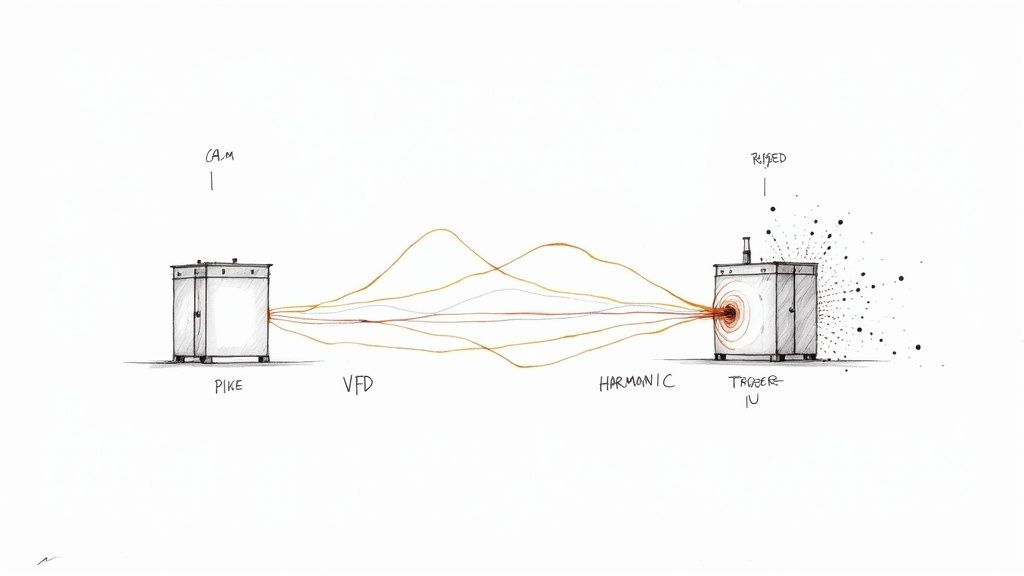

Think of a harmonic filter as a cleanup crew for your electrical system. When you install a Variable Frequency Drive (VFD), you get incredible control over your motors and save a ton of energy. The catch? VFDs create a lot of electrical “noise,” also known as harmonics, which can wreak havoc on your facility's power grid. A filter steps in to clean up that mess, ensuring everything runs on clean, stable power.

Why VFDs and Harmonic Filters Go Hand-in-Hand

Let’s use an analogy. Imagine your facility’s power grid is a perfectly smooth-flowing river. A VFD, for all its benefits, is like a machine that starts chopping up that smooth flow, creating all sorts of turbulence and messy currents.

That electrical turbulence is what we call harmonic distortion. It pollutes the power quality for every piece of equipment connected to that grid. We get into the nitty-gritty of how they work in our guide on variable frequency drive basics, but the most important thing to know is that VFDs are non-linear loads.

Instead of drawing power in a smooth, continuous wave, they take it in short, sharp gulps. Those abrupt pulses are the very source of harmonic pollution.

The Real-World Impact of Harmonics

Ignoring harmonics isn't just a technical detail—it's a direct threat to your plant's reliability and your bottom line. This "dirty power" travels everywhere, causing all sorts of strange, intermittent problems that are a nightmare to diagnose.

Without a good filter, you’re likely to see issues like:

- Overheating Equipment: Transformers, motors, and even wiring can start running dangerously hot, drastically shortening their service life.

- Nuisance Tripping: Circuit breakers pop for no obvious reason, causing frustrating and expensive downtime.

- Control System Glitches: PLCs, sensors, and even your network equipment can start acting up or failing because their power source is corrupted with noise.

- Wasted System Capacity: Harmonics eat up the capacity of your electrical system, meaning you can't add new equipment without first making expensive upgrades.

A harmonic filter is essentially a water treatment plant for your electrical river. It intercepts the pollution from the VFD and restores the clean, smooth power that your other equipment needs to run properly.

