When you hear "electric motor service," what comes to mind? For many, it's the frantic call you make after a critical motor grinds to a halt. But that’s a reactive, costly way to operate.

True electric motor service is about proactive management—a strategic blend of inspections, diagnostics, and smart maintenance designed to keep your motors running at peak performance and prevent failures before they ever happen. It’s the difference between managing a predictable asset and getting blindsided by a production-killing crisis.

Your Best Defense Against Downtime Is Proactive Motor Service

Let’s be honest: unplanned downtime is the biggest threat to your bottom line. When a key motor fails, the ripple effect is immediate and expensive, shutting down an entire line and putting production targets in jeopardy. Seeing electric motors service as just a repair function is a massive, and all-too-common, blind spot.

Think of it more like the rigorous maintenance schedule for a high-performance engine. You don't wait for it to break down on the highway. A smart service strategy isn't about just fixing things; it’s about building a powerful, proactive defense that keeps your operation humming. This requires a calculated mix of preventive care, predictive diagnostics, and rapid, effective repairs when they’re absolutely necessary.

The Core Pillars of Effective Motor Management

To build this defense, you need a plan that looks beyond just the motor itself. A truly effective strategy integrates the mechanical health of your motors with the intelligence of their control systems, giving you a complete, 360-degree view of how your assets are performing.

This holistic approach delivers tangible results you can see and measure:

- Slash Unplanned Downtime: Catching issues before they escalate means you schedule maintenance on your time, not in the middle of a production emergency.

- Extend Equipment Lifespan: Proper care, from lubrication to alignment, can dramatically extend the life of your motors and maximize your capital investment.

- Boost Operational Safety: A well-maintained motor is a safe motor. Proactive service helps you spot and fix potential electrical hazards before they can cause an accident.

- Lower Your Total Cost of Ownership: Fewer emergency repairs and more energy-efficient operation translate directly to lower long-term costs. A great starting point is building out a solid schedule, and you can find helpful resources like a preventive maintenance schedule template to get started.

A Growing Market Proves Reliability is King

The global demand for reliable motors is exploding. The market is set to jump from USD 212.96 billion in 2025 to a massive USD 405.67 billion by 2033, fueled by a powerful 8.5% annual growth rate.

This isn't just a number; it's a clear signal that operational reliability is more critical than ever. It also highlights the incredible value of having an experienced partner in your corner, like E & I Sales, who has been a trusted electric motor distributor and system integrator since 1974.

By ditching the "fix-it-when-it-breaks" mindset for a proactive service strategy, you turn your maintenance department from a cost center into a powerful competitive advantage that drives reliability and protects your bottom line.

Decoding Motor Health with Key Diagnostic Checkpoints

Trying to understand what’s happening inside an industrial motor with just a visual inspection is like trying to diagnose a patient from across the room. You need to get closer and use the right tools. That's where key diagnostic checkpoints come in—they act as an early warning system, translating subtle signals from your equipment into hard, actionable data.

This isn't about guesswork. It's about shifting your maintenance strategy from a reactive firefight to a proactive, scheduled process that catches problems before they become catastrophic failures. Each test gives you a different piece of the puzzle, building a complete picture of your motor's health so you can make smart decisions.

Vibration Analysis: The Stethoscope for Your Machinery

Just like a doctor listens to a patient’s heartbeat with a stethoscope, our technicians use vibration analysis to listen to the mechanical "hum" of your motors. Every single rotating part—from the shaft and bearings to the cooling fan—creates its own unique vibration signature when it's running smoothly.

The moment a component starts to wear out, fall out of alignment, or become imbalanced, that signature changes. These tiny shifts are often detectable long before you could ever hear or see a problem. A skilled technician can read these vibration patterns to pinpoint the exact source of a developing issue, whether it’s a minor imbalance or the very first signs of bearing fatigue. In fact, predictive maintenance programs driven by this kind of data have been shown to slash equipment breakdowns by up to 70%.

