Ever wondered how you can shrink an entire high-voltage electrical substation down into a single, compact, weatherproof unit? That’s the magic behind gas insulated switchgears (GIS). This technology swaps out open air for sulfur hexafluoride (SF6) gas as its electrical insulator, which allows for an incredibly smaller and more reliable design.

Understanding Gas Insulated Switchgears

At its core, a gas insulated switchgear is a highly engineered system that protects, controls, and isolates high-voltage electrical equipment. Its main job is to safely cut the flow of electricity, whether that’s during routine operations or, more importantly, during a major fault like a short circuit. This stops catastrophic damage to expensive machinery and keeps the power grid stable.

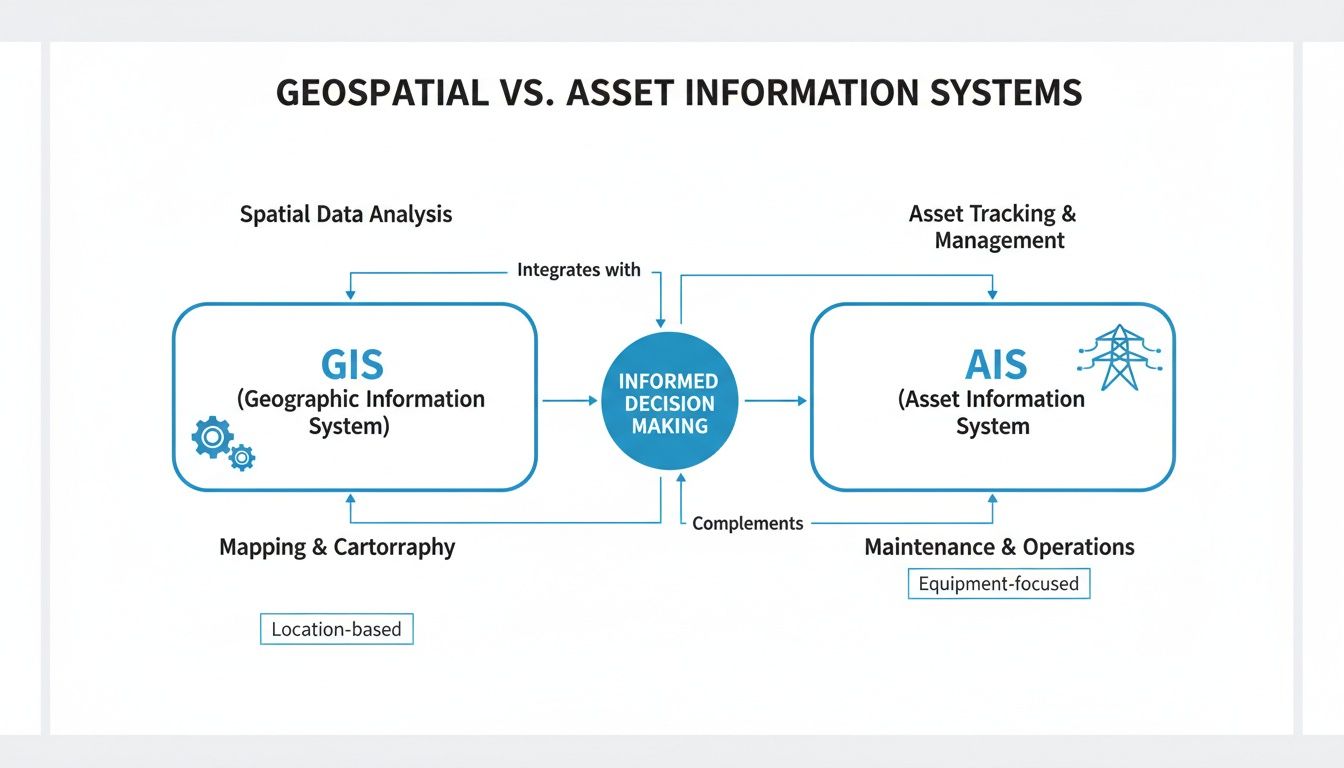

Think of it as the master control panel for a section of the electrical grid, just built with military-grade precision. Traditional Air Insulated Switchgear (AIS) relies on the surrounding air to stop electrical arcs from jumping between components. The problem? Air isn't a great insulator, so you need a ton of physical space between parts, leading to massive, sprawling substations.

