When most people think of "maintenance," they picture a technician with a wrench, fixing something that's already broken. But in the world of industrial operations, that's just a tiny piece of the puzzle. Real engineering maintenance is less about fixing and more about preventing.

More Than Just a Fix-It Crew

Think of it like the pit crew for a Formula 1 car. They aren't just waiting for a tire to blow out. They're constantly monitoring, tweaking, and swapping components to keep that machine screaming around the track at peak performance. That’s the essence of engineering maintenance services. It’s the strategic discipline of keeping your most critical assets—the heart of your operation—running like a Swiss watch.

This is the fundamental shift from a reactive, fire-fighting culture to a proactive, controlled one. Instead of scrambling when a critical motor grinds to a halt and brings your entire production line down, a smart maintenance strategy anticipates the failure before it ever happens. It’s about having experts who understand the intricate language of your machinery, from the subtle vibrations of a generator to the precise calibration of a control panel.

The Real-World Value of Maintenance

Let's be clear: investing in professional engineering maintenance isn't a cost center. It's a direct investment in your company's profitability and resilience. When you have a solid maintenance program in place, you're not just oiling gears; you're protecting your bottom line.

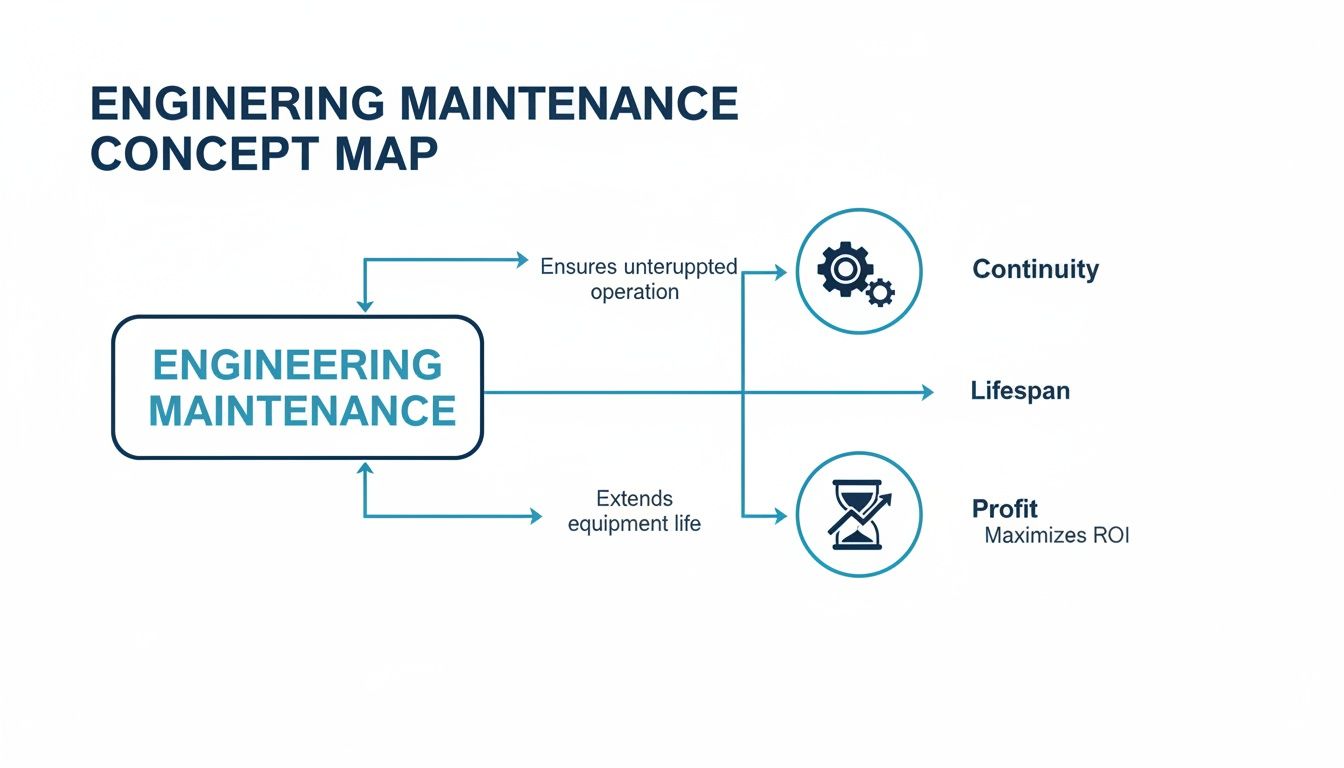

A well-executed strategy directly supports your core business goals:

- Getting More from Your Assets: Expert care stops premature wear and tear in its tracks, squeezing every last drop of productive life out of your expensive equipment.

