Ever tried to squeeze a massive, sprawling electrical substation into a space the size of a large room? It sounds impossible, but that's precisely the problem gas insulated switchgear (GIS) was designed to solve. This technology takes all the critical, high-voltage equipment—circuit breakers, switches, busbars—and seals them inside a compact, metal-enclosed housing filled with an insulating gas.

The result is a dramatic reduction in physical footprint, turning a land-intensive engineering challenge into a manageable one.

What Is Gas Insulated Switchgear and How It Works

Think about the difference between a classic, air-cooled engine with all its exposed parts and a modern, liquid-cooled system. The liquid coolant is a much more efficient medium, allowing the entire engine to be smaller, more powerful, and more reliable.

Gas insulated switchgear applies this same core principle to high-voltage power equipment. Instead of relying on open air to insulate components—which demands huge safety clearances to prevent electrical arcs—GIS uses a specialized gas that is far more effective.

This simple shift in approach lets engineers shrink the switchgear's footprint by up to 90% compared to conventional air-insulated switchgear (AIS). For projects in dense urban centers or crowded industrial plants where every square foot counts, this is a total game-changer.

The Power of Compact Design

The magic behind GIS is its exceptional dielectric strength—the insulating gas's ability to handle immense electrical stress without breaking down. The industry standard, Sulfur Hexafluoride (SF6), is several times more effective at insulating than plain air. This means high-voltage conductors and components can be safely placed just inches apart, rather than many feet.

This incredibly compact, modular design delivers a few powerful advantages:

- Massive Space Savings: GIS can be installed indoors, underground, or tucked away in tight industrial spaces where a traditional AIS substation simply wouldn't fit.

- Unmatched Reliability: The sealed, controlled environment protects all the internal components from the outside world. Dust, moisture, salt spray, and other contaminants can't get in, leading to a much longer service life and fewer outages.

- Superior Safety: With all live parts completely enclosed and grounded, the risk of accidental contact for personnel is virtually eliminated.

The market's growth tells the story. Valued at USD 22 billion in 2022, the global gas insulated switchgear market is on track to hit an incredible USD 55.8 billion by 2034. As cities expand and industries modernize, the demand for efficient, space-saving power infrastructure is only going up. You can dig deeper into these market trends for gas insulated switchgear over at gminsights.com.

The choice between GIS and AIS is a fundamental one that reshapes the entire approach to a project. It transforms a major land-use problem into a straightforward architectural one, opening up new possibilities for development in constrained areas.

GIS technology is a cornerstone of modern electrical substation design, allowing more power to be delivered more reliably in less space. From data centers and manufacturing plants to urban high-rises, GIS provides a tough, dependable solution where both performance and footprint are non-negotiable.

GIS vs AIS At a Glance

To put it all in perspective, here's a quick comparison of the two technologies. While both serve the same fundamental purpose of controlling and protecting electrical circuits, their design philosophies are worlds apart.

| Feature | Gas Insulated Switchgear (GIS) | Air Insulated Switchgear (AIS) |

|---|---|---|

| Insulation Medium | Pressurized gas (typically SF6) | Atmospheric air |

| Footprint | Extremely compact; up to 90% smaller | Very large; requires significant land area |

| Installation | Typically indoors, underground, or enclosed | Almost always outdoors |

| Environmental Exposure | Fully protected and sealed | Exposed to weather, pollution, animals |

| Maintenance | Minimal; very long intervals | Regular (cleaning, inspections, etc.) |

| Capital Cost | Higher initial investment | Lower initial investment |

| Safety | Very high; all live parts are enclosed | Lower; live parts are exposed |

| Ideal Applications | Urban areas, offshore platforms, harsh environments | Rural areas, locations with ample space |

Ultimately, GIS represents a more advanced, contained, and robust approach to switchgear, trading a higher upfront cost for long-term reliability, safety, and a much smaller physical presence.

Understanding What’s Inside a GIS System

To really get what makes gas-insulated switchgear so different, you have to look inside that sealed, metal enclosure. It’s not just a box; it's a precisely engineered ecosystem where every component works together to control and protect high-voltage circuits. Think of it as a specialized crew operating in a perfectly controlled environment.

Each part is designed for maximum performance and a long service life, all contained within a single housing filled with an insulating gas. This fundamental design is the secret behind GIS's compact size, incredible reliability, and enhanced safety.

