Let's be honest, if you walked onto a factory floor and saw a separate, tangled mess of wires and control boxes for every single motor, you’d probably turn right back around. It would be a chaotic, unsafe, and downright impossible system to manage.

This is where the Motor Control Center, or MCC, comes in. Think of it as the central command hub for every motor-driven piece of equipment in your facility.

Decoding the Motor Control Center

At its core, an MCC is just a smart way of organizing things. It’s a large, free-standing metal cabinet that brings together all the starters, breakers, and other control gear for dozens or even hundreds of motors into one convenient location.

Instead of having controls scattered across the plant floor—one for that pump, another for this conveyor, a third for that fan—everything is neatly arranged in a single, safe enclosure. This centralization is the key.

The Apartment Building Analogy

The best way to understand an MCC is to picture a high-rise apartment building. The building itself is the MCC structure—a steel framework providing the main power feed and a safe place for everything to live.

Within this "building," you have:

- The Main Power Bus: This is like the main utility line running up through the building, delivering power to every floor and every unit. It’s the electrical backbone.

- Each Bucket: Think of these as the individual apartments. Every "bucket" is a self-contained, modular drawer that holds all the necessary controls for one specific motor—its starter, circuit breaker, and control wiring.

- The Modular Design: Here’s the brilliant part. A technician can safely disconnect and pull out a single "apartment" (the bucket) to perform maintenance or repairs without cutting power to anyone else. The rest of the "tenants" (the other motors) keep running without interruption.

This simple concept—centralizing control while keeping it modular—is what makes the MCC an absolute game-changer in industrial environments. It takes a potential nightmare of distributed controls and turns it into a streamlined, safe, and easily serviceable system.

By organizing motor controls this way, facilities unlock massive gains in safety, troubleshooting time, and future scalability. It provides a clean, logical foundation for complex automation, making it infinitely easier to manage and expand your operations as your needs change. Now, let's open one up and see what’s inside.

A Look Inside the MCC: A Component Breakdown

To really get what an MCC is, you have to look past the steel doors and see how it's put together. The best way to think about it is like an electrical city. Power comes into town on a massive superhighway and gets routed through a structured grid of streets to reach every "house"—in this case, each individual motor. This brilliantly organized layout is what makes the MCC so powerful and reliable.

The whole journey starts with the main power bus. These are thick, heavy-duty bars of copper or aluminum that typically run horizontally across the top or back of the entire MCC lineup. This bus is the main artery, the electrical interstate, fed by an upstream transformer or switchgear. All the power for every single motor flows through here first.

From this main highway, power peels off onto smaller "exit ramps" called vertical bus bars. These bars run up and down inside each MCC section, acting as the local streets that deliver power directly to the individual motor control units stacked within. It's a clean, direct, and safe way to ensure every unit gets the juice it needs.

This centralized design isn't just neat and tidy; it delivers tangible benefits in the real world.

As you can see, organizing everything into one central hub directly translates to a safer, more scalable, and far more manageable system.

The Real Genius of the MCC: The "Bucket"

Now for the heart of the system: the individual units, which everyone in the industry calls “buckets.” Each bucket is a self-contained, removable drawer that holds all the gear needed to control and protect one motor. It’s a true plug-and-play design and the secret sauce behind the MCC's flexibility.

Think about it—if a component fails, you don't have to rewire anything in a live cabinet. A technician can de-energize that single bucket, pull it out, and slide a spare one in its place in minutes. This dramatically slashes downtime, which is a massive win in any production environment.

Let's unpack what you'll typically find inside one of these buckets. This table breaks down the key players and their roles, using a simple traffic analogy to make it clear.

Key Components Inside an MCC and Their Functions

| Component | Primary Function | Analogy |

|---|---|---|

| Motor Starter | Safely starts and stops the motor, managing the initial inrush of current. | The On-Ramp/Off-Ramp that lets the car (motor) safely merge onto and exit the highway (circuit). |

| Overload Relay | Monitors motor current and trips if it draws too much power for too long. | A Traffic Cop monitoring speed. If a car goes too fast (overloads) for too long, it gets pulled over. |

| Circuit Breaker/Fuse | Provides instantaneous protection against short circuits or major faults. | A Guardrail. It does nothing until a catastrophic event (a crash/fault) happens, then it stops it cold. |

| Variable Frequency Drive (VFD) | Controls the motor’s speed by adjusting the electrical frequency. | The Accelerator/Brake Pedal. It gives you precise control over how fast or slow the car (motor) is going. |

Each of these components works together within the bucket to ensure a motor runs not just effectively, but safely. You’ve got the starter to get things moving, the overload relay to prevent burnout, and the breaker for catastrophic failure. For a deeper dive into how these protective devices work, we have a great guide on the fundamentals of motor protection.