- Keeping the Lights On: Proactive maintenance is the enemy of unplanned downtime. It keeps your lines running, your orders shipping, and your customers happy.

- Protecting Your Profits: A single catastrophic failure can easily cost millions in lost production, emergency repair bills, and potential safety incidents. Good maintenance is your best insurance policy.

- Keeping Your People Safe: There's no way around it—well-maintained equipment is safer equipment. This protects your team and keeps you on the right side of safety regulations.

This isn't just a niche idea; it's a massive, growing industry. The global maintenance services market is a powerhouse, valued at USD 81.86 billion and on track to hit USD 122.09 billion. That’s a 10.5% compound annual growth rate, driven by a global push for sustainability and the urgent need to keep aging infrastructure online. You can dive deeper into the maintenance services market report on researchandmarkets.com.

From massive manufacturing plants to sprawling energy facilities, every industry relies on these specialists to build a foundation of reliability and safety. This proactive mindset is what makes everything else possible, paving the way for the specific strategies we'll get into next.

The Four Core Maintenance Strategies You Need to Know

When it comes to keeping a facility running, there's no single magic bullet. Effective engineering maintenance isn't about a one-size-fits-all approach; it's about having the right tool for the right job. Think of it like taking care of your car—you don't treat a burnt-out headlight the same way you treat a weird noise coming from the engine.

A smart maintenance program blends different strategies to create a balanced, cost-effective plan that keeps the gears turning. Let's break down the four core approaches every plant manager should understand.

As you can see, the end goal is always the same: keep the operation running, get the most out of your equipment, and protect the bottom line. How we get there is where these strategies come into play.

1. Preventive Maintenance: The Scheduled Checkup

This is the one most people are familiar with. Preventive maintenance (PM) is all about routine, scheduled work designed to catch problems before they become catastrophes. It’s the industrial version of changing your car’s oil every 5,000 miles. You do it based on a calendar or a usage meter, not because something is actually wrong.

The triggers are simple: inspect a motor every quarter, or lubricate a bearing after every 1,000 hours of runtime. While it's a massive leap forward from just waiting for things to break, you do run the risk of performing unnecessary work on perfectly healthy components. A well-organized preventive maintenance schedule template is your best friend here, helping you map out and track every task.

2. Predictive Maintenance: The Smart Warning System

Now we're getting smarter. Predictive maintenance (PdM) is a condition-based strategy that relies on real-time data to tell you when a machine needs attention. Think of it as the check engine light on your dashboard—it warns you about low tire pressure before you end up with a flat on the side of the highway.

Using tools like vibration analysis, thermal imaging, and oil analysis, PdM lets technicians see a failure coming. This allows you to step in at the perfect moment—not too early, not too late. You get to maximize the life of your parts, slash maintenance costs, and dramatically reduce unplanned downtime. This data-driven approach is at the heart of modern engineering maintenance services.

3. Corrective Maintenance: The Necessary Fix

Let's be honest: sometimes, things just break. Corrective maintenance—also known as reactive maintenance—is the straightforward strategy of fixing something once it has failed. While it might sound like a plan for disaster, it actually has a strategic place in any good maintenance program.

You wouldn't schedule preventive maintenance for a lightbulb in the breakroom, would you? You just wait for it to burn out and then replace it. The same logic applies to non-critical, redundant, or low-cost assets where the consequence of failure is minimal. The trick is to apply this "run-to-failure" approach intentionally and not let it become the default for your critical machinery.

4. Shutdown Maintenance: The Planned Overhaul

This is the big one. Shutdown maintenance (or a turnaround) is when you take an entire plant or production line offline for a planned period of intensive, large-scale work. It’s like a full frame-off restoration of a classic car—an all-hands-on-deck effort to inspect, repair, and upgrade everything at once.

This strategy is reserved for complex jobs that are simply impossible to do while the plant is running. It demands military-grade planning and coordination to get everything done efficiently before bringing the whole system back online.