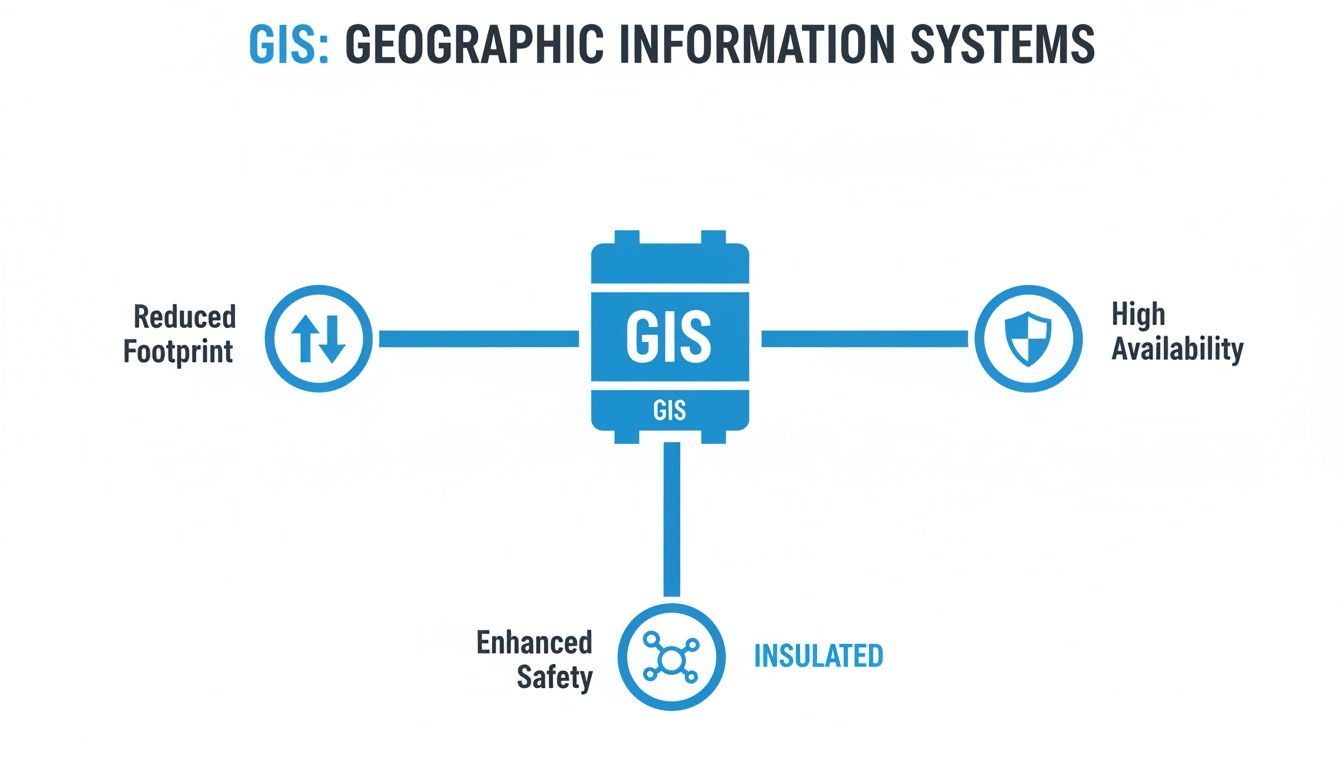

The image below sums up how these core principles translate into real-world benefits.

As you can see, the superior insulation is the key—it enables everything else, from the smaller footprint to rock-solid reliability. Now, let’s unpack the components that make it all happen.

The Protective Core: Circuit Breaker and Switches

The circuit breaker sits at the very heart of the switchgear. It's the system's first line of defense, designed to slam the door on electricity flow in milliseconds when it detects a fault like a short circuit. Inside a GIS, this all happens within the insulating gas, which is exceptionally good at extinguishing the massive electric arc that forms when a high-voltage circuit is broken.

But the breaker doesn't work alone. Two other switches are crucial for safe operation and maintenance:

- Disconnectors (or Isolators): These create a clear, physical air gap in the circuit for total isolation. They’re only operated when the circuit is already de-energized, giving crews a visible guarantee that a piece of equipment is safely disconnected before they start work.

- Earthing Switches (or Grounding Switches): Once a section is isolated by the disconnector, this switch connects the conductors directly to the ground. It’s a non-negotiable safety step that drains any residual charge and prevents induced voltage from becoming a hazard to personnel.