More Than Just On/Off: Advanced Components

Modern MCCs aren't limited to simple start/stop functions. It's common to find buckets equipped with much more sophisticated technology.

A Variable Frequency Drive (VFD), for example, is a popular addition. Instead of just turning a motor on, a VFD gives you granular control over its speed. This is incredibly useful for applications like pumps and fans, where you can fine-tune performance to save a tremendous amount of energy and improve your process.

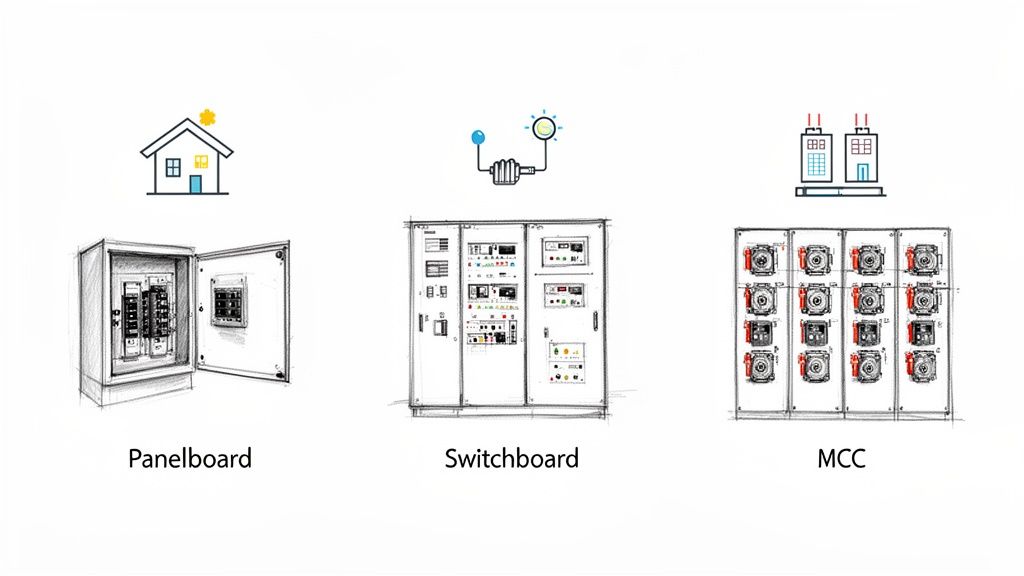

MCC vs Switchboard vs Panelboard

Walk onto any large commercial or industrial site, and you'll find an array of electrical gear. Three pieces that often get mixed up are the Motor Control Center (MCC), the switchboard, and the panelboard. While they all manage electricity, they have fundamentally different jobs.

Getting it wrong isn't just a technical mix-up; it can lead to major design flaws, safety risks, and a system that just doesn't work for its intended purpose.

Think of a panelboard as the breaker box in your house. It’s the last stop for power, breaking it down into small, manageable circuits for things like lights, wall outlets, and small appliances. They're typically mounted on a wall and provide simple, direct overcurrent protection.

A switchboard is a step up the ladder. It’s the main distribution hub for a facility, taking the big power feed from the utility and splitting it into larger circuits. These circuits might feed an entire floor, a massive HVAC unit, or a series of downstream panelboards. Its job is bulk power distribution, not fine-tuned control.

The MCC: The Industrial Specialist

This is where the Motor Control Center comes in. The MCC is a specialist, purpose-built with one core mission: to centralize the control and protection of electric motors.

This isn't just about turning motors on and off. An MCC is a sophisticated assembly of combination starters, VFDs, and soft starters, all housed in modular, pull-out "buckets." This design is the heart of what makes an MCC so essential in tough environments like factories, refineries, and processing plants where dozens—or hundreds—of motors need to work together flawlessly.

A key takeaway is that an MCC's design prioritizes motor control, modularity for maintenance, and integration with automation systems, setting it apart from general power distribution equipment. While a switchboard is about routing power, an MCC is about controlling what that power does.

