A microgrid control system is the command center—the digital brain—of a localized power grid. It’s what manages all the moving parts, from energy generation and storage to final distribution.

Think of it like the conductor of an orchestra, making sure every instrument—whether it’s solar panels, backup generators, or battery banks—plays its part in perfect harmony to deliver clean, reliable power.

The Brains Behind Resilient Power

Picture a hospital, a bustling manufacturing plant, or a mission-critical data center. For them, a sudden outage from the main utility isn't just an inconvenience; it can be catastrophic. This is exactly where a microgrid, guided by its intelligent control system, proves its worth. It can operate as a self-sufficient energy island, completely disconnected from the main grid when needed.

The microgrid control system is the decision-making engine that makes this all possible. It’s constantly watching grid conditions, tracking energy prices, and anticipating the facility’s power needs. If it senses a problem, like a voltage dip that signals an impending blackout, it can seamlessly switch the entire facility over to its own power sources.

This transition happens in milliseconds—so fast that sensitive equipment keeps running without a single hiccup.

Why This Control Is So Important

At its core, a control system’s job is to maintain that delicate balance between electricity supply and demand. This gets a lot more complex inside a microgrid, which often has to juggle multiple, variable energy sources.

Here's what it handles:

- Ensuring Grid Stability: It actively manages voltage and frequency to maintain high-quality power, whether you're connected to the utility or running on your own.

- Optimizing Energy Costs: The system is smart enough to decide when to use stored battery power, pull from the grid when rates are low, or even sell excess solar energy back to the utility. It's all about minimizing what you spend.

- Integrating Renewables: It smooths out the peaks and valleys of solar and wind power by coordinating them with battery storage and other generators, guaranteeing a consistent and predictable energy supply.

A microgrid's true value isn't just in its physical assets like batteries and generators. It's in the intelligence of the control system that orchestrates them. This digital layer is what unlocks real resilience, efficiency, and sustainability.

A Rapidly Growing Market

It's no surprise that demand for these advanced systems is surging. As more industries look for greater energy independence and reliability, the market is taking off.

The global microgrid control systems market shot up from an estimated $4.05 billion to a projected $4.74 billion in just one year. This explosive growth is being driven by the need for a more modern grid and better ways to manage renewable energy. You can dig deeper into these market dynamics over at Mordor Intelligence. This trend really highlights the critical role these systems play in building a more resilient energy future.

Core Architectures of Microgrid Control

Just like there are different ways to run a company, microgrid control systems have a few distinct blueprints. The architecture you choose dictates how decisions get made, how information flows, and ultimately, how fast the system can react when things change. Getting this right is fundamental, whether you're managing a single factory or a sprawling campus.

We generally see three main approaches: centralized, hierarchical, and distributed. Each has its own operational logic, and understanding the trade-offs is the first step toward building a system that’s both smart and tough.

The controller's job is a constant balancing act. It has to juggle the competing demands of resilience, renewable energy integration, and cost management. Every decision tips the scales one way or another.

This constant push and pull between reliability, sustainability, and economics is at the heart of what a good control system does.

Centralized Control: The Single Commander

The centralized model is the classic, top-down approach. Think of it like a military command center with one all-powerful brain—the Microgrid Central Controller (MGCC). This single unit pulls in data from every generator, battery, and load, crunches the numbers, and sends out direct orders.

This design makes management straightforward since all the intelligence lives in one place. It’s fantastic for system-wide optimization because the MGCC has a bird's-eye view, allowing it to make the most efficient and cost-effective calls.

But there's a catch: this design has a glaring vulnerability. If that central controller goes down, the whole microgrid can go dark with it. This single point of failure makes it a risky choice for applications where uptime is everything.

Hierarchical Control: A Team of Managers

A hierarchical setup offers a more layered and robust structure. You still have a central controller at the top, but it delegates authority to local controllers that manage specific zones or groups of equipment. For example, one local controller might handle a solar array and its battery, while another is in charge of a block of industrial machinery.

