So, what exactly is an electrical Motor Control Center (MCC)?

Put simply, it’s the nerve center for all the electric motors in an industrial facility. Think of it as a single, centralized cabinet built to house, power, and protect a whole group of motors and their associated gear.

What an MCC Does, and Why You Need One

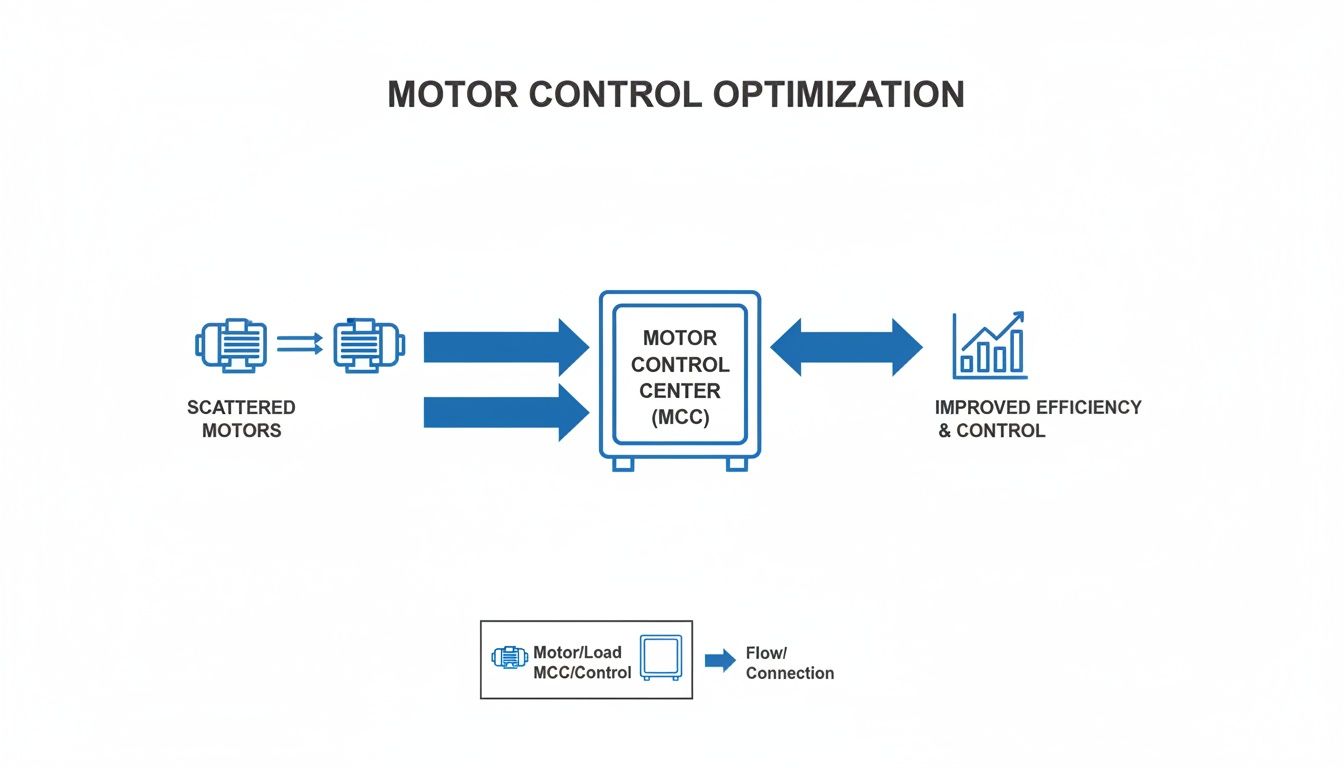

To really get what an MCC does, let's take a step back. Picture a sprawling factory floor from a few decades ago. Every pump, conveyor, and fan would have its own starter, disconnect switch, and overload protection bolted to a wall or column nearby.

This setup was a mess. It was a maintenance nightmare, a serious safety hazard, and a huge time sink for any technician trying to track down a problem.

