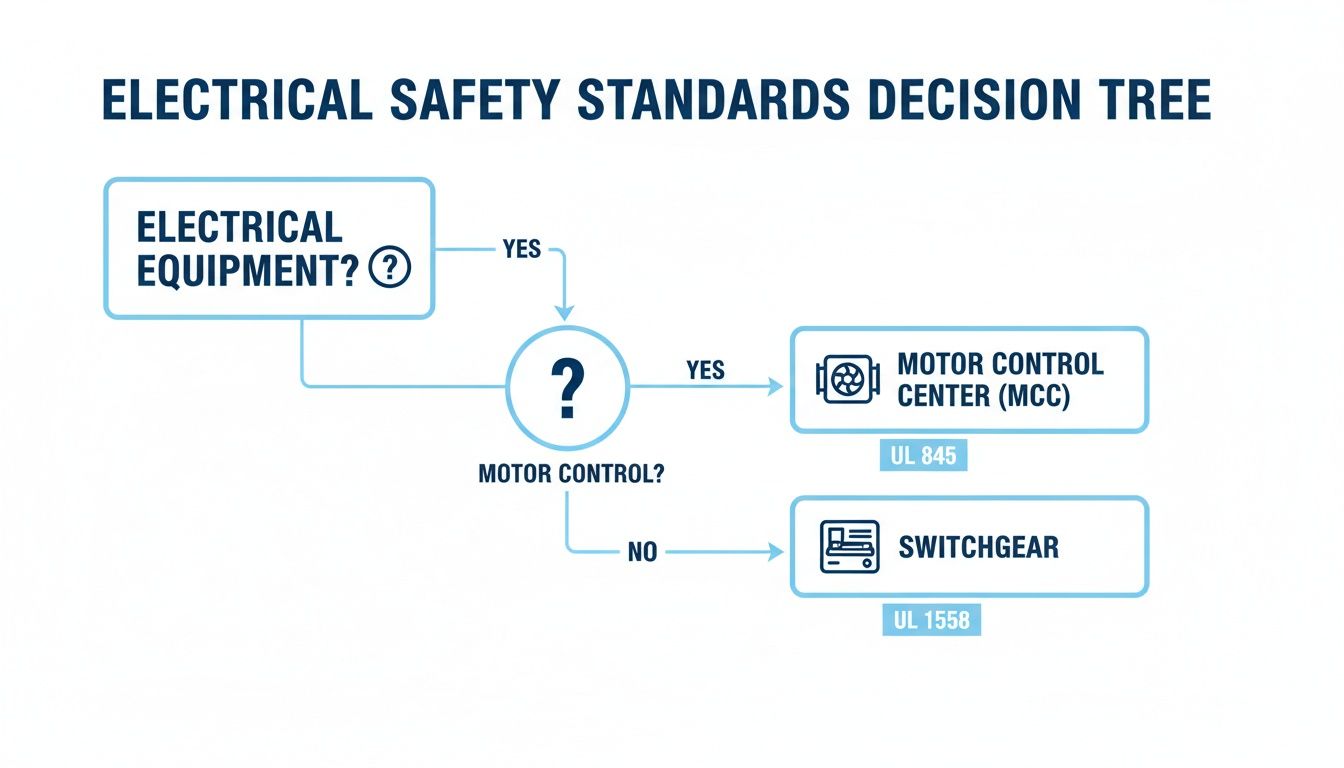

When you're dealing with high-power electrical equipment, safety isn't just a goal—it's a non-negotiable requirement, policed by a web of codes and standards. The whole conversation around motor control centers vs. switchgear is steeped in these regulations. Each piece of gear is designed, tested, and certified against different benchmarks, and knowing the difference is crucial for protecting your team, keeping the plant running, and staying compliant.

These aren't just suggestions from governing bodies. They dictate the very DNA of the equipment—its construction, performance limits, and the gauntlet of tests it must survive. A UL label, for instance, is more than a sticker. It's proof that the equipment has been through the wringer and passed rigorous, standardized safety trials.

For any engineer or facility manager, choosing equipment without a solid grasp of these standards is asking for trouble. The right certification is your assurance that the gear can handle the application's voltage, potential fault current, and the environment it's going into.

