Think of industrial controls automation as the central nervous system of a modern factory. It’s the combination of hardware and software that orchestrates everything from a single robotic arm to an entire production line. This isn't about replacing people; it's about replacing manual, repetitive oversight with intelligent, consistent processes that just work.

What Is Industrial Controls Automation?

At its heart, industrial controls automation is about giving machinery a brain. Walk into any advanced manufacturing plant today, and you won't see hundreds of operators flipping switches or turning dials. What you will see is a symphony of motion, precision, and speed, all thanks to a carefully designed network of automated systems.

This is the invisible force that guarantees the thousandth product off the line is identical to the first.

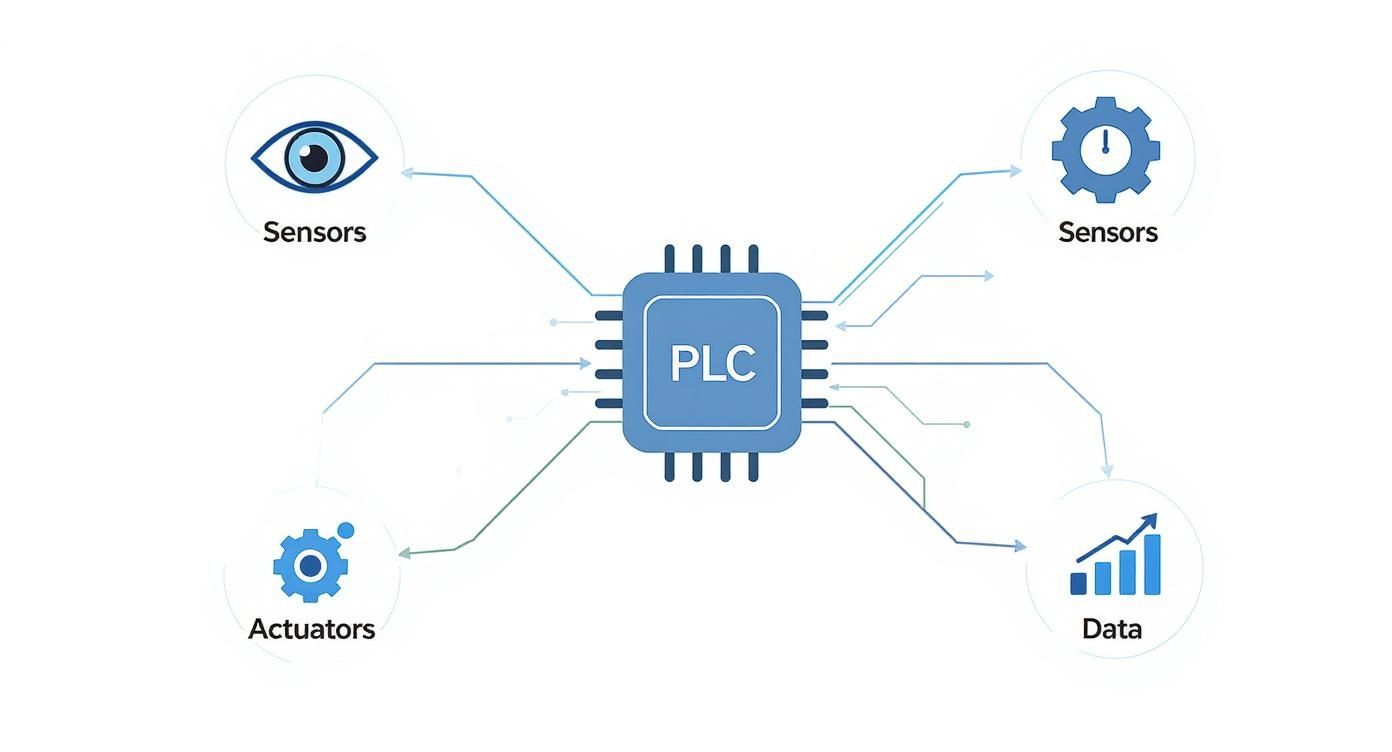

This whole system runs on a simple, continuous loop. Sensors act as the eyes and ears, gathering real-time data on things like temperature, pressure, or position. That information gets sent to the "brain"—usually a Programmable Logic Controller (PLC)—which makes split-second decisions based on its programming. From there, actuators like motors, valves, and grippers act as the "muscles," carrying out those commands with perfect accuracy.