The Motor Control Center was invented to fix all of that. It takes all those scattered components and organizes them into one purpose-built, engineered assembly. It’s like going from a chaotic neighborhood of single-family homes, each with its own separate utilities, to a modern high-rise with everything managed from a central, secure utility room. The operational payoff is massive.

The Three Pillars of an MCC

At its core, an MCC is all about improving three key things:

- Safety: It neatly tucks away high-voltage components inside a grounded metal cabinet. With features like interlocking door handles, it drastically cuts down the risk of accidental contact and protects your team from dangerous arc flash events.

- Efficiency: Instead of hunting down components across the plant, technicians can troubleshoot, service, and swap out motor controls from one spot. This means less downtime and lower labor costs. Simple as that.

- Organization: An MCC brings a clean, logical layout to your motor circuits. This makes reading electrical schematics a breeze and simplifies any future expansions or system changes.

Now, it’s easy to confuse an MCC with other big electrical cabinets, but they serve very different roles. We’ve put together a guide that breaks down the specifics, and you can learn more about the comparison between a motor control center vs switchgear to see why an MCC is a specialized piece of equipment for motor management, not just general power distribution.

Ultimately, an MCC is more than just a box of parts; it’s a strategic investment in how you manage power. It’s a system designed from the ground up for reliability, safety, and the long-term health of any operation that runs on electric motors.

Exploring The Anatomy Of A Motor Control Center

Pop open the door of a Motor Control Center (MCC), and it might seem a bit overwhelming at first. But what looks like a complex maze of components is actually a brilliantly organized system. Forget any images of a chaotic web of wires; a modern MCC is built on a framework designed for safety, modularity, and easy access.

I like to think of it as an electrical command center. The entire structure consists of one or more vertical metal cabinets bolted together. The backbone of the whole setup is the common power bus—a set of heavy-duty copper or aluminum bars running horizontally through the sections. This bus is the superhighway for electricity, distributing high-amperage power to every single unit and getting rid of the need for miles of individual wiring to each motor.

This flowchart really nails the core principle: taking scattered, hard-to-manage motors and bringing them under one roof for streamlined control.

As you can see, centralizing everything in a single, accessible enclosure is a huge win for efficiency and makes maintenance worlds easier.

Inside The MCC Buckets

The true genius behind the MCC is found in its motor control units, or as everyone in the field calls them, "buckets." These are essentially removable drawers that plug right into that main power bus. Each bucket is a self-contained module, dedicated to controlling and protecting one specific motor out on the plant floor.

This plug-and-play design is a lifesaver for maintenance teams. When a component inside a bucket fails, a technician can de-energize it, pull the entire bucket out, and slot in a spare. Just like that, the motor is back online in minutes, not hours. The faulty unit gets taken back to the shop for repair on a workbench, safely away from any live equipment.

To help you get familiar with what you'll find inside, here's a quick rundown of the essential parts packed into a standard MCC bucket.

Key Components Inside Every MCC Bucket

| Component | What It Does | Why It Matters |

|---|---|---|

| Motor Starter | An electrical contactor that opens or closes a circuit to start and stop the motor. | This is the primary on/off switch, directly controlling the motor's operation. |

| Overload Relay | Monitors the current flowing to the motor and trips if it detects a sustained overload. | Acts as a critical safety net, preventing the motor from overheating and burning out. |

| Circuit Breaker | Provides short-circuit and overcurrent protection for the entire bucket circuit. | Protects the wiring and components from catastrophic failure and serves as a local power disconnect. |

These three components form the core of what's often called a "combination starter," providing the fundamental control and protection every motor needs.

By official definition, an MCC is an assembly of one or more enclosed vertical sections sharing a common power bus and principally containing motor control units. Low-voltage MCCs typically handle motors from 220V to 600V, while their medium-voltage counterparts can manage massive motors running up to 15 kV. You can find more of the formal definitions over on the Wikipedia page for Motor Control Centers.