A Growing Industrial Necessity

The link between VFDs and harmonics is so strong that the filter market is growing right alongside VFD adoption. Projections show the harmonic filter market climbing from USD 933.86 million in 2025 to over USD 1.18 billion by 2030.

This isn't a coincidence. As more industries rely on VFDs, they're discovering that a standard six-pulse drive can easily push distortion levels into a problematic 30–40% range if left unchecked. As companies get serious about reliability and meeting power quality standards, filters are moving from a "nice-to-have" to a must-have component. You can see more on this trend in this harmonic filters market forecast.

When it's time to choose a harmonic filter for your VFD, you’ll quickly find yourself at a fork in the road: Passive or Active. This isn't about picking the "best" one, but about finding the right tool for the job. The decision you make here will ripple through your system's performance, your budget, and even long-term reliability.

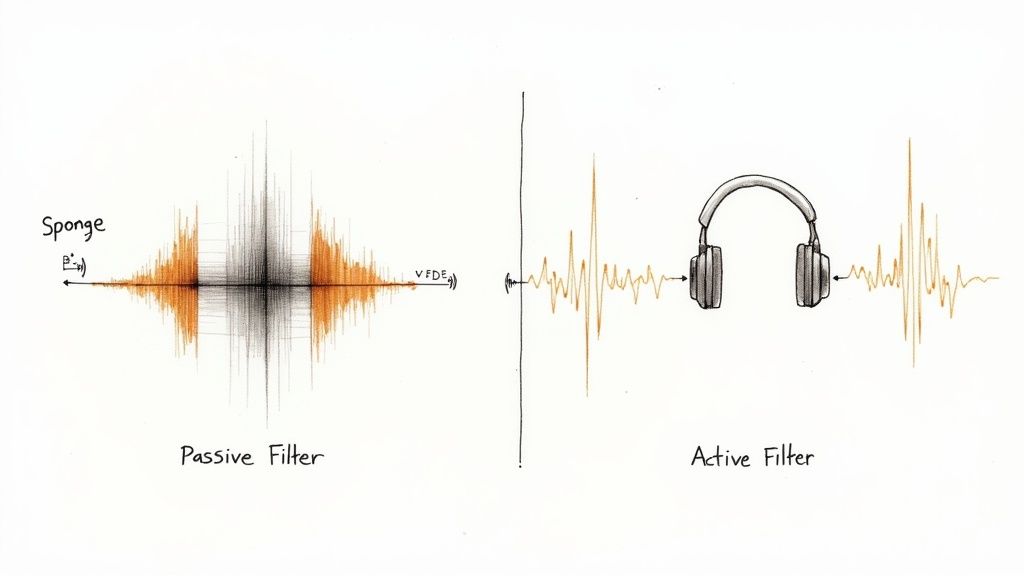

To get a grip on the difference, think of it like dealing with unwanted noise.

A passive filter is like a well-designed soundproofing panel. It’s made of specific materials—inductors, capacitors, and resistors—that are perfectly tuned to absorb a particular frequency of noise. It just sits there and does its one job really, really well.

An Active Harmonic Filter (AHF), on the other hand, is like a pair of high-end noise-canceling headphones. It actively listens to the noise, figures out its pattern, and generates an exact opposite sound wave to completely cancel it out in real time. It's a smart, dynamic solution.

The Passive Filter Approach

Passive filters are the tried-and-true workhorses of harmonic mitigation. They are built from simple components—inductors and capacitors—that are precisely tuned to a specific harmonic frequency. They create an easy path to ground, essentially trapping and diverting that specific flavor of electrical noise away from your system.

Because they are “tuned” for common troublemakers like the 5th or 7th harmonics that VFDs love to create, they are fantastic in predictable environments. If you have a steady load and know exactly what you’re dealing with, a passive filter is a robust and cost-effective solution.

- Best For: Single VFDs or a bank of drives that all run at a consistent speed and load.