For a deeper dive into how MCCs stack up against other heavy-duty equipment, this detailed breakdown comparing a motor control center vs switchgear provides some great context.

To really nail down the differences, let's put them side-by-side.

Comparison of MCCs, Switchboards, and Panelboards

This table breaks down the core distinctions at a glance, making it easy to see where each piece of equipment fits.

| Attribute | Motor Control Center (MCC) | Switchboard | Panelboard |

|---|---|---|---|

| Primary Function | Centralized motor starting, control, and protection. | Main power distribution for a building or large area. | Final distribution to smaller branch circuits (e.g., lights, outlets). |

| Key Components | Combination starters, VFDs, soft starters, overload relays. | Large circuit breakers, switches, and metering. | Small circuit breakers for individual circuits. |

| Construction | Modular, with withdrawable buckets for each motor. | Free-standing floor-mounted enclosure. | Typically smaller, wall-mounted cabinet. |

| Typical Application | Industrial plants, factories, water treatment facilities. | Commercial buildings, data centers, large institutions. | Homes, offices, small commercial spaces. |

| Flexibility | High; easily add or modify motor control units. | Moderate; requires significant work to modify. | Low; fixed number of circuit positions. |

Ultimately, choosing between an MCC, switchboard, or panelboard comes down to the application. If you're managing a fleet of motors in an industrial process, the MCC is your tool. If you're distributing power across a commercial building, you need a switchboard. And for the final circuits, a panelboard gets the job done.

Decoding Key Safety and Design Standards

When you're dealing with industrial power, safety isn't just a suggestion—it's everything. The standards that govern MCC design are the very foundation of a reliable and safe system. They’re what stand between a smooth-running operation and a catastrophic failure like an arc flash.

For anyone working in North America, the conversation starts and ends with UL 845. This is the specific Underwriters Laboratories standard for Motor Control Centers. Think of it as the ultimate rulebook for how an MCC must be built, tested, and rated to perform under pressure. When you see a UL 845 mark, it means an independent body has verified that the MCC meets incredibly strict requirements for its wiring, busbar bracing, overall structure, and—most importantly—its ability to handle a short-circuit event without falling apart.

An MCC without a proper UL listing isn't just a compliance headache; it's a massive safety liability. That UL 845 certification is your third-party guarantee that the gear is built to a recognized safety benchmark, protecting both your people and your facility.

Matching Enclosures to the Environment

It’s not just what’s on the inside that counts. The physical cabinet, or enclosure, has to be tough enough for the world it lives in. This is where NEMA (National Electrical Manufacturers Association) ratings come into play, defining how well an enclosure protects against things like dust, water, and corrosion.

Picking the right one is a make-or-break decision for the MCC's lifespan:

- NEMA 1: This is your standard indoor-use enclosure. It’s perfect for a clean, dry electrical room, mainly designed to keep people from accidentally touching live parts.

- NEMA 12: Step it up for more typical industrial indoor spots. This rating adds protection against dripping liquids (non-corrosive), falling dirt, and circulating dust.

- NEMA 4X: This is the heavy-hitter. Built to be watertight and corrosion-resistant, it's the go-to choice for washdown areas in a food processing plant or for outdoor installations near the coast where salt spray is a concern.

It’s also crucial to understand the nuances of certifications. For instance, knowing the difference between a product being UL Listed vs. UL Recognized is a big deal for system integrators, as it impacts how a component can be legally and safely integrated into a larger certified assembly.

A Global Perspective on MCC Standards

While UL and NEMA are the law of the land in North America, the rest of the world often looks to IEC (International Electrotechnical Commission) standards. The main equivalent to UL 845 is IEC 61439, which sets the rules for low-voltage switchgear and controlgear assemblies globally.

Even though the design philosophies and testing methods have their differences, both UL and IEC standards are chasing the same goal: ensuring the equipment is safe, reliable, and performs as expected. For companies with a global footprint, being fluent in both languages is essential to deliver compliant systems no matter the market.

Where Motor Control Centers Really Shine

Enough with the theory and diagrams. Let's talk about where the rubber meets the road. Motor Control Centers are the absolute workhorses of modern industry, the central nervous system that keeps the lights on and the products moving in some of the toughest environments you can imagine.

Once you see them in action, their value just clicks.