GIS technology completely flips that model on its head. It takes all the live parts—like circuit breakers, busbars, and disconnectors—and seals them inside a grounded metal container filled with SF6 gas.

The SF6 Gas Advantage

Sulfur hexafluoride (SF6) is a non-toxic, inert gas with an incredible dielectric strength that's about 2.5 to 3 times greater than air. This superior insulating power is the secret sauce behind the compact size of gas insulated switchgears. Because SF6 is so good at preventing electrical arcs, engineers can pack high-voltage components much closer together without any risk.

This simple change brings some huge operational wins:

- Massive Space Savings: A GIS installation can take up as little as 10% of the footprint of an equivalent AIS substation. This makes it a perfect fit for dense urban areas, industrial plants with tight real estate, or offshore platforms.

- Rock-Solid Reliability: The sealed, grounded metal housing shields all internal parts from environmental headaches like dust, moisture, salt spray, and pollution. This immunity to the outside world means extremely high operational reliability and way less maintenance.

- Next-Level Safety: With every live part completely enclosed and shielded, the risk of accidental contact for personnel is practically zero. The grounded enclosure also safely contains any potential faults, making GIS one of the safest switchgear options out there.

A typical GIS unit has a lifespan of 40–50 years and requires very little maintenance. The properties of SF6 gas are a major reason why these systems last so long and can interrupt large currents with great reliability.

By trading wide-open air insulators for a compact, controlled gas environment, gas insulated switchgears deliver a robust, safe, and space-saving solution for modern power distribution.

To really see the difference, it helps to put GIS and AIS side-by-side.

Comparing GIS vs Air Insulated Switchgear (AIS)

| Attribute | Gas Insulated Switchgear (GIS) | Air Insulated Switchgear (AIS) |

|---|---|---|

| Insulation Medium | Sulfur Hexafluoride (SF6) Gas | Atmospheric Air |

| Footprint | Very compact, up to 90% smaller | Large and sprawling |

| Installation | Mostly factory-assembled, faster site work | Requires extensive on-site assembly |

| Maintenance | Minimal, with intervals of 20+ years | Frequent, requires regular cleaning/inspections |

| Reliability | Extremely high, protected from environment | Vulnerable to pollution, weather, and animals |

| Upfront Cost | Higher initial investment | Lower initial investment |

| Lifecycle Cost | Lower due to minimal maintenance | Higher due to ongoing maintenance needs |

| Safety | Very high; all live parts are fully enclosed | Lower; exposed live parts pose a risk |

While the initial price tag for GIS might be higher, its long-term benefits in reliability, safety, and reduced maintenance often make it the more economical choice over the life of a project.

A Look Inside the Core Components of GIS

To really get a feel for what makes gas insulated switchgears so effective, you have to peek inside their sealed, self-contained world. It's a stark contrast to a sprawling air-insulated substation where everything is spread out. A GIS packs it all into a compact, metallic box—an entire ecosystem engineered from the ground up for safety and uptime.

The magic ingredient holding it all together is the insulating medium itself: sulfur hexafluoride (SF6) gas. With a dielectric strength roughly three times that of air, SF6 is incredibly good at quenching electrical arcs and stopping faults in their tracks. This superior insulation is exactly what allows engineers to shrink the distance between conductive parts, giving GIS its signature compact design.

The Power Trio Inside the Enclosure

Within this SF6-filled environment, a few key players work in lockstep to manage high-voltage electricity. Think of them as the vital organs of the system; each one has a critical job to do.

