When you need to protect an electrical circuit, you might think of a fuse. But what if you could have a smarter, reusable fuse? That's essentially what a miniature circuit breaker, or MCB, is. It’s an automatic switch built to shield electrical circuits from the damage that excess current can cause.

Instead of blowing and needing a replacement, an MCB simply trips—shutting off the power. Once you've sorted out the underlying problem, you just flip it back on.

What a Miniature Circuit Breaker Really Does

At its heart, an MCB is the unsung hero in your electrical system. Whether it's tucked inside a complex UL control panel or on a manufacturing line, this little device is your first line of defense. Its job is simple but critical: watch the current flowing through a circuit and cut the power the second it detects danger.

Getting to grips with miniature circuit breakers is non-negotiable for real electrical safety. Without them, a minor wiring mistake or a failing motor could spiral into catastrophic equipment failure, a fire, or worse, a serious injury.

The MCB's Role in Industrial Control Panels

In the world of industrial controls, the stakes are even higher. These panels are packed with sensitive, high-value components like PLCs, VFDs, and motors that are incredibly vulnerable to electrical hiccups. This is where an MCB truly proves its worth.

To get a clearer picture of what an MCB is actually doing inside a control panel, let's break down its core protective duties.

MCB Core Functions at a Glance

| Protective Function | Description | Typical Scenario |

|---|---|---|

| Overload Protection | Trips when a circuit draws slightly too much current over a period of time. This is a slow-acting response. | A conveyor belt motor is struggling under a heavy load, causing it to pull more amps than it's rated for. |

| Short-Circuit Protection | Trips almost instantly when it detects a massive, sudden surge of current, interrupting power in milliseconds. | A frayed wire makes contact with a metal enclosure, creating a direct path for current to flow to the ground. |

| Selective Coordination | Ensures only the breaker closest to a fault trips, isolating the issue without killing power to the entire system. | An issue with a single sensor's power supply trips its dedicated MCB, but the main panel breaker stays on. |

These functions ensure that a localized problem doesn't cascade into a full-system shutdown, saving immense amounts of time and money in a production environment.

The growing reliance on these devices is clear in the market trends. The global miniature circuit breaker market has already ballooned past USD 5.7 billion. Industry analysis projects that number to more than double, hitting around USD 14.4 billion by 2034, all thanks to the increasing demand for dependable circuit protection.

An MCB is far more than a simple on/off switch; it’s a precision-engineered safety instrument. Its real magic lies in its ability to tell the difference between a harmless inrush of current—like a motor kicking on—and a genuinely dangerous fault. That intelligence is what makes it indispensable.

This guide is for the industrial buyers, panel builders, and engineers who need to go beyond the basics. We're going to dive into how they work, how to read their ratings and trip curves, and most importantly, how to choose the right one for your application to maximize both safety and uptime.

How an MCB Protects Your Circuits

On the outside, a miniature circuit breaker looks like a simple on/off switch. But tucked away inside that compact housing is a clever, two-part safety system built to stop two very different kinds of electrical threats: slow-building overloads and lightning-fast short circuits. This dual-action approach is what makes the MCB such a reliable defender of sensitive industrial equipment.

Think of it like having two security guards on duty. One is patient, always watching for trouble that builds up over time. The other is a hyper-alert sentry, ready to jump into action in a split second. Together, they ensure your circuits are protected from the full range of common electrical faults.

These two jobs are handled by two distinct but linked components: a thermal element and a magnetic element. Let's break down how each one works to keep your systems safe and sound.

The Thermal Trip for Overload Protection

The first line of defense is the thermal trip mechanism, which is designed to handle overloads. An overload is what happens when a circuit is forced to carry more current than it's rated for over a period of time—it's not a dead short, but it's still dangerous. A classic example is a pump motor straining under a heavy load or simply too many machines plugged into one line.

The magic behind this mechanism is a surprisingly simple part: a bimetallic strip.

