An arc flash hazard analysis is a deep-dive engineering study that figures out the sheer thermal energy that could be unleashed during an electrical fault. Think of it as a specialized forecast for your facility's electrical system, predicting the intensity of a potential explosion so you can protect your people from horrific harm.

Why an Arc Flash Analysis Is a Non-Negotiable Safety Pillar

Picture a lightning bolt trapped inside a metal cabinet. That’s the kind of raw, explosive power an arc flash can unleash. It’s a violent blast of energy that creates superheated plasma, blinding light, and a concussive pressure wave strong enough to throw a person across the room.

An arc flash hazard analysis goes way beyond just acknowledging this danger. It’s a meticulous investigation of your entire electrical system, calculating the precise level of hazard at every single point where your team might interact with energized equipment.

This isn't just about checking a box for compliance. It's about preventing life-altering injuries and fatalities. The numbers are grim: globally, there are an estimated 30,000 arc flash incidents every year. These events result in thousands of severe burn injuries and hundreds of deaths annually. You can get more insights on arc flash accident statistics from sources like AllumiaX. A proper analysis is the first and most critical step to keep your facility from becoming another statistic.

Understanding the Core Objectives

The whole point of the study is to arm you with actionable data that keeps your team safe. It's a journey into the DNA of your electrical distribution network, starting from where the utility feeds your plant all the way down to individual control panels. By modeling how the system will react under fault conditions, the analysis answers the tough questions that are the bedrock of any real electrical safety program.

A comprehensive arc flash study nails down several key goals:

- Identifies Hazards: It pinpoints the exact locations—like switchgear, motor control centers (MCCs), and panelboards—where arc flash and shock dangers are lurking.

- Quantifies Risk: The analysis calculates the specific incident energy (measured in cal/cm²) that a worker could be hit with. This number is what directly determines the level of personal protective equipment (PPE) they need to wear.

- Defines Safety Boundaries: It establishes clear, non-negotiable approach boundaries. This includes the Arc Flash Boundary, which is the distance from the equipment where an unprotected worker would suffer a second-degree burn.

- Ensures Compliance: The process is essential for meeting the critical safety standards mandated by OSHA and detailed in industry guides like NFPA 70E.

An arc flash analysis transforms an invisible, unpredictable electrical threat into a known, manageable risk. It replaces guesswork with data, empowering your team to work safely and confidently around energized equipment.

Ultimately, skipping this process isn't just a compliance miss—it’s a direct threat to your people, your equipment, and your ability to stay in business. The analysis lays the foundation for everything else, from accurate equipment labeling and PPE selection to effective worker training. It’s how you build a workplace where safety isn't left to chance.