It’s a lot like how a big factory is run—a main supervisor oversees several floor managers. The top controller sets the big-picture strategy (like "let's save money today"), and the local units handle the second-by-second execution. This takes a huge load off the main controller and speeds up response times.

Many large-scale systems are built this way, often blending technologies like SCADA and DCS. If you want to dive deeper into those, we have a guide that breaks down the SCADA and DCS control systems.

The real beauty of this layered approach is the built-in redundancy. If a local controller fails, it only affects its own little zone. The rest of the microgrid keeps on running, guided by the central brain.

Distributed Control: The Collaborative Network

The distributed, or decentralized, architecture is the most modern and resilient of the bunch. Here, there’s no single boss. Instead, intelligent controllers embedded in each device talk directly to one another on a peer-to-peer network.

Imagine a highly skilled team where every member makes autonomous decisions based on what their colleagues are doing. A solar inverter, a battery system, and a generator all adjust their own output to keep the grid stable, all without waiting for orders.

- Enhanced Resilience: With no single point of failure, the system is incredibly tough. If one component drops out, the others automatically pick up the slack.

- Scalability: Adding a new solar panel or battery is a breeze. The new device simply joins the network and starts contributing.

- Rapid Response: Decisions are made locally and instantly. This is perfect for handling the fast-changing conditions common with renewable energy.

This "plug-and-play" nature makes distributed microgrid control systems exceptionally flexible and robust—a perfect fit for complex sites with a diverse mix of energy assets.

Comparing Microgrid Control Architectures

Each architecture brings something different to the table. Choosing the right one depends entirely on your project's specific needs for resilience, cost, and scalability.

| Architecture | Control Logic | Key Advantages | Key Disadvantages | Best For |

|---|---|---|---|---|

| Centralized | Top-down; one master controller (MGCC) makes all decisions. | Simple to manage; optimal for system-wide economic dispatch. | Single point of failure; communication bottlenecks can slow response. | Small, simple microgrids where cost optimization is the primary goal. |

| Hierarchical | A central controller coordinates multiple local controllers. | Balanced approach; improved reliability and faster local responses. | More complex to design and implement than a centralized system. | Large industrial campuses or utility microgrids with distinct zones. |

| Distributed | Peer-to-peer; intelligent devices communicate and decide locally. | Highest resilience (no single point of failure); easily scalable. | Complex control algorithms; system-wide optimization is more challenging. | Mission-critical facilities and microgrids with many diverse energy sources. |

Ultimately, the goal is to match the control philosophy to the operational reality. A simple system might thrive with a centralized brain, while a complex, dynamic one will benefit from the collaborative intelligence of a distributed network.

Essential Microgrid Operating Modes

A microgrid’s real value comes from its ability to adapt. The control system is the brain behind this flexibility, constantly ready to shift its behavior to keep the lights on, no matter what’s happening on the main utility grid. Think of it as a seasoned musician who can play in a full orchestra, lead a small ensemble, or perform a stunning solo at a moment's notice.

This operational agility is the bedrock of microgrid resilience. The controller has to fluidly transition between these modes to guarantee stability, whether it’s running in sync with the utility or standing entirely on its own.

Grid-Following: The Synchronized Player

Most of the time, a microgrid operates in grid-following mode. While connected to the utility, it behaves like a disciplined musician in a large orchestra. The main grid is the conductor, setting the tempo—the voltage and frequency—and the microgrid’s inverters simply follow that lead.

The focus here is purely economic. The control system is busy with tasks like:

- Managing Power Flow: It intelligently decides when to push surplus solar power back to the grid for credits or pull power from the utility when rates are low.

- Optimizing Local Assets: It juggles its own generators and batteries to slice the facility's energy bills, a practice we call economic dispatch.

This is the standard, efficient mode for daily operations. But it’s completely dependent on a stable utility grid. If the conductor falters, the microgrid must be ready to switch roles instantly or risk going down with it.

