Think of an industrial control panel as the central nervous system for your entire automated operation. It’s what gives life to everything from a basic motor starter to a complex, multi-axis robotic cell. This isn't just another component you order off a shelf; it's the very core of your facility's safety, efficiency, and uptime.

That’s why picking a manufacturer is less like a simple purchase and more like entering into a long-term strategic partnership.

Choosing the Right Partner, Not Just a Panel Builder

Let’s be honest, anyone can stuff components into a box. What separates a true solutions provider from a basic assembly shop is their ability to deliver a fully engineered, code-compliant system that works seamlessly from day one. They do more than just build; they become an extension of your own engineering team.

This guide is designed to help you look past the spec sheets and see the bigger picture. We’re digging into what makes a premier partner—someone who delivers a complete solution that minimizes risk, cuts down on headaches, and gets your project across the finish line faster.

Why a Partnership Approach Matters

When you treat your manufacturer like a partner, you unlock a ton of value. Their experts can spot potential design flaws or compliance issues long before they become expensive problems on the shop floor. They provide the kind of guidance that only comes from years of hands-on experience, ensuring the final product is a perfect fit for your operational needs.

This collaborative mindset is crucial, especially in an industry that's growing like crazy. The global industrial control panel market is already a giant, valued at around $15 billion in 2025, and it’s expected to blow past $25 billion by 2033. This surge is all thanks to the non-stop push for more automation in manufacturing, energy, and just about every other sector. A solid partnership ensures you’re not just keeping up, but leading the pack.

What to Expect from a Top-Tier Manufacturer

A top-tier control panel builder brings a lot more to the table than just assembly work. Their value is in the comprehensive support they provide from the initial concept all the way through commissioning.

- Deep Engineering Expertise: They live and breathe the nuances of UL-listed systems, motor control centers (MCCs), and how to integrate everything without a hitch.

- Proactive Problem Solving: The best partners anticipate problems. They’ll question a drawing or suggest a better component before it ever causes a delay.

- Turnkey Solutions: Many of the best shops offer the whole package—design, fabrication, programming, and even on-site startup support.

The right manufacturer delivers more than just hardware; they deliver confidence. It's the confidence that comes from knowing your control systems are built to the highest standards of safety, quality, and reliability, ready for seamless integration and built to last.

Ultimately, the goal is to find a partner who can provide a complete, dependable solution that’s truly built for your specific application. That starts with understanding the difference between someone who just builds panels and a partner who builds solutions.

Decoding Essential Certifications and Capabilities

When you're vetting industrial control panel manufacturers, it’s easy to get fixated on the price tag. But the real story isn't in the quote; it's in their core competencies. Not all panel shops are built the same, and their certifications and proven capabilities are the true measure of quality, safety, and long-term reliability.

Think of it like hiring a specialized surgeon. You wouldn’t shop around for the cheapest option, would you? You’d be looking for board certification, a track record of success with complex procedures, and deep expertise. The same logic applies here. A manufacturer’s credentials aren't just logos on a website—they're your assurance that they have the documented processes and expertise to build a panel that’s safe, compliant, and ready for the plant floor.

The Gold Standard: UL 508A Certification

In North America, one certification stands above all others: UL 508A. This is the undisputed gold standard for industrial control panels. When a shop is certified by Underwriters Laboratories (UL), it means they are authorized to design, build, and apply the UL mark to panels that meet incredibly rigorous safety standards. The program audits everything from how they select components and route wires to the enclosure ratings they use.

Having that UL 508A label on your panel is a massive advantage. It dramatically simplifies the final inspection process on-site. When the Authority Having Jurisdiction (AHJ) sees that mark, it serves as immediate proof of compliance, helping you avoid costly and frustrating delays during commissioning. It is the single most important credential to look for. To get a better handle on the specifics, you can learn more about the differences between UL Listed vs. UL Recognized components in our detailed guide.

A UL 508A certified shop isn't just following a rulebook; they're demonstrating a deep-rooted culture of safety and quality control. This certification validates that their entire process—from design to final testing—is built to mitigate electrical hazards and ensure operational integrity.

Core Technical Capabilities to Verify

Beyond the paperwork, a top-tier partner needs to have a broad arsenal of technical skills. A simple assembly shop might be fine for basic relay logic, but modern industrial processes demand a whole lot more. It’s also critical to ensure your partner is up-to-date with evolving regulations, like the Cyber Resilience Act (CRA) and its associated CRA Manufacturer Obligations.