- How It Works: This isn't just one piece of metal. It's two different metals fused together, each one expanding at a different rate when it gets hot. As current passes through the strip, it naturally generates some heat.

- Detecting an Overload: When an overload occurs, the extra current makes the strip get much hotter than usual. Because one metal expands faster than the other, this heat forces the strip to bend.

- Tripping the Breaker: If the overload doesn't stop, the strip will bend far enough to physically shove a trip lever. That lever unlatches the switch contacts, breaking the circuit and shutting off the power.

This whole process is deliberately slow. This design prevents nuisance trips from brief, harmless current spikes, like the inrush current when a large motor kicks on. It only reacts to sustained overcurrents that signal a real risk of overheating, which could damage equipment or even start a fire. This is our patient guard, taking its time to correctly identify a problem that develops over seconds or minutes.

The Magnetic Trip for Short Circuit Protection

While the thermal trip patiently handles slow-burn problems, the magnetic trip mechanism is all about raw speed. Its only job is to react instantly to the catastrophic danger of a short circuit. A short happens when a low-resistance path forms between conductors, causing current to spike to hundreds or even thousands of times its normal level in an instant.

This kind of emergency demands a response far faster than a warming bimetallic strip can offer. That’s where an electromagnet comes in.

A short circuit is an electrical emergency. The magnetic trip function of a miniature circuit breaker is designed to react in milliseconds—often less than 10 milliseconds—to disconnect power and prevent catastrophic damage, arc flashes, and fires.

Inside the MCB, a coil of wire acts as an electromagnet. During normal operation, its magnetic field is negligible. But the moment a short circuit occurs, the massive surge of current flowing through the coil generates a powerful magnetic field.

This magnetic force is strong enough to yank a small plunger or armature, which in turn strikes the trip lever with incredible speed. The contacts are forced apart, and the power is cut—all in the blink of an eye. This is our fast-acting sentry, whose immediate action is absolutely essential for protecting people and equipment from the violent energy of a short-circuit event.

By combining these two distinct yet complementary trip mechanisms, a single MCB provides comprehensive protection. It intelligently differentiates between a motor starting up, a dangerously overloaded circuit, and a critical short-circuit fault, applying the right level of protection at exactly the right time.

Decoding MCB Trip Curves for Industrial Loads

Picking the right miniature circuit breaker goes way beyond just matching the amperage to the load. The real secret to bulletproof protection lies in understanding its reaction time—what we in the industry call its trip curve. This single characteristic defines how quickly an MCB shuts down under different fault conditions, and it's absolutely critical in an industrial setting.

Think of a trip curve as the MCB's "personality." Some are hair-trigger sensitive, reacting to the smallest hiccup. Others are more patient, built to ignore the brief, massive current spikes that are just part of a normal day for heavy machinery. Get this choice wrong, and you're staring down one of two barrels: constant nuisance tripping that kills production, or far worse, a breaker that doesn't act fast enough, leading to catastrophic equipment failure.

This behavior all comes down to the dual-trip system inside every MCB. A thermal element handles the slow-burn overloads, while a magnetic element reacts in a flash to dangerous short circuits.

The trip curve is all about tuning the sensitivity of that magnetic response. Let's break down the common types you'll find in the field.

Type B: The Sensitive Protector

A Type B MCB is the quickest on the draw. It’s designed to trip magnetically the moment the current hits 3 to 5 times its normal rating. This lightning-fast response is perfect for protecting purely resistive loads or circuits where you expect virtually no startup surge.

- Best For: Heating elements, standard lighting circuits, and sensitive electronics that don't have big, beefy power supplies.

- Industrial Scenario: A Type B is the perfect choice for the control wiring going to a PLC or for a small heating coil in a process machine. It gives you immediate protection without having to worry about a big inrush current.

But try to use a Type B on a motor, and you’re just asking for headaches. The motor's normal startup kick would blow right past that low magnetic threshold, tripping the breaker every single time you turn it on.