Grid-Forming: The Conductor

When the microgrid disconnects from the utility, it immediately enters grid-forming mode. Now, it has to become the conductor. It must create its own stable rhythm from scratch. The control system instantly assigns one or more of its inverters—usually those tied to a battery system—to generate and maintain a clean, stable voltage and frequency for the entire site.

This is a much tougher job. The grid-forming inverters become the undisputed source of power quality. They establish the beat that all other generators, solar arrays, and equipment on the microgrid must sync to. This is the crucial function that transforms a collection of individual assets into a cohesive, self-sufficient power system.

Islanding: The Solo Performance

The act of separating from the grid is known as islanding. This is the critical moment when the microgrid executes a flawless, planned break from the utility during an outage and begins its solo performance. A high-speed breaker at the point of common coupling (PCC) physically opens in milliseconds to create the "island."

The ability to seamlessly island is the hallmark of a resilient microgrid. It’s the planned, controlled separation from a failing utility grid that ensures critical loads—like hospital equipment or manufacturing lines—never experience an interruption.

Once islanded, the microgrid control system takes complete command. It has to perfectly balance its internal power generation with the site's real-time energy demand. The microgrid can continue this solo act for as long as needed—hours, days, or even weeks—until the utility grid is stable again. At that point, it can safely resynchronize and return to its normal grid-following role.

The growing demand for this kind of sophisticated control is obvious in the market. The global microgrid controller software market is projected to skyrocket from $5.06 billion to $33.90 billion in just a decade, a massive annual growth rate of 23.55%. You can explore more insights into this expanding market at Precedence Research. This explosion in growth shows just how vital this advanced software is to achieving true energy independence and resilience.

Talking the Talk: Microgrid Communication Protocols and Standards

A microgrid controller is like the conductor of an orchestra. But what happens if the conductor only speaks English, the strings speak French, and the brass section speaks German? You get noise, not music. The same chaos happens in a microgrid when devices from different manufacturers can't communicate effectively.

This is where communication protocols and industry standards become the unsung heroes of the project. Protocols are the common languages that allow all the equipment—from inverters to generators—to share data and commands. Standards are the rulebooks that ensure everything is connected safely and plays nice with the larger utility grid. Without them, you don't have an intelligent, unified system; you just have a very expensive collection of parts.

The Languages of Industrial Control

Over the years, a few key protocols have become the go-to languages for the energy and industrial worlds. A truly capable microgrid control system needs to be multilingual, speaking the native tongue of every asset you connect to it.

-

IEC 61850: Think of this as the high-speed, modern language of substations and smart grid devices. It’s built for the rapid-fire, peer-to-peer communication needed for protective actions that keep a microgrid stable during a fault. Its structured, object-oriented approach to data is a huge win for simplifying integration.

-

DNP3 (Distributed Network Protocol 3): A long-time favorite of North American electric utilities, DNP3 is the rugged, reliable choice. It's fantastic for SCADA systems talking to remote equipment over networks that might not be perfect, ensuring critical messages get through no matter what.

-

Modbus: This one is the old, reliable workhorse. As one of the most widely adopted industrial protocols ever, Modbus is your key to connecting with all sorts of factory equipment, sensors, and meters. Its simplicity is its strength, making it a must-have for bringing older, legacy assets into your microgrid.

And you can't forget about BACnet, which is incredibly common in building management systems. If your microgrid needs to integrate with a facility's HVAC or lighting controls, you'll need to know your way around it. For a deeper dive, check out our complete guide to the BACnet communication protocol.

The diagram below shows how a standard like IEC 61850 organizes this communication traffic into logical layers, from the equipment on the ground floor all the way up to the central control room.

This layered design is what keeps everything organized and prevents a communication free-for-all, ensuring data flows where it needs to, when it needs to.

The Rulebook for Playing with the Grid

Beyond just speaking the right language, a microgrid has to follow a strict set of rules, especially when it’s connected to the main utility. In the United States, the single most important rulebook is IEEE 1547.