The Insulating Medium: The Secret Sauce

The real star of the show in a gas insulated switchgear system is the gas filling the enclosure. For many years, that gas was Sulfur Hexafluoride (SF6), a synthetic compound with incredible dielectric strength—basically, its ability to stop electricity from arcing where it shouldn't. To put it in perspective, SF6 is roughly 2.5 times more effective as an insulator than pure nitrogen and lightyears ahead of air.

The catch? SF6 is also a powerful greenhouse gas. With environmental regulations becoming stricter, the industry is quickly moving toward SF6-free alternatives. These "green" gases, like fluoronitrile-based mixtures or even highly pressurized clean air, offer similar insulating performance with a much, much smaller environmental footprint.

The insulating gas is the game-changer that allows for such a dramatic size reduction. By preventing arcs between live parts, it removes the need for the wide, open-air gaps you see in conventional switchgear. This lets engineers pack everything closer together, making the whole assembly smaller and far more robust.

The Monitoring and Measurement Tools

You can't control what you can't measure. That’s where instrument transformers come in—they are the eyes and ears of the GIS, constantly monitoring the system's vital signs.

You'll always find two main types:

- Current Transformers (CTs): These devices safely measure the massive currents flowing through the conductors. They "step down" the current to a low, manageable level that can be read by protective relays and meters without vaporizing them.

- Voltage Transformers (VTs): In the same way, VTs measure the extremely high system voltage, reducing it to a standardized, low value that monitoring and protection equipment can safely handle.

When you put it all together—the breakers, the switches, the gas, and the transformers—you get a completely self-contained and highly integrated system. Every single part is optimized to function perfectly within that controlled gas environment, achieving a level of performance and reliability that's tough for traditional, air-insulated gear to match. This tight integration is what makes gas-insulated switchgear the go-to choice for so many critical applications.

Why GIS Is a Smarter Choice for Industrial Operations

Picking the right switchgear isn't just a technical detail—it's a strategic decision that ripples through your entire operation, impacting efficiency, safety, and your bottom line. For any industrial facility, gas-insulated switchgear (GIS) makes a compelling business case by turning its sophisticated design into real-world, tangible benefits. This is about more than just managing power; it’s about optimizing your whole operational environment.

Let’s dig into the four key advantages that make GIS the go-to choice for plant engineers, project managers, and operations leaders who expect more from their critical infrastructure.

Free Up Your Most Valuable Asset: Space

In any industrial plant, floor space is gold. Every square foot tied up by non-production equipment is a missed opportunity for revenue-generating machinery or a more efficient workflow. This is where the compact nature of gas-insulated switchgear delivers its most immediate and striking advantage.

Because all its key components are sealed inside a gas-filled tank, a GIS unit can be up to 90% smaller than its air-insulated cousins.

This isn't just a minor perk; it's a strategic game-changer. It can be the deciding factor that allows a facility expansion to move forward instead of stalling due to site constraints. For a packed manufacturing floor, it could free up enough room for an entire new production line, directly boosting output and profitability.

Elevate Plant and Personnel Safety

Safety is absolutely non-negotiable in an industrial setting, and GIS is fundamentally built for it. Traditional air-insulated switchgear often has exposed live conductors, which poses a constant risk of accidental contact for any personnel working nearby.

With GIS, every live component is completely contained within a grounded metal enclosure. This design all but eliminates the risk of electric shock, making it an inherently safer technology for environments where people are working in close proximity to high-voltage equipment.

The sealed-for-life design of gas-insulated switchgear creates a controlled internal environment that is immune to external factors. This not only enhances reliability but also creates a formidable barrier between high-voltage electricity and the people who work around it every day.

This built-in safety shield reduces the chance of accidents and simplifies critical lockout-tagout procedures, leading to a more secure and efficient workplace. It also means the equipment is protected from accidental bumps from forklifts or other machinery, further protecting your operations.

Achieve Superior System Reliability

Industrial processes live and die by a constant, uninterrupted flow of power. Unplanned downtime can rack up thousands of dollars in losses every single minute, which puts equipment reliability at the very top of the priority list.

The sealed design of gas-insulated switchgear is its greatest strength. It essentially creates a fortress, shielding all critical internal parts from the harsh realities of an industrial plant.

