A Factory Acceptance Test (FAT) is more than just a final hurdle before shipment; it's a critical project milestone that validates equipment performance, ensures safety, and prevents costly on-site failures. For electric motor distributors, UL control packagers, and system integrators, a robust FAT process is the bedrock of project success and client trust. However, a generic, tick-box approach often misses subtle but critical issues that can lead to significant downtime and budget overruns later. This guide moves beyond the basics, offering a detailed, actionable factory acceptance test checklist designed specifically for the complexities of integrated electrical and mechanical systems.

We will break down the eight essential verification stages, from functional performance to documentation review, providing practical templates and expert insights to ensure your equipment is not just built correctly, but is ready to perform reliably from day one. By adopting this comprehensive approach, you can transform your FAT from a simple inspection into a powerful risk mitigation tool that guarantees quality and builds lasting customer confidence. The principles of meticulous, stage-by-stage verification are universal, much like how a detailed construction quality control checklist ensures structural integrity long before a project is completed.

We'll explore how to streamline this process, ensuring every component, from electric motors to custom UL control panels, meets the highest standards of performance and safety before it ever leaves the factory floor. This comprehensive checklist provides the framework to catch discrepancies early, verify specifications meticulously, and deliver a system that integrates seamlessly upon arrival.

1. Functional Performance Verification

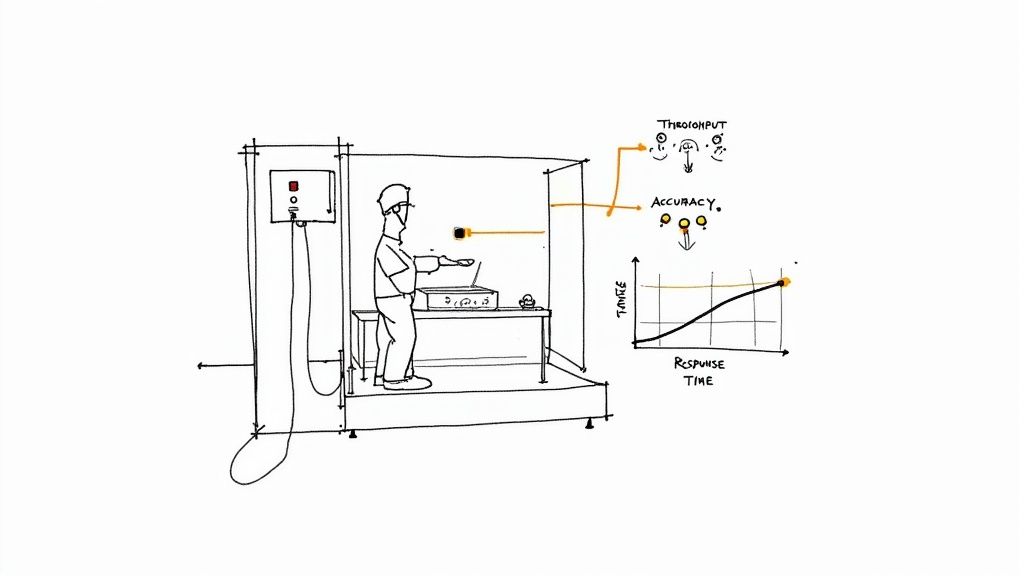

Functional Performance Verification is the cornerstone of any robust factory acceptance test (FAT). This phase moves beyond static checks and component-level inspections to actively test the entire system's operational capabilities. It is a systematic process designed to confirm that the assembled equipment performs its intended tasks according to the precise design specifications, engineering drawings, and customer requirements. This involves running the machine through its operational sequences to validate performance metrics like speed, throughput, accuracy, and cycle times.

The primary goal is to simulate real-world production scenarios in a controlled factory environment. By doing this, you can identify and rectify any performance-related issues before the equipment is shipped and installed at the final site, preventing costly delays and complex on-site troubleshooting.

Real-World Application Examples

- Pharmaceutical Manufacturing: A tablet press is tested to confirm it can produce a specified number of tablets per minute while maintaining consistent weight and hardness, meeting stringent regulatory standards.