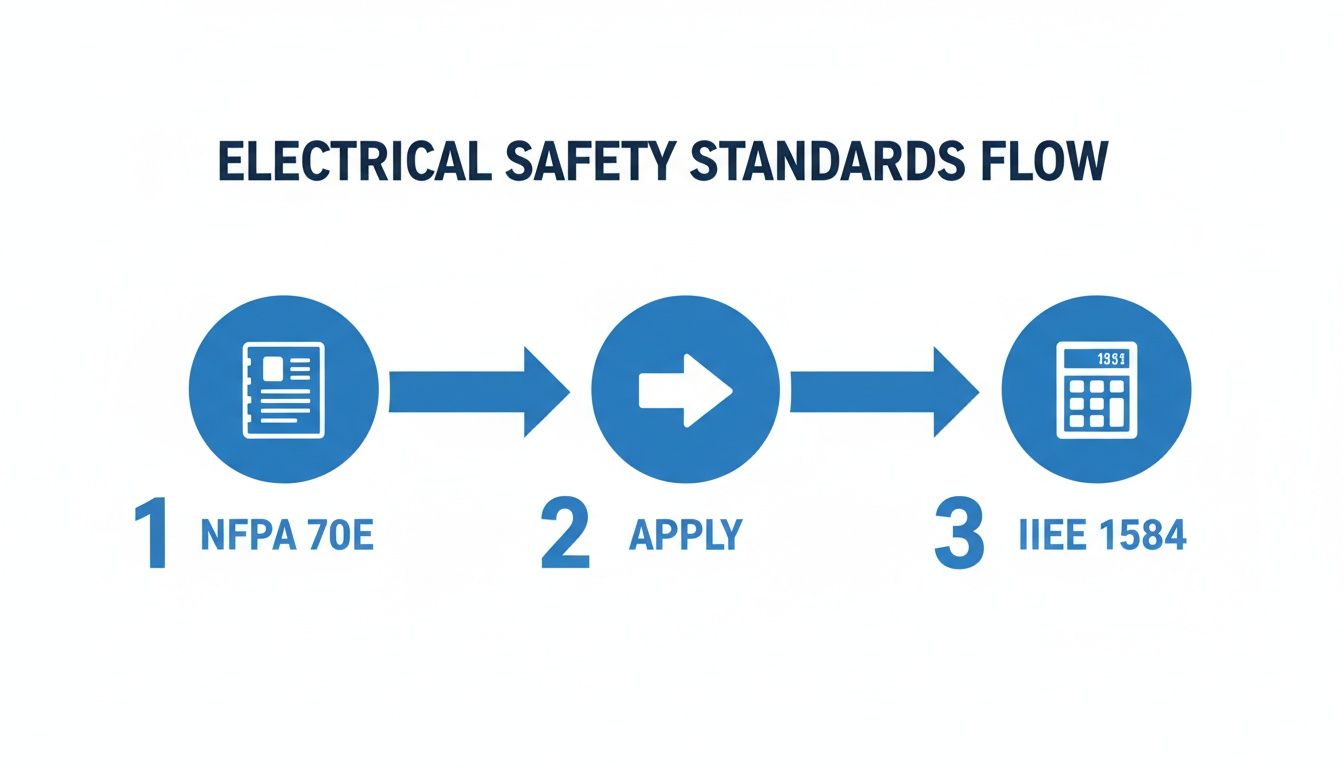

Decoding the Standards: NFPA 70E and IEEE 1584

Trying to get a handle on electrical safety standards can feel like learning a new language. When you're dealing with an arc flash hazard analysis, two documents are the absolute bedrock of the entire process: NFPA 70E and IEEE 1584. They work in tandem, but they have very different jobs.

Here’s the best way to think about it: NFPA 70E is the “Rulebook for Safe Electrical Work,” while IEEE 1584 is the “Engineering Manual” that gives us the math. One tells you that you have to figure out the danger and how to act around it; the other tells you exactly how to calculate its intensity.

Getting how these two standards play off each other is non-negotiable for anyone in charge of electrical safety. They aren't interchangeable—they're deeply connected, creating a complete system to keep your team out of harm's way.

NFPA 70E: The Rulebook for Safe Practices

The National Fire Protection Association's NFPA 70E, officially the Standard for Electrical Safety in the Workplace®, is your go-to guide for safe work practices. It lays out what employers and employees must do to protect against electrical hazards, focusing on real-world application and human behavior.

At its core, NFPA 70E answers one critical question: "What do we need to do to keep our people safe?" It sets the stage for creating and maintaining an electrically safe work environment.

Here's what NFPA 70E demands:

- Establish an Electrically Safe Work Condition: This is the top priority. The standard makes it crystal clear that de-energizing equipment is always the safest route, and it outlines the exact steps for lockout/tagout.

- Perform a Risk Assessment: It mandates that employers identify electrical hazards, figure out the likelihood and severity of an injury, and put protective measures in place. This is the origin point for needing an arc flash study.

- Select Personal Protective Equipment (PPE): The standard provides the framework for choosing the right arc-rated clothing and other PPE based on the hazards you’ve identified.

- Label Equipment: NFPA 70E requires that electrical gear likely to be worked on while energized must have a label detailing specific arc flash hazard information.

NFPA 70E is the bridge between regulations and what your team actually does on the floor. It doesn't get into the weeds with complex formulas, but it sets the firm expectation that a detailed analysis must be done to understand the risks workers are up against.

This standard is the entire reason facilities conduct an arc flash hazard analysis. It’s the "why" behind the whole effort, all driven by the simple goal of making sure every single worker goes home safe.