- Example Application: Think of a big exhaust fan or a pump in an HVAC system that just runs at a steady clip all day long.

- Key Advantage: They are simple, tough, and much easier on the initial budget. With fewer moving parts, there’s less that can go wrong.

But that specialization is also their biggest drawback. If your system’s frequency profile changes, or if the utility power feeding your plant is already messy, a passive filter can lose its effectiveness. In a worst-case scenario, a poorly matched passive filter can actually create resonance and make your harmonic problems even worse.

The Active Filter Advantage

Active Harmonic Filters are a whole different ballgame. They use sophisticated power electronics—fast-switching transistors (IGBTs) and a smart controller—to constantly watch the electrical system.

A current transformer (CT) acts as the filter's "ears," measuring the distorted current waveform coming from the VFD. The AHF’s controller instantly analyzes this dirty signal and injects a perfectly opposing current to cancel out the harmonic distortion. This happens thousands of times a second, allowing the filter to adapt on the fly to whatever the VFDs are doing.

An active filter doesn't just block noise; it actively erases it. By injecting a mirror-image counter-current, it forces the waveform drawn from the power grid back into a clean, smooth sine wave.

This incredible adaptability makes active filters the clear winner for complex facilities. If you’ve got multiple VFDs, loads that are all over the place, or you’re under the gun to meet tough power quality standards, an AHF is often the only way to get there. They can tackle a whole range of harmonics at once and even help out with power factor correction as a bonus.

Passive vs Active Harmonic Filters At a Glance

Choosing between these two technologies really boils down to balancing your immediate needs and your budget. Here’s a quick rundown of how they stack up.

| Characteristic | Passive Filter | Active Filter |

|---|---|---|

| Mitigation Method | Diverts specific, targeted frequencies | Injects an opposing current to cancel distortion |

| Performance | Good for specific, predictable harmonics | Excellent, broad-spectrum correction |

| Adaptability | Fixed; performance can drop with system changes | Highly dynamic; adapts instantly to changing loads |

| Initial Cost | Lower | Higher (often 2-3x the cost of a passive unit) |

| Size | Can be quite large, especially for high amps | Generally more compact |

| Ideal Load | Stable, consistent loads | Dynamic, variable, and multiple non-linear loads |

| Complexity | Simple and rugged | Complex power electronics require skilled integration |

For a facility with a lot of non-linear loads all feeding into a common bus, or for anyone who absolutely has to meet strict IEEE 519 standards, an active filter is almost always the answer. The upfront investment is higher, no doubt. But in complex industrial environments where uptime is everything, the superior performance and operational flexibility often deliver a far better return in the long run.

Playing by the Rules: Why IEEE 519 Matters

When we talk about standards like IEEE 519, it's easy to get lost in the numbers and think of it as just another compliance hurdle. But it’s much simpler than that. Think of it as being a good neighbor on the electrical grid. Your utility company works hard to deliver clean, stable power to your facility, and in return, they need you to avoid dumping electrical "noise" back onto the line.

That noise is what we call harmonic distortion, and it's a natural byproduct of modern equipment like VFDs. If every facility let its harmonics run wild, the combined effect could destabilize the entire grid. That’s why these standards exist—to keep the shared power source clean and reliable for everyone connected to it.

Finding the Line: The Point of Common Coupling

So, where do the utility police actually measure this "noise"? That happens at a specific spot called the Point of Common Coupling (PCC).

The PCC is simply the official handoff point where your facility’s electrical system connects to the utility's grid. Picture it like the water meter at your property line; it’s the exact spot where the utility company measures what you're sending back. It’s at this PCC where your harmonic levels have to meet the limits set by IEEE 519.

At its core, IEEE 519 is a gentleman's agreement. The utility promises to deliver clean power, and you promise not to pollute that shared power. Harmonic filters are what allow you to hold up your end of the bargain.