Think about it: you can schedule a quick, minor fix like rebalancing a rotor on your own terms, instead of being forced into a massive, production-halting motor rebuild in the middle of a critical run.

Thermal Imaging: Spotting Hidden Hotspots

Heat is the silent killer of electric motors. When things get too hot, insulation starts to degrade, lubrication breaks down, and every component begins to wear out faster. Thermal imaging, or thermography, lets us see what the naked eye can't by creating a visual map of heat signatures.

A quick thermal scan can immediately flag problems that would otherwise go unnoticed:

- Overloaded Circuits: A high-resistance connection in the terminal box will glow like a beacon.

- Failing Bearings: As a bearing starts to fail, the increased friction generates a ton of heat.

- Blocked Ventilation: Clogged cooling fins or a dead fan will cause the entire motor casing to overheat.

Catching these thermal anomalies early means you can address the root cause—like tightening a loose wire or just cleaning out a vent—before it snowballs into a serious electrical or mechanical failure. This is also a massive safety issue. Staying on top of motor health isn't just about uptime; it's about protecting your team. Anyone responsible for workplace safety should Master NFPA 70E Electrical Safety Guidance to keep everyone safe.

Motor Circuit Analysis: A Window into Winding Health

While vibration and thermal checks give us a great look at the mechanical and heat-related stresses, Motor Circuit Analysis (MCA) goes a level deeper into the motor's electrical integrity. This powerful diagnostic sends a series of low-voltage signals through the windings to measure critical electrical properties like resistance, inductance, and how well the insulation is holding up.

MCA is fantastic at finding those tricky, hard-to-detect issues that other tests might miss entirely. It can spot the very beginning of insulation breakdown between winding turns, a slowly deteriorating connection, or even contamination from dust and moisture. We dive deeper into these concepts in our article on the protection of motors.

This electrical assessment gives you a clear, definitive baseline of your motor's condition. From there, you can track any degradation over time and make an informed call on scheduling a rewind or replacement long before an electrical fault shuts down your line without warning.

Making The Critical Decision: Repair Or Replace Your Motor?

When a critical motor goes down, your whole line grinds to a halt. Suddenly, you're on the clock, facing a high-stakes decision under a ton of pressure: do you repair the failing motor or spring for a brand-new replacement? This is way more than just comparing two price tags. It's a complex operational and financial choice that will echo in your budget and productivity reports for years.

The smart play here is to look past the immediate repair quote. You need to think in terms of Total Cost of Ownership (TCO). This framework forces you to balance the upfront cash outlay against the long-term realities—things like energy consumption, the odds of another failure, and the pure lead time to get your line humming again. A cheap, quick fix might seem like a win today, but it could end up costing you a fortune down the road.

Evaluating Key Decision Factors

Every motor failure is its own little drama, but a structured approach helps you take the emotion out of it. Picture a scale. On one side, you've got the immediate cost and speed of a repair. On the other, you have the long-term efficiency, rock-solid reliability, and warranty that come with a new motor.

The motor's age is a huge piece of the puzzle. An older, standard-efficiency motor that’s been rewound a few times isn't the same machine it was. Each rewind can chip away at its efficiency, which means your energy bills creep up over its remaining life.

On the flip side, a modern NEMA Premium efficiency motor could deliver some serious energy savings, often paying for itself over time. How critical is the application? That's another big question. For a motor on a piece of non-essential equipment, a repair might be perfectly logical. But for the motor that’s the heart and soul of your main production line? The peace of mind from a new, reliable unit often makes the higher upfront cost a no-brainer.