The Defining Standards for MCCs

Motor Control Centers live and breathe by UL 845, the Standard for Motor Control Centers. This is the playbook. It outlines every critical detail, from the bracing of the busbars and wire bending space to how each individual MCC bucket is built. Its entire focus is on ensuring an MCC can safely pack motor starters, VFDs, and other control devices into its dense, modular framework.

Compliance with UL 845 means the MCC was tested as a complete, unified assembly. That’s a critical point. It guarantees that all the internal parts play nicely together under both normal and fault conditions. It’s also vital to know the difference between a product being UL Listed versus just containing UL Recognized components. We break down the important distinctions in our guide to UL Listed vs UL Recognized certifications.

Core Regulations for Low Voltage Switchgear

Switchgear is built to handle much bigger electrical punches, so it operates under a different, more demanding set of rules. The gold standard for low-voltage switchgear is UL 1558, the Standard for Metal-Enclosed Low-Voltage Power Circuit Breaker Switchgear. This standard is all about one thing: the equipment's ability to withstand and safely interrupt massive fault currents.

UL 1558 has strict mandates for things like:

- Busbar Strength and Spacing: The busbars have to be braced to survive the incredible magnetic forces that erupt during a short circuit.

- Compartmentalization: Key components like breakers and busways are isolated behind grounded metal barriers to contain a fault and stop it from spreading.

- Circuit Breaker Performance: The breakers aren't just rated; they're physically tested to prove they can interrupt the maximum available fault current without a catastrophic failure.

The standards tell the story of their intended jobs. UL 845 is about the safety of integrated motor control assemblies. UL 1558 is all about raw power handling and the brute force needed to interrupt faults at the main distribution level.

Understanding Arc Flash Safety Implications

Maybe the most sobering safety issue is arc flash—a violent, explosive release of energy that happens during a short circuit. Because switchgear sits upstream in the power system where the available fault current is highest, arc flash mitigation is baked into its very design. This is a massive differentiator in the motor control center vs. switchgear debate.

Switchgear is often built to be arc-resistant, a specific construction defined by IEEE C37.20.7. This isn't just a heavy-duty box. It's a system designed to contain an arc blast and channel the explosive energy away from anyone standing in front of it, typically venting it out the top or back. It's a lifesaving feature that you won't typically find on a standard MCC.

MCCs still face arc flash risks, but their position downstream usually means the incident energy levels are lower. That doesn't make them "safe"—it just changes the approach. Safety protocols like proper personal protective equipment (PPE) and energized work permits are just as critical. The design focus for MCCs tends to be more on compartmentalization and features that allow for remote operation, rather than the heavy-duty blast containment you see in arc-resistant switchgear.

How To Choose The Right Solution For Your Application

When it comes down to the motor control center vs switchgear decision, you have to ask one simple question: what’s the primary job this equipment needs to do in my system? Are you commanding a fleet of motors, or are you distributing and protecting the main power feeds for an entire facility?

Answering that question honestly will point you right to the solution. This isn't about which technology is "better" in a vacuum. It’s about matching the equipment's fundamental design to your specific operational reality. A mismatch here leads to blown budgets, compromised safety, and a system that fights you every step of the way.

This visual decision tree is a great starting point. It helps clarify which UL standard—and therefore, which type of equipment—aligns with the core function you have in mind.

As you can see, the paths diverge based on function. Motor-centric tasks fall under UL 845 and point to MCCs, while power distribution and protection duties are governed by UL 1558 for switchgear.

When To Specify A Motor Control Center

In any environment where you have a high density of motors that need to be managed from one spot, the MCC is the undisputed champion. Its whole design—modular, centralized, and focused on individual motor control—makes it the obvious choice for process-heavy industries.

Think of these classic MCC scenarios:

- Manufacturing Plants: Picture a factory floor with dozens of conveyor belts, mixers, and pumps all running at once. An MCC gathers all the starters, VFDs, and protection into a single, organized enclosure. This dramatically simplifies wiring, day-to-day operation, and troubleshooting.

- Wastewater Treatment Facilities: These plants are a complex web of pumps, aerators, and clarifiers. An intelligent MCC can integrate these assets into a SCADA system, enabling automated control and remote monitoring—a must-have for modern operational efficiency.

- HVAC Systems in Large Buildings: The fans, chillers, and pumps that keep a commercial high-rise running are perfect candidates for an MCC. It centralizes control, making it far easier for facility managers to manage building climate and keep energy costs in check.