IEEE 1547 is the master standard that lays out all the technical requirements for connecting distributed energy resources (like your microgrid) to the electric grid. This isn't just a suggestion—compliance is your ticket to legally and safely interconnecting with the utility.

Following this standard means your microgrid acts like a good neighbor. It dictates exactly how your system must react to grid problems, how it should support overall grid stability, and—most critically—how it must stop sending power back to the utility's lines during an outage to keep line workers safe. Making sure your inverters and controllers are certified to the latest version of IEEE 1547 isn't just a box to check; it’s a fundamental part of a safe and successful project.

The push for this kind of intelligent, compliant technology is driving some serious market growth. The global microgrid controller market is forecast to explode from USD 3 billion to USD 22.4 billion over the next decade, a blistering annual growth rate of 22.3%. This incredible expansion is a direct result of the growing demand for real-time, smart energy management. You can discover more insights on this market growth at Global Market Insights Inc.

Alright, let's get this section sounding like it was written by a seasoned pro who's been in the trenches, designing these systems for years.

Here is the rewritten section, following the specified style, tone, and requirements.

Designing and Integrating Your Microgrid System

Getting a microgrid from the drawing board to a fully operational reality is where the rubber meets the road. For an industrial site, this is a serious undertaking, and every bit of planning you do upfront will pay you back tenfold down the line. It all starts with getting to know the unique energy heartbeat of your facility.

This isn't just about picking out shiny new hardware. It’s about building a finely tuned ecosystem where every single component pulls in the same direction, delivering the resilience and efficiency you’re after.

Start with a Detailed Load Profile

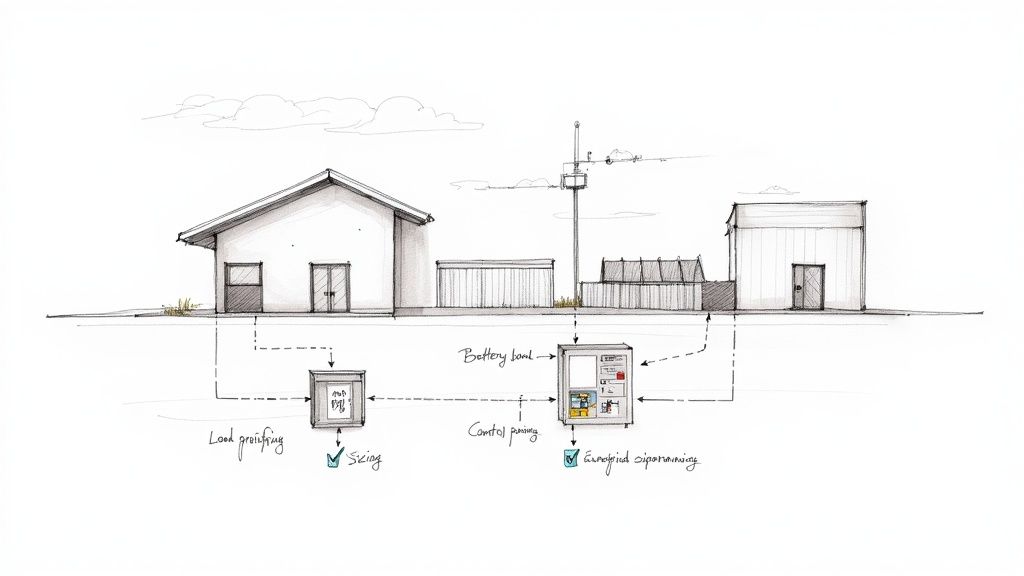

Before you even think about specifying a single piece of equipment, you absolutely have to know how, when, and where your facility uses electricity. This is what we call load profiling, and it's non-negotiable.

Think of it as an energy audit on steroids. You’ll dig into your consumption data over a long period to pinpoint critical loads, identify those costly peak demand windows, and truly understand your operational patterns. This data becomes the bedrock for every other decision you make, from sizing your battery bank to choosing the right control architecture. A solid load profile tells you exactly what must stay running during an outage and what can be shed to conserve precious power.