- Automotive Assembly: A robotic welding arm is run through its complete cycle to verify it can perform all welds within the required cycle time and to the exact positional accuracy needed for vehicle frame integrity.

- Food Processing: A bottling line's performance is verified by running it at maximum speed to ensure it can fill, cap, and label a target number of bottles per hour without errors or product spillage. This often involves testing components like the variable speed drives controlling conveyor motors to ensure they ramp up and down correctly.

Actionable Tips for Implementation

To ensure this verification is thorough and effective, follow a structured approach. A well-executed functional test on your factory acceptance test checklist provides concrete evidence that the equipment is ready for deployment.

- Develop Detailed Test Protocols: Before the FAT begins, create a comprehensive test script that outlines each specific function to be tested, the expected outcome, and the pass/fail criteria.

- Test Beyond Nominal Conditions: Don't just test at the standard operating speed. Run the equipment at minimum, maximum, and various intermediate speeds and loads to understand its full operational range and identify potential stress points.

- Conduct Endurance Runs: Operate the equipment for an extended, continuous period (e.g., 4-8 hours) to check for thermal stability, performance degradation, or intermittent faults that may not appear during short tests.

- Maintain Meticulous Records: Document every test result with timestamps, the name of the technician performing the test, and the specific serial numbers of the calibrated instruments used for measurement. This creates an auditable trail of performance.

2. Safety Systems and Interlock Testing

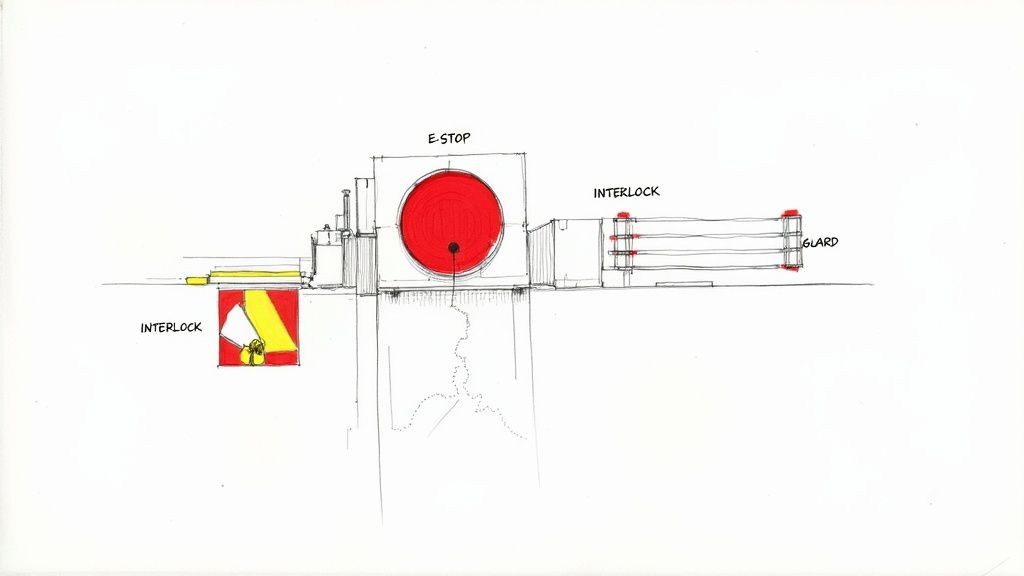

Verifying the safety systems and interlocks is a non-negotiable part of any factory acceptance test (FAT). This critical phase goes beyond basic operation to ensure that all protective mechanisms are fully functional and capable of safeguarding personnel and equipment from harm. It involves a systematic check of emergency stops, light curtains, safety gates, mechanical guards, and all logic-based interlocks that prevent hazardous machine states. This process confirms that the equipment meets all specified safety standards and regulatory requirements before it leaves the controlled factory environment.

The primary goal is to simulate fault conditions and user errors to prove that the safety systems respond correctly and predictably. Rigorously testing these features during the FAT is essential for preventing workplace accidents, ensuring compliance, and avoiding significant liabilities and operational shutdowns once the equipment is commissioned on-site.

Real-World Application Examples

- Automotive Assembly: On a large stamping press, the test involves activating the light curtain with an object to confirm the press immediately halts its stroke, preventing potential crush injuries.