The Driving Force Behind Modern Production

Let's be clear: adopting industrial controls automation isn't just a trend. It's a fundamental shift in how things get made. The main goal is to take human inconsistency out of the equation for repetitive tasks, paving the way for operational excellence.

The numbers back this up. The global industrial automation market was valued at around USD 228.9 billion in 2024 and is expected to rocket to nearly USD 590.9 billion by 2035. For a deeper dive into these figures, Mordor Intelligence offers a detailed analysis of the industry's growth trajectory.

This explosive growth is happening for one reason: automation delivers tangible, bottom-line results across every sector you can imagine, from car manufacturing to food and beverage packaging.

The real objective of industrial controls automation is simple: to create systems that are more efficient, safer, and more reliable than any manual process could ever be. It’s about achieving predictability in a complex environment.

Core Goals and Business Impact

At the end of the day, any decision to automate is tied directly to clear business goals. While the technology itself can get complex, the reasons for using it are refreshingly straightforward—it’s all about improving the bottom line and making operations more stable.

The table below breaks down the primary objectives that drive automation projects.

| Objective | Description | Example Impact |

|---|---|---|

| Boost Efficiency & Throughput | Automating processes allows machinery to run faster and longer than humanly possible, often 24/7. | A packaging line that once produced 100 units per hour can now produce 300 with the same footprint. |

| Improve Product Quality | Automation eliminates human error from assembly and processing, ensuring every product meets exact specifications. | Defect rates in a CNC machining process drop from 3% to less than 0.1%, drastically reducing material waste. |

| Enhance Workplace Safety | Dangerous, repetitive, or strenuous tasks are handed over to machines, moving people out of harm's way. | Robotic welding cells eliminate worker exposure to harmful fumes, intense light, and high temperatures. |

| Reduce Operational Costs | Automation cuts long-term costs related to manual labor, rework, material waste, and downtime from errors. | A facility saves thousands per year by automating palletizing, reducing labor costs and injury-related expenses. |

Ultimately, a well-implemented automation system is what allows a manufacturer to truly compete. It provides the tools needed to produce high-quality goods quickly, safely, and cost-effectively, which is the name of the game in today's global market.

The Building Blocks of a Control System

At its heart, an industrial control system is a lot like the human body. It has distinct parts that all work in harmony to pull off some pretty complex tasks. To really get a handle on industrial controls automation, you first need to know the core components—the actual hardware that senses what's happening, makes decisions, and then acts with incredible precision.

Picture a modern bottling plant. You’ve got thousands of bottles zipping down a conveyor, getting filled, capped, and labeled, all without a single person laying hands on them. This high-speed choreography is only possible because every piece of the automation puzzle knows exactly what it's supposed to do and when.

This diagram shows how the system's "brain" connects to its "senses" and "muscles."

As you can see, the PLC is the central hub. It's constantly crunching data from sensors to tell actuators what to do, creating a non-stop feedback loop that keeps everything running smoothly.

The Senses of the System: Input Devices

Every automated action has to start with information. Input devices, which are mostly sensors, act as the "senses" of the machine. Their job is to detect what’s going on in the real world and translate those physical conditions into electrical signals the control system can understand.

You'll find all kinds of input devices on a factory floor:

- Proximity Sensors: These guys detect if an object is present without actually touching it. Back in our bottling plant, a proximity sensor confirms a bottle is perfectly positioned before the filling nozzle even thinks about activating.

- Photoelectric Sensors: Using a beam of light, these can spot objects, check for colors, or even read marks. One might be used to verify a cap is properly twisted onto a bottle before it gets sent down the line.

- Temperature and Pressure Sensors: Absolutely vital for process control. In a pasteurization line, these sensors make sure the product hits and holds a specific temperature for just the right amount of time.

- Level Sensors: These measure how much liquid or material is in a tank or silo, telling a pump when it's time to kick on or shut off.

Without accurate and reliable data from these devices, the whole system would be flying blind.

The Brain of the Operation: Controllers

If sensors are the senses, then the controller is definitely the brain. This is where all the logic lives. The controller grabs all the incoming signals from the input devices, runs them through its programmed instructions, and then fires off commands to the output devices.