Sizing Your Energy Resources and Control

With that load profile in your back pocket, you can start sizing your Distributed Energy Resources (DERs). This is a careful balancing act, weighing your operational needs against the hard realities of your budget.

- Battery Energy Storage System (BESS): This needs to be big enough to carry your most critical loads for a set amount of time during an outage and to help you shave those expensive demand peaks.

- Generation Assets: Whether it's solar panels or generators, they need enough muscle to meet your demand and recharge your batteries—even on cloudy days or during a multi-day grid failure.

- Control System Selection: Your choice between a centralized, hierarchical, or distributed control system really depends on your site’s complexity. For mission-critical industrial operations, we often lean toward a distributed model simply because of its built-in redundancy.

A classic mistake is getting the sizing wrong. Go too big, and you've wasted capital. Go too small, and the system will fail you when you need it most. Proper sizing, guided by your load profile, is the key to hitting that sweet spot.

Smart Procurement for Faster Integration

How you buy your components can make or break your project timeline. Instead of sourcing every little part and trying to build it all from scratch on-site—a recipe for delays and headaches—a much smarter approach is to use pre-engineered, packaged solutions.

Specifying a UL-listed control panel is a huge step in the right direction. This certification means the panel has been built and tested to strict, nationally recognized safety standards. It shows up on your site ready to go, which dramatically cuts down on field wiring, testing time, and commissioning nightmares. This approach to industrial controls and automation is how you get a faster, safer, and more reliable deployment.

Commissioning and Verification Checklist

The last mile is commissioning. This is the systematic, step-by-step process of testing every component and function to prove the system does what you designed it to do. This is where you find out if your microgrid can actually handle the scenarios you’ve been planning for.

A rock-solid commissioning plan must include:

- Component-Level Testing: Confirming every inverter, generator, and battery is talking correctly to the controller.

- Full System Functional Tests: Running simulations of different operating conditions, including a planned islanding event.

- Black Start Capability Test: Proving the system can bring itself back online from a total shutdown with zero help from the utility grid.

- Compliance Verification: Making sure the system checks all the boxes for your utility's interconnection requirements. It’s also vital to ensure you're aligned with any applicable national standards and UK grid regulations like G98, G99, and G100.

Only when your system passes these grueling tests with flying colors can you finally be confident that your microgrid is ready to deliver the resilience and control you paid for.

Securing Your Microgrid from Cyber Threats

As microgrids get smarter and more connected, they also show up more brightly on the radar of cyber attackers. The very things that make them so powerful—remote access, live data streams, and automated controls—unfortunately double as open doors for disruption.

Common-sense oversights like internet-exposed controllers, lax remote access for vendors, and unmonitored industrial protocols are the low-hanging fruit for bad actors. Let’s be clear: cybersecurity for your microgrid control system isn’t an add-on anymore. It’s a fundamental operational requirement.

A Layered Defense-in-Depth Strategy

The old "castle-and-moat" security model is dead. Building a strong perimeter and trusting everything inside is a recipe for disaster. Once an attacker is inside that wall, they have free rein. The modern playbook calls for a "defense-in-depth" strategy, which assumes a threat can originate from anywhere, inside or out.

This approach involves several critical layers:

- Network Segmentation: This is about creating bulkheads in your ship. You divide the control network into smaller, isolated zones. If one area is breached, the damage is contained and can’t sink the entire system.

- Strict Access Control: Every remote access point needs multi-factor authentication, period. It's also crucial to operate on the principle of least privilege—users and devices should only have the absolute minimum access required to do their job. Nothing more.

- Data Encryption: Think of this as sealing your communications in an envelope. All data flying between controllers, inverters, and other devices must be encrypted. This stops attackers from listening in on commands or, worse, injecting their own malicious data.