What the Numbers Actually Mean

IEEE 519 isn't a one-size-fits-all rule. The harmonic limits you need to hit will change based on your system's voltage and how much power you draw. The general rule of thumb? The bigger your service and the higher the voltage, the tighter the limits get.

The standard really boils down to two key things:

- Total Harmonic Distortion (THD): This is the big-picture number. It’s an overall score that represents the total amount of harmonic noise you're creating.

- Individual Harmonic Limits: The standard also gets specific, putting caps on the individual troublemakers—like the 5th, 7th, and 11th harmonics—that VFDs are notorious for producing.

These limits are always expressed as a percentage of your maximum load. A very common target, for instance, is keeping your Total Demand Distortion (TDD)—which is just THD measured under full load—below 5% at the PCC. To get there, you almost always need properly engineered harmonic filters for VFD applications.

Tackling harmonics does more than just keep the utility happy; it makes your own system more efficient. Cleaning up your power reduces heat and wasted energy, which can also help improve your power factor. If you want to go deeper on that, our guide on the power factor definition is a great place to start. In the end, meeting IEEE 519 standards isn't just about avoiding a penalty—it’s about running a smarter, more reliable, and more efficient operation.

How to Size and Select the Right Harmonic Filter

Choosing the right harmonic filter isn't like picking a part off a shelf. It’s much more like getting a prescription filled—it has to be the right solution for a specific problem. If you undersize it, the filter won't do its job. Oversize it, and you’re just wasting money. The sweet spot is finding a solution that cleans up your power just enough without over-engineering the fix.

This is where we move from theory into the real world. The entire process starts with one critical step: gathering the right data. Before you even glance at a product spec sheet, you need a clear, accurate picture of your electrical environment.

Start with a Power Quality Analysis

First thing's first: you need a power quality analysis. Skipping this is like a doctor prescribing medicine without running any tests—you're just guessing, and the consequences can be serious. This analysis gives you the hard data, the baseline you absolutely need to specify the right harmonic filter for your VFD.

The process involves hooking up a power quality meter at critical points in your system, especially at the Point of Common Coupling (PCC). This isn't a quick snapshot; the meter stays on for a period to capture the full ebb and flow of your facility's operational loads.

Here’s what you’re looking for:

- Existing Background Distortion: What's the Total Harmonic Distortion (THD) on your system before adding the new VFD or filter? This tells you if you're starting with a clean slate or walking into an existing mess.

- VFD Load Profile: How much current is the VFD actually drawing, and how much does it change? A fan running at a steady 80% speed creates a much different harmonic signature than a crane VFD with its wild, unpredictable load swings.

- Specific Harmonic Orders: The analysis breaks down the distortion into its component parts—the 5th, 7th, 11th harmonics, and so on. This is crucial for picking a filter that targets the frequencies causing the most trouble.

- System Impedance: You need to understand how "stiff" your electrical system is. This helps predict how the grid will react to both the VFD and the filter you're about to add, letting you sidestep dangerous resonance problems.

Decoding Filter Specifications

Once you have that data in hand, you can finally start looking at filters. The numbers on a spec sheet aren't just marketing fluff; they are performance metrics that should directly map back to the problems you just measured.

You'll see terms like correction current, which is the maximum amount of harmonic garbage the filter can actively cancel out. This number needs to be higher than the harmonic current your VFD is producing. You'll also find attenuation levels, often shown on a chart, which detail how well the filter knocks down specific harmonic orders.

Think of it this way: Your power quality analysis tells you the size and shape of your harmonic problem. The filter’s spec sheet tells you the size and shape of the solution it provides. Your job is to find the perfect match.

This decision tree gives you a great starting point for that first big question: are you compliant with standards like IEEE 519 right now?

If you land on the "Filter" branch, the real work begins. Now you have to match the right technology to your specific application.

Matching Filter Technology to Your Needs

The data from your analysis will point you toward the right type of filter. If your VFD runs a stable, predictable load, a simple and cost-effective passive filter tuned to the problem frequencies (usually the 5th and 7th) is often all you need.