Each of these four strategies plays a crucial role. The best maintenance programs don't just pick one; they artfully combine all four based on equipment criticality, failure patterns, and cost.

Comparing Core Maintenance Strategies

To make it even clearer, here's a side-by-side look at how these four strategies stack up against each other.

| Strategy Type | Trigger | Primary Goal | Example Application |

|---|---|---|---|

| Preventive | Time or Usage Schedule | Prevent failures before they occur | Quarterly inspection of an HVAC unit |

| Predictive | Real-time Condition Data | Intervene just before failure | Analyzing motor vibrations to detect bearing wear |

| Corrective | Equipment Failure | Restore functionality after a breakdown | Replacing a blown fuse on a control panel |

| Shutdown | Pre-planned Outage | Perform major overhauls and upgrades | Relining a blast furnace during a plant turnaround |

As you can see, the trigger for action and the ultimate goal are what really set them apart. By understanding these differences, you can start building a maintenance program that ensures rock-solid reliability without wasting a dime—striking the perfect balance between proactive care and practical reality.

What a Maintenance Partner Actually Covers

So, we've talked strategy. Now, let's get down to the nuts and bolts. When you bring on an engineering maintenance partner, what are they actually doing on your facility floor? This isn't about vague promises; it's about a hands-on partnership designed to protect your most critical assets.

A good service agreement cuts through the fluff and focuses on the specialized electrical and mechanical systems that are the lifeblood of your operation. It’s about having an expert eye on the equipment that, if it goes down, grinds everything to a halt.

Let's pull back the curtain on what's typically covered.

Critical Care for Electric Motors

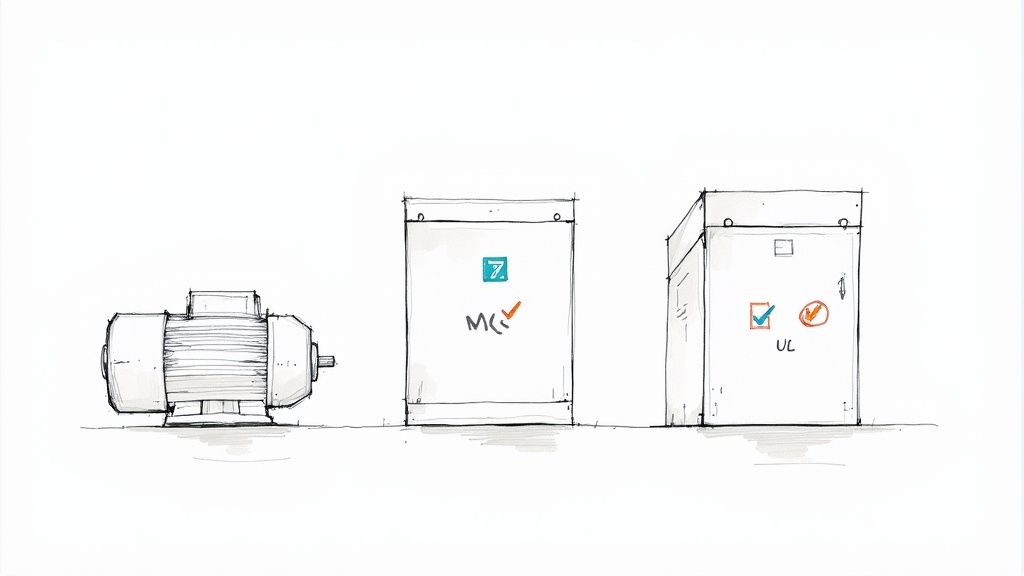

Think of electric motors as the workhorses of your plant. They run tirelessly, and you absolutely can't afford for them to quit. Maintaining them is a specialized craft.

Motor service goes way beyond a quick shot of grease. We're talking detailed inspections and diagnostics to catch things like bearing wear, insulation breakdown, or slight misalignments before they turn into a catastrophic failure that forces a costly rewind or a full replacement.

Servicing Motor Control Centers (MCCs)

If motors are the muscle, the Motor Control Center (MCC) is the brain. This is where you'll find the starters, variable frequency drives (VFDs), and programmable logic controllers (PLCs) that orchestrate your entire process.