- Immunity to Contaminants: Dust, moisture, corrosive chemicals, and other particles common in industrial settings simply can't get inside to degrade the components.

- Stable Performance: The controlled gas atmosphere provides consistent insulating performance, no matter what the external humidity or altitude is doing—factors that can easily affect air-insulated gear.

- Fewer Outage Risks: This protection dramatically cuts down the risk of flashovers and faults caused by environmental contamination, giving you significantly higher uptime for your most critical processes.

Minimize Maintenance and Lower Lifecycle Costs

While the initial price tag for GIS can be higher, its long-term economic advantages are undeniable. The equipment is engineered for a service life of 30 to 40 years with very little intervention needed. Since the internal parts aren't exposed to environmental wear and tear, the need for routine cleaning and inspection is drastically reduced.

This all translates to fewer planned shutdowns, lower labor costs for maintenance, and a much smaller spare parts inventory to manage. When you look at the total cost over the equipment's entire lifecycle, these savings in operational expenses often make gas-insulated switchgear the more cost-effective solution. This superior technical design is precisely why GIS is a cornerstone of modern power infrastructure. You can find more insights on the global GIS market over at techsciresearch.com.

While GIS is a powerhouse for high-voltage distribution, it often works alongside other key equipment. To see how it fits into the bigger picture, check out our guide comparing motor control centers vs. switchgear.

How to Specify and Procure the Right GIS Solution

Picking the right gas-insulated switchgear isn't just a purchase; it's a major investment in your electrical system's future. To get it right, you have to look beyond the basic voltage rating and dig into a detailed specification process. It’s all about balancing technical muscle, lifecycle costs, and what the future might throw at you.

Let’s walk through a framework that helps engineers and procurement managers make a truly informed decision, not just a quick one.

Defining Your Technical Specifications

The first step is getting crystal clear on your core electrical and physical needs. This is about more than just the system voltage—it's about deeply understanding the real-world demands the GIS will face every day and during a worst-case scenario fault.

Think of your technical spec sheet as the blueprint for the entire project. If it's vague, you're inviting mismatched quotes and costly delays. You need to nail down every critical parameter.

Key electrical numbers you absolutely must define include:

- Rated Voltage and Frequency: The fundamentals, like 145 kV at 60 Hz.

- Rated Continuous Current: The absolute maximum current the main components can handle non-stop without breaking a sweat.

- Short-Circuit Withstand Current: The gut-punch of a fault current the GIS has to survive without damage for a specific time, usually 1 or 3 seconds.

- Basic Insulation Level (BIL): This proves the gear can handle massive voltage surges from things like lightning strikes or other switching events on the grid.

But don't stop there. You have to consider the physical world your GIS will live in. Is it going into a brand-new concrete building, a compact e-house, or being squeezed into a tight basement? Get the tape measure out. Document the exact footprint available, paying close attention to height limits and access routes needed for both installation and future maintenance.

Evaluating the Insulation Medium

For decades, SF6 gas was the undisputed king of insulation. But the world is changing. Environmental regulations are getting tighter, and that's pushing SF6-free alternatives from a "nice-to-have" to a "must-consider."

The EU, for instance, is already moving to phase out SF6 in new switchgear, with the first major deadline hitting in 2026 for medium-voltage equipment. That’s a clear signal of where the entire industry is headed.

When you're talking to potential suppliers, press them on the gas issue:

- SF6-Free Options: Do they have field-proven alternatives? Are they using modern gas mixtures based on fluoronitriles or even just clean air? Ask for case studies and operational history.

- Global Warming Potential (GWP): Get the numbers. Compare the GWP of their proposed alternative directly against SF6. Today's best options can slash GWP by over 99%.

- Gas Handling: What’s the real story on handling and recycling the new gas? What special equipment or training is needed for installation and eventual decommissioning?

Opting for an SF6-free solution today is a smart move. It effectively de-risks your investment against future carbon taxes or outright bans, protecting your asset for the long haul.