For anyone specifying or building systems—OEMs, packagers, integrators—getting a grip on these applications is everything. It’s how you move the conversation from a list of parts to the real-world, bottom-line benefits your clients actually care about.

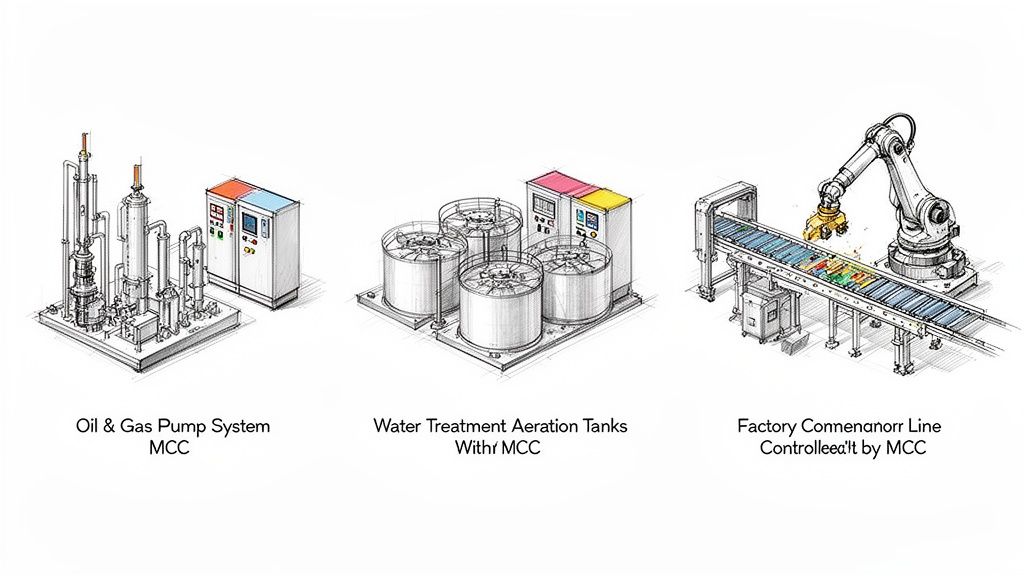

Oil and Gas Operations

Out on a rig or in a sprawling refinery, "downtime" is a four-letter word that costs millions. Here, reliability isn't just a feature; it's the entire game. An MCC is the heart of the operation, controlling the massive pumps, compressors, and drilling gear that make it all happen.

That modular bucket design we talked about? This is where it's a lifesaver. When a motor starter fails, a tech can pull the bucket, slap in a spare, and get a critical process back online in minutes. No rewiring, no complex troubleshooting under pressure. Just swap and go.

Water and Wastewater Treatment

Think about your local water treatment plant. It's a non-stop, 24/7 operation. MCCs are running the show from start to finish—intake pumps, chemical dosing systems, giant aeration blowers, you name it.

By centralizing all this control in a clean, dry electrical room, you're protecting all the sensitive VFDs and PLCs from the wet, corrosive environment of the plant floor. It’s a simple concept, but it's what ensures that essential public services run without a single hiccup.

The big takeaway is this: in any process-heavy industry, the MCC doesn't just send power to motors. It orchestrates the entire physical workflow. This centralization and modularity are why over 70% of motors above 10 hp in large facilities are fed from MCC lineups.

Advanced Manufacturing and Automation

Step inside a modern factory, and the MCC is the command center for the whole production line. It's the silent conductor making sure conveyors, robotic arms, mixers, and packaging machines all work in perfect harmony.

This is where intelligent MCCs really come into their own. They talk directly to the plant's main automation system, giving operators real-time performance data and even flagging potential issues before they cause a breakdown. This is the kind of control you need to hit the efficiency and uptime numbers that keep you competitive.

We see this same need for precise control in all sorts of settings, like in the specialized role of motor control centers in HVAC applications. And that simple bucket concept? It lets plants stock a handful of common spares, which can slash maintenance inventory costs to the bone.

How to Specify an MCC for Your Project

Specifying a Motor Control Center is a lot more than just checking boxes on a form. You’re really designing the nerve center for your entire operation. Nail the specs, and you get a safe, reliable system that just works. Get them wrong, and you're in for a world of operational headaches and costly fixes down the road.

The whole process kicks off with a deep dive into your electrical and mechanical needs. Before anything else, you have to get a handle on your total motor loads. That means creating a detailed motor list—every single one—with its horsepower (HP), full-load amps (FLA), and voltage. This list is the absolute foundation for sizing your main busbars and every individual circuit correctly.