IEEE 1584: The Engineering Calculation Engine

While NFPA 70E tells you to assess the hazard, the Institute of Electrical and Electronics Engineers' IEEE 1584, the Guide for Performing Arc-Flash Hazard Calculations, provides the accepted engineering muscle to get it done. This is the technical engine that powers the whole analysis.

If NFPA 70E is the rulebook, think of IEEE 1584 as the high-powered calculator. It’s packed with the detailed, empirically-derived equations needed to accurately predict the incident energy from a potential arc flash. This is a highly technical document built for the engineers running the numbers.

The main job of IEEE 1584 is to give us a standardized, repeatable way to calculate:

- Arcing Short-Circuit Current: This is the amount of current that actually flows through the plasma arc—it’s different from the bolted fault current you might be used to seeing.

- Incident Energy: This is the big one. It’s the amount of thermal energy (measured in cal/cm²) that would hit a worker at a specific distance from the arc. It's the key number for choosing the right PPE.

- Arc Flash Boundary: This is the "stay-back" distance from a potential arc where the incident energy drops to 1.2 cal/cm²—the point where a second-degree burn can happen.

The formulas in IEEE 1584 are incredibly granular, taking things like system voltage, electrode configuration, equipment type, and conductor spacing into account. That level of precision is what makes the final results of an arc flash hazard analysis something you can truly count on.

The Arc Flash Hazard Analysis Process From Start to Finish

So, what exactly is an arc flash hazard analysis? Think of it as creating a digital twin of your entire electrical system so you can safely simulate the absolute worst-case scenarios without putting anyone in harm's way. It’s an engineering study that turns an abstract electrical threat into a known, measurable risk you can plan for.

The whole process lives and dies by one simple rule: accuracy at every step. Even a tiny mistake during the initial data gathering can snowball into a massive miscalculation later on, leading to the wrong PPE recommendations and a dangerously false sense of security. It's a methodical process where each stage builds on the last, creating a reliable blueprint for electrical safety.

And this isn't just a niche concern anymore. The global market for arc flash risk assessments is expected to jump from USD 0.6 billion in 2025 to USD 0.9 billion by 2035. That's not just a number—it shows a major global shift toward proactive safety, pushed by tougher regulations and the real-world need to protect people on the ground. You can read more about these arc flash assessment market trends on futuremarketinsights.com.

Step 1: Data Collection and Site Survey

This is where the real detective work begins, and it's the foundation for everything that follows. We start by collecting all the existing paperwork we can find—electrical one-line diagrams, equipment specs, and fault current data from the utility company. This gives us a starting map of your facility's electrical distribution.

But here’s the thing: documents are almost always out of date. That's why the next step, a physical site survey, is non-negotiable. A qualified engineer has to physically walk down the entire system to verify every single piece of information. They're meticulously checking everything from transformer nameplates and conductor sizes to the exact settings on every circuit breaker and fuse.

For an analysis to be worth its salt, you absolutely have to gather the right information from the get-go. Here’s a look at the essential data points we're after during that site survey.

Key Data Points for an Arc Flash Analysis

| Data Category | Specific Information Required | Why It's Critical |

|---|---|---|

| Utility Source | Available short-circuit current from the electric utility. | This is the starting point for all fault current calculations. Without it, the entire study is based on a guess. |

| Transformers | kVA ratings, primary/secondary voltage, impedance (%Z). | Transformer impedance is a major factor in limiting fault current; incorrect values will skew all results. |

| Conductors | Length, size (AWG/kcmil), and material (copper/aluminum) of all cables and busways. | The length and size of a conductor determine its resistance, which affects the amount of fault current that can reach downstream equipment. |

| Protective Devices | Manufacturer, model, and specific trip settings for all circuit breakers, relays, and fuses. | These settings determine how quickly a device will operate to clear a fault, which is a direct input for calculating the duration of an arc flash. |

This hands-on verification isn't just about double-checking—it's about ensuring the digital model we build in the next phase is a perfect mirror of what’s actually installed in your facility.