Modern security philosophies like a robust Zero Trust Architecture are quickly becoming the standard for stopping sophisticated attacks. The premise is simple but powerful: never trust, always verify. Every single connection, every single data packet gets verified.

Adhering to Cybersecurity Frameworks

There's no need to start from scratch. Proven, battle-tested frameworks give you a roadmap for building a resilient operation. The NIST Cybersecurity Framework is one of the most respected guides out there for protecting critical infrastructure.

The Framework provides a structured, risk-based approach to cybersecurity, organizing activities around five core functions: Identify, Protect, Detect, Respond, and Recover. It helps you understand, manage, and reduce cybersecurity risk in a way that’s aligned with your business objectives.

What makes the framework so effective is that it creates a common language and a repeatable methodology that everyone—from the engineer on the plant floor to the executive in the boardroom—can understand and follow.

NIST visualizes these five functions as a continuous cycle, not a one-and-done checklist.

This integrated approach drives home the point that security isn't a project with an end date. It's a constant process of improvement and adaptation to whatever new threats come next.

By building a layered defense, locking down access, and following established standards like the NIST Framework, you can develop a security posture that’s truly robust. This proactive stance is the only way to safeguard your microgrid control system, ensuring it remains an asset for resilience, not a point of failure.

Frequently Asked Questions

When you start digging into microgrid controllers, a few common questions always seem to pop up. Let's tackle some of the most frequent ones to clear up the details, especially when you're comparing technologies or planning future upgrades.

Controller Versus Building Automation

What’s the real difference between a microgrid controller and a building automation system (BAS)?

Think of them as two different managers running the same facility, each with a very specific job. The microgrid control system is your power czar. It’s completely focused on energy generation, storage, and grid stability. Its prime directive is to keep the lights on with reliable power, no matter what—especially if it has to island from the utility.

A Building Automation System (BAS), on the other hand, is the efficiency guru. It looks inward, managing all the building loads like HVAC and lighting to keep everyone comfortable while cutting energy waste. While these two systems absolutely can and should talk to each other, the microgrid controller always has the final say on power, while the BAS handles the building's internal climate and environment.

Integrating with Existing Solar

Can I add a microgrid control system to the solar panels I already have?

Absolutely. In fact, this is one of the most common and powerful ways to upgrade a facility. A modern microgrid controller can be retrofitted to work with existing assets like solar arrays and backup generators, essentially giving them a new, much smarter brain.

The controller steps in as the new command center, coordinating your legacy equipment with new components like a battery energy storage system (BESS). This creates a cohesive, fully functional microgrid. The most important step is just making sure the controller you pick can "speak the same language" by supporting your existing equipment's communication protocols.

This ability to integrate what you already own is a huge deal for making microgrids more accessible. It means facilities can upgrade their energy systems in phases, adding advanced control and storage to unlock the full potential of equipment they’ve already paid for.

The Role of AI and Machine Learning

How are AI and machine learning changing microgrid control systems?

Artificial intelligence and machine learning are giving microgrid controls a crystal ball. Instead of just reacting to what’s happening right now, these advanced systems can predict what's coming next—and that’s a total game-changer for efficiency and cost savings.

Here’s how they make a real difference:

- Predictive Forecasting: AI algorithms can chew through weather data to predict, with surprising accuracy, how much solar energy your panels will produce tomorrow.

- Load Prediction: By analyzing historical consumption data, machine learning models can forecast your facility’s energy demand with incredible precision.

Having this kind of foresight lets the microgrid control system make much smarter, proactive decisions. It can store excess solar power when it knows a cloudy day is on the horizon or pre-charge batteries right before a predicted spike in demand. This isn't just clever tech; it directly optimizes your operating costs and makes the entire system run better.

At E & I Sales, we specialize in designing and delivering the robust, UL-listed control panels that are the heart of any reliable microgrid. From initial spec to final commissioning, our team delivers the integrated solutions that bring your energy resilience goals to life. See how our expertise can power your next project at https://eandisales.com.