Here are the key capabilities that separate a true engineering partner from a basic assembler:

- Motor Control Centers (MCCs): If your facility runs a lot of motors, expertise in designing and building MCCs is non-negotiable. An experienced manufacturer knows how to create centralized, modular systems that make maintenance easier, improve safety, and are built for future expansion.

- Variable Frequency Drives (VFDs): Anyone can mount a VFD in a box, but properly integrating one for energy efficiency and precise motor control is an art. This means understanding heat dissipation, harmonic mitigation, and the right programming to optimize performance and prevent premature equipment failure.

- Medium Voltage (MV) Switchgear: Working with equipment above 600V is a whole different ballgame. The ability to handle medium voltage applications is a highly specialized skill that requires advanced engineering knowledge and a strict adherence to safety protocols that many shops simply don't have.

Verifying these capabilities upfront ensures your manufacturer can handle the full scope of your project. You'll get a robust, integrated solution—not just a collection of parts in an enclosure.

Evaluating Design Engineering and Quality Control

A great control panel isn't just about skilled wiring; it’s born from a disciplined engineering process. The real difference between a reliable, workhorse panel and a source of constant frustration often comes down to the manufacturer's commitment to a structured design workflow and relentless quality checks. This is where you separate the mere assemblers from true engineering partners.

Top-tier industrial control panel manufacturers don't just build to a print you hand them. They dig in. They question it. They scrutinize your specifications to spot potential issues, check for compliance with NEC and NFPA standards, and make sure the design is truly robust and maintainable. This kind of proactive thinking prevents costly mistakes from getting "wired in" from the very beginning.

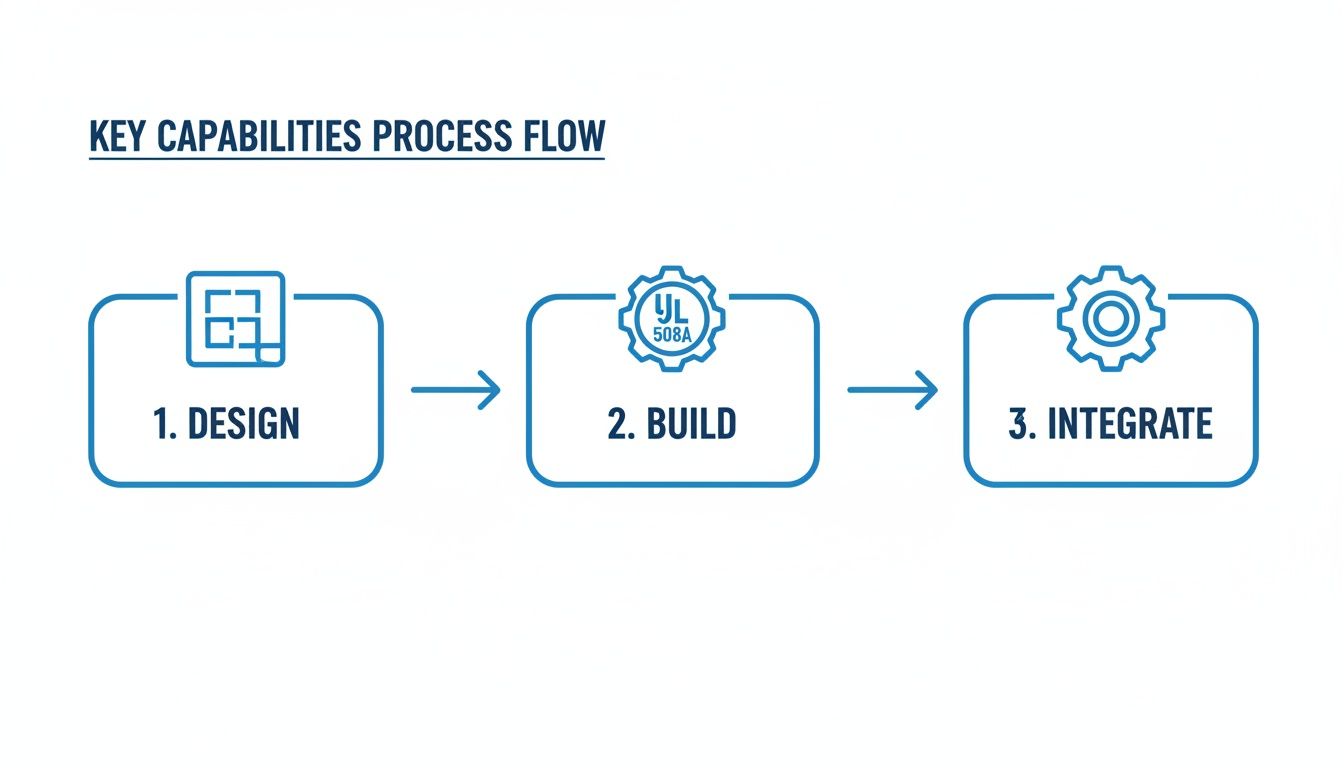

This flow chart gives you a bird's-eye view of a quality-driven manufacturing process.