You can't have a safe, reliable GIS without these three:

- Circuit Breakers: These are your first line of defense. Their one and only job is to cut the flow of current the instant a fault, like a short circuit, happens. Inside a GIS, the breaker operates right in the SF6 gas, which helps extinguish the massive arc created during the break. This protects everything downstream from catastrophic damage. To see how this critical function works, you can learn more about vacuum circuit breakers, a technology often at the heart of these systems.

- Disconnect and Earthing Switches: Think of these as the ultimate safety gates for maintenance crews. A disconnect switch creates a clear, visible air gap, proving a circuit is completely de-energized before anyone gets near it. The earthing switch then grounds that isolated circuit, bleeding off any leftover charge and protecting technicians from shock.

- Busbars: These are the electrical superhighways inside the switchgear. Busbars are simply conductive bars that route power to the various circuits. In a GIS, they are also completely bathed in SF6 gas, keeping them fully insulated and shielded from dust, moisture, and other environmental headaches.

It's the perfect harmony between these components—all operating inside a controlled, pressurized SF6 atmosphere—that makes GIS so incredibly reliable. The sealed design locks out external contaminants, which are a frequent cause of failure in traditional air-insulated equipment.

This diagram helps visualize the fundamental difference between the compact, sealed world of GIS and the sprawling footprint of traditional air-insulated systems.

You can immediately see how the enclosed, gas-filled design of GIS not only saves a huge amount of space but also provides far better protection from the elements.

The Support Systems Working Behind the Scenes

Beyond the heavy-hitting power components, a GIS relies on a few crucial auxiliary systems to keep it running smoothly for the long haul. They work quietly in the background, kind of like a car's onboard computer, constantly monitoring and maintaining optimal conditions.

A typical GIS installation always keeps a close eye on a few things:

- Gas Density Monitoring: This is, without a doubt, the most critical support system. The insulating power of SF6 depends entirely on its density (which is a function of both pressure and temperature), so sensors monitor it 24/7. If the density starts to drop because of a leak, the system triggers alarms at different levels, giving operators plenty of warning before it ever becomes a problem.

- Control and Interlocking Mechanisms: This is the brain of the whole operation. A series of mechanical and electrical interlocks physically prevent unsafe actions. For instance, they make it impossible to operate a disconnect switch while the circuit is live or to open a compartment before it’s been properly grounded.

- The Enclosure Itself: Usually built from aluminum or steel, the grounded metal enclosure does more than just hold everything together. It contains the SF6 gas, provides the structural backbone for all the internal parts, and acts as a safe, grounded shield to protect personnel from any exposure to high voltages.

What's the Real Payoff? The Strategic Edge of GIS

When you're deciding on high-voltage switchgear, you're not just picking a piece of equipment. You're making a strategic decision that echoes through your project's timeline, your operational budget, and its long-term financial health. For project managers, plant engineers, and EPC firms, choosing gas insulated switchgear isn't just a technical detail—it's a powerful investment in efficiency and resilience.

The first thing you’ll notice is just how ridiculously small GIS is. By using sulfur hexafluoride (SF6) gas as an insulator, GIS can slash the footprint of a high-voltage substation by up to 90% compared to an old-school air-insulated design. Let that sink in. This is a game-changer.

Think about what that means in a packed city or an expanding industrial plant where every square foot is gold. That land you just saved can become a new production line, extra storage, or anything else that actually makes you money, instead of just sitting there housing a sprawling substation.

Built for Reliability, Designed for Less Upkeep

One of the biggest wins with gas insulated switchgear is its rock-solid reliability. Every single critical, live component is tucked away inside a sealed, grounded metal enclosure. It's a perfect, controlled environment, completely cut off from all the nasty stuff that gives traditional switchgear headaches.

This sealed design shields the gear from common threats like:

- Contaminants: Dust, moisture, and corrosive salt air have no way to get in and mess with the internal parts.