GIS Specification Checklist

To make sure you cover all your bases, a detailed checklist is your best friend. It transforms your requirements from a simple list into a robust specification that suppliers can quote against accurately. Here’s a practical template to get you started.

| Parameter | Key Considerations | Example Specification |

|---|---|---|

| Voltage & Current | System voltage, frequency, continuous current needs, and short-circuit withstand for 1s or 3s. | Rated Voltage: 145 kV; Rated Current: 2500 A; Short-Circuit: 40 kA for 3s. |

| Insulation Level (BIL) | Must withstand lightning and switching surges common to your grid environment. | Lightning Impulse (BIL): 650 kVp. |

| Insulating Medium | Is SF6 acceptable, or is an SF6-free alternative required? Consider GWP, handling procedures, and long-term viability. | Gas mixture with GWP < 1. Supplier to provide gas handling and lifecycle plan. |

| Footprint & Layout | Maximum allowable dimensions (L x W x H). Access requirements for installation and maintenance. Indoor or outdoor placement? | Indoor installation; Max footprint: 15m x 5m x 4m (L x W x H). |

| Configuration | Single busbar, double busbar? Number of incoming and outgoing feeder bays required. | Single busbar configuration; 2x Incoming Lines, 4x Transformer Feeders. |

| Maintenance Philosophy | Define expected maintenance intervals. Are sealed-for-life components a priority? | Minimal maintenance required; major inspection interval > 20 years. |

| Ambient Conditions | Operating temperature range, altitude, and seismic requirements for the installation site. | Temperature: -5°C to +40°C; Altitude: < 1000m; Seismic Zone 3 compliant. |

| Standards & Testing | Specify compliance with IEC or ANSI/IEEE standards. Mandate a full Factory Acceptance Test (FAT). | Compliance with IEC 62271-203. FAT to be witnessed by owner's engineer. |

Using a structured checklist like this ensures nothing falls through the cracks and you get a GIS that’s perfectly suited for the job.

Looking Beyond the Price Tag to Total Cost

One of the biggest mistakes you can make is choosing a GIS based on the initial price tag alone. You have to think bigger. A true evaluation looks at the Total Cost of Ownership (TCO), and this is where GIS often shines, even if the upfront cost is higher.

Why? The incredibly compact footprint.

The decision to use GIS can reduce land acquisition or building construction costs so drastically that it more than offsets the higher equipment price. For urban projects or plant expansions, this factor alone can make GIS the most economically viable choice.

When you run the numbers for TCO, be sure to include:

- Land and Civil Works: The smaller footprint means a smaller bill for real estate and construction. It’s that simple.

- Installation and Commissioning: GIS modules are typically assembled and tested in the factory, which dramatically cuts down on the time and complexity of on-site work.

- Maintenance Costs: The sealed-for-life design means far less maintenance. That translates to lower labor costs and less planned downtime over a 30-40 year service life.

Ensuring Compliance and Quality

Finally, you need to be uncompromising on quality assurance. Your GIS is a linchpin of your electrical system, and its reliability hinges on strict adherence to international standards and rigorous testing. Don't be shy about making demands.

Before you sign any contract, get clear, written answers to these questions:

- Standards Compliance: Does the equipment fully comply with the relevant IEC or ANSI/IEEE standards for design, manufacturing, and testing? Ask for the specific standard numbers.

- Factory Acceptance Testing (FAT): A comprehensive FAT is non-negotiable. It's your chance to verify the equipment performs as promised before it ever leaves the factory. To get a better handle on this, check out our guide on what a factory acceptance test checklist should cover.

- Commissioning Support: What level of hands-on support will the supplier provide on-site? This includes installation supervision, gas filling, and the final commissioning tests to bring the system online.

By following this structured path—nailing down your technical needs, weighing the new gas alternatives, analyzing the total cost, and demanding tough quality checks—you can confidently choose a GIS that will deliver safety, reliability, and value for decades to come.

Getting GIS Installation and Maintenance Right

A gas-insulated switchgear system is built to last, often designed for a service life of 30 to 40 years. But getting there isn't a given. That kind of longevity depends entirely on a flawless installation and a smart, forward-thinking maintenance plan. This is the stage where your investment’s long-term reliability is truly locked in.

The initial setup is, without a doubt, the most critical phase in a GIS's entire life. Unlike its air-insulated cousins that are more forgiving, a GIS demands precision and a controlled environment. Any shortcut or mistake made here can plant a hidden problem that might not show itself for years.

Executing a Flawless GIS Installation

Putting together a GIS is less like construction and more like performing surgery. The whole point is to assemble the factory-built modules while keeping the insides completely pristine—free of any contaminants that could weaken the insulating gas.

A clean, dry, and controlled setting is non-negotiable. Dust, moisture, or even tiny metallic shavings can cripple the dielectric strength of the SF6 gas. That’s why the assembly is often done inside temporary clean rooms or under positive-pressure tents right on the construction site.