The workhorse controller in most manufacturing is the Programmable Logic Controller (PLC). Think of a PLC as a super-tough industrial computer built to survive the heat, dust, and vibration of a factory. It runs its program in a continuous, lightning-fast loop, making it incredibly reliable for machine control. Everything from the conveyor speed to the exact fill volume is dictated by the PLC's logic. Our internal guide takes a closer look at proper industrial control panel design, where these critical brains are housed.

The Voice and Eyes: The Human-Machine Interface

Even though a system is automated, you still need a human in the loop. The Human-Machine Interface (HMI) is the operator's window into the whole process. It’s usually a touchscreen panel that shows real-time data, alarms, and production status in an easy-to-read graphical format.

An HMI translates complex machine data into actionable information. It allows an operator to monitor the process, adjust settings like production speed, and troubleshoot issues without needing to understand the underlying PLC code.

From the HMI in our bottling plant, an operator could see how many bottles have been filled, get an alert if a capper jams, or switch the entire line over to run a different bottle size with just a few taps.

The Muscles of the Machine: Output Devices

Okay, so a decision has been made. Now what? Something has to physically happen. That's where output devices, or actuators, come in. They are the "muscles" of the system, taking commands from the PLC and turning electrical energy into real-world motion.

A few key output devices include:

- Electric Motors: The movers and shakers that power conveyors, pumps, and fans.

- Valves: Solenoid valves open and close to control the flow of liquids or gases—like the one dispensing soda into each bottle.

- Actuators: These are typically pneumatic or hydraulic cylinders that push, pull, lift, or clamp things. An actuator might be what presses the label onto a finished bottle.

- Relays and Contactors: These are essentially heavy-duty switches. They take a small signal from the PLC and use it to turn on and off much bigger equipment, like high-power motors.

Tying all of this together is the system's communication layer. Having a robust network infrastructure is non-negotiable; it's what ensures all these components can talk to each other without a hitch. Together, these building blocks create a cohesive system where every part knows its job, turning simple inputs into complex, high-speed production.

Understanding Control System Architectures

Knowing the individual parts of a control system is one thing. Understanding how they work together as a team is where the real magic happens. The way you organize those parts is the system's architecture, and picking the right one is like setting a formation for a football team—it all comes down to the scale and complexity of the game you’re playing.

You wouldn't use a single, localized controller to manage a sprawling chemical plant, just like you wouldn’t have one quarterback try to run an entire league. The architecture determines how data flows, where decisions get made, and how resilient the whole operation is when things go wrong.

Getting this right is more critical than ever. The industrial automation control market is on track to hit around USD 160 billion by 2029, driven by a global push for smarter, more efficient systems. You can dig into the numbers and trends in this detailed industry analysis from Technavio.