- Critters: Say goodbye to outages caused by wildlife, a surprisingly common issue in outdoor substations.

- Pollution: GIS setups run perfectly in gritty industrial environments without their performance taking a hit.

This built-in protection means you can practically forget about maintenance. It’s no surprise the global market for gas insulated switchgears is expected to jump from USD 25.1 billion in 2024 to USD 37.4 billion by 2030. A huge driver for that growth is this "set it and forget it" nature. We’re talking major inspections only every 10-15 years, which is worlds apart from the yearly checkups that air-insulated gear demands. Over its life, this can easily cut lifecycle costs by 20-25%. You can get more insights on GIS market trends over at psmarketresearch.com.

The sealed-for-life design of a GIS turns maintenance from a constant, nagging operational cost into a predictable, scheduled event years down the road. That frees up plant managers to focus on making things better, not just fixing what's broken.

Putting Safety Front and Center

In high-voltage work, safety isn't just a line item—it's everything. And this is where GIS really shines. The whole concept is built around enclosing all the live conductors inside a grounded metal housing, creating a "dead-front" construction. This design makes it virtually impossible for your crew to accidentally touch an energized part.

Even better, that tough enclosure is engineered to contain the immense energy of an internal arc fault. If something does go wrong, the explosion is kept inside the switchgear. It prevents a catastrophic failure that could injure people or destroy surrounding equipment. This level of protection delivers serious peace of mind and makes gas insulated switchgear a go-to choice for any organization that truly walks the talk on safety.

How to Specify and Procure the Right GIS

Picking the right Gas Insulated Switchgear (GIS) is one of those foundational decisions that echoes for decades. It shapes your project’s reliability, safety, and what you’ll be spending on operations long after the installation crew has gone home. For engineers and procurement teams, this isn't just about getting a good price; it's about balancing technical precision with a clear-eyed view of the future.

You have to look past the initial quote to see the whole picture—performance, support, and the total cost of ownership.

The first step, always, is to nail down the core electrical parameters. These are the non-negotiables, the technical backbone of your GIS. They must match your system’s demands exactly, ensuring the gear can handle everything from normal daily loads to the worst-case fault scenarios.

Defining Your Technical Requirements

Before you even think about talking to vendors, you need a rock-solid understanding of what your application truly demands. This goes way beyond just the big three numbers. It’s about anticipating the unique environmental and operational stresses the equipment will face day in and day out.

Your spec sheet needs to be precise. It must detail:

- Voltage Rating (kV): The maximum voltage the system is built for. This has to line up perfectly with your grid or facility’s nominal voltage.

- Current Rating (A): The max continuous current the main busbars can carry without breaking a sweat—or overheating.

- Fault Current Capacity (kA): This is a critical safety number. It tells you the maximum short-circuit current the GIS can safely interrupt and contain without catastrophic failure.

Think of it like ordering a custom-built vehicle. You wouldn't just ask for "a truck." You'd specify the engine, the towing capacity, and whether it needs an off-road package. Your GIS needs that same level of custom tailoring to its working environment.

Assessing Application-Specific Needs

Where the switchgear lives matters. A lot. A GIS destined for a humid, salt-sprayed coastal refinery faces a completely different set of challenges than one installed in a high-altitude data center.

These environmental and site-specific details are just as critical:

- Ambient Temperature: Specify the full operational range, from the coldest winter morning to the peak heat of a summer afternoon.

- Altitude: Air gets thinner the higher you go, which directly impacts external cooling and insulation. It can’t be overlooked.

- Seismic Resilience: If you’re in an earthquake-prone area, the GIS and its entire support structure must be rated to handle specific seismic events.

- Compliance Standards: Be explicit about whether the equipment needs to follow IEC (International Electrotechnical Commission) or IEEE/ANSI (Institute of Electrical and Electronics Engineers/American National Standards Institute) standards.

This level of detail makes sure that when vendors send you a quote, they’re bidding on equipment that’s genuinely fit for the job.