Type C: The Industrial Workhorse

The Type C curve is what you'll find in the vast majority of industrial control panels, and for good reason. It’s engineered to trip magnetically when the current spikes to 5 to 10 times its rating. That wider window gives it just enough breathing room to handle the normal inrush from most industrial loads without causing false alarms.

For general-purpose industrial use, the Type C curve strikes the perfect balance. It's tough enough to manage the startup demands of small-to-medium motors and inductive loads, yet it still provides rock-solid protection against true short-circuit faults.

Its versatility makes it the go-to for a huge range of equipment. This is a big plus for panel builders and maintenance crews because it simplifies stocking and specifying. We get into the nitty-gritty of sizing these correctly in our complete guide to the protection of motors.

Type D: The Heavy-Duty Specialist

When you're dealing with the real brutes of the industrial world—equipment with massive startup demands—you need a Type D MCB. This heavy-hitter is designed to hold on until the current reaches an incredible 10 to 20 times its rated amperage.

This high threshold allows it to completely ignore the huge, temporary current draw from large-scale industrial machinery firing up.

- Best For: Large electric motors, transformers, industrial welders, and X-ray machines.

- Industrial Scenario: Think about a giant conveyor system powered by a high-torque motor. It's going to pull an insane amount of current for a split second. A Type D breaker is built for exactly that, letting the motor start without a fuss while staying armed and ready for a genuine short circuit.

Matching the trip curve to your load’s electrical signature is the final, crucial step in specifying a reliable MCB. Get it right, and you ensure uptime by eliminating false trips while guaranteeing the device does its job when it counts.

Picking the Right MCB for Your UL Control Panel

Specifying a miniature circuit breaker for a UL 508A industrial control panel isn't just about grabbing something off the shelf that fits the DIN rail. It’s a job that demands precision. Every choice you make impacts the safety, compliance, and long-term reliability of the entire panel.

Think of it as the pre-flight checklist for your panel's electrical system. Get it right, and you've built a solid, safe foundation. Get it wrong, and you're setting yourself up for costly mistakes or, worse, dangerous failures down the line.

The first hurdle—and one of the most common trip-ups in panel design—is getting the UL standard right.

UL 489 vs. UL 1077: The Critical Distinction

These two UL standards look similar, but they define two very different jobs a circuit protector can do inside a panel. They are absolutely not interchangeable.

-

UL 489 Circuit Breakers: These are your heavy hitters, certified for branch circuit protection. A UL 489 breaker is built to be the first line of defense, capable of stopping the massive fault currents that can come from the main power feed. They’re required for protecting the main wiring and everything downstream.

-

UL 1077 Recognized Components: These are supplementary protectors. Think of a UL 1077 device as a specialist providing extra, more sensitive protection for a specific component, like a PLC or a power supply. It must be installed downstream of a primary UL 489 breaker.

Dropping a UL 1077 device into a spot where a UL 489 is required is a major code violation. It will instantly fail a UL inspection and, more importantly, it's a serious safety hazard. A supplementary protector simply isn't engineered to handle the raw energy of a major branch fault.

Calculating the Right Amperage Rating

Once you’ve locked in the correct UL listing, it's time to size the breaker’s amperage. This isn't as simple as matching the number on the nameplate of the load. The National Electrical Code (NEC) requires a built-in safety margin to prevent nuisance trips and overheating.

For most non-motor loads, the rule of thumb is to size the breaker for 125% of the continuous load current. For motors, things get a bit more complex, often starting at 250% of the motor's full-load amperes (FLA) and then adjusting for other factors. Nailing these load calculations is a cornerstone of good industrial control panel design and is non-negotiable for a safe system.

Don't Overlook the Short Circuit Current Rating (SCCR)

The Short Circuit Current Rating (SCCR) might be the single most important safety rating on an MCB. It tells you the maximum fault current the breaker can interrupt without literally blowing itself apart.

Your chosen MCB must have an SCCR that is equal to or greater than the available fault current at the point of installation. No exceptions.