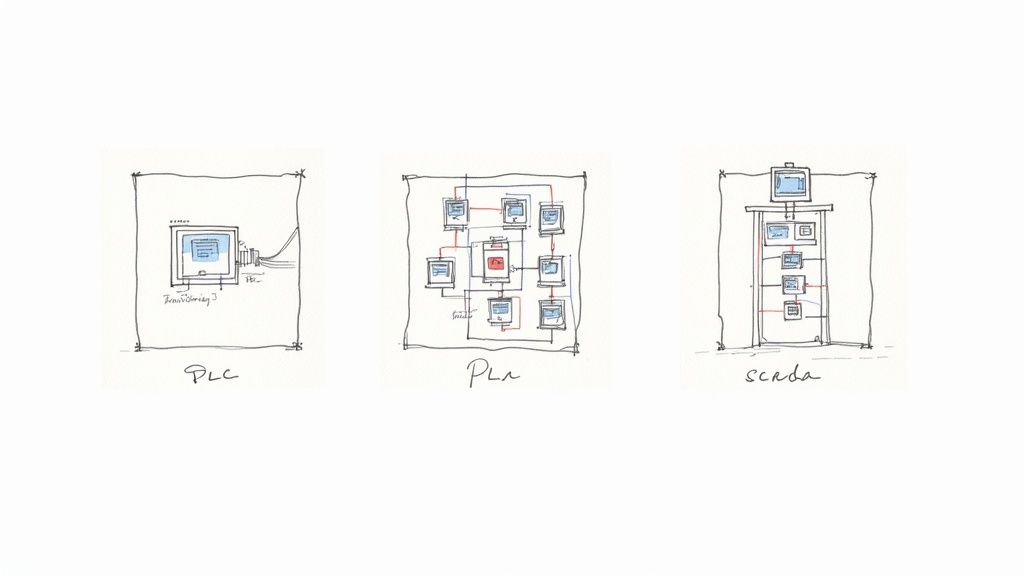

The PLC-Based Approach: Centralized Control

The most direct and common setup is centralized control, usually built around a single Programmable Logic Controller (PLC). Think of it as a "one-machine, one-brain" system. It's the go-to choice for self-contained, discrete manufacturing tasks where everything is happening in one spot.

A few classic examples include:

- A single packaging machine that forms, fills, and seals boxes in sequence.

- A CNC milling machine laser-focused on executing a specific cutting program.

- An automated welding robot on an assembly line, repeating the same welds all day.

In this setup, one PLC is the undisputed boss. It takes in all the sensor data, runs the logic, and fires off all the commands. It’s simple, cost-effective for smaller jobs, and a lot easier to troubleshoot because you know exactly where to look.

Centralized control is the workhorse of machine-level automation. It excels at high-speed, self-contained tasks where simplicity and responsiveness are paramount.

Distributed Control Systems (DCS) for Plant-Wide Processes

But what happens when your "machine" is an entire plant? When you need to control a whole process spread across a massive facility, a single brain just won't cut it. That's where a Distributed Control System (DCS) steps in.

Instead of one central controller, a DCS uses multiple controllers, or "brains," distributed throughout the plant. Each one is responsible for a specific part of the process.

Picture a large oil refinery. You have separate processes for cracking, distillation, and treatment, all happening at once but all needing to work in perfect harmony. A DCS puts a dedicated controller at each of these stages. These local controllers handle their own business while reporting back to a central supervisory system, making sure the entire plant operates like a single, well-oiled machine. This design is also incredibly reliable—if one controller goes down, the whole plant doesn't grind to a halt.

SCADA Systems: The Control Tower View

Now, let's zoom out even further. What if you need to monitor and control operations spread across different sites, or even an entire state? This is the domain of a Supervisory Control and Data Acquisition (SCADA) system.

Think of SCADA as the "air traffic control tower" for your industrial operations. It doesn't usually get bogged down in the millisecond-by-millisecond control logic; it leaves that to the PLCs and DCS controllers out in the field.

SCADA's job is to:

- Gather data from all your remote equipment and sites.

- Display that data on a central HMI for a human operator.

- Let the operator issue high-level commands, like turning on a pump station fifty miles away.

SCADA is the backbone of our modern infrastructure—it runs everything from municipal water systems and electrical grids to oil and gas pipelines. It gives you the 30,000-foot view you need to manage assets that are miles apart.

To make sense of these options, it helps to see them side-by-side. Each architecture is tailored for a specific type of job.

Control System Architectures Compared

| Architecture Type | Best For | Key Feature | Typical Scale |

|---|---|---|---|

| PLC-Based (Centralized) | Discrete, high-speed, single-machine tasks. | A single, powerful controller manages a localized process. | Machine or work cell. |

| DCS (Distributed) | Complex, continuous processes across a single, large facility. | Multiple interconnected controllers, providing high reliability and redundancy. | Entire plant or large processing facility. |

| SCADA (Supervisory) | Monitoring and controlling geographically dispersed assets and facilities. | Centralized monitoring and high-level control over remote sites. | Multiple sites, region, or entire pipeline. |

Ultimately, the goal is to match the architecture to the operational reality. A simple PLC is perfect for a single machine, a DCS is built for a complex plant, and SCADA is designed to give you command over a sprawling territory.

The Critical Role of Safety and Compliance

In industrial automation, it’s easy to get caught up in the drive for more speed and higher efficiency. But the real bedrock of any great control system isn’t how fast it runs—it’s how safe it is. Without a rock-solid commitment to safety standards and compliance, even the most sophisticated automation setup is just an accident waiting to happen.