The common thread here is the need for granular control over multiple motor loads. It's no surprise that for industrial OEMs and packagers, the industrial end-use captured 73.7% of the MCC market share. You can discover more data on MCC market trends and see just how dominant they are in these applications.

When To Specify Switchgear

Switchgear enters the picture when the primary job is robust, high-current power distribution and bulletproof system-wide protection. It’s the main electrical gatekeeper for a facility, built to handle the full force of the utility feed and isolate catastrophic faults.

You absolutely need switchgear in these situations:

- Utility Substations: This is the natural habitat for medium and high-voltage switchgear. Its sole purpose is to protect the grid and manage the flow of power from generation sources to various load centers.

- Data Center Main Power Distribution: Downtime is not an option in a data center. Switchgear provides the critical, high-reliability power distribution and fault isolation needed to protect servers and guarantee uptime. Its heavy-duty construction is designed to protect the integrity of the main power feed at all costs.

- Main Service Entrance for Industrial Plants: Before power ever gets to an MCC or a single machine, it first has to pass through the main switchgear. This equipment is the first line of defense, protecting the entire facility from major faults and providing the primary disconnect from the grid.

The Core Decision Criteria: Choose MCCs when your primary need is centralized motor control and operational flexibility. Choose switchgear when your primary need is robust power distribution, protection, and isolation.

The Most Common Scenario: Hybrid Systems

In the real world, the choice is rarely "motor control center vs switchgear" in isolation. Most industrial facilities need both, working in concert as a coordinated power distribution and control system. The switchgear acts as the primary hub, feeding protected power to downstream MCCs.

To help clarify this relationship, this decision matrix maps common industrial needs to the most appropriate solution.

Application Decision Matrix: MCC Vs. Switchgear

| Application Scenario | Primary System Need | Recommended Solution | Key Consideration |

|---|---|---|---|

| Factory Assembly Line | Centralized control of 50+ conveyor and pump motors | Motor Control Center (MCC) | Modularity for future expansion and easy troubleshooting. |

| Commercial Building HVAC | Coordinated control of fans, pumps, and chillers | Motor Control Center (MCC) | Integration with Building Automation System (BAS) is critical. |

| Utility Substation | Grid protection and high-voltage power distribution | Medium/High-Voltage Switchgear | Must meet utility-grade reliability and safety standards. |

| Data Center Power Feed | Uninterruptible, high-amperage power distribution | Low-Voltage Switchgear | Arc-flash safety and selective coordination are non-negotiable. |

| Main Plant Service Entrance | Facility-wide overcurrent protection and main disconnect | Low-Voltage Switchgear | Must be rated to handle the full available fault current. |

| Oil & Gas Pumping Station | Remote and automated control of multiple large pumps | Intelligent MCC | Needs robust communication for SCADA/DCS integration. |

This matrix shows that the two systems are not competitors; they are partners in a safe and reliable power distribution network. A typical hierarchy looks like this:

- Medium-Voltage Switchgear takes the main power feed from the utility.

- It feeds a transformer, which steps the voltage down to a usable level like 480V.

- Low-Voltage Switchgear then distributes this power to major sections of the plant.

- Finally, this power is sent to multiple Motor Control Centers, which handle the final control and protection of the individual motors running the machinery.

Understanding this hierarchy is key. The real job for an engineer isn’t picking one over the other, but correctly specifying each component for its intended role within that larger system.