- Pharmaceutical Manufacturing: A high-speed centrifuge's lid interlock is tested to ensure the motor cannot start while the lid is open and that the lid remains locked until the rotor has completely stopped spinning, preventing operator exposure to high-speed components. Proper motor protection protocols are integral to these safety mechanisms.

- Industrial Robotics: A robotic cell's safety fence interlock is tested by opening the access gate during operation. The test verifies that the robot arm immediately enters a safe-stop condition and that all associated machinery, like conveyors, also ceases movement.

Actionable Tips for Implementation

To conduct a thorough and compliant safety system verification, a structured and documented approach is essential. A successful safety check on your factory acceptance test checklist provides undeniable proof that the equipment is safe for operation.

- Create a Hazard Analysis Matrix: Before testing, develop a matrix that identifies every potential hazard and the corresponding safety function designed to mitigate it. Use this as the foundation for your test plan. Before designing functional and safety tests for your factory acceptance checklist, it's crucial to consult a plant risk assessment guide to ensure all potential dangers are identified.

- Test Each Safety Device Individually: Actuate every emergency stop button, open every interlocked guard, and interrupt every light curtain to verify it sends the correct stop signal to the control system.

- Verify System Response: Don't just confirm a signal is sent; document that the equipment responds appropriately. Measure the time it takes for the machine to reach a safe state (e.g., stopping motion) and ensure it meets the required performance level (PL) or safety integrity level (SIL).

- Simulate Fault Conditions: Where possible, simulate failures like a short circuit or a loss of power to a safety device to confirm the system defaults to a safe state as designed. This is a key principle of robust safety engineering.

3. Dimensional and Tolerances Inspection

Dimensional and Tolerances Inspection is a critical, detail-oriented phase of the factory acceptance test (FAT) focused on physical verification. This process involves the meticulous measurement of the equipment's critical dimensions, geometric tolerances, and overall assembly to confirm it has been manufactured precisely according to the approved engineering drawings and design specifications. It ensures that all individual components and the final assembly adhere to the strict physical constraints required for proper fit, function, and long-term reliability.

This inspection uses precision, calibrated instruments to measure attributes like length, width, height, angles, flatness, and parallelism. The core objective is to identify any manufacturing deviations or fabrication errors before the equipment leaves the facility. Catching a dimensional discrepancy at the FAT stage is far more efficient and cost-effective than discovering that a multi-ton piece of equipment will not fit through a doorway or align with existing infrastructure during on-site installation.

Real-World Application Examples

- CNC Machine Tools: Technicians use laser interferometers and precision dial indicators to measure spindle runout and axis alignment, ensuring the machine can achieve the sub-micron accuracy required for high-precision machining.

- Pharmaceutical Equipment: The die cavities on a tablet press are measured with a coordinate measuring machine (CMM) to verify they are within the tight tolerance band necessary for producing tablets of consistent weight and dosage.

- Automotive Castings: An engine block casting undergoes a detailed dimensional verification using 3D scanners to ensure all mounting points, cylinder bores, and fluid passages are located exactly as specified in the CAD model.

Actionable Tips for Implementation

A successful dimensional check on your factory acceptance test checklist provides undeniable proof that the equipment is physically built to specification. To execute this properly, a systematic and precise methodology is non-negotiable.

- Use Calibrated Precision Instruments: Ensure all measurement tools, such as micrometers, calipers, height gauges, and CMMs, are properly calibrated with traceability to recognized standards.

- Create Highlighted Inspection Drawings: Prior to the FAT, mark up a set of drawings that clearly identifies all critical dimensions and geometric tolerances that must be verified. This becomes the inspector's roadmap.

- Measure at Multiple Data Points: For critical surfaces or alignments, take measurements at several different locations to verify consistency and check for issues like warping or tapering that a single-point check might miss.

- Establish Acceptance Criteria First: Define the acceptable pass/fail tolerance range for each measurement before the inspection begins. This removes ambiguity and subjectivity from the evaluation process.