This isn't just about ticking boxes for an inspector. It’s about protecting your people, your multi-million dollar equipment, and your entire operation from preventable disasters. You wouldn’t build a high-rise without following the building code to the letter, right? The exact same logic applies to industrial control panels. These standards are the collected wisdom of decades of engineering, specifically designed to prevent fires, electrical shocks, and catastrophic failures.

The Gold Standard: UL 508A

When we talk about control panel safety in North America, one name stands above the rest: UL 508A. This is the official standard for the construction of Industrial Control Panels. If you see a panel with the UL 508A Listed mark, it means it was designed and built to meet the tough safety requirements set by Underwriters Laboratories.

A UL 508A listing is far more than a simple sticker. It’s a third-party guarantee that the panel's design, components, and assembly meet strict safety and performance criteria. It gives inspectors, insurers, and the people on the floor total peace of mind.

This certification covers just about every part of the panel build, ensuring the final product is both safe and dependable. The standard gets very specific about:

- Component Selection: It mandates using UL-recognized components that have already been tested for their intended use.

- Wiring and Sizing: It lays out the exact rules for wire sizing, insulation types, and termination methods to stop overheating and electrical faults before they start.

- Enclosure Integrity: It ensures the panel’s cabinet is correctly rated for its environment, protecting the sensitive electronics inside from dust, water, and corrosion.

- Spacing and Layout: UL 508A dictates precise clearances between components to prevent dangerous short circuits and electrical arcing.

Following these rules isn’t optional. It’s how you build systems that don’t just work well, but are fundamentally safe.

A Complete Safety Framework

While UL 508A is the cornerstone for the panel itself, it doesn't exist in a vacuum. It’s part of a much larger ecosystem of codes and standards that govern the entire electrical installation.

The big one is the National Electrical Code (NEC), also known as NFPA 70. The NEC sets the ground rules for the safe installation of all electrical equipment and wiring in the U.S., from how conduit is run to how everything is properly grounded.

Another key piece of the puzzle is NFPA 79, the Electrical Standard for Industrial Machinery. This standard zeroes in on the electrical equipment of machines, making sure their control systems are safe for operators to work with day in and day out. Of course, you also have to think about power quality inside the panel. For example, knowing how a harmonic filter for VFD can stabilize the system is a crucial part of a truly comprehensive and safe design.

Together, these standards create a layered defense. Sticking to them isn't about navigating red tape; it's about building strong, reliable industrial automation systems that protect your most important assets—your people and your ability to produce.

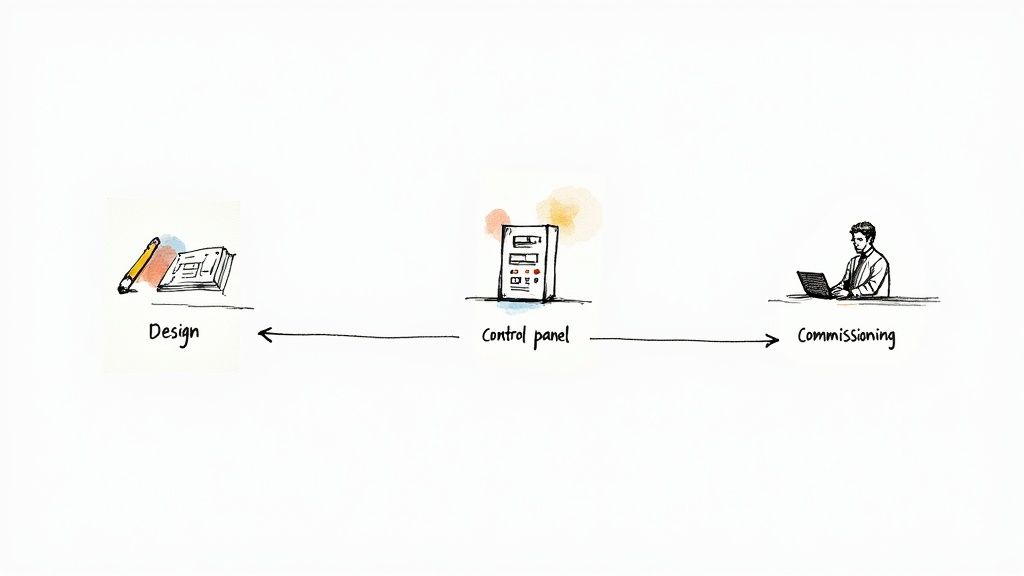

A Practical Roadmap for Your Automation Project

Taking an industrial controls project from a bright idea on a whiteboard to a humming, productive system on your floor demands a clear, disciplined approach. You wouldn't build a house without a blueprint, a solid crew, and a final inspection, and automation is no different.