An MCC is a dense, complex hub of electrical gear that needs serious attention. Ignoring it is like never checking the main breaker panel in your house—when something goes wrong here, it can take out an entire wing of your facility. That's why proper motor control center maintenance is non-negotiable for operational stability.

A poorly kept MCC isn't just an operational risk; it's a major safety hazard, with the potential for arc flash incidents. Regular service involves torquing connections, detailed cleaning, and using thermal imaging to find hot spots before they erupt.

Maintaining Custom UL Panels

Your custom UL-certified control panels are the bespoke brains behind specific machines or integrated systems. They’re engineered to run everything from complex automation sequences to critical safety interlocks.

Keeping these panels in top shape means ensuring every relay, breaker, terminal block, and power supply is working exactly as it was designed. This isn't just for reliability—it's essential for keeping the panel's UL listing valid, staying compliant, and guaranteeing the safety of the equipment it commands.

Low to Medium Voltage Switchgear Upkeep

Your switchgear is the gatekeeper of your entire electrical system. It's the first line of defense, protecting all your expensive downstream equipment from overloads and short circuits. It is, without a doubt, one of the most critical pieces of infrastructure you own.

A failure here isn't a minor hiccup. It can trigger a plant-wide blackout and create incredibly dangerous arc flash conditions. Professional engineering maintenance services for switchgear are your direct defense against these high-stakes disasters.

A solid switchgear service plan always includes:

- Circuit Breaker Testing: Making sure the breakers will actually trip when they're supposed to.

- Protective Relay Calibration: Verifying the "brains" of the gear are correctly set to spot problems.

- Busbar Inspection and Cleaning: Preventing dangerous flashovers caused by dust, moisture, or loose connections.

These principles of electrical safety and uptime aren't confined to the factory floor. For a different perspective, this complete guide to EV charger servicing applies a similar logic to public infrastructure. In both worlds, the mission is the same: keep it safe, keep it running, and protect the investment. Once you understand what a true maintenance partner covers—from the motor to the main switchgear—you're in a much better position to know what your facility really needs.

How to Measure Maintenance Success and ROI

Spending on engineering maintenance shouldn't feel like a black box. How do you actually prove that the money you're putting in is a strategic investment and not just another line item on an expense report? The answer is simple: you track the right data and connect it directly to your bottom line.

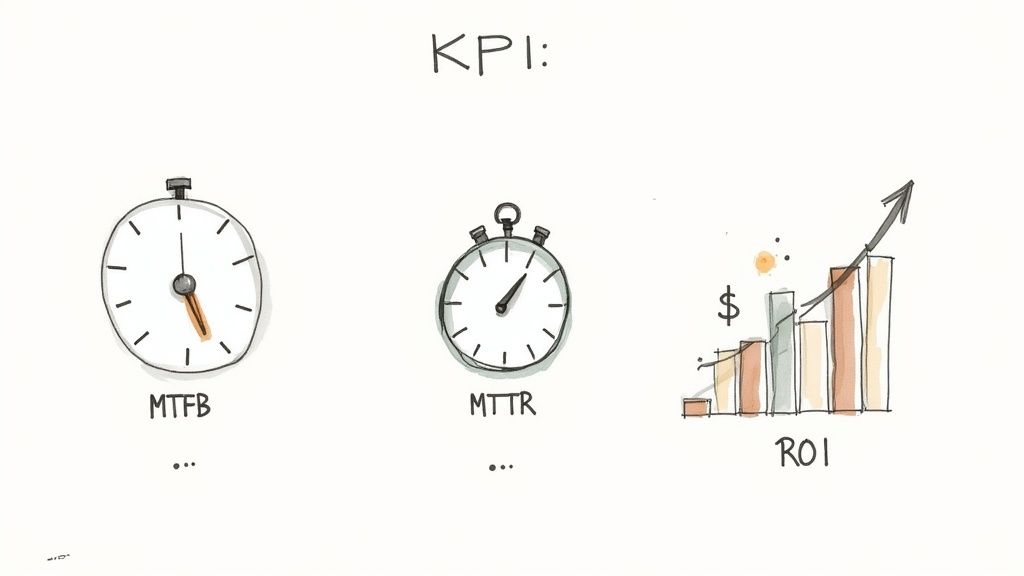

Vague feelings about "things running better" won't convince a CFO. To justify and optimize your maintenance budget, you have to speak the language of numbers. This means adopting Key Performance Indicators (KPIs) that turn maintenance activities into clear, measurable outcomes that directly impact profitability.