4. Electrical Systems and Control Integration Testing

Electrical Systems and Control Integration Testing is a critical phase in a factory acceptance test checklist, focusing on the safety, integrity, and functionality of the entire electrical and control architecture. This step verifies that all wiring, power distribution, control panels, programmable logic controllers (PLCs), and human-machine interfaces (HMIs) are installed correctly, operate safely, and communicate seamlessly as an integrated system. It ensures the equipment is not only mechanically sound but also electrically safe and intelligent.

The process involves a series of systematic checks, from basic continuity and voltage tests to complex PLC logic and communication protocol validation. The primary goal is to confirm that the electrical system can reliably power and control the equipment according to design specifications while adhering to mandatory safety standards like the National Electrical Code (NEC). This verification prevents catastrophic failures, protects personnel from electrical hazards, and ensures the machine's control logic performs flawlessly before it arrives on-site.

Real-World Application Examples

- Industrial PLC Program Simulation: Before energizing a large conveyor system, its PLC logic is run in a simulation mode. This allows engineers to test the entire operational sequence, including start-up, shutdown, and fault conditions, without any physical movement, preventing potential crashes.

- Three-Phase Motor and VFD Testing: The control panel for a large pump system is tested by verifying the correct voltage and phasing for its motor. The Variable Frequency Drive (VFD) is then commanded through the HMI to confirm it can accurately control motor speed, acceleration, and deceleration.

- SCADA System Integration: For a water treatment plant, the FAT includes testing the communication link between the local control panel and the central SCADA system. Technicians verify that all data points, such as tank levels and flow rates, are transmitted accurately and that remote commands are executed correctly.

Actionable Tips for Implementation

A methodical approach to electrical testing is non-negotiable for a successful FAT. It provides irrefutable proof that the system is electrically robust and ready for integration.

- Use Lock-Out/Tag-Out (LOTO) Procedures: Always implement strict LOTO procedures when technicians are physically inspecting wiring or making connections. Safety is the absolute priority during any hands-on electrical verification.

- Verify All Work Meets NEC Standards: Inspect panel wiring, grounding, wire sizing, and overcurrent protection to confirm full compliance with the NEC and any other applicable local or international standards. Proper industrial control panel design is fundamental to passing this check.

- Test Logic Before Energizing: Run the control logic in a simulation or "dry run" mode first. This allows you to identify and correct programming errors in a safe, controlled environment before powering up motors and actuators.

- Document All Electrical Schematics: Ensure that the as-built electrical drawings are a perfect match for the final physical wiring. Mark up any field changes directly on the schematics during the FAT and ensure a final, updated version is included in the documentation package.