The journey is best navigated with a phased roadmap. This breaks the whole complex undertaking down into manageable chunks, each with its own goals and deliverables. It’s the secret to minimizing those costly surprises and keeping the project on track, on time, and on budget.

Phase 1: The Design and Engineering Stage

This is where it all begins, and honestly, it's the most critical part of the whole process. Getting the design right now saves a world of headaches and expensive changes later.

It all starts by getting crystal clear on the project's goals. What problem are we really trying to solve? Are we chasing higher throughput, tighter quality control, or a safer environment for our team?

Once the "why" is established, we get into the "how" with a detailed Functional Specification document. Think of this as the system's biography—it describes exactly how the system needs to operate, from every sequence and alarm to every button an operator will push. From there, engineers can draft the electrical schematics, the true blueprints of the control panel that map out every last component, wire, and connection.

Phase 2: The Build and Assembly Stage

With approved designs in hand, the project jumps from the screen to the shop floor. This is where skilled technicians take over, fabricating, wiring, and assembling the control panel. It's a game of precision where attention to detail is everything.

The build process typically looks like this:

- Enclosure Layout: Components like PLCs, power supplies, and terminal blocks are physically placed inside the enclosure, ensuring everything fits while allowing for proper airflow and wiring paths.

- Component Mounting: All the hardware gets securely bolted to the panel’s backplane, following the schematics to the letter.

- Wiring and Termination: Technicians meticulously run every wire—cutting, labeling, and landing each one on the correct terminal. Following UL 508A standards here isn't optional; it's essential for a safe, compliant panel.

A well-built control panel is more than just functional; it's a work of art. Neat wire management, crystal-clear labels, and precise assembly aren't just for show—they make the panel far easier to troubleshoot and maintain for years to come.

Before the panel ever leaves the shop, it goes through a rigorous quality check to make sure the physical build perfectly matches the drawings.

Phase 3: The Commissioning and Startup Stage

This is the moment of truth when the system comes to life. Commissioning is the methodical process of testing and proving that every single part of the system works together as intended.

It often kicks off with a Factory Acceptance Test (FAT) right at the panel builder’s shop. This gives you, the client, a chance to see the panel powered up and test its core logic before it even ships—a massive risk-reduction step.

Once the FAT is signed off, the panel heads to your facility for installation. The commissioning team then gets to work:

- I/O Checkout: Every sensor, switch, motor, and valve is checked, verifying the signal path from the field device all the way back to the PLC and out again.

- Functional Testing: The system is put through its paces, running every operational sequence to confirm it behaves exactly as laid out in the functional spec.

- Safety System Verification: All emergency stops, light curtains, and other safety circuits are tested relentlessly to ensure they perform flawlessly when it matters most.

The project wraps up with a Site Acceptance Test (SAT), where you formally sign off that the system meets every requirement. Pulling off these phases smoothly requires real-world experience, which is why partnering with the right team is so important. For more on what to look for, you can explore our guide on choosing an industrial automation system integrator.

Measuring the True Value of Your Investment

Any industrial controls automation project is a serious capital expense. Once the dust settles, you've got to prove it was worth every penny, especially if you want to secure funding for the next big thing.

This isn't just about ticking a box. It's about turning a necessary expenditure into a powerful competitive advantage by showing clear financial and operational wins. The trick is to measure what actually matters and translate those shop-floor improvements into the language everyone in the C-suite understands: money.

Beyond the Price Tag: Calculating True ROI

The most straightforward way to justify the project is to calculate the Return on Investment (ROI). But a common mistake is only comparing the upfront cost to direct labor savings. A real ROI calculation for automation goes much deeper, accounting for a whole range of benefits that hit the bottom line.

To build a compelling business case, you need to track the specific Key Performance Indicators (KPIs) that your new automation system directly impacts. This hard data moves the conversation away from "cost" and firmly into "investment" territory.