Step 2: System Modeling and Analysis

Once we have all that verified data, we head back to the office and use specialized software to build a detailed computer model of your electrical system. This digital replica is where the magic happens, allowing us to simulate fault conditions without anyone or anything getting hurt.

With the model built, we run a series of interconnected engineering studies:

- Short-Circuit Study: First, we calculate the maximum potential fault current that could flow at every single point in your system. This number is the bedrock for all the other calculations.

- Protective Device Coordination Study: Next, we analyze how your breakers and fuses work together. The goal is to make sure the device closest to the fault trips first, isolating the problem without knocking out a whole section of your plant.

- Arc Flash Calculation: Finally, we take the results from the first two studies and plug them into the complex formulas from the IEEE 1584 standard. The software then crunches the numbers to determine the incident energy and arc flash boundary for each piece of gear.

This flowchart really shows how the overarching safety standards connect to the nitty-gritty technical calculations.

It all flows from NFPA 70E's mandate for safety down to IEEE 1584's "how-to" guide for the calculations. This is what makes an analysis both compliant and truly effective.

Step 3: Reporting and Label Generation

The final step is all about translating those complex engineering calculations into clear, practical information your team can use every day. The main deliverable is a comprehensive report that breaks down the findings, assumptions, and our recommendations for reducing risk.

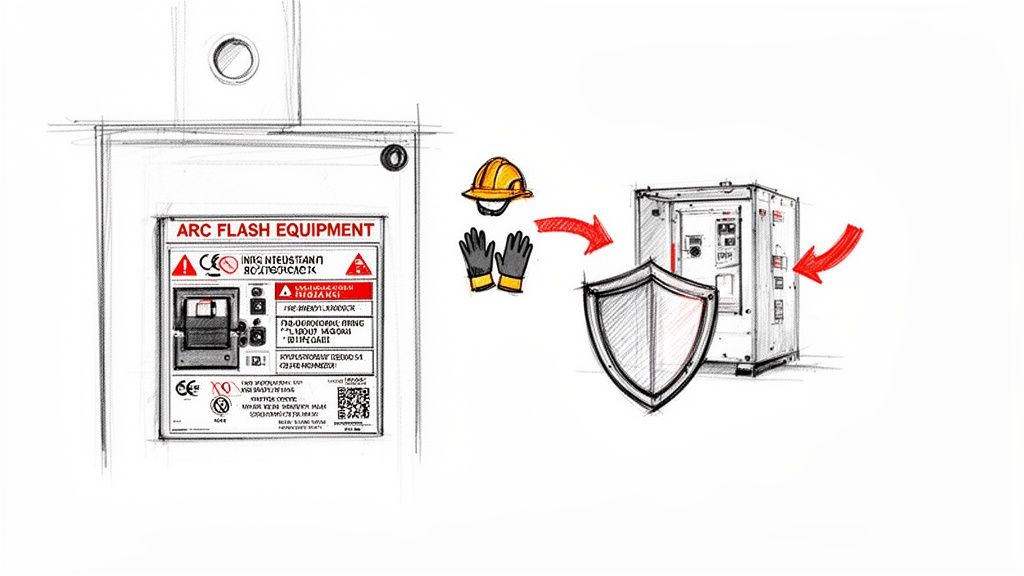

A key output of any arc flash hazard analysis is the equipment label. This isn't just a sticker; it's a critical communication tool that instantly tells a qualified worker the specific hazards they face and the PPE required to work safely.

We generate these labels and install them on every piece of equipment we analyzed—switchgear, panelboards, motor control centers, you name it. They provide the at-a-glance data needed for safe work practices, like the incident energy level and the required working distance.

This whole process closes the loop, turning theoretical data from a computer model into a practical, life-saving tool right there on the plant floor. To see how these principles apply to even larger power systems, you can dig into our guide on electrical substation design.

Putting Your Arc Flash Study Results into Action

An arc flash hazard analysis is just a pile of data until you actually do something with it. The final report and its complex calculations are the blueprint for a safer facility, but the real value comes from using that information to protect your team on the plant floor, day in and day out. This is where the engineering study meets the real world.