With your technical spec locked down, you can start building your shortlist. The following table provides a quick-scan checklist to help you organize these critical parameters.

Key GIS Specification Checklist

| Parameter | Key Consideration | Typical Range or Standard |

|---|---|---|

| Rated Voltage (kV) | Must match system nominal voltage plus a safety margin. | 72.5 kV to 1200 kV |

| Rated Current (A) | Determined by maximum continuous load demand. | 630 A to 5000 A+ |

| Fault Current (kA) | Based on system fault studies; critical for safety. | 25 kA to 63 kA |

| Impulse Withstand (BIL) | Protection against lightning and switching surges. | Per IEC 62271 / IEEE C37 |

| Ambient Temperature | Full operational range, including solar gain. | -30°C to +50°C |

| Altitude | Affects external dielectric strength and cooling. | Specify if >1000m above sea level |

| Seismic Rating | Required for earthquake-prone zones. | IEEE 693 or local codes |

| Governing Standard | Determines design, testing, and safety protocols. | IEC or IEEE/ANSI |

| Enclosure Type | Single-phase or three-phase enclosures. | Application dependent |

| SF6 Gas Pressure | System pressure and alarm/lockout setpoints. | Manufacturer specific |

This checklist is your starting point. A comprehensive spec sheet will have far more detail, but getting these fundamentals right is the key to a successful project.

Evaluating Vendors and Solutions

Once you have that solid technical spec, the process shifts. Now you're evaluating partners, not just products. And while price is always part of the conversation, it should never be the only part. A lowball offer can quickly become a very expensive problem if it’s backed by poor support, sparse documentation, or unexpected installation nightmares.

The market for gas insulated switchgear is booming—it's projected to hit USD 36.60 billion by 2026. That kind of growth brings a lot of players to the table, making a thorough vetting process more important than ever.

When you're comparing vendors, dig deeper.

- What are their factory acceptance testing (FAT) procedures?

- Can you see examples of their technical documentation?

- What does their long-term service and support structure look like?

Finally, think about the big picture. Is a turnkey solution—where one vendor handles everything from design to commissioning—a better fit than sourcing bits and pieces yourself? For a better grasp of how different electrical distribution equipment compares, check out our guide on the differences between motor control centers and switchgears. A turnkey approach often simplifies project management and guarantees that all the components will play nicely together, giving you a much smoother path from procurement to a fully operational, compliant installation.