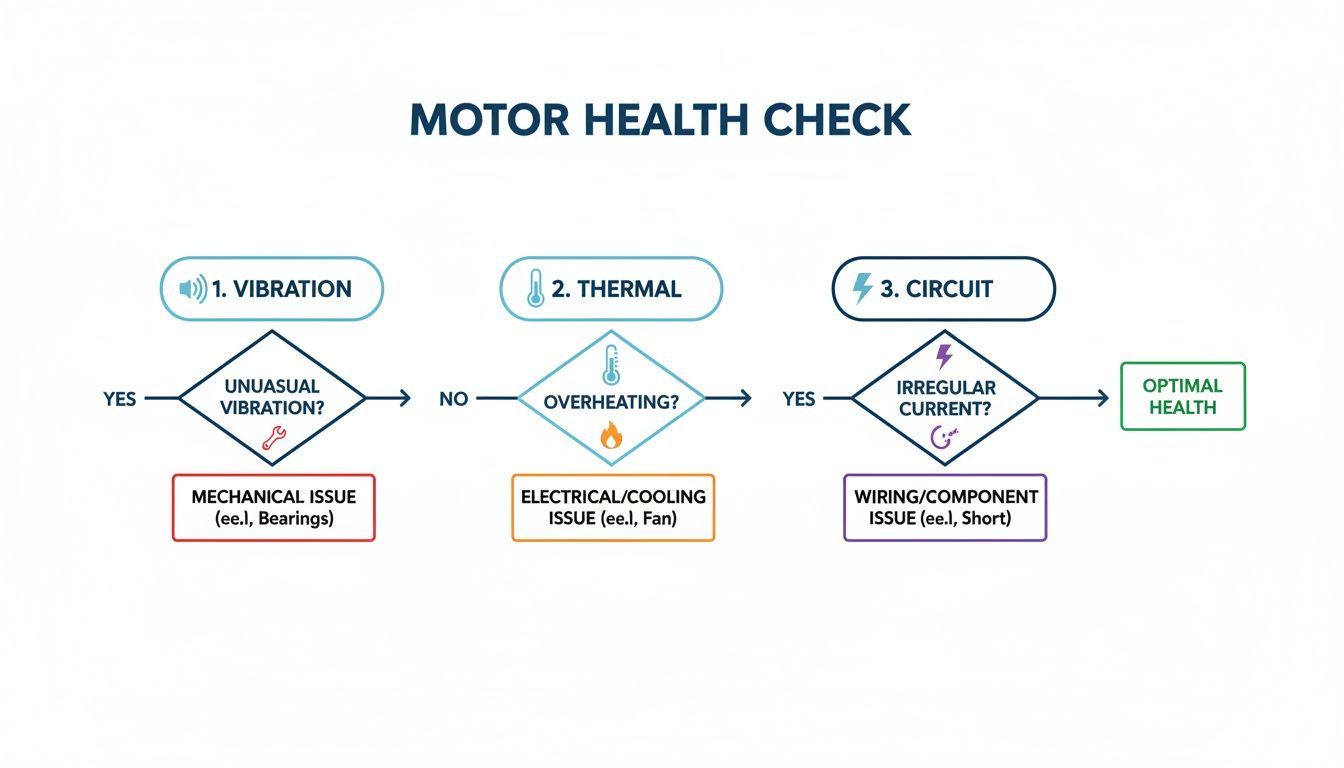

A quick health check using a few key diagnostics can give you the hard data you need to make a smarter call. This flowchart breaks down a simple 3-step process for getting a real feel for your motor's condition.

As you can see, checking vibration, thermal signatures, and circuit integrity paints a complete picture. It helps you see if a simple fix will do the trick or if deeper problems are signaling it's time for a replacement.

Repair vs. Replace Decision Matrix

To help you weigh your options practically, we've put together a simple decision matrix. Think of it as a cheat sheet for organizing your thoughts when you're under pressure.

| Decision Factor | Favoring Repair | Favoring Replacement |

|---|---|---|

| Motor Age | Relatively new (under 5-7 years) with a first-time failure. | Older motor (10+ years), especially if it has been rewound before. |

| Repair Cost | Less than 50% of the cost of a new, comparable motor. | Repair quote is over 50% of the replacement cost. |

| Criticality | Non-critical application where downtime is manageable. | Heart of the production line; reliability is non-negotiable. |

| Energy Efficiency | Motor is already an energy-efficient model. | Current motor is standard efficiency; a new premium model offers major savings. |

| Lead Time | Repair can be completed much faster than a new motor can be sourced. | A new motor is readily available, and repair time is uncertain. |

| Warranty | N/A (repairs may have limited warranty on work performed). | Comes with a full manufacturer's warranty for peace of mind. |

Looking at these factors side-by-side helps clarify which path offers the best long-term value, not just the quickest fix.