It really highlights how a disciplined workflow should move seamlessly from the initial design and engineering phase, through certified assembly, and into the final system integration.

The Blueprint for Reliability

A manufacturer's design process is the absolute foundation of quality. Today, modern panel shops lean heavily on advanced CAD software to create precise electrical schematics and detailed 3D panel layouts. These digital models aren't just pretty pictures; they allow engineers to verify component clearances, plan out clean wire routing, and generate dead-on accurate bills of material before anyone even drills a single hole.

When you're evaluating a partner, ask them about their design tools and how they document everything. A well-documented process is a dead giveaway of a mature and reliable operation. If you want to get into the nitty-gritty, our guide on industrial control panel design offers a much deeper dive.

The Quality Management System

So, how does a manufacturer guarantee that the thousandth panel they build is just as perfect as the first? The secret is their Quality Management System (QMS). A real QMS isn't just a dusty binder on a shelf; it’s a living, breathing framework that dictates every single step of production, from receiving to shipping. When vetting a manufacturer, it’s critical to ask about their adherence to robust standard operating procedures.

A strong QMS will always include several key pieces:

- Document Control: A formal system for managing schematics, revisions, and work instructions. This ensures every technician is working from the latest, correct version. No excuses.

- Component Verification: A process for checking every incoming part against the bill of materials to catch mistakes before they get anywhere near the assembly floor.

- In-Process Checks: Point-to-point wiring verification and component torque checks that happen during the build, not just at the final inspection.

- Functional Testing: A full power-up test and functional simulation of the panel's logic. This confirms it operates exactly as intended before it ever leaves their shop.

Quality control isn't a single event at the end of the line; it’s a series of checkpoints integrated throughout the entire design and build process. This continuous verification is what guarantees consistency, reliability, and safety in every panel delivered.

Before we move on, here’s a quick checklist you can use to frame your conversations with potential partners.

Key Manufacturer Evaluation Criteria

| Evaluation Area | What to Look For | Why It Matters |

|---|---|---|

| Design Engineering | Use of modern CAD/CAE tools, schematic review process, 3D panel layouts, revision control. | Ensures design accuracy, proper component fit, and that everyone is working from the correct set of prints. |

| Quality System (QMS) | Documented SOPs, formal quality manual, evidence of in-process checks (e.g., torque sheets, point-to-point logs). | Provides a framework for repeatable quality and consistency from the first panel to the last. |

| Component Sourcing | Verification of incoming parts against the BOM, use of authorized distributors, counterfeit part avoidance policies. | Guarantees that the specified components are actually what get installed, preventing performance issues. |

| Testing & Validation | Full power-up functional testing, I/O simulation, detailed factory acceptance test (FAT) procedures. | Verifies the panel operates exactly as designed before it arrives at your facility, minimizing startup delays. |

| Documentation | As-built drawings, component manuals, test reports, and a complete final documentation package. | Critical for installation, troubleshooting, and long-term maintenance of the system. |

Ultimately, a manufacturer with a transparent and well-documented process isn't just selling you a product. They’re delivering the peace of mind that comes from knowing your critical systems are built correctly, documented thoroughly, and ready to perform for years to come.

Looking Beyond the Build to Integration and Support

An industrial control panel isn’t a gadget you just plug in and forget. Its real job only starts when it's talking perfectly with every other motor, sensor, and PLC on your plant floor. The project isn't done when the panel ships out; in many ways, it's just getting started.

This is exactly why the best industrial control panel manufacturers are the ones who stick around for the whole journey. They don't just build a box and send an invoice. They’re the ones who bridge that critical, often-tricky gap between the panel they built and the process you need it to control. It's the difference between a simple transaction and a genuine partnership.

From Their Factory Floor to Your Floor

A top-tier partner offers services that go way beyond their own four walls. They get that a smooth transition from installation to full-blown production is everything. This is where services like on-site integration and commissioning become absolute game-changers, helping you sidestep huge project risks and costly delays.

Think about a major plant upgrade. The shiny new control panel arrives, but now you have to connect it to a web of existing machinery, legacy sensors, and your plant’s network. That’s a massive headache waiting to happen. A manufacturer who sends their experts to your site turns that potential nightmare into a smooth, managed process.