Getting GIS Installation and Maintenance Right From Day One

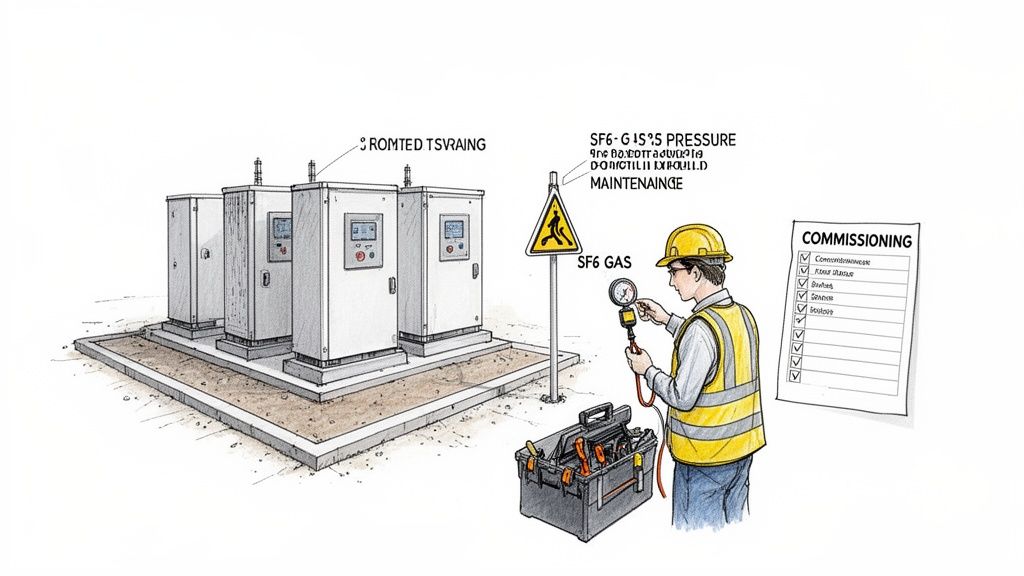

A successful GIS deployment is a masterclass in precision. It's about much more than just buying the right equipment. Getting the installation and commissioning right is the absolute bedrock for the asset's long-term reliability.

Unlike its air-insulated cousins, GIS modules require an almost surgically clean environment during assembly. Any contamination, even microscopic dust or a hint of moisture, can compromise the SF6 gas's insulating properties for decades to come. Think of it less like traditional construction and more like assembling a high-tech instrument in a cleanroom.

That's why following the manufacturer's strict protocols for foundation prep, module alignment, and connection isn't just a recommendation—it's non-negotiable for a flawless start.

Flawless Installation and Commissioning

The journey from the delivery truck to going live has several make-or-break stages. A small misstep early on can easily snowball, turning a hyper-reliable asset into a maintenance nightmare.

The first phase is all about preparation:

- Foundation and Civil Works: The concrete pad has to be perfectly level and fully cured, meeting the manufacturer's exact specs for load-bearing and anchor bolt placement. No exceptions.

- Clean Assembly Environment: Crews will often erect a temporary, controlled environment—like a specialized tent—around the installation site. This shields the sensitive components from dust, rain, and humidity while everything is being pieced together.

- Module Handling: GIS modules are heavy but delicate. They demand extreme care and the use of specified lifting gear to prevent any mechanical stress on the sealed enclosures.

Once assembled, the real proving ground begins: commissioning. This is where the system is put through its paces to verify its integrity before it ever sees a live load. This involves critical on-site tests like high-voltage withstand tests to check insulation, SF6 gas quality analysis to confirm purity, and functional checks of every single mechanical and electrical interlock.

A "low-maintenance, not no-maintenance" mindset is crucial. While GIS is incredibly reliable, its longevity hinges on proactive monitoring and scheduled check-ups, not a 'set it and forget it' attitude.

A Long-Term Maintenance Strategy

With a service life that can easily push past 40 years, the maintenance strategy for GIS is all about being proactive, not reactive. The goal is simple: monitor the system's health to catch tiny issues long before they have a chance to become big problems. This is how you guarantee maximum uptime over its entire operational life.

Of course, safety is paramount. Working with high-voltage gear like GIS means adhering to strict safety protocols is an absolute must. For anyone involved, understanding the NFPA 70E electrical safety standards is essential.

The good news is that routine maintenance is mostly observational, not invasive. The single most critical task is keeping a constant eye on the SF6 gas density. Modern GIS units have online monitoring systems that provide real-time data, and they'll sound an alarm if the density drops below a safe threshold—a clear sign of a potential leak.

Other best practices are just as straightforward:

- Regular Visual Inspections: Walk the site. Look for any signs of corrosion on the enclosure, check that control cabinet seals are intact, and make sure all indicators and gauges are functioning correctly.

- SF6 Gas Management: Always use specialized gas handling equipment. This prevents SF6 from being released into the atmosphere and ensures the gas can be recovered and recycled responsibly during any major repair or decommissioning work.

- Mechanism Checks: Every so often, it’s wise to operate the circuit breakers and switches. This confirms their mechanical systems are moving smoothly and within the manufacturer's specified timing.

The global GIS market is booming, with the Asia-Pacific region alone accounting for over 40% of the market share. A huge driver for this growth is the technology's tiny footprint—it takes up just 10-15% of the space of traditional switchgear, making it a perfect fit for urban projects where space is at a premium. If you’re involved in facility planning, our guide on designing an electrical substation is a great next step.