Analyzing Maintenance and Total Cost of Ownership

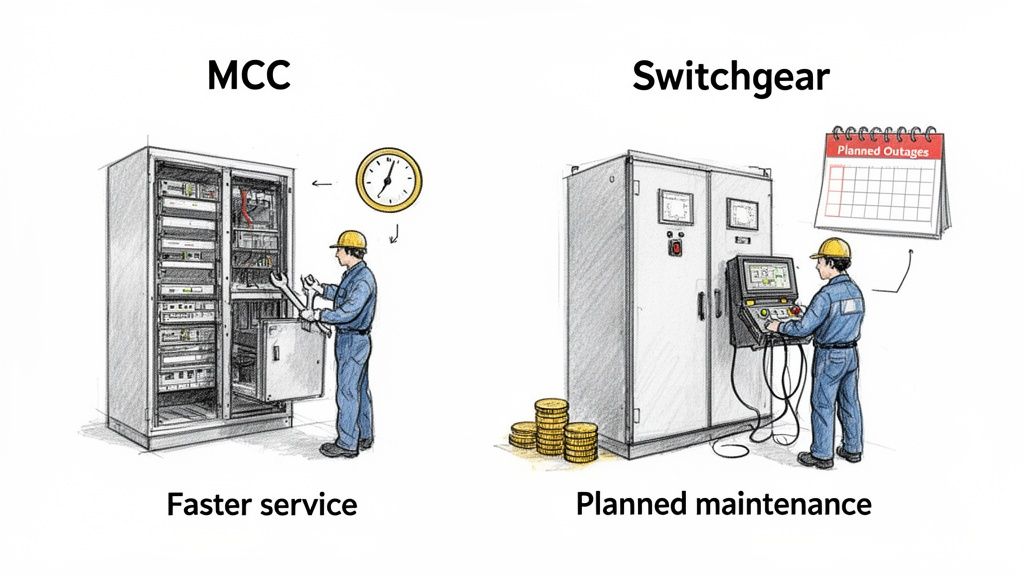

The sticker price is just the beginning. When you’re looking at major electrical equipment like an MCC or switchgear, the real cost shows up over years—sometimes decades—of operation, maintenance, and potential downtime. Their designs are so fundamentally different that they lead to completely separate paths when it comes to long-term cost and upkeep.

Think of it this way: an MCC is built for speed and uptime, letting you get a single motor back online fast. Switchgear, on the other hand, is all about system-wide stability and requires a much more deliberate, planned approach to maintenance. This core difference dictates everything from a routine check-up to an emergency repair.

Maintenance Lifecycle of an MCC

The draw-out, modular design is the MCC's secret weapon. Every motor starter, VFD, or soft starter sits in its own "bucket" that you can pull out and swap in minutes. For anyone who's ever dealt with a production line grinding to a halt, this feature is an absolute game-changer.

When a component inside a bucket fails, the fix is incredibly straightforward. A technician can kill the power to that single unit, pull it out, and slide a spare in its place. The motor is running again almost instantly, while the failed bucket gets taken to the shop for a closer look.

This "swap and repair" model gives you some serious advantages:

- Minimal Downtime: Your Mean Time to Repair (MTTR) is slashed. You're only dealing with one motor circuit being down, and only for as long as it takes to swap the unit.

- Safer Work Conditions: The technician isn't hunched over live equipment. They can work on the de-energized bucket on a workbench, far from any electrical hazards.

- Easier Troubleshooting: With the problem isolated to one removable module, finding the root cause is much less of a headache.

This design philosophy is all about containing the blast radius of a component failure, which is a huge deal when you start calculating the real cost of ownership. We dive deeper into best practices in our guide to motor control center maintenance.

The Switchgear Maintenance Approach

Working on switchgear is a different beast entirely. It’s a more methodical, high-stakes process because this equipment is the protective backbone for huge sections of your facility. You can't just swap out a breaker like you would an MCC bucket; maintenance here almost always means a planned shutdown of everything that piece of switchgear feeds.

Typical maintenance tasks are much more involved:

- Circuit Breaker Testing: This calls for specialized gear to make sure the breaker’s trip mechanisms and arc-quenching abilities are up to spec.

- Protective Relay Calibration: Technicians have to meticulously verify that the relays will trigger correctly under specific fault conditions.

- Busbar Inspection and Torquing: This is a critical check to ensure all high-current connections are tight to prevent overheating—a major cause of catastrophic failure.

These jobs require highly trained technicians and a lot of planning. The downtime is significant and has to be scheduled well in advance, usually during a plant-wide shutdown. Regardless of what you choose, implementing a robust preventive maintenance schedule is non-negotiable for managing total cost and keeping the lights on.

It really boils down to this: MCCs are built for fast reactive maintenance to minimize production loss. Switchgear demands disciplined, proactive maintenance to guarantee system-wide reliability.

Calculating the Total Cost of Ownership

The Total Cost of Ownership (TCO) is where the rubber meets the road. It forces you to look past the initial price tag and consider installation, maintenance, the cost of downtime, and eventually, decommissioning.