Advanced Components For Modern Control

Of course, it doesn't stop with the basics. Today’s MCCs are far more than just glorified switchboards. Open up a bucket in a modern facility, and you’re just as likely to find some pretty sophisticated technology.

Two of the most common upgrades are Variable Frequency Drives (VFDs) and soft starters. A VFD gives you incredibly precise control over a motor's speed by changing the frequency of the power it receives—a must-have for applications like pumps, fans, and conveyors where speed matters. A soft starter, on the other hand, gently ramps up a motor's voltage when it starts, which dramatically reduces the mechanical shock on equipment.

These "intelligent" components turn a simple power distribution hub into the brains of the operation, enabling advanced process control and serious energy savings.

Making Sense of NEMA and UL Standards

Step into the world of industrial electrical gear, and you'll quickly run into a sea of acronyms. But when you’re talking about Motor Control Centers, two of them are non-negotiable marks of quality: NEMA and UL.

These aren't just letters stamped on a box for show. Think of them as the building codes for your electrical system. They're the framework that guarantees your MCC can handle its environment and has been put through the wringer to test against failure. You wouldn't skip the building codes on a new facility, and you shouldn't skip these on your MCC.

Getting a handle on these standards is crucial for anyone trying to pin down an electrical MCC definition or spec out a new project. They create a common language for performance and protection, taking all the guesswork out of the equation.

Decoding NEMA Enclosure Ratings

The National Electrical Manufacturers Association (NEMA) created a rating system that’s all about one thing: how well an enclosure protects the sensitive gear inside from the outside world. This is your MCC's first line of defense against dust, dripping water, corrosive salt spray, and everything in between.

Choosing the right NEMA rating is simply a matter of matching the MCC’s physical armor to its battlefield. You'll see these ratings pop up all the time:

- NEMA 1: This is your standard indoor-rated enclosure. It’s perfect for a clean, dry electrical room where the main goal is to keep dust out and prevent someone from accidentally touching a live part.

- NEMA 3R: Built for the outdoors, this rating can handle rain, sleet, and snow. It’s a solid choice for equipment that’s outside but not getting blasted with high-pressure water jets.

- NEMA 4X: When things get tough, you call in the 4X. It’s watertight, dust-tight, and—crucially—corrosion-resistant. This makes it the go-to for washdown areas in food plants or coastal locations where salt spray would eat a lesser enclosure for lunch.

It's a balancing act. Paying for a NEMA 4X enclosure when you only need a NEMA 1 is just throwing money away. But skimping on the rating can lead to a fried MCC and a seriously dangerous situation.

The Importance of the UL 845 Listing

While NEMA tells you how tough the box is, the UL 845 listing from Underwriters Laboratories certifies the safety of the entire MCC assembly. This is a much bigger deal. UL 845 digs into everything from the internal wiring and bus bar spacing to whether the unit can safely handle a massive short-circuit event.

A UL 845 listing is your proof that the MCC has been independently tested to meet strict national safety standards. It’s the seal of approval that confirms the unit was built right, with the right components, dramatically cutting down the risk of fire and electrical shock.

For facility managers and engineers, that UL 845 stamp is pure peace of mind. It makes life easier with inspectors and gives you confidence that you have a cohesive, safely engineered system, not just a random collection of parts.

Without this listing, you are essentially accepting an unknown level of risk. That’s a gamble no one in this industry should be willing to take.

The Shift to Intelligent Motor Control

The very idea of a Motor Control Center is changing. It's no longer just a big, gray cabinet for housing motor starters. These days, modern MCCs are being completely reimagined, evolving from simple power distribution hubs into the data-gathering nerve centers of the smart factory floor.