Never install a miniature circuit breaker with an SCCR lower than the available fault current. Doing so creates a significant risk of an arc flash explosion, as the device could fail violently when attempting to clear a major short circuit.

Figuring this out is a system-level task. If you're not absolutely certain what the available fault current is, you need to have a qualified engineer perform a study to determine it.

This need for properly specified components is a global issue. As industrialization ramps up, especially in regions like Asia Pacific, the demand for reliable circuit protection has skyrocketed, making it the largest market for miniature circuit breakers. It’s a clear sign that modern electrical systems, no matter where they are, depend on getting these fundamental choices right.

MCB vs. Other Overcurrent Protection Devices

A miniature circuit breaker doesn't work in a vacuum. It's just one player on a much larger team of protective devices, and knowing where it fits is absolutely critical for designing a safe and reliable electrical system.

Each device has a very specific job to do. Mixing them up or assuming they're interchangeable is a recipe for disaster, leaving dangerous gaps in your system's safety net. To build a truly bulletproof panel, you need to understand how an MCB stacks up against the other common devices you'll find in any industrial facility. Let's break down the distinct roles of fuses, MCCBs, and RCDs/GFCIs so you're always grabbing the right tool for the job.

MCB vs. The Classic Fuse

For decades, the humble fuse was the king of overcurrent protection. It’s brilliantly simple: a small piece of wire engineered to melt and break the circuit when current gets too high. But that simplicity is also its greatest weakness.

Once a fuse blows, it's done. You have to replace it. That means stocking spares, dealing with downtime while someone hunts for the right one, and running the risk of an operator grabbing a fuse with the wrong rating just to get the machine back online.

This is where the miniature circuit breaker really shines:

- It's Reusable: When an MCB trips, you just flip a switch to reset it. In a production environment where every minute counts, this is a massive advantage over digging through a parts drawer for a new fuse.

- It's Smarter: A fuse just melts from heat. An MCB, on the other hand, has two distinct trip mechanisms working together—thermal for slow, creeping overloads and magnetic for sudden, dangerous short circuits.

- It's Obvious: A quick glance at the panel tells you which circuit has tripped. No need for a multimeter to test a row of fuses.

While fuses definitely still have their place, especially in some high-rupture capacity applications, the MCB's convenience and superior, dual-action protection have made it the modern standard for branch circuits.

MCB vs. Molded Case Circuit Breaker (MCCB)

At first glance, an MCB and a Molded Case Circuit Breaker (MCCB) look like they do the same thing. They're both reusable breakers, right? Yes, but the difference is all about scale.

Think of it this way: an MCB is the security guard for a single office, while the MCCB is the security guard for the entire building lobby.

Your typical MCB is designed for lower-current applications, usually topping out at 125 amps. Its job is to protect the final branch circuits—the individual lines feeding a motor, a PLC, or a set of lights.

The MCCB is a completely different beast. It's a much beefier, more industrial device built for the heavy-lifting.

An MCCB is engineered to handle much higher currents, with ratings that can range from around 15 amps up to 2,500 amps. They are used to protect main feeders, distribution panels, and large-scale industrial equipment where the available fault current is significantly higher.

Another key difference is that many MCCBs have adjustable trip settings. This allows engineers to dial in the protection characteristics to precisely match the needs of a large motor or complex system. An MCB, by contrast, has fixed trip points set at the factory. If you're sizing protection for a main feed or a large piece of machinery, you should be looking at options like an ABB circuit breaker of the MCCB variety.

MCB vs. RCD and GFCI

Pay close attention to this one, because it's the difference between protecting equipment and protecting people. It's the most common and dangerous point of confusion.

An MCB is an overcurrent protection device. Period. Its entire purpose is to prevent fires and equipment damage when too much current flows.

A Residual Current Device (RCD), or its North American cousin, the Ground Fault Circuit Interrupter (GFCI), is a personnel protection device. It couldn't care less about overcurrent. Instead, it does something far more sensitive: it constantly measures the current flowing out on the hot wire and compares it to the current returning on the neutral.