It’s this shift in perspective that's crucial for showing real value and securing ongoing support for your maintenance programs.

Key Metrics That Tell the Real Story

You don't need dozens of complex formulas to get started. A handful of core KPIs can give you a powerful snapshot of how effective your maintenance program really is. Think of them as the vital signs for your plant's health.

Two of the most fundamental metrics are:

- Mean Time Between Failures (MTBF): This is the average time a piece of equipment runs smoothly before it breaks down. A higher MTBF is a crystal-clear sign of improved reliability.

- Mean Time To Repair (MTTR): This tracks the average time it takes to get failed equipment back online, from the moment it stops to the moment it's running again. A lower MTTR reflects a more efficient maintenance operation.

Let's put that into perspective. Imagine a critical bottling line conveyor. If its MTBF jumps from 500 hours to 1,500 hours, you’ve just tripled its reliability and slashed production interruptions. If your team also cuts its MTTR from four hours down to one, you're back in business that much faster when a failure does happen.

By focusing on improving just these two numbers, you create a powerful ripple effect. Higher reliability (MTBF) and faster recovery (MTTR) directly translate into more uptime, higher output, and increased revenue.

Calculating the True Return on Investment

Beyond the day-to-day operational metrics, the ultimate measure of success is Return on Investment (ROI). This calculation ties your maintenance spending to tangible financial gains, making the value proposition impossible to ignore.

The ROI formula for maintenance is pretty straightforward:

(Financial Gain from Maintenance – Cost of Maintenance) / Cost of Maintenance

The real trick is accurately calculating the "Financial Gain." This isn’t just about the money you saved on a specific repair; it’s about the massive cost of the downtime you prevented.

Think about this scenario:

- A predictive maintenance program costs you $50,000 for the year.

- This program helps your team spot a failing gearbox on the main production line before it completely seizes up.

- An unexpected failure of that gearbox would have caused 48 hours of downtime, costing $10,000 per hour in lost revenue—that’s a $480,000 loss.

In this case, your $50,000 investment prevented a disaster worth nearly half a million dollars. The ROI is massive, proving that proactive maintenance isn't a cost center; it's a high-yield investment. This financial reality is driving huge growth, with the maintenance and support segment projected to hit USD 753.5 million. In North America, companies are already cutting unplanned downtime by 30-40% by outsourcing maintenance and using predictive analytics. You can dig into more of these engineering services market trends on grandviewresearch.com.

Building a Culture of Measurement

Putting KPIs in place is more than just a technical exercise—it’s a cultural shift. It means getting serious about collecting data consistently, reporting it clearly, and committing to using those insights to get better every day.

Start by getting a baseline for your most critical assets. Once you know where you stand, you can set realistic targets for improvement and track your progress. This data-driven approach is what transforms maintenance from a necessary evil into a strategic driver of operational excellence and, ultimately, profitability.

Choosing the Right Engineering Maintenance Partner

Picking an engineering maintenance services partner is one of the biggest calls an operations manager has to make. This isn't just about getting someone to fix what’s broken. You're building a strategic relationship that has a direct line to your plant's safety, uptime, and bottom line.

The right partner feels like a natural extension of your own team. The wrong one? They can become a constant source of risk, inefficiency, and headaches. You need to look past the price tag and take a methodical approach to find a provider who truly gets your operation and shares your commitment to safety.

Do They Have the Right Kind of Experience?

First things first, your partner needs to have serious technical chops in your specific world. A team that excels in food and beverage processing understands sanitary standards and the relentless pace of production in a way that an oil and gas specialist simply won't.

Don't be shy about asking for proof. Request case studies or, even better, references from companies that look a lot like yours. You're looking for verifiable expertise—certified technicians and engineers who know their way around everything from your medium voltage switchgear to the PLCs running your lines. As facility owners know, a partner who can work with your existing digital tools is a huge plus, which is why integrating BIM for owners in maintenance planning has become such a critical conversation.

Often, the best partners go beyond just repairs. They can act as an effective industrial automation system integrator, helping you find new ways to improve your entire process.

A Rock-Solid Safety Record Isn't Negotiable

In our world, safety is everything. A provider's safety record is a crystal-clear indicator of their discipline and professionalism. It tells you exactly how they’ll operate when they’re on your floor.