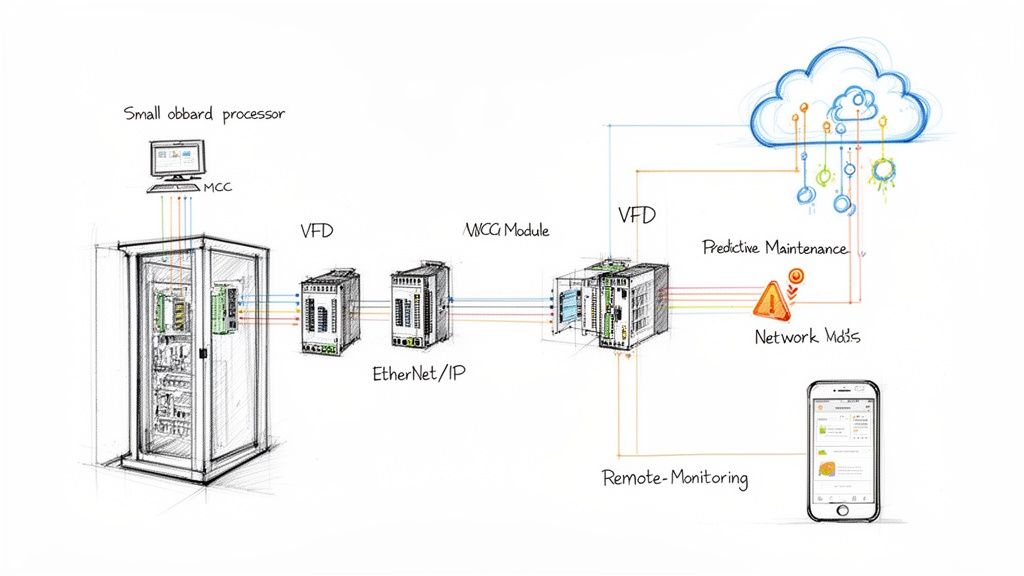

This leap forward is all thanks to advanced communication networks like EtherNet/IP getting baked right into the MCC's architecture. By embedding smart components and processors directly into each bucket, the MCC stops being a passive piece of hardware. It becomes an active, intelligent source of information that talks directly to your plant's main control systems.

This level of integration isn't just for show—it unlocks real, tangible benefits that hit your bottom line and make the plant floor a safer place to be.

From Reactive to Predictive Operations

Here’s where an intelligent MCC really shines: it can spot trouble long before it happens. In the old days, MCCs were purely reactive. A motor would fail, an overload would trip, and you'd dispatch a maintenance crew to figure it out after the fact.

An intelligent MCC flips that script entirely by providing a constant stream of real-time data from every single motor it’s connected to.

It's always watching key metrics like:

- Motor current and voltage to spot weird power draws.

- Operating temperature to catch overheating conditions early.

- Vibration analysis to warn you about potential mechanical failures.

By gathering and analyzing this data, the system can flag issues and send out predictive maintenance alerts. Imagine getting a heads-up that a pump motor's current draw is slowly creeping up, pointing to a bearing that's about to fail. This lets you schedule the repair on your own terms, avoiding a catastrophic failure and the costly unplanned downtime that comes with it. To get a feel for the tech making this possible, it's worth understanding the role of AI, IoT, and Edge Computing in industrial applications.

A traditional MCC was a simple arrangement of starters and breakers. Today's intelligent MCCs embed networked components that are always talking. Major manufacturers estimate these smart systems can cut unplanned downtime by 20–30% simply by keeping a constant eye on equipment health.

A Cornerstone of Industry 4.0

This evolution plugs the MCC right into the bigger picture of Industry 4.0, where data is the fuel for efficiency and safety. Smart components like Variable Frequency Drives (VFDs) can be tweaked and monitored from anywhere, letting you fine-tune energy consumption and process control without sending a technician to stand in front of the cabinet. If you want to get into the weeds on how these work, our guide on Variable Frequency Drive basics is a great place to start.

At the end of the day, a smart MCC acts as a critical data node in a modern, connected facility. It transforms a legacy piece of electrical gear into a strategic asset that tightens up safety, drives productivity, and delivers the insights you need to stay competitive.