Next up is the short-circuit current rating, or SCCR. This isn't a ballpark figure; it’s a critical safety calculation. The SCCR of your MCC absolutely must be higher than the available fault current at the spot where it's installed. An underrated MCC is a ticking time bomb that can fail catastrophically during a short circuit.

Key Specification Details to Consider

Once you’ve got the heavy-hitting electrical parameters sorted out, you can zoom in on the specific components and features your application actually needs. It's not enough to just say, "I need a starter." You have to think about the job each motor is doing.

Here’s a quick checklist to guide your thinking:

- Component Type: Does that conveyor motor need a simple across-the-line starter, or would a soft starter be better to reduce wear and tear? What about that pump—does it need the precise speed control only a VFD can offer?

- Enclosure Rating: Think about where this MCC will live. A clean, dry electrical room is fine with a NEMA 1 enclosure. But if it’s going in a washdown area in a food and beverage plant, you’ll need the protection of a NEMA 4X.

- Intelligence Level: Are you okay with simple local start/stop buttons? Or do you need an intelligent MCC where all the components are networked, feeding data back to a central PLC for advanced control and diagnostics?

My best advice? Get an experienced system integrator or a UL 508A certified panel shop involved from the very beginning. Their expertise is pure gold when you're navigating complex design choices and trying to stay on the right side of the code.

Bringing in an expert early is a game-changer. They can look over your plans, spot potential problems you might have missed, and recommend solutions that are both reliable and cost-effective. They act as the perfect translator between your big-picture operational goals and the nitty-gritty technical details, ensuring the final MCC is a perfect fit, built safely, and made to last.

Common Questions About Motor Control Centers

Even after you get the basics down, you'll find that a whole new set of questions pop up when you're actually in the field working with Motor Control Centers. Let's tackle a few of the most common ones we hear from engineers and technicians to help connect the dots between the textbook and the job site.

What Is the Main Advantage of a Withdrawable Bucket?

The biggest win with a withdrawable MCC bucket is the massive improvement it offers for both safety and maintenance speed. Plain and simple.

Think about it: a qualified technician can completely de-energize, disconnect, and physically pull an individual motor control unit right out of the structure. And the best part? They can do it without having to shut down the entire MCC.

This is basically "hot-swapping" for motor controls. A bad unit can be swapped for a spare in a matter of minutes, which slashes expensive downtime. It also makes for a much safer repair job, since the complex work can be done on a bench, miles away from any live, high-voltage bus bars.

What Makes an MCC Intelligent?

An "intelligent" MCC, or iMCC, is one that has modern communication and diagnostic tech baked right into its components. Instead of just handling simple start/stop commands, the units inside an iMCC are packed with networked devices—think overload relays, VFDs, and soft starters that are all chatting over an industrial network.

This setup opens up a world of possibilities. You get remote monitoring, real-time diagnostics, and even predictive maintenance data streamed directly to a central PLC or SCADA system. The payoff comes from faster troubleshooting, a huge drop in unplanned downtime, and detailed energy monitoring that helps you find new ways to improve efficiency.

At its heart, an intelligent MCC turns what was once just a "dumb" electrical cabinet into a goldmine of operational data. It gives plant managers a level of insight into the health and performance of their motors that was unheard of just a few years ago.

How Is the Required SCCR Determined?

Figuring out the required Short-Circuit Current Rating (SCCR) for an MCC isn't guesswork—it's a critical safety calculation. The SCCR is determined by the available fault current at the exact spot where the MCC will be installed.

This has to be calculated by a qualified electrical engineer as part of a formal, system-wide fault current study. No exceptions.

The rule is simple: the MCC's SCCR must be equal to or greater than the maximum potential fault current it could ever face. If you specify an MCC with a rating that's too low, you're creating a serious safety hazard and a direct violation of the National Electrical Code (NEC). An undersized MCC can fail catastrophically during a short-circuit, with devastating consequences.

At E & I Sales, we live and breathe this stuff. We specialize in designing and building custom, UL-listed control panels and MCCs that are a perfect fit for your project's unique demands. From the first spec sheet to the final commissioning, our team has the expertise to make sure your system is safe, reliable, and built for the long haul. Learn how our system integration services can get your next project off the ground and running smoothly.