Here’s what to look for:

- Experience Modification Rate (EMR): An EMR under 1.0 is the gold standard. It shows they are statistically safer than the industry average.

- OSHA Compliance: Ask them directly about their history of OSHA recordable incidents and the safety programs they have in place.

- Technician Training: How do they train their people? Dig into their safety protocols, certifications, and what they do for ongoing education.

A partner with a stellar safety record isn't just protecting their own crew. They're protecting your people, your equipment, and your business from liability and disaster.

Understanding the Money: Comparing Pricing Models

You need to know how a potential partner bills so you can budget properly and make sure you're getting real value. It usually comes down to two main approaches.

1. Fixed-Fee Contracts

You pay one set price for a clearly defined list of services over an agreed-upon time. This model gives you predictable costs, which is perfect for routine preventive maintenance schedules where there are few surprises.

2. Time-and-Materials (T&M) Contracts

With T&M, you're billed for the actual hours worked plus the cost of any parts or materials used. It’s a flexible model that works well for unpredictable corrective maintenance jobs or special projects where it's tough to nail down the full scope from the start.

The global engineering services market is huge, valued at around $2.0 trillion. This is driven by all sorts of regional needs, like the push in North America for energy-efficient retrofits to cut operational risks. Getting the pricing model right is your first step in tapping into these services effectively.

Your Engineering Maintenance Questions Answered

Diving into industrial upkeep always stirs up a few questions. Picking the right strategy—or the right partner—for your engineering maintenance services is a big deal, and you need straight answers. Let's tackle some of the most common questions we hear from plant managers and engineers to give you that clarity.

What Is the Difference Between Facility Maintenance and Engineering Maintenance?

It’s easy to lump all maintenance into one bucket, but they’re two completely different animals.

Think of it this way: facility maintenance takes care of the building itself. Engineering maintenance takes care of the highly specialized production equipment inside that building.

- Facility Maintenance is all about the building’s core infrastructure. We're talking HVAC repairs, plumbing, lighting, and general structural work needed to keep the place safe and comfortable.

- Engineering Maintenance, on the other hand, is laser-focused on the complex machinery that actually makes your product. This means servicing things like electric motors, custom UL control panels, and medium-voltage switchgear—assets that demand certified engineering know-how to handle safely.

One keeps the roof over your head, and the other keeps your production lines moving.

The distinction is critical. Your facility tech can fix a leaky pipe, but only a qualified maintenance engineer can properly diagnose and service the variable frequency drive running your main conveyor system.

How Can a Small Business Afford Comprehensive Maintenance Services?

If you're running a smaller operation, a full-blown maintenance contract can sound like a budget-buster. But you don't need an all-or-nothing plan to get real results. Smart, targeted strategies make professional maintenance totally accessible.

The best place to start? Identify your most critical assets. Pinpoint the handful of machines that would cause the most financial pain if they went down. From there, you can build a focused preventive maintenance plan just for that high-priority equipment. It's a surgical approach that delivers the most bang for your buck.

Another great option is a retainer-based contract for corrective maintenance. This gives you an expert on-call when you need one most, without the overhead of a full-time, in-house team. It's a model that gives you peace of mind and scales right alongside your business, offering a practical path to better reliability.

What Role Do AI and IoT Play in Modern Maintenance?

This isn't just hype. Artificial Intelligence (AI) and the Internet of Things (IoT) are completely changing the maintenance playbook. They’re helping us shift from being reactive to being predictive, giving teams the power to stop failures before they ever happen. It’s a massive leap forward.

IoT sensors are like a 24/7 health monitor for your equipment. You place them on motors, pumps, and other critical assets, and they constantly collect real-time data on vibration, temperature, and energy use. This firehose of information is where AI steps in.

AI algorithms chew through all that data, spotting subtle patterns a human could never see. The system can then predict when a part is likely to fail, giving you a heads-up weeks or even months in advance. This move to condition-based maintenance is just incredibly efficient—it gets rid of unnecessary scheduled work and helps you squeeze every bit of productive life out of your most important assets.

At E & I Sales, we know that reliable equipment is the backbone of your operation. We bring the expert support, custom control solutions, and deep product knowledge you need to keep your facility running at its absolute best. Let's build a more reliable future for your plant together.