The most visible result of the analysis is the new arc flash label stuck to your electrical equipment. This isn't just another warning sticker; it's a critical safety dashboard. It gives qualified workers the vital, on-the-spot information they need to work safely. Getting a handle on what these labels mean is the first step in turning study results into real protection.

How to Read an Arc Flash Label

Think of an arc flash label as the "nutritional facts" for electrical hazard exposure. It instantly tells a worker what they're up against and what they need to wear to go home in one piece. While the exact layout might look a little different from one place to the next, every NFPA 70E-compliant label has to include a few key pieces of information.

Here’s what you need to look for:

- Incident Energy: This is the big one, the headline number. It’s measured in calories per square centimeter (cal/cm²) and tells you exactly how much thermal energy could hit a worker at a specific distance. If a label shows 8.2 cal/cm², the worker must be wearing PPE with a rating that meets or beats that number. No exceptions.

- Arc Flash Boundary: This is your "stay-back" line. It marks the perimeter where an unprotected person could get a second-degree burn (where incident energy hits 1.2 cal/cm²). Anyone who isn't a qualified worker has no business crossing this boundary when the gear is being serviced.

- Required PPE: The label cuts through the confusion by either listing the incident energy or spelling out the required Arc-Rated (AR) PPE Category. This takes all the guesswork out of the equation.

- Shock Hazard Information: Don't forget about shock. The label also details the voltage level and the "approach boundaries" (Limited and Restricted) to keep workers safe from electrocution.

The arc flash label is the most direct link between the engineering analysis and the person doing the work. It turns complex calculations into simple, life-saving instructions.

Mitigation Beyond Just Wearing PPE

Look, PPE is the absolute last line of defense. It's essential, but the real goal is to engineer the hazard away completely. A good arc flash hazard analysis doesn't just point out the dangers; it gives you the hard data you need to implement strategies that actually fix the problem at its source. This is where the hierarchy of controls comes in, pushing us to find engineering and administrative fixes instead of just relying on gear.

The cost of getting this wrong is staggering, both in dollars and in human lives. The arc flash protection market is on track to hit USD 3.6 billion by 2035, a number fueled by the awful consequences of these events. With more than 2,000 workers hospitalized every year from arc blasts and a single incident often costing over $1 million, being proactive isn't just about safety—it's a smart business decision. You can dig into the growth of the arc flash protection market on factmr.com.

Before we dive into specific engineering controls, let's look at the big picture. The "Hierarchy of Controls" is a framework used in safety management that ranks risk control methods from most to least effective.

Arc Flash Mitigation Hierarchy of Controls

The idea is simple: it's always better to remove the hazard entirely than to just put up a shield against it. This table breaks down the different levels of control.

| Control Level | Example Strategy | Impact on Risk |

|---|---|---|

| Elimination | De-energize the equipment before work begins. | Completely removes the arc flash and shock hazard. |

| Substitution | Replace older, high-risk equipment with modern arc-resistant switchgear. | Replaces a high hazard with a significantly lower one. |

| Engineering | Adjust protective device settings for faster clearing times. | Reduces the severity of the hazard if an event occurs. |

| Awareness | Install clear arc flash warning labels and conduct regular training. | Informs workers of the danger but doesn't reduce the hazard itself. |

| Administrative | Implement a robust electrical safety program and safe work permits. | Changes how people work around the hazard. |

| PPE | Require workers to wear appropriate arc-rated clothing and face shields. | Protects the worker but does nothing to reduce the actual hazard. |

As you can see, relying solely on PPE is the least effective—though still necessary—approach. The real wins come from moving up the hierarchy.

Engineering Controls to Reduce Hazards

Engineering controls are the heavy hitters because they physically change the system to make it safer. They're designed to either dramatically lower the incident energy or make an arc flash far less likely to happen in the first place.

Here are a few powerful engineering strategies we often recommend:

- Adjusting Protective Device Settings: Sometimes, the simplest fix is the best. Tweaking the trip settings on an upstream circuit breaker can slash the arc duration. A faster trip means the arc has less time to build up and release its destructive energy, which directly lowers the incident energy. This is often done as part of a coordination study. For a refresher on the basics, check out our article on proper circuit breaker sizing.