The Future of Switchgear Technology

The world of high-voltage equipment is staring down two massive shifts: the demand for environmental sustainability and the rise of digital intelligence. For decades, sulfur hexafluoride (SF6) gas was the undisputed king of insulation for compact switchgear. Its performance was fantastic, but it came with a steep environmental price tag.

SF6 is the most potent greenhouse gas out there, with a global warming potential 24,300 times higher than carbon dioxide. That single, staggering fact is forcing a global move toward greener alternatives, completely redrawing the map for gas insulated switchgears.

The Shift to SF6-Free Alternatives

The industry isn't just talking about change; it's actively developing and deploying new insulating gases to slash environmental impact without compromising performance. This isn't just a trend—it's fast becoming law. The EU, for example, is set to phase out SF6 in new medium-voltage equipment as early as 2026.

This regulatory push has lit a fire under innovation, giving us several solid SF6-free options:

- Fluoronitrile-Based Mixtures: Gases like C4F7N, mixed with CO2 and O2, deliver excellent dielectric strength. This means you can get designs just as compact as old-school SF6 GIS but with a tiny fraction of the GWP.

- Vacuum Technology with Clean Air: This approach is beautifully simple. It pairs proven vacuum interrupters with pressurized "clean air" (a mix of nitrogen and oxygen) for insulation. It completely cuts out fluorinated gases, giving it a GWP of practically zero.

- CO2 and O2 Mixtures: For certain applications, like outdoor breakers, a straightforward mixture of carbon dioxide and oxygen can provide effective insulation with a minimal environmental footprint.

Making a smart investment today means getting ahead of this curve. Choosing an SF6-free GIS solution helps your facility crush its sustainability goals while dodging the long-term headaches and risks of tightening environmental laws.

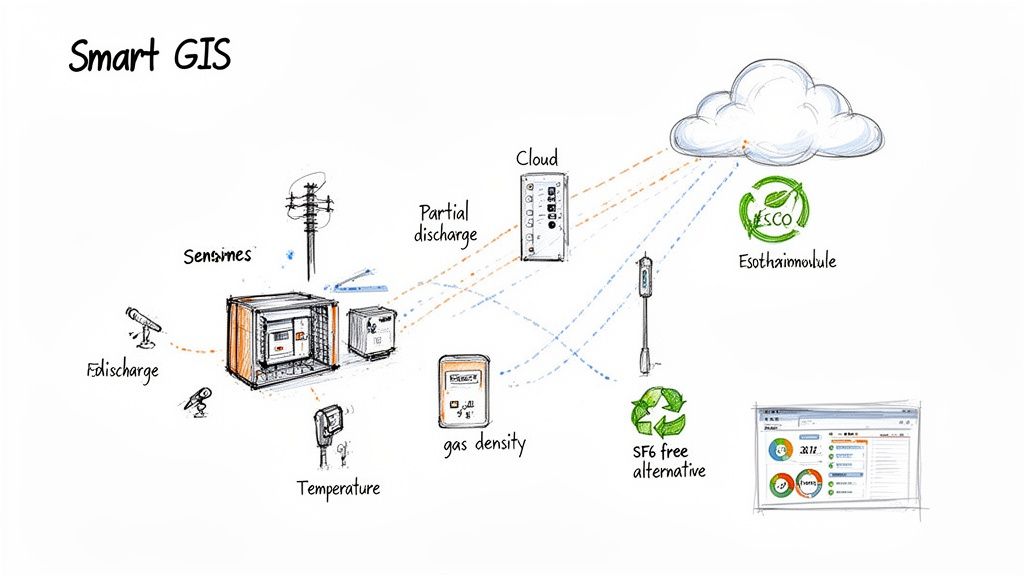

The Rise of Smart Gas Insulated Switchgears

At the same time we're going green, a digital revolution is making GIS smarter than ever before. "Smart GIS" isn't just a buzzword; it's about embedding advanced sensors and connectivity right into the equipment. This turns what was once a passive box into an active, data-pumping node on your grid.