5. Hygienic Design and Cleanability Verification

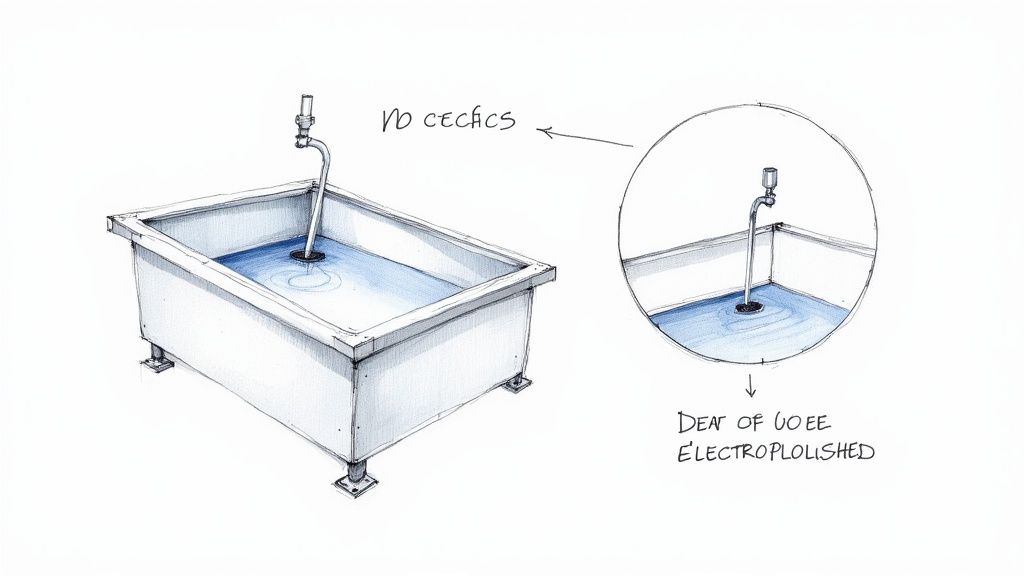

For industries like food, pharmaceuticals, and biotechnology, hygienic design and cleanability verification is a non-negotiable component of a factory acceptance test checklist. This phase goes beyond mechanical function to critically assess whether the equipment's design prevents product contamination and facilitates effective, repeatable cleaning and sanitization. The inspection focuses on material suitability, surface finishes, component geometry, and accessibility to ensure the equipment meets stringent regulatory and quality standards.

The core purpose is to confirm the equipment is free from crevices, dead legs, and other design flaws where microorganisms or product residue could accumulate. Verifying cleanability at the factory prevents catastrophic contamination events, costly recalls, and extensive downtime for deep cleaning or redesign once the equipment is installed in a cleanroom or production environment.

Real-World Application Examples

- Pharmaceutical Manufacturing: A new tablet press undergoes verification to ensure all product-contact surfaces are electropolished to the specified Ra value (surface roughness) and that it can be fully disassembled for cleaning without specialized tools, preventing cross-contamination between batches.

- Dairy Processing: The Clean-in-Place (CIP) system for a pasteurization skid is tested to validate that flow rates and spray ball coverage are sufficient to clean all internal surfaces, including welds and gaskets, as confirmed by post-rinse riboflavin tests.

- Biotechnology: A bioreactor's design is inspected to ensure all interior welds are smooth and flush, there are no dead-end ports, and the vessel drains completely to prevent microbial growth and ensure product purity.

Actionable Tips for Implementation

A systematic approach is essential to confirm that the equipment's design is inherently hygienic and simple to clean. Rigorous verification at this stage provides the confidence needed for GMP (Good Manufacturing Practices) compliance.

- Reference Design Standards: Benchmark the equipment design against established guidelines, such as those from 3-A Sanitary Standards, EHEDG (European Hygienic Engineering & Design Group), or FDA guidance documents on hygienic design.

- Verify Material Certifications: Scrutinize all material certificates of conformance (CoC) for product-contact parts, confirming they are the specified grade (e.g., 316L stainless steel) and meet requirements for biocompatibility or food safety.

- Conduct Cleaning Validation Trials: Use the customer’s actual cleaning agents and protocols to perform a test cleaning cycle. Afterward, conduct ATP (adenosine triphosphate) swab testing in hard-to-reach areas to scientifically measure residual organic matter and verify cleaning effectiveness.

- Document Visual and Physical Inspections: Meticulously inspect and photograph all welds, gaskets, seals, and drain points. Verify that surfaces are self-draining and free of pits, cracks, or crevices where contaminants could harbor. Involve the end-user's quality and microbiology teams in this verification process.

6. Documentation Review and Traceability Verification

Documentation Review and Traceability Verification is a critical administrative checkpoint within the factory acceptance test (FAT). This process involves a systematic audit of all project-related documents to ensure they are complete, accurate, and correspond directly to the equipment being tested. It serves as the official record, confirming that what was specified is precisely what has been built, using the correct materials and approved components. This step verifies everything from high-level assembly drawings and schematics to granular details like material certificates and component manuals.

The primary goal is to establish a clear, auditable trail from the initial design specifications to the final physical asset. Proper documentation is essential for future operation, maintenance, and regulatory compliance. Catching discrepancies at this stage prevents major issues down the line, such as using incorrect spare parts, failing a compliance audit, or being unable to troubleshoot the equipment effectively once it is installed on-site.

Real-World Application Examples

- Pharmaceutical Manufacturing: An inspector verifies that the material certificates of conformance (COCs) for all product-contact surfaces (e.g., stainless steel piping) match the specified grade (e.g., 316L) to meet FDA and GMP standards for cleanliness and non-reactivity.

- UL Control Panel Shop: During the FAT for a custom control panel, the inspector cross-references the electrical schematic's revision level with the as-built panel to confirm all wire gauges, breaker sizes, and component part numbers match the approved UL 508A design.