These critical post-build services usually include things like:

- Factory Acceptance Tests (FAT): This is your chance to see the panel run under simulated plant conditions before it ever leaves their shop. It’s a crucial step to make sure everything works as designed, catching issues early.

- On-Site Commissioning Supervision: Having an expert from the panel shop on-site during startup is invaluable. They know the system inside and out, can troubleshoot problems on the fly, and ensure it integrates cleanly with your existing equipment.

- Operator and Maintenance Training: A great partner doesn’t just hand over the keys and walk away. They make sure your team knows how to operate the new system and perform basic maintenance, setting you up for long-term success.

A manufacturer's responsibility shouldn't end at the shipping dock. True project ownership means ensuring the solution performs not just in their shop, but in your facility, under real-world production demands. This commitment to integration and support is a key differentiator.

The Real-World Impact of Full-Lifecycle Support

Let’s play out a common scenario: a manufacturer ships the panel and a bill, and that’s it. Your team is left digging through schematics, wrestling with the integration, and trying to squash programming bugs. This hands-off approach almost always leads to extended downtime, blown deadlines, and a whole lot of frustration.

Now, picture it with a partner who sees the project through. Their engineer is on-site, supervising the installation and working right alongside your technicians to commission the system. They make sure your operators are comfortable with the new HMI screens before they leave. This hands-on approach catches small problems before they balloon into big ones and can easily shorten your startup timeline by days or even weeks.

Ultimately, picking a manufacturer is about so much more than the physical build quality. It’s about finding a team that’s invested in your success long after the last wire is terminated. That holistic support is what ensures your new system actually delivers on its promise of better safety, efficiency, and reliability from day one.

Understanding Cost, Lead Times, and Long-Term Value

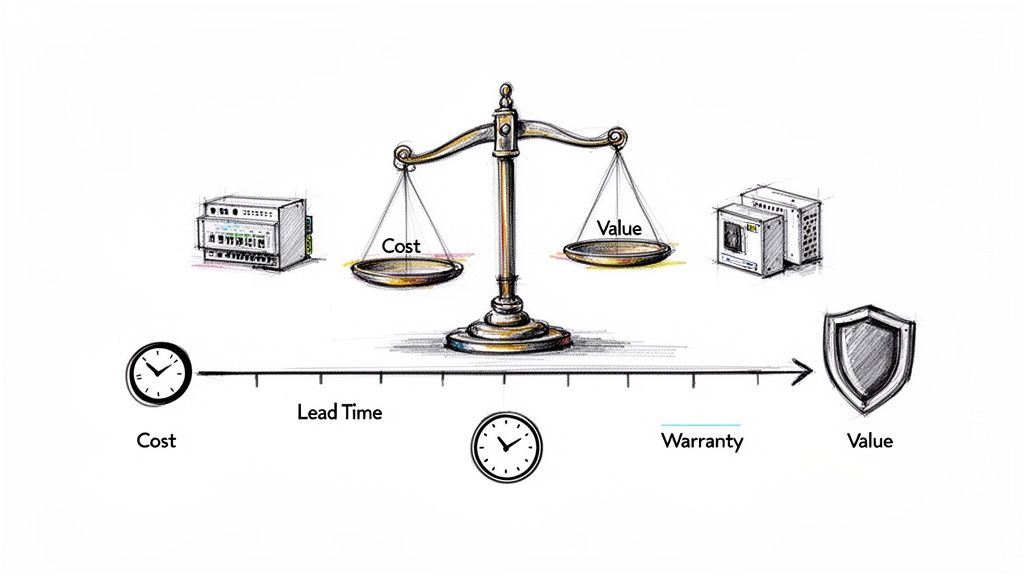

When you're sourcing an industrial control panel, it's tempting to just compare the final numbers on the quotes. But the initial price tag is only one piece of a much larger puzzle. The real value comes from finding the sweet spot between upfront cost, production timelines, solid warranty coverage, and the long-term reliability of that panel on your floor.

Think about it like buying a new CNC machine. You wouldn't just grab the cheapest one without digging into its performance specs, expected lifespan, and the kind of support you'll get when something inevitably goes sideways. You have to apply that same strategic thinking to your control panels. A slightly higher investment today in better components or a more thoughtful design can easily pay for itself a hundred times over by preventing even a single hour of unplanned downtime tomorrow.

Key Factors That Drive Panel Costs

A few key things really move the needle on the final quote you'll get from industrial control panel manufacturers. Getting a handle on these drivers means you can have much better conversations with potential partners and make smart trade-offs.