The integrity of a GIS is established the moment its compartments are sealed. A single foreign particle or a trace of moisture introduced during assembly can become a nucleation point for partial discharge, slowly degrading the insulation and leading to a potential failure down the road.

Beyond the environment, the people doing the work are just as crucial. Handling the gas—filling the compartments with SF6 or an alternative—is a job for certified technicians. They use specialized gear to make sure the gas is at the perfect density and purity, because even small deviations can throw off performance. This is the kind of precision that separates a world-class installation from a future headache.

Pre-Commissioning Tests: The Final Gatekeeper

Before a new GIS system ever sees a live current, it has to pass a tough battery of pre-commissioning tests. Think of these as the final quality check, proving that the on-site assembly went perfectly and the gear is ready to do its job.

Here are the must-pass checks:

- High-Voltage Withstand Test: This is where we apply a high voltage for a specific time to make sure the insulation system is solid and that no hidden defects from shipping or assembly exist.

- Gas Quality and Leak Checks: Technicians verify the purity and moisture content of the gas. They also run highly sensitive leak detection tests on every flange and joint to ensure the system is sealed tight, targeting leakage rates below 0.1% per year.

- Operational Checks: Every moving part—circuit breakers, disconnectors, earthing switches—is operated multiple times. This confirms they all move smoothly and within the manufacturer's specified timings.

Long-Term Care: What "Maintenance-Free" Really Means

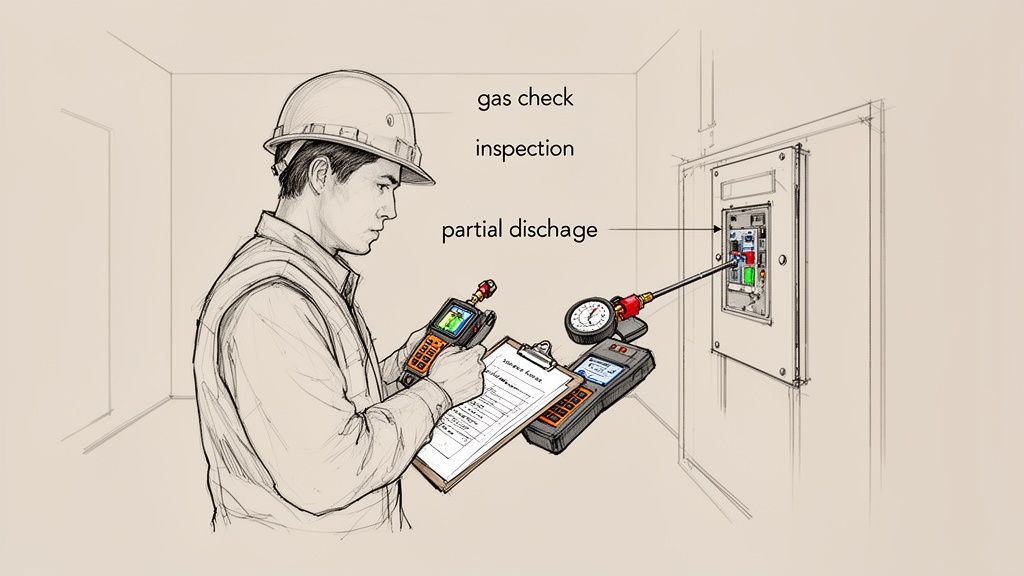

You’ll often hear GIS described as "maintenance-free," but that term can be a bit misleading. It doesn’t mean you can just install it and walk away. What it really means is that GIS requires far less invasive maintenance than air-insulated switchgear. The focus shifts from constant cleaning and parts replacement to smart, non-invasive monitoring.

Routine care for a GIS comes down to a few key activities. The most basic is keeping a close eye on the gas density. Modern systems have sensors that constantly track the temperature-compensated pressure, giving you an early warning if a leak develops.

Periodic visual inspections are also essential. A simple walk-through can catch a lot—signs of corrosion on the enclosure, checking that control circuits are in good shape, and making sure all monitoring gauges are working properly.

Advanced diagnostics are where modern GIS care really shines. Techniques like Partial Discharge (PD) monitoring can detect tiny electrical sparks inside the insulation, which are often the very first sign of a developing fault. Similarly, acoustic monitoring can pick up on unusual mechanical vibrations from moving components. This condition-based approach means you schedule work when it's actually needed, not just because the calendar says so, maximizing uptime and helping your GIS deliver reliable power for decades.