The Real-World ROI of Replacement

Let's walk through a real scenario. A packaging plant was running a 15-year-old, 100 HP motor on its main conveyor. After a bearing failure, they got a quote for $7,000 for a full rebuild. Not bad, right? But a brand-new, premium-efficiency motor was $12,000. While the repair was cheaper upfront, someone did the math. The old motor was sucking down an extra $4,500 a year in electricity compared to the new model.

By choosing to replace it, the plant hit its payback in just over a year on energy savings alone. Plus, they got a new warranty and wiped out the risk of another age-related failure popping up next quarter. This kind of data-driven thinking turns a simple maintenance headache into a strategic investment. To get these calculations right, you need a solid grasp of motor performance; our guide on torque calculation for motor is a great place to start.

Weighing The Strategic Variables

Let's face it, the industrial world runs on AC electric motors, especially those over 1 hp. They're the backbone of just about every automated process. Getting your service strategy right can extend the life of these critical assets by as much as 50% and slash energy use by 10-20%. The repair-or-replace decision is right at the center of capturing those gains.

The decision to repair or replace isn't just a technical choice—it's a business strategy. By evaluating total cost of ownership, application criticality, and long-term energy savings, you can make a data-backed decision that boosts reliability and improves your bottom line.

At the end of the day, the goal is to make a choice that delivers operational stability and financial health. A great rule of thumb we've used for years is the "50% rule": if the repair costs more than half the price of a new replacement, it's almost always smarter to replace it. Combine that guideline with a clear-eyed look at your specific situation, and you can navigate this critical decision with confidence.

Choosing the Right Service Partner

Picking a partner for your electric motors service is a huge deal. Get it right, and you’ve got an extension of your own team—an expert who sees trouble coming and keeps your plant running smoothly. Get it wrong, and you're just paying someone to fix what’s broken, trapping you in a never-ending cycle of putting out fires.

This isn’t about finding the lowest price. It's about finding a team that gets the whole picture, from the motor spinning on the floor to the complex controls making it happen. Their real value lies in their technical chops, how fast they respond, and their mindset. That's what separates a simple vendor from a true strategic partner.

The Technical Non-Negotiables

Before you even think about anything else, a potential partner has to clear a few technical hurdles. These are the absolute basics, the proof that they can handle modern industrial equipment safely and correctly.

Your checklist should start here:

- Proven Field Service Expertise: Can they get a qualified tech to your site, pronto? Whether it’s for troubleshooting, a new install, or commissioning, on-site support is everything when a line goes down.

- UL 508A Panel Shop Certification: This one’s a biggie. A UL 508A certification is your proof that they build control panels to the highest industry standards for safety and reliability. It’s not just a nice-to-have; it’s a mark of quality.

- Deep Industry Experience: Do they speak your language? A partner who’s worked in packaging, food and beverage, or your specific manufacturing world will understand your operational headaches and get to the right solution much faster.

Think of these as your first filter. If a provider can't check these boxes, they don't have the foundational skills you need.

Beyond the Spec Sheet: The Traits of a True Partner

Once you’ve confirmed the technical skills are there, the real evaluation can begin. The best service partners bring a lot more to the table than what you’ll find on a line card. These are the qualities that make for a solid, long-term relationship.

You’re looking for a provider who shows:

- Responsive Communication: When you're facing downtime, you need answers, not voicemails. A partner who picks up the phone and gives you clear, honest updates is worth their weight in gold during a crisis.