But for more complex systems—think multiple VFDs or loads that are all over the place—an active harmonic filter (AHF) is almost always the better bet. We're seeing much faster adoption of active filters in the field because their performance is so immediate and measurable compared to older passive designs. Industry reports show the AHF market is growing quickly as facility managers realize the value of real-time, dynamic correction for fluctuating VFD loads.

A properly sized active filter can take your THD from an unfiltered mess down to single-digit territory, often <5–8%, which is what you need to meet strict utility limits. You can see more on this trend in this harmonic filter market analysis. By putting in the work to gather data upfront, you guarantee the filter you choose is a precise, effective, and financially sound investment.

Installation Best Practices for Peak Performance

You’ve done the hard work and selected the perfect harmonic filter for your VFD. That's a huge step, but the job is only half done. A top-of-the-line filter installed the wrong way is like buying a high-performance engine but forgetting to hook up the fuel line—all potential, no results.

Proper installation is what turns your investment into real-world performance. Getting it right from the start means you avoid common headaches like poor filter effectiveness, nagging safety hazards, and even interference with the very equipment you’re trying to protect.

Let's walk through the best practices that ensure your harmonic filter for VFD systems deliver from day one.

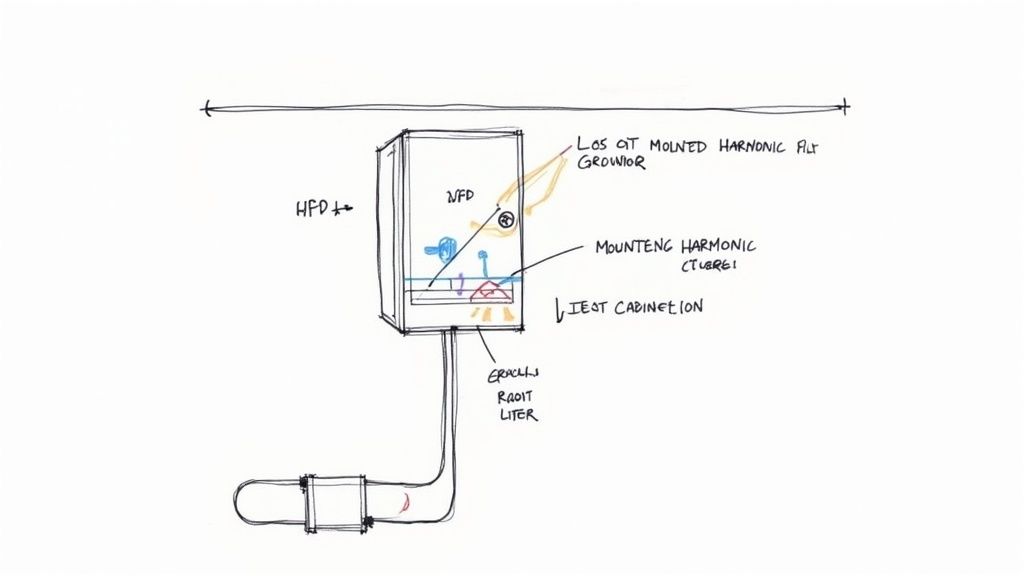

Location, Location, Location

Just like in real estate, placement is everything. The physical spot you choose for the filter in relation to the VFD has a massive impact on its effectiveness. Botch the location, and you’re setting yourself up for compromised performance and future maintenance nightmares.

Here’s what really matters for physical placement:

- Get Close to the VFD: Your filter needs to be installed as close to the VFD as physically possible. Shorter conductor runs between the two mean less voltage drop and less radiated noise (EMI). Long cables can act like antennas, broadcasting the very electrical noise you’re trying to eliminate.

- Give It Room to Breathe: Both VFDs and harmonic filters throw off a good bit of heat. Squeezing them into a stuffy, unventilated cabinet is a surefire way to cause overheating and premature failure. Always follow the manufacturer’s clearance requirements to ensure there's enough airflow. For bigger filters, this might even call for a dedicated ventilated cabinet.