When MCCs first appeared back in the 1950s, they were revolutionary because they centralized motor starters, cutting factory wiring and installation costs by as much as 30% compared to individual panels. Fast forward to today, and you see integrators blurring the lines, engineering UL-listed MCCs that cleverly incorporate switchgear components into custom setups. This hybrid approach can trim project timelines by 20-25% by using a single source and simplifying coordination on site.

When you run the TCO numbers, an MCC often comes out ahead in process-heavy industries where every minute of downtime costs a fortune. In contrast, while switchgear might have a higher upfront cost and more expensive maintenance, its role is to prevent a system-wide blackout. That risk mitigation delivers a massive—if harder to quantify—return on investment.

Your Top Questions About MCCs and Switchgear, Answered

Even after you've got the basics down, a few questions always pop up on real-world projects. I get these all the time from engineers and facility managers trying to navigate the fine details between a motor control center and switchgear.

Let's clear up some of the most common points of confusion with some straightforward, practical answers.

Can a Motor Control Center Do the Job of Switchgear?

Absolutely not. An MCC is built for a totally different purpose and trying to make it act like switchgear is a major safety and design mistake.

An MCC is all about controlling and protecting specific motor loads. It's home to starters, VFDs, and circuit protection for those individual machines. Switchgear, on the other hand, is the heavy-hitter upstream. It's engineered to be the main gatekeeper, handling massive fault currents and providing the primary isolation for your entire facility's electrical system.

Think of it like this: your main water valve for the whole building is the switchgear. The MCC is the manifold that splits the water off to individual sinks and showers, each with its own little shut-off valve. You'd never use a sink valve to shut off the water to the whole building, and the same logic applies here.

What's the Deal with an "Intelligent MCC"?

An "intelligent MCC," or iMCC, is a game-changer. It takes a standard MCC and weaves in a communication network, like EtherNet/IP or PROFINET. This network links all the motor starter units back to a central PLC or a larger Distributed Control System (DCS).

This is a huge leap from old-school MCCs, which needed a massive bundle of control wires running to each bucket for simple start/stop signals and status lights.

The real power of an iMCC is the firehose of data you get. Instead of just knowing if a motor is on or off, you get real-time info on energy use, performance trends, and early fault warnings. This is what enables you to shift from reactive repairs to predictive maintenance.

Plus, you eliminate a ton of field wiring. Getting rid of hundreds of individual control wires not only slashes labor costs and installation time but also removes countless potential points of failure, making commissioning a whole lot smoother.

When Do I Need to Step Up to Medium Voltage Switchgear?

You'll need medium voltage (MV) switchgear, which typically handles power in the 2.4kV to 38kV range, anytime your facility is taking power directly from the utility at that higher voltage. It becomes your main service entrance equipment—the first and most critical line of defense and disconnection from the grid.

You'll see MV switchgear in places like:

- Large Industrial Plants: Think refineries, paper mills, or sprawling manufacturing campuses that have their own substations to handle their massive power needs.

- Data Centers: These facilities can't afford downtime, so they often bring in medium voltage power to feed their power distribution units for maximum reliability.

- Utility Distribution Networks: MV switchgear is the fundamental building block of the electrical grid itself, directing power through local circuits.

From there, the MV switchgear usually feeds transformers that step the voltage down to a more usable level, like 480V. That power is then sent to low-voltage switchgear, which in turn feeds your downstream equipment like MCCs.

How Do I Tie an MCC into a Building Automation System?

The cleanest and most effective way to integrate an MCC with a Building Automation System (BAS) or SCADA system is by using an intelligent MCC. The iMCC's built-in network is the perfect data bridge.

The process is pretty slick. A network gateway inside the iMCC gathers all the data from the individual motor units. This gateway then talks to the BAS over a standard protocol, creating a single point of connection.

With this link, facility managers can monitor and control every pump, fan, and chiller from one central screen. It’s the key to truly optimizing your building’s energy performance, streamlining maintenance, and getting a complete picture of what your mechanical systems are doing.

Navigating motor control, automation, and power distribution requires a partner who understands how all the pieces fit together. E & I Sales delivers engineered UL-listed control panels, premium electric motors, and turnkey system integration that brings it all into one cohesive solution. If you want to standardize your equipment, move your project forward faster, and ensure code-compliant safety from day one, see what our custom solutions can do for you.