- A Genuine Problem-Solving Mindset: Do they just slap a band-aid on the issue, or do they dig in to find out why it happened? A great partner is obsessed with finding the root cause to make sure it doesn't happen again.

A true single-source partner doesn't just supply a motor or build a panel. They take ownership of the entire system, from initial specification and design to seamless integration and startup, dramatically reducing project complexity and helping you get operational faster.

The Power of a Single-Source Integrator

Trying to manage separate vendors for motors, control panels, and on-site integration is a classic recipe for disaster. It’s a mess of missed deadlines, crossed wires, and blown budgets. And when something inevitably goes wrong, the finger-pointing starts, with you stuck right in the middle.

A single-source partner cuts through all that chaos.

By handling everything from motor selection to panel design and final commissioning, they give you one point of contact and one team that’s accountable for the entire project. This integrated approach ensures that every single component is designed from the get-go to work together perfectly.

This is especially powerful for OEMs and plant engineers looking to standardize their equipment. A good integrator can help you build repeatable, rock-solid solutions that make maintenance easier, slash your spare parts inventory, and deliver consistent performance across every line. At the end of the day, choosing an electric motors service provider is about finding a partner who is as invested in your success as you are.

Integrating Motor Service with Controls and Automation

An industrial motor is never a solo act. It’s the powerhouse at the heart of a much bigger system, taking its cues from a whole network of controls, drives, and automation logic. That’s precisely why modern electric motors service has to look beyond the motor itself and see the entire ecosystem.

Fixing a motor in a vacuum is like a mechanic tuning an engine without ever plugging into the car's computer. You might fix one problem but miss the root cause entirely. The real reliability—the kind you can count on—comes when the motor and its controls are working in perfect harmony.

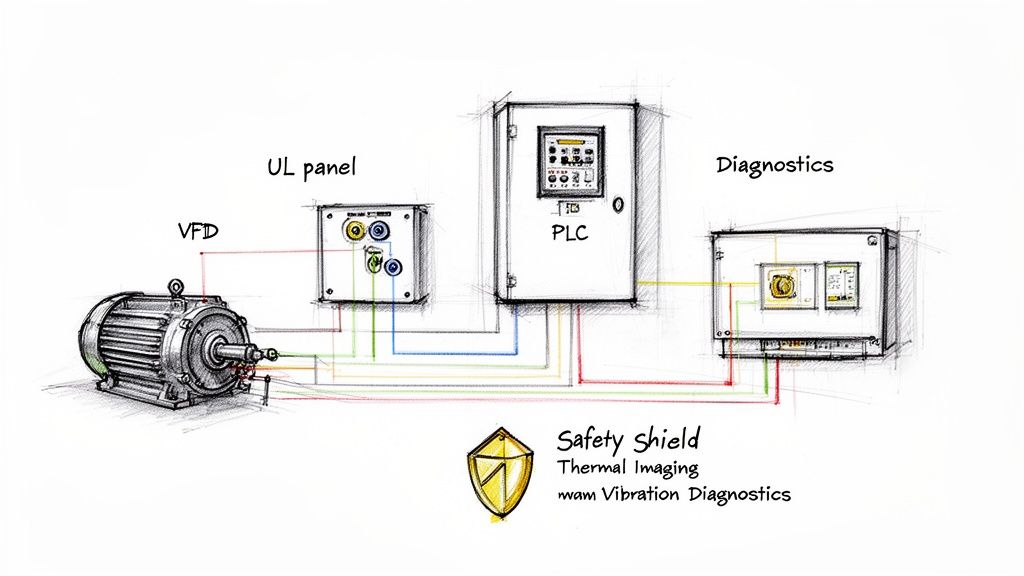

Think about it: a Variable Frequency Drive (VFD) could be sending out flawless power, but if the motor's overload settings aren't dialed in correctly on the PLC, you're just one jam-up away from a catastrophic burnout. A true system integrator lives and breathes this delicate balance, making sure every piece of the puzzle is set up to protect the others.