Here are the big ones to watch:

- Increased Throughput: How many more widgets are you making per hour or per shift? It's the cleanest measure of a productivity boost.

- Reduced Material Waste: Precision automation means fewer mistakes and less scrap. Tracking this reduction is a direct line to cost savings.

- Decreased Downtime: How much less time are you spending on unplanned shutdowns? Every minute a line is down, money is walking out the door.

- Improved Quality: Look at the drop in product rejection rates or customer returns. Better quality means fewer costly recalls and warranty headaches.

The Gold Standard: Overall Equipment Effectiveness (OEE)

If you want one single metric that tells the whole story, it's Overall Equipment Effectiveness (OEE). OEE is the gold standard for measuring manufacturing productivity because it rolls three critical factors into one clean score, giving you a powerful, holistic view of your operation's health.

OEE essentially measures how much of your planned production time is genuinely productive. A world-class OEE score is 85% or higher, but honestly, many facilities start much lower. That just means there's a massive opportunity for improvement with automation.

OEE is calculated by multiplying three core components:

- Availability: This tracks any event that stops planned production—think equipment failures or material shortages. An Availability score of 100% means the process ran without any stop-loss during its planned time.

- Performance: This accounts for anything that makes the process run slower than its theoretical top speed, like micro-stops or reduced-speed cycles. A 100% Performance score means you're running as fast as theoretically possible.

- Quality: This one's simple—it tracks defective parts, including those that need to be reworked. A 100% Quality score means you're producing nothing but good parts.

By tracking your OEE score before and after the automation project goes live, you create an undeniable, data-driven narrative of success. It transforms the value of industrial controls from an abstract idea into a concrete, measurable business achievement.

Got Questions About Industrial Controls? We’ve Got Answers.

Diving into industrial controls automation can feel like learning a new language. You’ve got the big picture, but the devil is always in the details. Let's tackle some of the most common questions that come up when people are moving from theory to the factory floor.

Core Technology and Project Timelines

What’s the real difference between a PLC and a DCS?

It's a classic question. Think of it like this: a PLC (Programmable Logic Controller) is a highly specialized sprinter. It’s built for one primary job—controlling a specific machine or a small, self-contained process with lightning-fast reflexes and rock-solid reliability.

A DCS (Distributed Control System), on the other hand, is the plant’s quarterback. It’s designed to see the whole field, managing and coordinating large, sprawling, continuous processes. A DCS brings all the individual plays together into one unified, plant-wide strategy.

How long does an industrial automation project actually take?

That's the million-dollar question, and the honest answer is: it depends entirely on the scope. A straightforward control panel for a single machine? We could be looking at just a few weeks from design to commissioning.

But if you're talking about a full-scale system integration across your entire facility, you’re in for a longer haul. These projects can easily take many months, sometimes even over a year, once you factor in equipment lead times, custom software development, and the crucial design and engineering phase.

The bottom line: Project timelines are a direct reflection of complexity. Small, well-defined jobs are quick wins. Large, multi-system integrations are a marathon, not a sprint, requiring a detailed roadmap from day one.

Compliance and Modernization

Why is everyone so insistent on a UL-listed control panel?

It’s all about safety and accountability. A UL-listed control panel isn't just a fancy sticker; it's your proof that the panel has been built to meet rigorous safety standards tested by an objective third party, Underwriters Laboratories.

This certification is your ticket to passing inspections, satisfying insurance requirements, and protecting your people and equipment from fire and electrical hazards. In most places, it's not a "nice-to-have"—it's a non-negotiable requirement.

Can I actually put modern controls on my old machinery?

Absolutely, and it’s one of the smartest moves you can make. This is called a retrofit, and it's a super common and cost-effective way to modernize.

We see it all the time: a machine is mechanically sound—the "bones" are good—but the controls are from a different era. By swapping out the old relays and timers for modern PLCs, HMIs, and sensors, you get all the benefits of automation—better data, higher efficiency, improved safety—without the massive capital expense of buying a brand-new machine. The first step is always a deep-dive assessment of the existing equipment to build a solid game plan.

Turning these concepts into a reliable, high-performing system takes a partner who knows both the parts and the process inside and out. At E & I Sales, we deliver complete integration services, from custom UL control panel design to full system commissioning, making sure your project is built right, fully compliant, and ready to perform.