If that difference is as tiny as 4-6 milliamperes, it knows that current must be leaking somewhere it shouldn't be—potentially through a person. It then trips the circuit in a fraction of a second, long before a fatal shock can occur. An MCB would be completely blind to a fault that small.

A truly safe system never forces you to choose. It uses both. The MCB protects the wires from melting, and the RCD/GFCI protects the operator from a lethal shock.

Getting Installation and Maintenance Right

A miniature circuit breaker is only as reliable as the hands that installed it. Getting the mounting, wiring, and routine checks right isn't just "best practice"—it's the only way to guarantee the device will do its job when it counts. Cut corners here, and you're setting the stage for overheating, premature failure, or worse.

This is where theory meets the real world. For the technicians and facility managers tasked with turning a box of components into a reliable, long-lasting asset, these practical steps are what truly matter.

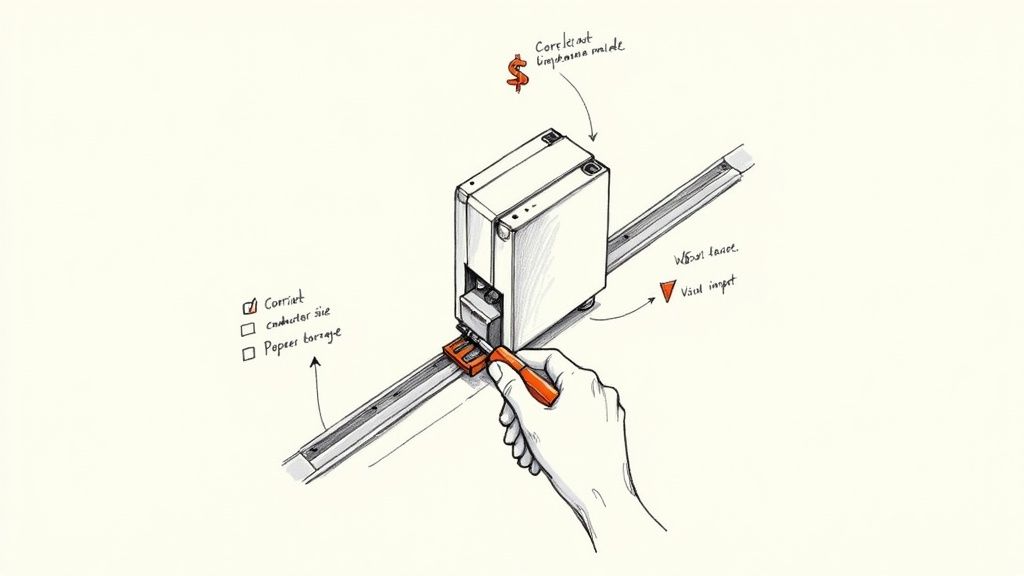

Proper Installation Procedures

Solid installation is the foundation of electrical safety. Rushing these steps can create hidden problems that only show up during a fault condition—exactly when you need the protection to work. To build a rock-solid and safe connection from the start, focus on these key points.

-

Secure DIN Rail Mounting: Make sure the breaker snaps firmly onto the DIN rail. A loose MCB will vibrate, which can lead to iffy connections and wear out the terminals over time.

-

Use the Right Wire: Always match the wire gauge to the breaker's amp rating and what the load demands, following NEC guidelines. Undersized wires are a classic cause of overheating, creating the very fire hazard the MCB is there to prevent.

-

Get the Torque Right: This is one of the most critical and easily overlooked steps. Use a calibrated torque screwdriver to tighten the terminal screws to the manufacturer's exact spec. Over-tightening can crack the terminal, but under-tightening is just as bad—it creates a high-resistance hot spot.

Before energizing any system, running through a comprehensive electrical rough-in inspection checklist is a crucial final step. It’s your last chance to verify that every component is installed correctly and up to code.