The Critical Role of UL-Listed Control Panels

Right in the middle of all this sits the control panel. This is command central, the box that houses the motor starters, VFDs, and PLCs that make the whole operation intelligent. For any serious industrial setup, specifying a custom UL-listed control panel isn't just a good idea—it's non-negotiable.

That UL mark is so much more than a sticker. It's your guarantee that the panel was designed and built to meet the industry's highest safety and quality standards. It certifies that every single component, from the wiring gauge to the circuit breakers, was chosen, installed, and tested to perform safely under real-world industrial loads.

A service partner with an in-house UL 508A panel shop brings a ton of value to the table:

- Ensuring Compliance: They build panels that satisfy strict national safety codes, which is step one in protecting your people and your plant.

- Designing for the Application: They can build a panel perfectly tailored to your motor and process, instead of trying to shoehorn an off-the-shelf box into a job it wasn't made for.

- Streamlining Integration: When the same team that understands your motor also designs and builds its controls, you eliminate those frustrating compatibility headaches from the start.

Weaving Diagnostics into Your Automation System

The most sophisticated operations take this a step further. They don't just protect their motors; they actually listen to them. Today's VFDs and smart relays are packed with incredibly valuable diagnostic data, tracking everything from current draw and operating temperature to torque load.

A skilled integrator can tap into this stream of data and feed it directly into your plant's main automation platform, like a SCADA or HMI. Suddenly, your control room becomes a central hub for motor health monitoring. Instead of waiting for a maintenance tech to walk the floor and take a reading, your operators can spot a potential overload or an overheating trend in real-time, right on their screen.

Partnering with an expert in both motors and controls creates a unified system where every component works together. This holistic approach leads to safer, more reliable, and far more efficient industrial operations.

This push for deeper integration is all about the relentless pursuit of efficiency. The global electric motor market, valued at USD 152.2 billion in 2024, is expected to hit USD 206.4 billion by 2029. A massive part of that growth is the switch to high-efficiency motors, which can slash energy consumption by 20-40%. Turnkey services that standardize motor control centers (MCCs) and switchgear are essential, often cutting commissioning time by weeks and dramatically reducing downtime risks. You can explore more about these market trends and their impact on industrial applications to get the full picture.

Maximizing Your ROI with a Strategic Service Plan

It's easy to look at electric motors service as just another line item on the expense sheet. But that’s an outdated, and frankly, expensive way of thinking.

Let’s reframe this. A strategic service plan isn't a cost center. It's a powerful profit driver that aggressively protects your most valuable asset: uptime. This isn't about reactive firefights anymore; it's a calculated business strategy that delivers a real, measurable return on your investment (ROI).

Every decision—from running proactive diagnostics to planning a system-wide integration—feeds directly back to your bottom line. Think of it like a flywheel. Each smart service action builds momentum, creating benefits that compound across your entire operation. Working with the right service partner unlocks this value, turning motor management into a genuine competitive advantage.

Translating Service into Financial Wins

So, where does this ROI actually show up? It’s not some abstract concept; you’ll see it in clear, undeniable ways on your financial statements. It's cash you save and production you gain.

A well-executed plan directly chips away at operational costs while boosting your output. Here’s where you’ll see the return:

- Drastically Lower Energy Bills: Modern, well-maintained motors are just plain thriftier on power. Simply replacing or properly servicing an older motor can slash its energy use by 10-20%. Those savings add up every single hour it’s running.

- Reduced Unplanned Downtime: This is the big one. Predictive maintenance catches failures before they happen, letting you schedule repairs on your terms. Moving from emergency response to planned action can save you thousands in lost production and frantic overtime costs.

- Longer Asset Life: Simple, proactive care like proper lubrication and alignment can extend a motor's working life by as much as 50%. You get more out of your initial capital investment and push those big replacement costs further down the road.

Putting a strategic service plan in place is one of the most effective ways of reducing the total cost of ownership for your equipment.