- Component Selection: The brands you call out for the big-ticket items—PLCs, VFDs, circuit breakers—are a huge cost driver. Sure, sticking to your plant standard makes life easier for your maintenance team, but having some flexibility can open up options for more cost-effective or, more importantly, available alternatives.

- Enclosure Type and Rating: The box itself really matters. A basic NEMA 1 enclosure for a clean, dry room is a world away from the cost of a NEMA 4X stainless steel cabinet built to survive a corrosive chemical washdown.

- Design Complexity: The more you ask the panel to do, the more it's going to cost. Things like high I/O counts, complex programming logic, and custom-crammed back panels all add up in both engineering and assembly labor.

Navigating Production Lead Times

In today's world, lead times are everything. A standard custom control panel build can take anywhere from 4 to 12 weeks, but that number can swing wildly. The biggest wildcard is almost always the availability of a key component. A single, specific PLC or drive on backorder can bring your entire project to a screeching halt.

Don't just ask, "What's your lead time?" A much better question is, "What are the long-lead items in my design, and are there any good alternatives we should look at to speed things up?" This simple shift puts you in the driver's seat and can keep your project moving.

The True Meaning of a Strong Warranty

Last but not least, don't just glance at the warranty. A manufacturer's warranty is a direct statement about how much they believe in their own work. A flimsy warranty might cover a faulty part, but it'll leave you holding the bag for the labor to swap it out.

A truly great warranty, on the other hand, backs the whole package. It should cover the parts, the workmanship, and the integrity of the design itself. This is your assurance that the panel was built right from the start and that the builder will be there for you, giving you peace of mind long after the check has cleared.

Tying Up Loose Ends: Your Final Questions Answered

Even after you've done your homework and narrowed down the list, a few lingering questions always seem to pop up. Getting straight answers to these final-stage queries is what separates a good choice from a great one, giving you the confidence that you're picking the right industrial control panel manufacturer.

Think of this as the last gut check before you sign on the dotted line. These are the practical, real-world questions that truly reveal how a partner operates.

What’s the Big Deal with UL 508A Certification?

In North America, the UL 508A certification is the gold standard, and honestly, it should be non-negotiable. It means a manufacturer has been audited by Underwriters Laboratories (UL) and has proven they can build panels to an incredibly high, nationally recognized safety standard. It’s not just a sticker on the box; it's a guarantee that their entire process—from how they select components to their specific wiring techniques—is designed to prevent fires and electrical hazards.

For you, a UL-listed panel delivers two huge wins. First, you get an immediate baseline of quality and safety you can count on. Second, it makes life infinitely easier during on-site electrical inspections. When the Authority Having Jurisdiction (AHJ) sees that UL mark, they recognize it as proof of compliance on the spot, which helps you dodge expensive delays when you’re trying to get up and running.

How Can I Get the Most Accurate Quote?

The quote you get back is only as good as the information you put in. To get a price that’s both accurate and competitive, your scope of work needs to be buttoned up. The more detail you provide upfront, the less guesswork the panel shop has to do—and guesswork always costs more.

To set them (and yourself) up for success, be sure to include:

- A complete bill of materials that calls out your preferred brands for major hardware like PLCs and VFDs.

- A sequence of operations that spells out, in plain English, how the system is supposed to work.

- A detailed I/O (Input/Output) list that accounts for every single connection point.

- All motor and load information so they can size circuit protection correctly.

- The specific enclosure you need, like a NEMA 4X stainless steel unit for a washdown environment.

If you have existing electrical drawings or P&ID diagrams, send them over. That level of detail is worth its weight in gold and ensures the quote you get is for the panel you actually need.

What's the Difference Between a System Integrator and a Panel Shop?

It's a great question, and the lines can definitely get blurry. A dedicated control panel manufacturer is laser-focused on the physical world inside the enclosure. They specialize in the design, assembly, wiring, and testing of the panel itself, all based on a set of engineering prints.

A system integrator, on the other hand, usually takes a wider, 10,000-foot view. They’re often responsible for designing the complete automation system, which includes programming the PLC and HMI, and then integrating that new panel with all the other machines, sensors, and software on your factory floor.

The real magic happens when you find a partner who does both. A company that can handle everything from fabricating the panel to commissioning the system on-site offers a huge advantage. It creates a single point of responsibility, which streamlines the project, kills communication gaps, and eliminates the finger-pointing that can happen when you have two different vendors.

Ready to partner with a team that offers deep expertise in both custom UL control panel manufacturing and full-system integration? E & I Sales has been delivering reliable, code-compliant solutions since 1974. Connect with our experts today to discuss your next project by visiting us at https://eandisales.com.