- Installing Arc-Resistant Switchgear: This is the gold standard. This specialized gear is built to contain an arc flash and blast the energy up and away from a worker standing in front of it. It’s a top-tier solution for new builds or major upgrades in your most critical areas.

- Using Remote Racking or Switching: These systems are a game-changer. They let operators rack breakers in or out from a safe distance, well outside the arc flash boundary. You're physically removing the person from the line of fire, which is a massive leap forward in safety.

- Implementing Arc-Limiting Fuses: Don't sleep on modern fuses. Today's current-limiting fuses can snuff out a fault in less than half a cycle, cutting the energy off at the knees before it can grow into a monster. This is often a surprisingly cost-effective way to retrofit existing gear and knock down the incident energy on everything downstream.

Documentation, Training, and Maintaining Compliance

Getting your arc flash hazard analysis done is a huge step, but it’s really the starting line, not the finish. The study gives you a pile of critical documents, and the real work begins now: turning that data into a living, breathing part of your facility's safety culture.

If that report just sits on a shelf collecting dust, you’ve missed the point entirely. This final phase is all about taking complex engineering data and making it practical and sustainable for your team on the ground.

The main deliverables—the final report, your freshly updated one-line diagrams, and all those new equipment labels—are your new foundation. They're a detailed snapshot of your system's hazards, a roadmap for safe work practices, and the guide for any future electrical work.

But documents don't keep people safe. People do. This is where training becomes the single most important part of your investment.

Training Your Qualified Persons

At the end of the day, it all comes down to the human element. NFPA 70E is crystal clear on this: only 'qualified persons' can work on or near energized equipment. That’s not just a title; it means they have the specific skills and safety training to recognize the dangers and, more importantly, how to avoid them.

Your training needs to hit these key points hard:

- Hazard Recognition: Teaching your crew to instantly spot the difference between shock and arc flash hazards.

- Label Interpretation: Making sure every single worker can read an arc flash label, understand what "incident energy" and "arc flash boundary" mean, and grab the right PPE without hesitation.

- Safe Work Procedures: Hammering home the right way to establish an electrically safe work condition, especially proper lockout/tagout (LOTO) protocols.

- PPE Use and Care: It’s not enough to have the gear. They need to know how to use it, inspect it, and take care of it so it can take care of them.

Great training is what makes the numbers and warnings from the arc flash hazard analysis actually mean something on the plant floor. To really get into the weeds on this, check out our complete guide on what constitutes effective arc flash safety training.

An arc flash study tells you what the hazards are. Solid training teaches your team how to manage those hazards safely, day in and day out.

Maintaining Compliance as a Living Process

Your electrical system isn't a museum piece; it changes. Equipment fails and gets replaced, a new line is added, or the utility makes a change upstream. That's why an arc flash study isn't a "one-and-done" deal.

NFPA 70E actually requires you to review the analysis at least every five years, or anytime you make a major change to the system. Think of it as a living document.

This ongoing cycle looks something like this:

- Documenting Changes: Get religious about updating your one-line diagrams the moment a significant change is made. Don't wait.

- Periodic Reviews: Put it on the calendar. Every five years, a formal review is needed to make sure the study still reflects reality.

- Refresher Training: Skills get rusty and people forget. Regular safety training keeps your team sharp and current.

This isn't just about arc flash, either. Consistently meeting security compliance in your business is a fundamental part of running a safe and responsible facility. It’s an active, never-ending process that protects your people, limits your liability, and builds a culture where everyone goes home safe.

A Few Common Questions About Arc Flash Studies

Even after you get the basics down, a lot of plant managers and safety pros still have questions about what an arc flash hazard analysis looks like in the real world. The process is critical, no doubt, but it can feel a bit overwhelming. Let's walk through some of the most common questions to clear things up.

Getting these details right is the difference between a study that just checks a box and one that actually keeps your team safe. Think of this as the practical FAQ for putting your electrical safety plan into action on the plant floor.

How Often Do We Really Need to Do This?

This is probably the number one question I get, and for good reason. An arc flash study isn't a "one-and-done" deal. Your electrical system is a living, breathing thing, and your analysis has to keep up with the changes to be worth anything at all.