- Aerospace Component Production: The traceability of a critical fastener is verified by checking its batch code against procurement records and material certificates to ensure it meets the required tensile strength and fatigue life specifications.

Actionable Tips for Implementation

A thorough documentation review on your factory acceptance test checklist ensures the equipment is not only functionally sound but also fully compliant and maintainable. To execute this step effectively, a structured and detail-oriented approach is paramount.

- Develop a Documentation Matrix: Before the FAT, create a checklist or matrix listing every required document (e.g., P&IDs, electrical schematics, operating manuals, spare parts lists, material COCs) and its required revision level.

- Cross-Reference Physical to Paper: During the inspection, physically verify key component nameplates (motors, drives, PLCs) against the bill of materials (BOM) and engineering drawings to ensure a one-to-one match.

- Assign a Dedicated Document Controller: Designate one person with the responsibility for collecting, organizing, and verifying all documentation to avoid confusion and ensure no items are missed.

- Request Digital and Hard Copies: Secure both digital and physical copies of all final, as-built documentation before signing off on the FAT, ensuring long-term accessibility for maintenance and operations teams.

7. Environmental and Utility Compatibility Testing

Environmental and Utility Compatibility Testing is a critical part of the factory acceptance test checklist that verifies the equipment can operate reliably under the specific site conditions it will face. This goes beyond standard performance checks to ensure the system is resilient to variations in its operating environment and compatible with the utilities supplied at the final installation facility. This testing confirms that factors like temperature, humidity, power quality, and compressed air purity will not compromise performance or safety.

The core objective is to challenge the equipment within the specified environmental and utility ranges it will encounter in the real world. By simulating these conditions in a controlled factory setting, you can identify and resolve potential incompatibilities or weaknesses before shipment, preventing costly on-site modifications, performance degradation, and unexpected downtime. It ensures the machine is not just functional but also robust enough for its intended home.

Real-World Application Examples

- Semiconductor Manufacturing: A sensitive deposition tool is tested in a chamber that mimics the target cleanroom's stringent temperature and humidity specifications to ensure process stability and prevent wafer defects.

- Pharmaceutical Production: Equipment destined for a facility at a high altitude is operated in a reduced atmospheric pressure chamber during the FAT to confirm that motors, seals, and pneumatic systems function correctly without overheating or leaking.

- Data Center Cooling: A rack cooling unit is run in an environmental test chamber at its maximum rated ambient temperature and humidity to verify it can maintain the required thermal management performance under worst-case heat load conditions.

- Food and Beverage: A pneumatic valve system for a bottling plant is tested with compressed air at the lower end of the plant's specified pressure and dew point range to ensure it actuates reliably without sticking or malfunctioning.

Actionable Tips for Implementation

A systematic approach to this testing is essential for confirming that the equipment will integrate seamlessly into the production environment. Properly executed utility and environmental checks provide confidence that the system is truly ready for its final destination.

- Obtain Detailed Site Specifications: Before the FAT, request and review the customer's site utility specifications for electrical power (voltage, frequency, phase stability), compressed air (pressure, purity, flow), and water (pressure, temperature, quality).

- Test at Environmental Extremes: Don't just test at nominal conditions. If possible, perform cold-start tests and operate the equipment at the upper and lower limits of its specified temperature and humidity range to identify potential failure points.

- Analyze Power Quality: Use a portable power quality analyzer to monitor voltage, current, and harmonics during testing. This is especially important for systems with sensitive electronics or large variable frequency drives that can be affected by power fluctuations.

- Document Utility Consumption: Measure and record the equipment's actual consumption of electricity (kW), water (GPM), and compressed air (CFM) at various operating loads. This data is vital for facility planning and utility capacity verification.

8. Vibration, Noise, and Structural Integrity Assessment

A comprehensive Vibration, Noise, and Structural Integrity Assessment is a critical, yet often overlooked, component of a factory acceptance test (FAT). This stage evaluates the dynamic behavior of the equipment under operational stress, ensuring it runs smoothly, quietly, and safely. The process involves measuring vibration levels, acoustic emissions, and meticulously inspecting the physical structure to confirm it can withstand operational forces without deformation, cracking, or component failure.