This tech integrates sensors to keep a constant watch on critical health indicators in real-time.

By continuously tracking gas density, partial discharge, and temperature, Smart GIS provides a complete, live picture of the equipment's condition. This moves maintenance from a reactive, schedule-based task to a proactive, predictive strategy.

This constant stream of data is where the real magic happens. IoT connectivity funnels this information to analytics platforms that can spot negative trends long before they turn into catastrophic failures. For plant engineers, this means fewer surprise outages, smarter maintenance schedules, and a much longer, more reliable service life from their most critical assets. This intelligent approach is exactly what's needed to build a tougher, more resilient power grid.

Got Questions About Gas Insulated Switchgear?

Even after you get the hang of the technology, a few practical questions always pop up when you start planning a project. Let's tackle those head-on. Getting these cleared up early makes the business case stronger and the decision-making a whole lot easier.

Here are the answers to some of the most common things we hear from engineers and project managers.

How Does the Total Cost of Ownership Really Stack Up Against AIS?

When you look at the total cost of ownership (TCO) over a typical 30-year lifecycle, GIS almost always comes out on top, even though it costs more to buy upfront. It's a classic tortoise and hare story. Air Insulated Switchgear (AIS) looks like a bargain at first, but its long-term running costs can really sting.

AIS needs constant attention—regular cleaning of insulators, inspections, and servicing different parts. All of that adds up in labor and materials, year after year. GIS, on the other hand, is a sealed, low-maintenance unit. You might not need to do any major service for 20 years or more.

Over three decades, the huge savings from less maintenance, minimal downtime, and the smaller physical footprint of GIS typically result in a much lower total cost. The money you save on operations almost always makes up for the higher initial price tag.

What’s the Deal with SF6 Gas Regulations?

Sulfur hexafluoride (SF6) is an incredible insulator, but there's a catch: it's a seriously potent greenhouse gas. We're talking a global warming potential over 24,000 times that of CO2. Because of this, how you handle it is tightly regulated.

The rules really boil down to a few key things:

- Leak Detection and Repair: You have to have a solid monitoring program to find and fix any SF6 leaks right away.

- Certified Handling: Only certified pros who are trained in proper gas handling can legally fill, top off, or recover SF6. This isn't a job for just anyone.

- Strict Record-Keeping: Companies are legally required to keep detailed logs of all SF6 gas they buy, use, and have in inventory. It's all about accountability.

These regulations are in place to keep the gas out of the atmosphere and ensure it’s managed responsibly from cradle to grave.

Can I Upgrade My Old AIS Substation with GIS?

Absolutely. In fact, it's a pretty common scenario. Creating a hybrid substation by adding GIS to an existing AIS setup is a great strategy, especially when you need to add new circuits but have run out of room. You can tuck a compact GIS unit into a small, available space and connect it right into the existing air-insulated busbars.

This approach lets you boost your facility's capacity and reliability without tearing everything out and starting from scratch. It's a smart, practical way to modernize older infrastructure, particularly in tight spots.

What’s a Realistic Lead Time for a GIS Solution?

The timeline for getting a medium-voltage GIS solution up and running can vary quite a bit, depending on how complex your project is and what the manufacturer's backlog looks like. That said, a good rule of thumb is to expect anywhere from 8 to 14 months from the time you sign the purchase order to final commissioning.

This window covers all the major steps: detailed engineering and design approvals, manufacturing and factory acceptance testing (FAT), shipping, and finally, the on-site installation and commissioning. If you need a custom-engineered solution or specialized components, you can bet it'll be on the longer end of that spectrum.

At E & I Sales, we live and breathe this stuff. We provide turnkey integration that ties together your power distribution, automation, and motor control. Our team has the deep expertise to help you specify, procure, and commission the perfect switchgear solution for your world. Learn more at eandisales.com.