MCC Configurations and Real-World Applications

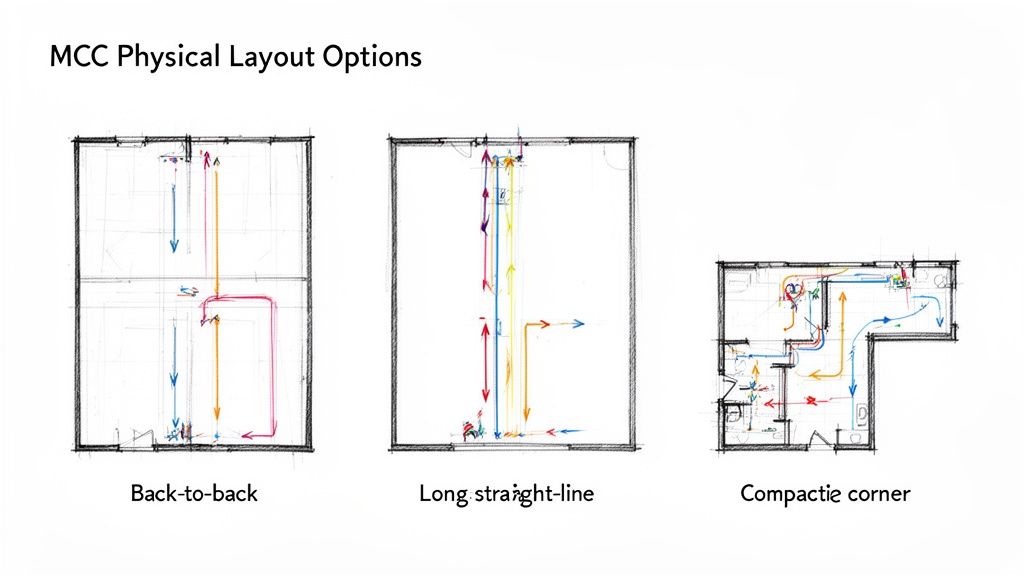

Knowing what’s inside an MCC is one thing, but seeing how they’re actually put to work is where it all clicks. The first decision you'll face is the physical layout, and this is almost always dictated by the space you have and how your team needs to work. It’s a perfect example of form following function.

For instance, if you're working with a long, narrow electrical room, a straight-line configuration is a no-brainer. You just line up the vertical sections in a single row against a wall. This gives you wide-open, easy access to the front of every single unit.

But what if floor space is at a premium? That’s when a back-to-back configuration becomes your best friend. By placing sections back-to-back, you can almost double your control density without taking up another square foot.

The right choice comes down to balancing accessibility with your space constraints, and always keeping an eye on future expansion. Getting the layout right from the start is a massive win for efficient operations and safe access down the line. Smart planning and regular upkeep are key, which we cover in our guide to motor control center maintenance.

Where You Actually Find MCCs

Physical layouts are just the start. The real definition of an MCC is written in the jobs it does. These control centers are the unsung heroes humming away behind the scenes in just about every industry imaginable, keeping critical processes running safely and reliably.

Their modular design is what makes them so incredibly versatile.

- Water Treatment Plants: Think about all the pumps, aerators, and chemical feeders. MCCs are the central nervous system, giving operators precise control over water flow and treatment to protect public health.

- Manufacturing Facilities: On a busy production floor, an MCC is the command center for an entire assembly line. It’s powering conveyor belts, robotic arms, industrial mixers, and packaging equipment—all from one organized, protected cabinet.

- Oil and Gas Operations: In these tough environments, failure is not an option. MCCs run the heavy-hitters like compressors, pipeline pumps, and drilling motors, where even a minute of downtime can cost a fortune.

Every job has different needs. A simple conveyor belt might just need a basic starter to turn it on and off. But a variable-flow pump? That's going to require a sophisticated Variable Frequency Drive (VFD) to dial in the exact speed. The MCC's greatest strength is its ability to house both, side-by-side, in the same enclosure.

Whether they're running ventilation fans in a skyscraper or giant rock crushers in a mine, MCCs provide the safe, centralized control that modern industry is built on. They're the critical link between the smarts of an automation system and the brute force of the motors doing all the heavy lifting.