This assessment is vital for predicting the long-term reliability and safety of the equipment. Excessive vibration can lead to premature wear of bearings, motors, and other mechanical parts, while high noise levels can violate workplace safety regulations. A thorough structural check confirms that welds, fasteners, and frame components are sound, preventing catastrophic failures once the equipment is in production.

Real-World Application Examples

- Industrial Pump Systems: A large centrifugal pump undergoes acoustic analysis to detect cavitation, a destructive phenomenon that can quickly erode impellers. Vibration sensors are placed on the motor and pump bearings to ensure readings are within ISO standard limits.

- CNC Machining Centers: A high-speed spindle is tested for runout and vibration. This ensures it can produce parts with the required surface finish and dimensional accuracy without chatter marks or premature tool wear.

- HVAC and Blower Units: An industrial air handling unit is run at various fan speeds to verify that its vibration isolation mounts are effective and that the noise generated does not exceed the levels specified for the installation environment.

Actionable Tips for Implementation

To properly execute this part of your factory acceptance test checklist, you need a combination of specialized tools and systematic inspection procedures. These steps will help you gather objective data to validate the equipment's mechanical and structural soundness.

- Establish Baseline Signatures: Use a portable vibration analyzer to record the equipment's initial vibration signature across various speeds and loads. This baseline is invaluable for future predictive maintenance and troubleshooting.

- Conduct Multi-Point, Multi-Load Testing: Do not limit testing to a single operating point. Measure vibration and noise at minimum, nominal, and maximum speeds to identify any resonant frequencies or load-dependent issues.

- Perform Thorough Structural Inspections: Visually inspect all structural welds for quality and completeness. For critical joints, consider using non-destructive methods like liquid penetrant testing to identify surface-breaking defects.

- Document and Compare to Standards: Record all measurements meticulously, noting the location, operational speed, and instrument used. Compare these findings against recognized industry standards (e.g., ISO 10816 for vibration) or the project's specific acceptance criteria to make a clear pass/fail determination.

8-Point Factory Acceptance Test Comparison

| Test | Complexity 🔄 | Resources ⚡ | Expected outcomes ⭐📊 | Ideal use cases | Key advantages 💡 |

|---|---|---|---|---|---|

| Functional Performance Verification | Medium–High — systematic, time-consuming procedures | High — skilled technicians, test rigs, extended runtime | Confirms throughput, accuracy, response times; baseline performance data | Production machinery, semiconductor tools, assembly lines, food equipment | Identifies defects pre-shipment; reduces field failures; documented performance |

| Safety Systems and Interlock Testing | High — requires safety engineering and controlled tests | High — safety engineers, specialized fixtures, possible hazardous setups | Verified emergency stops, interlocks and shutdown behavior; regulatory evidence | Presses, robots, chemical plants, containment systems | Prevents injuries; ensures compliance; lowers liability |

| Dimensional and Tolerances Inspection | Medium — precision, detail-oriented measurements | Medium–High — calibrated gauges, metrologists, lab time | Confirms geometric conformance, fit and alignment; traceable measurement records | CNC tools, dies/cavities, castings, cleanroom equipment | Prevents assembly issues; ensures interchangeability; quality validation |

| Electrical Systems and Control Integration Testing | High — complex logic and safety-critical checks | High — licensed electricians, analyzers, PLC/HMI simulation tools | Validates electrical safety, control logic, communication and power quality | PLC systems, VFDs, SCADA, industrial control panels | Prevents electrical hazards; validates automation; finds wiring/design issues |

| Hygienic Design and Cleanability Verification | Medium–High — domain-specific and validation-heavy | Medium — microbiology/quality teams, CIP rigs, sampling kits | Confirms cleanability, material compatibility, eliminated dead legs | Pharma, food, biotech tanks, CIP systems | Prevents contamination/recalls; meets sanitary regulations |

| Documentation Review and Traceability Verification | Medium — detailed administrative verification | Low–Medium — document control resources, checklists | Complete traceability, accurate manuals and spare parts lists | Regulated purchases, long-life assets, audit-prep equipment | Prevents spec disputes; supports maintenance and compliance |