The Advantage for Every Stakeholder

A well-oiled service strategy isn't just about the maintenance department—it creates a cascade of positive outcomes for everyone involved in the production lifecycle. It smooths out processes, removes bottlenecks, and empowers your teams to hit their goals with more confidence and far fewer surprises.

Embracing a proactive electric motors service plan is the cornerstone of operational excellence. It is a fundamental shift that empowers your entire team to move from merely fixing problems to actively preventing them, driving reliability and profitability.

Just think about how the benefits ripple out:

- For OEMs and Packagers: When you have standardized, reliable motor and control solutions, projects get done faster. Your final product is higher quality, and you get to market quicker.

- For Plant Managers: Consistent uptime and predictable maintenance schedules make it infinitely easier to meet—and even beat—those demanding production quotas.

- For Maintenance Teams: With fewer emergencies blowing up their day, technicians can finally focus on high-value preventive work instead of constantly putting out fires.

Ultimately, it’s time to stop thinking about service and start thinking about strategy. Partner with an expert who gets the entire system—from the motor to its controls—and unlock the immense value just waiting to be tapped in your facility.

A Few Common Questions About Electric Motor Service

Even the most experienced plant managers and engineers have questions when it comes to fine-tuning their electric motor service strategy. Let's tackle a few of the most common ones we hear out in the field.

Getting the right answers here can help you sharpen your maintenance plan, sidestep common failures, and make sure you're getting real value from your service partner.

What Is the Most Common Cause of Industrial Motor Failure?

Bearings. Hands down. Bearing issues are the undisputed champ of motor failure, causing over 50% of all breakdowns. The thing is, this isn't just a string of bad luck—it's almost always preventable.

So what's taking them out? It usually comes down to one of these culprits:

- Improper Lubrication: This is a big one. Using the wrong grease, adding too much, or not adding enough is a surefire way to kill a bearing.

- Contamination: When dirt, dust, or moisture find their way into the bearing housing, they act like sandpaper, creating friction that destroys precision surfaces.

- Shaft Misalignment: If the motor shaft isn't perfectly aligned with the load, it puts incredible stress on the bearings, forcing them to wear out long before their time.

- Excessive Vibration: An unbalanced rotor or some other mechanical gremlin sends damaging vibrations right through the shaft and into the bearings.

Your best line of defense is a proactive service plan. Making regular lubrication and vibration analysis a non-negotiable part of your routine is the key to stopping these killers in their tracks.

How Often Should My Critical Motors Be Serviced?

There's no magic number here. The right service interval really depends on the motor's job, its working environment, and how critical it is to your operation.

Think of it in tiers:

- High-Priority Motors: For the workhorses running 24/7 in hot, dirty, or demanding conditions, getting them checked out quarterly is a smart move.

- Standard-Duty Motors: For motors in cleaner, more controlled settings that aren't quite as critical, an annual service and inspection is often plenty.

The best approach? Work with an experienced service provider to walk your floor. They can help you build a custom maintenance schedule that makes sense for your plant's specific equipment and production needs.

Just guessing at maintenance intervals is a recipe for disaster. You either end up wasting money on service you don't need or facing a surprise breakdown you can't afford. A schedule based on real-world conditions ensures you're servicing the right motor at the right time.

Can a Variable Frequency Drive Damage a Motor?

Absolutely. A VFD can definitely cause serious damage, but only if it's installed or configured incorrectly, or if it's a poor match for the motor itself. The two biggest problems we see are bearing damage from stray electrical currents (a phenomenon called fluting) and winding insulation breakdown caused by sharp voltage spikes from the drive.

This is exactly why a holistic approach to electric motors service is so critical. A good partner doesn't just sell you a VFD. They make sure the entire system—the motor, the drive, and the cabling—is engineered to work together flawlessly. That's how you protect your investment and get the performance and efficiency you're paying for.

Ready to build a service strategy that drives reliability instead of just reacting to failures? The experts at E & I Sales design, build, and support integrated motor and control solutions that prevent downtime and maximize performance. Contact us today to optimize your operations.