- Plan for Maintenance Access: While you want the filter snugged up next to the VFD, don't make it impossible to work on. Make sure a technician can safely get to the terminals for inspections, connections, or troubleshooting without having to kill power to half the plant.

The Critical Role of the Current Transformer

When you're dealing with an active harmonic filter (AHF), no single component is more crucial to its operation than the Current Transformer (CT).

Think of the CT as the filter's eyes and ears. It's constantly measuring the harmonic currents flowing from the VFD and feeding that data back to the filter's brain. The filter then uses this information to calculate the exact counter-current it needs to inject to cancel out the distortion.

If the CT is in the wrong place, the active filter is effectively blind. It can't see the harmonic distortion it's supposed to cancel, rendering the entire unit useless.

The CT must be installed so it measures the current of only the non-linear loads (the VFDs) it’s meant to correct. It should be placed after the filter's point of connection but before the VFDs. If you put it where it can also measure the filter’s own corrective current, you’ll create a confusing feedback loop that sends the system into a tailspin.

Wiring and Grounding Done Right

Sloppy wiring and poor grounding are probably the two most common culprits behind post-installation problems. These aren't just minor details—they're the foundation for a safe and effective system.

- Use the Right Size Wire: Don't guess. Always use conductors sized for the filter's full load amperage, following all local electrical codes. Undersized wires can overheat, creating a serious fire hazard while also causing a voltage drop that cripples the filter's performance.

- Keep Power and Control Separate: Make it a rule to route your low-voltage control wires in a separate path from the high-power cables. Running them together in the same conduit is an open invitation for noise to bleed into the control circuits, which can cause erratic and unpredictable filter behavior.

- A Solid Ground is Non-Negotiable: A clean, low-impedance ground path is absolutely essential. It’s not just for safety; it’s what gives all that electrical noise a path away from your sensitive equipment. Use the dedicated grounding lug on the filter and connect it directly to the main system ground. No shortcuts.

Calculating the ROI of Harmonic Filtering

So, how do you justify the cost of a harmonic filter to the people signing the checks? It’s one thing to talk about meeting standards like IEEE 519, but the most convincing argument always comes down to the numbers. You have to prove that a filter isn't just another line-item expense—it's a smart investment that pays for itself.

Calculating the Return on Investment (ROI) is how you shift the conversation from a technical problem to a financial solution. A well-chosen filter doesn't just cost money; it makes and saves money over time, often in ways that are easy to miss. By putting real dollars to the benefits, you can show that doing nothing is actually the most expensive option.

Quantifying the Tangible Savings

The payoff from clean power goes way beyond just ducking utility fines. The real money is found in making your whole operation more efficient and reliable. These aren't just fuzzy concepts; they show up as real dollars on your balance sheet.

When building your case, you’ll want to hit these three financial pillars hard:

-

Reduced Energy Waste: Think of harmonic currents as electrical "junk food." They do nothing but create extra heat in your transformers, cables, and motor windings without contributing any real work. This wasted power, known as I²R losses, pads your utility bill every month. A filter cuts out this junk, which means you stop paying for energy that's just turning into heat. We dive deeper into this in our guide on VFD energy savings.

-

Extended Equipment Lifespan: That excess heat isn't just wasting energy; it’s actively cooking your equipment from the inside out. Transformers and motors running hot because of harmonics are on a fast track to failure. A filter acts like a bodyguard for these critical, expensive assets, helping them last longer and pushing huge replacement costs further down the road.

-

Minimized Costly Downtime: Nothing kills profits like an unplanned shutdown. Harmonics are a notorious cause of those frustrating "nuisance trips," where breakers pop for no clear reason, or sensitive PLCs and controls get scrambled, bringing a production line to a dead stop. By cleaning up the power, a filter stops these disruptive and incredibly expensive interruptions before they happen.