| Environmental and Utility Compatibility Testing | Medium — may need environmental simulation | Medium — utility hookups, chambers, power/flow analyzers | Validates operation across temp/humidity/power/water/air conditions | Semiconductor fabs, high-altitude sites, data centers, sterilizers | Prevents field incompatibility; defines infrastructure needs |

| Vibration, Noise, and Structural Integrity Assessment | Medium–High — analysis and inspection required | Medium–High — vibration analyzers, acoustic meters, specialists | Measures vibration/noise levels; detects structural defects and looseness | Rotating machinery, centrifuges, pumps, CNC spindles, HVAC | Early defect detection; ensures noise/vibration compliance |

From Checklist to Commissioning: Ensuring a Seamless Handover

The journey from a detailed equipment specification to a fully operational system is complex, but a comprehensive Factory Acceptance Test (FAT) serves as the most critical bridge between design and reality. By methodically progressing through a factory acceptance test checklist, you transform a theoretical plan into a verified, tangible asset. The preceding sections have detailed the essential checkpoints, from meticulous functional performance and safety system verification to in-depth electrical integration testing and documentation review. Each item on this checklist is not merely a box to be ticked; it is a strategic risk mitigation tool.

Completing the FAT is a monumental step, but its true value is realized in the weeks that follow. The ultimate goal is not just to pass a test in a controlled environment but to ensure a swift, trouble-free transition to the production floor. A well-executed FAT, guided by a robust checklist, directly translates into a more predictable and efficient Site Acceptance Test (SAT) and final commissioning. Issues discovered and rectified at the manufacturer's facility cost a fraction of what they would on-site, where they can cause significant delays, budget overruns, and operational disruption.

The FAT as a Blueprint for Success

Think of your completed factory acceptance test checklist and its associated report as more than just a historical record. It is an active blueprint for the final stages of your project.

- Punch List Prioritization: The FAT will inevitably uncover minor non-conformances or areas for improvement. Your detailed punch list becomes a clear, actionable roadmap for the manufacturer to resolve these items before shipment, ensuring the equipment arrives on-site in a state of near-perfect readiness.

- SAT Protocol Foundation: The data, test procedures, and performance benchmarks established during the FAT form the direct basis for your SAT protocol. This creates continuity and allows the on-site team to focus on verifying installation, integration with other systems, and performance under actual operating conditions, rather than re-testing basic functionality.

- Training and Familiarization: The FAT provides an unparalleled opportunity for your key operators and maintenance personnel to gain hands-on experience with the new equipment in a safe, controlled setting. This early exposure, guided by the checklist, accelerates their learning curve and builds confidence, ensuring they are prepared to take ownership from day one of commissioning.

Beyond the Checklist: A Mindset of Proactive Verification

Ultimately, mastering the FAT process is about cultivating a mindset of proactive verification. It’s about shifting the focus from reactive problem-solving during startup to proactive issue prevention during assembly. By rigorously validating every aspect of the system, from the dimensional accuracy of a mounting bracket to the logic of a PLC program, you are systematically eliminating uncertainty and de-risking your entire capital project.

The detailed verification of electrical systems, control integration, and safety interlocks is particularly crucial for system integrators and UL control packagers. These are the areas where hidden faults can lead to the most severe safety hazards and operational failures. A thorough factory acceptance test checklist ensures that these complex, interdependent systems are not just functionally correct in isolation but are harmonized to work flawlessly together, meeting all specified performance and safety standards.

Embracing this comprehensive approach guarantees that when the equipment arrives at your facility, it’s not just a collection of assembled parts. It is a proven, validated system ready for seamless integration, poised to deliver the reliability, safety, and performance your operations demand. This diligence transforms the FAT from a simple procedural hurdle into a powerful strategic advantage, paving the way for a successful project launch and long-term operational excellence.

Is your team facing a complex integration project involving custom control panels, motor control centers, or automation systems? Partner with E & I Sales to leverage deep engineering expertise that ensures your Factory Acceptance Test is comprehensive and aligned with real-world operational demands. Visit E & I Sales to see how our solutions can streamline your next project from FAT to final commissioning.