The official word from NFPA 70E is that a facility's arc flash hazard analysis needs a full review at least every five years. This check-up makes sure the calculations still match what's actually happening in your system.

But—and this is a big but—other things can trigger a review much sooner than that five-year mark:

- Big System Changes: If you add a massive motor, swap out a transformer, or significantly re-route your power distribution, the available fault current is going to change. That means you need to update the analysis right away.

- Utility Power Changes: It happens. The utility company upgrades their substation or lines feeding your plant, which can crank up the available fault current at your front door. If they send you a notice about it, it's time to revisit your study.

- Protective Device Tweaks: Swapping a fuse for a different type or changing a circuit breaker's trip settings might seem small, but it can drastically alter how long an arc lasts. A longer arc means higher incident energy, so any change like this requires an update.

Your arc flash analysis is basically a detailed hazard map for your electrical system. If you build a new road or the landscape shifts, you have to update the map. Otherwise, you're sending people out with bad directions.

Can OSHA Actually Fine Us for Missing Arc Flash Labels?

People get tangled up on this one all the time. An OSHA inspector won't write a ticket that specifically says "Violation of NFPA 70E, Article 130.5(H)." But can they fine you for it? Absolutely. OSHA just uses their own rulebook to enforce the same safety principles.

When it comes to arc flash, OSHA leans on a few key regulations to cite employers:

- The General Duty Clause: This is the big one. Section 5(a)(1) says employers must provide a workplace "free from recognized hazards." Arc flash is about as "recognized" as it gets, and NFPA 70E is the industry's consensus on how to handle it. A missing label is a giant red flag that you're not addressing a known killer.

- PPE Hazard Assessment (29 CFR 1910.132(d)(1)): This rule requires you to assess the workplace for hazards that demand PPE. The arc flash label is the direct output of that assessment for electrical work. No label usually means no assessment was ever done, leaving your workers guessing.

So, while the citation might not name-drop NFPA 70E, a missing label tells an inspector that a fundamental safety process—the arc flash hazard analysis itself—is either missing or ignored. That's a direct path to a citation.

What's the Difference Between the PPE Category Method and a Full-Blown Incident Energy Analysis?

NFPA 70E actually gives you two ways to figure out the right arc flash PPE. Knowing the difference is key to picking the right approach for your facility.

The PPE Category Method is often called the "table method." It's exactly what it sounds like. A qualified worker uses tables inside the NFPA 70E book to find a task (like racking in a breaker) on a certain type of equipment. If—and only if—the system's parameters fall within the table's very strict limits, it tells you the required PPE Category (e.g., CAT 2).

The Incident Energy Analysis Method is the full engineering study we've been talking about. This is where an engineer models your entire electrical system in specialized software to calculate the precise incident energy (measured in cal/cm²) at every single piece of equipment.

Here's a quick breakdown:

| Feature | PPE Category Method (Tables) | Incident Energy Analysis (Study) |

|---|---|---|

| Accuracy | General. It's based on worst-case scenarios and assumptions. | Precise. It's calculated for your specific system's conditions. |

| Worker Burden | High. The worker has to verify fault currents and clearing times on the spot. | Low. The worker just reads the label and puts on the right gear. No guesswork. |

| Flexibility | Rigid. You can't use it if your system falls outside the table's narrow limits. | Super flexible. Gives you exact data for every piece of equipment you analyze. |

| Initial Cost | Cheaper upfront, since you're not paying for a deep-dive engineering study. | Higher initial investment for the engineering time and software modeling. |

While the table method can be a compliant option for very simple, well-documented systems, the incident energy analysis is hands-down the safer and more reliable approach. It takes the guesswork and complex decision-making away from the person standing in front of the live gear, giving them a clear, data-driven instruction right on the label.

A solid, up-to-date arc flash hazard analysis is the bedrock of any modern electrical safety program. From the initial system modeling to the final labels and training, getting it right protects your people, period. At E & I Sales, we build the engineered UL-listed control panels and provide the system integration that creates a safe, reliable foundation. See how our expertise can support your next project.