A Real-World ROI Scenario

Let's put some numbers to it. Picture a mid-sized manufacturing plant with a bunch of VFDs on its main production lines. Before installing filters, they were burning through about one oversized motor a year from overheating, costing them $15,000 a pop. On top of that, nuisance trips were causing about four hours of unplanned downtime a year, and every hour the line was down cost them $10,000 in lost production.

Here’s how the math breaks down for them:

- Annual Cost of Downtime: 4 hours x $10,000/hour = $40,000

- Annual Motor Replacement Cost: 1 motor x $15,000 = $15,000

- Total Annual Avoidable Costs: $40,000 + $15,000 = $55,000

By investing $70,000 in a properly sized active harmonic filter, the facility could see a full payback in just over a year. After that, they’d be pocketing an extra $55,000 in savings, year after year.

This kind of breakdown changes everything. The filter is no longer just something you have to buy for compliance. It becomes a proactive move to boost reliability and efficiency. If you need to build an even more detailed business case, there are plenty of great ROI calculation resources out there that can help.

Common Questions About VFD Harmonic Filters

When you start digging into harmonic filters for VFDs, a bunch of practical questions pop up. When do I actually need one? Where does it go? Why is it so important? These things are absolutely critical for keeping your electrical system healthy, but it's easy to get bogged down in the technical details.

Let's cut through the noise. Here are some straightforward answers to the questions we hear most often, so you can make the right call and troubleshoot with confidence.

Do All VFDs Require a Harmonic Filter?

Not every single VFD needs a filter right out of the box, but in most real-world industrial and commercial shops, it’s something you have to seriously consider. The real decision comes down to a few key things: how big your drive is compared to your whole power system, how sensitive other equipment on the same circuit is, and what your local utility demands (like meeting the IEEE 519 standard).

Sure, one little VFD on a massive, bulletproof electrical system probably won’t cause enough of a ruckus to matter. But the moment you start adding multiple VFDs, or one single large drive, that harmonic noise adds up fast. In those cases, a filter stops being a "nice-to-have" and becomes essential for preventing system-wide headaches and staying compliant.

What Is Total Harmonic Distortion (THD)?

Total Harmonic Distortion, or THD, is the go-to metric for measuring the "cleanliness" of your power. Think of it like a single grade that tells you how much electrical garbage is polluting your power signal compared to a perfect, clean sine wave.

A low THD percentage means you’ve got clean, stable power. A high THD means you've got significant distortion that can beat up your equipment. Standards like IEEE 519 put hard limits on THD to keep the grid stable, often telling facilities they have to keep distortion below 5% where their power comes in.

Can a Harmonic Filter Improve Energy Efficiency?

Yes, absolutely. This is a big one that often gets overlooked. Harmonic currents are just wasted energy. They don't do any useful work—they can't help turn a motor shaft. All they do is create destructive extra heat in your transformers, wiring, and the motors themselves. That's pure wasted electricity, and you're paying for it on your utility bill.

By knocking out these useless harmonic currents, a filter cuts down on that wasted heat, what we call I²R losses. The result is a more efficient electrical system, less heat stress on your gear, and real, measurable energy savings over time.

Where Should a Harmonic Filter Be Installed?

The rule of thumb is that harmonic filters get installed on the "line side" of the system. This just means you place the filter between your main power feed and the Variable Frequency Drive.

Putting it there is strategic. It allows the filter to catch and scrub out the harmonic currents the VFD creates before they can bleed back into the rest of your facility's electrical network or escape out onto the utility grid. Getting the placement right isn't optional—it’s what makes the filter do its job and protect your whole system.

At E & I Sales, we live and breathe this stuff. We engineer rugged, reliable motor control solutions that keep your plant running without a hitch. If you're trying to sort out VFDs and harmonic mitigation, our team has the field experience to design and build a system that nails your exact requirements.

Contact us to make sure your power quality is locked in. Learn more at https://eandisales.com.