A Simple, Effective Maintenance Schedule

Once it's in the panel, an MCB isn't a "set it and forget it" device. A little proactive maintenance turns a passive component into a verified safety asset. This simple schedule helps you spot trouble long before it becomes a critical failure.

A regular inspection routine is the cheapest insurance you can buy for system safety and longevity. Finding a loose connection early prevents major downtime and costly equipment damage down the road.

A basic but effective maintenance plan doesn't have to be complicated:

- Quarterly Visual Checks: Just look for signs of trouble. Is there any discoloration or melting on the breaker's housing? That’s a dead giveaway for overheating. Check the wires connected to it for insulation that looks brittle or cracked—another symptom of too much heat.

- Annual Terminal Check: During a planned shutdown, re-torque the terminal connections. Over months of operation, the normal heating and cooling cycles can cause screws to slowly loosen.

- Annual Mechanical Test: While the power is off, just flip the MCB's switch on and off a few times. This simple action ensures the internal mechanism hasn't gotten stiff or seized, confirming it can physically trip when needed.

This straightforward approach to installation and maintenance will get the most life out of every MCB and, more importantly, reinforce the safety of your entire electrical system.

A Few Common Questions We Hear About MCBs

When you're in the weeds of a project, the practical questions always start to pop up. How you handle the small details around application, safety standards, and environmental conditions is what separates a reliable system from a problematic one.

We get these questions all the time from engineers and buyers in the field. Let's clear up a few of the most common points of confusion to make sure your electrical installations are safe, compliant, and built to last.

Can You Use a DC-Rated MCB on an AC Circuit?

This question comes up a lot, and the answer is a hard no. It's easy to think of a circuit breaker as just a simple switch, but the physics behind interrupting AC and DC power are worlds apart. The real challenge is snuffing out the electrical arc that forms when the contacts pull away from each other.

In an AC circuit, the current naturally drops to zero 120 times every second. This zero-crossing gives the breaker a built-in opportunity to kill the arc. DC current, on the other hand, is a constant flow with no zero-crossing point, which makes the arc incredibly stubborn and much harder to extinguish. Putting a DC breaker on an AC circuit (or vice versa) is a serious safety risk because the arc-quenching system just isn't designed for that type of current.

What's the Real Difference Between UL 489 and UL 1077?

If you're building control panels, this is a distinction you absolutely have to get right. These two UL standards define completely different roles for a protective device, and they are not interchangeable.

- UL 489 Circuit Breakers: Think of these as the main line of defense. They are certified for branch circuit protection and are built tough enough to handle the massive fault currents that can come from a main power feed.

- UL 1077 Supplementary Protectors: These are designed for more targeted protection within a piece of equipment. They sit downstream from a UL 489 device, offering more sensitive protection for specific components, but they simply don't have the muscle to interrupt a major branch fault.

How Does High Temperature Affect an MCB?

Heat is the natural enemy of an MCB’s thermal trip mechanism. Inside the breaker, a bimetallic strip is engineered to bend at a specific temperature generated by overcurrent, causing it to trip. When you install that breaker in a hot control panel or a high-ambient-temperature environment, that external heat gives the tripping process a head start.

This phenomenon is called thermal derating. It means the breaker will trip at a current well below its nameplate rating. To prevent frustrating nuisance trips, manufacturers provide derating curves that help you calculate the MCB's true operating capacity at elevated temperatures.

Should I Replace an MCB After a Major Fault?

Absolutely, yes. The safest and smartest move is to replace the breaker after it has interrupted a significant short-circuit. It might look perfectly fine on the outside and may even reset, but the violent forces at play during a major fault can cause serious, unseen internal damage.

A severe short circuit puts incredible stress on the internal components. It can weaken the contacts, damage the arc chute, or compromise the trip mechanism. Trusting a breaker that's been through that kind of event is a gamble you can't afford to take—it might not be there for you during the next fault.

At E & I Sales, we bring the expertise and the components you need to design and build reliable, code-compliant UL control panels. Explore our solutions and let's partner on your next project.