Your Guide to Specifying the Right MCC

Alright, let's move from theory to the real world. Specifying a Motor Control Center is where the rubber meets the road—it’s the point where a project's success is won or lost. A rock-solid specification is your blueprint. Get it right, and you get a system that fits your operation like a glove; get it wrong, and you're staring down the barrel of costly change orders and frustrating delays.

It all starts with the data. You absolutely must begin with a detailed motor list. I'm talking horsepower, full-load amps, and voltage for every single load that will connect to the MCC. This isn't just paperwork; this information is what dictates the size of every starter, every breaker, and the main bus itself. You have to ensure it can handle what you need today and what you might throw at it tomorrow.

And don't forget the environment. Is this MCC going into a clean, dry room or a washdown area? Specifying the correct NEMA enclosure is one of those details that seems small but is absolutely critical for the long-term health of your equipment.

Partnering for a Successful Outcome

Having a detailed motor list and knowing your site conditions is a fantastic start, but a truly great MCC goes deeper. This is where leaning on the expertise of a good system integrator can make all the difference.

An experienced partner does more than just sell you a box of parts. They're translators, turning your operational goals into a smart, functional electrical design. They make sure everything from the communication protocols to the last piece of control wiring works together as one cohesive system.

Think of it less like a transaction and more like a collaboration. A partner like E & I Sales helps you navigate the stuff that can trip you up, like:

- Custom Design: They'll work with you to tailor the physical layout and internal gear to your specific application, making sure it integrates smoothly with your existing automation and control systems.

- UL Compliance: This is a big one. They guarantee the final assembly is built to rigorous UL 845 standards, which is non-negotiable for safety and passing inspections.

- Turnkey Delivery: The best partners manage the whole process—from the initial idea and design, through fabrication, factory acceptance testing, and even support during final commissioning.

When you bring in an expert, you’re not just buying an MCC; you're building it for success. It transforms the whole process from a simple purchase order into a real investment in your facility's safety, efficiency, and reliability. The end result? A turnkey system that just works, right from day one.

Your Top MCC Questions, Answered

After covering the fundamentals, a few specific questions always seem to pop up. Let's tackle some of the most common ones we hear from engineers and technicians out in the field.

What's The Main Difference Between Switchgear and an MCC?

Think of it this way: switchgear is the main power gateway for your entire facility. It's the big, heavy-duty equipment that takes the high-voltage feed from the utility and breaks it down. It’s built to handle and protect the primary power for the whole plant.

An MCC, on the other hand, is much more specialized. It sits downstream from the switchgear and has a very focused job: organizing, protecting, and controlling a whole group of motors. Switchgear is about bulk power distribution; an MCC is about refining that power for specific motor-driven tasks, complete with individual controls and overload protection for each one.

Can I Add New Motor Controls to an Existing MCC?

You bet. That's one of the biggest strengths of an MCC—its modularity. Most are designed with spare spaces or empty "buckets" right from the factory, anticipating that you'll need to add more motor circuits as your operations expand.

But there's a crucial first step: you have to verify that the main horizontal bus has enough capacity for the new load. Before you add anything, a qualified engineer needs to run a load calculation. This isn't just a suggestion; it's a critical safety check to ensure you don't overload the entire system.

Why Is an Arc Resistant MCC So Important for Safety?

An arc-resistant MCC is a piece of life-saving equipment. It’s a specialized, heavy-duty enclosure engineered to contain and safely redirect the massive, violent energy of an arc flash—a dangerous electrical explosion. It achieves this with rugged construction, reinforced latches, and special vents designed to channel the blast away from anyone standing nearby.

For any facility that takes worker safety seriously and follows standards like NFPA 70E, specifying an arc-resistant MCC is non-negotiable. It’s one of the most effective ways to protect your team and minimize catastrophic equipment damage if a worst-case electrical fault happens.

Navigating the world of MCCs—from initial spec sheets to final commissioning—takes real-world expertise. The team at E & I Sales is here to be your partner, offering custom UL-listed control packaging and integration services. We make sure your project is safe, compliant, and built exactly for your needs. Learn how we can help build your next motor control solution.