Common Questions About Gas Insulated Switchgear

As gas insulated switchgear starts showing up more and more in critical power systems, it’s only natural for engineers, project managers, and facility owners to have questions. This technology is a different beast compared to traditional switchgear, and getting a handle on the specifics is key to making the right call.

We’ve rounded up some of the most common questions we hear about GIS. The goal here is to give you clear, straightforward answers that cut through the jargon and build on what we've already covered.

What Is the Primary Difference Between GIS and AIS?

It all comes down to the insulating medium. Think of it like this: traditional Air Insulated Switchgear (AIS) uses the air in the room to keep high-voltage components from arcing over. Since air isn't a fantastic insulator, you need a lot of space—big physical gaps between conductors. This is why AIS lineups are so massive.

Gas Insulated Switchgear (GIS), on the other hand, puts all its live components inside a sealed, grounded metal enclosure filled with a special insulating gas. This gas is a powerhouse insulator, with a much higher dielectric strength than air. That lets you safely place components incredibly close together.

The result? A GIS assembly can be up to 90% smaller than its air-insulated equivalent. It’s a game-changer for tight spaces like urban substations, crowded industrial plants, or offshore platforms.

Are There Environmental Concerns with the SF6 Gas Used in GIS?

Yes, that’s a fair question and a big topic in the industry. The gas traditionally used, Sulfur Hexafluoride (SF6), is an extremely potent greenhouse gas. To put it in perspective, its global warming potential (GWP) is about 24,300 times higher than carbon dioxide.

But it’s important to see the whole picture. Modern GIS units are built as sealed-for-life systems. They come with factory-guaranteed leakage rates that are incredibly low—typically less than 0.1% per year. The industry is also heavily regulated on how to handle, recycle, and dispose of SF6 to keep it out of the atmosphere.

The real story, though, is the rapid shift toward SF6-free alternatives. These "green" gases deliver the same great insulating performance but slash the global warming potential by over 99%. This move essentially neutralizes the long-term environmental footprint for new GIS installations.

This isn't just a voluntary trend; it's becoming law. The EU, for instance, is set to phase out SF6 in most new medium-voltage switchgear as early as 2026.

Is GIS More Expensive Than Traditional Switchgear?

If you only look at the initial price tag, yes, GIS equipment usually has a higher upfront cost than comparable AIS. But that's a very narrow way to look at it. A smart financial analysis always considers the total cost of ownership (TCO).

Over its lifespan, GIS often works out to be the more economical choice. The massive reduction in footprint alone can save a fortune in land or building costs, especially in pricey urban areas where every square foot counts.

On top of that, GIS is practically maintenance-free. With all the critical parts sealed away from dust, moisture, and corrosive air, you get some major long-term benefits:

- Lower operational and labor costs

- Far less planned downtime for cleaning and upkeep

- A longer, more reliable service life, often 30-40 years

When you run the numbers on all these factors, the GIS investment looks much more attractive and frequently beats the lower sticker price of AIS in the long run.

What Are the Typical Applications for Gas Insulated Switchgear?

GIS is incredibly versatile, but it really shines in places where space is tight, reliability is an absolute must, or the environment is just plain nasty.

Its tough, compact design makes it the go-to solution for a huge range of critical infrastructure.

You’ll find it in:

- Urban Power Substations: Perfect for tucking into buildings or even underground where real estate is scarce.

- Power Generation Plants: Including wind and solar farms where a small, reliable footprint is essential.

- Heavy Industrial Facilities: Think manufacturing plants, oil and gas rigs, and mines where dust, chemicals, and moisture would destroy conventional gear.

- Data Centers: Where an uninterruptible power supply is the lifeblood of the business.

- Transportation Infrastructure: Used extensively in railway systems and airports that can't afford downtime.

The plug-and-play, modular nature of GIS also makes it ideal for prefabricated e-houses and mobile substations that need to be deployed and energized fast.

Navigating the complexities of modern electrical systems requires a partner with deep expertise. At E & I Sales, we specialize in designing and integrating reliable power distribution and motor control solutions, from MV switchgear to custom UL control panels. If you're planning a project that demands performance and efficiency, our team has the field experience to deliver a solution that meets your exact specifications.