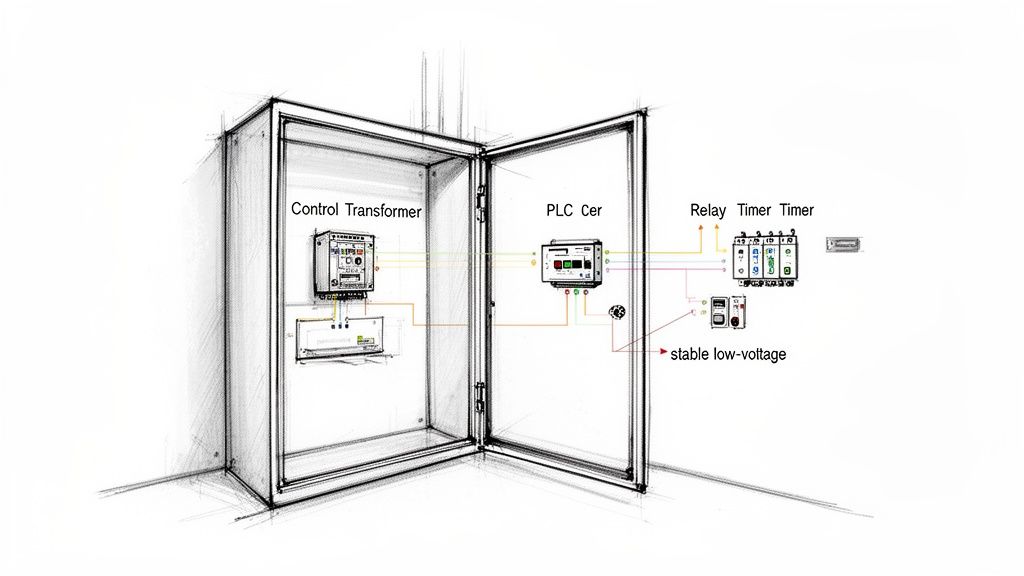

A control transformer isn’t just another component in an electrical cabinet; it’s the dedicated power supply that keeps your control circuits running smoothly and safely. At its core, it's an isolation transformer that takes high, often dangerous, system voltages and steps them down to a more manageable level, like 120V or 24V.

This stepped-down voltage is what powers the brains of the operation—the relays, timers, contactors, and other sensitive electronics that manage an entire industrial process.

The Unsung Hero Inside Your Control Panel

Picture a massive industrial machine. Its powerful motors might be chugging along on 480V, but the delicate control circuits orchestrating every move can't handle that kind of power. This is where the control transformer steps in, acting as the quiet guardian for the machine’s most critical electronics.

It’s helpful to think of the difference this way: a standard power transformer is like the utility pole bringing electricity to an entire neighborhood—it’s powerful but indiscriminate. A control transformer, on the other hand, is like a high-end, dedicated power conditioner for your most expensive piece of audio equipment. It’s not just about changing the voltage; it's about delivering clean, stable, and reliable power precisely where it matters most.

Why Is This Stability So Important?

When you fire up an industrial machine, components like motor starters, solenoids, and relays demand a massive, instantaneous surge of current to get going. This is called inrush current, and it can cause a momentary voltage drop—or "sag"—across the entire control circuit.

If that voltage dips too low, things start to go wrong. Relays might fail to pull in, contactors can chatter, and PLCs could glitch. A standard transformer would buckle under that sudden demand.

Control transformers, however, are built for this abuse. They are specifically engineered with low impedance windings to handle huge inrush currents without breaking a sweat. This ensures that even when a big motor contactor slams shut, the voltage feeding your sensitive PLC remains rock-solid.

A well-designed control transformer can handle inrush currents up to 10-12 times its nominal rating. This is its superpower, preventing voltage sags that could otherwise cause chaos in an automated system.

This built-in toughness is what makes control transformers non-negotiable for reliable automation. For any company building UL-listed control panels, choosing the right transformer is a foundational step in minimizing costly downtime for the end-user. After all, a solid industrial control panel design always starts with a stable power source.

To put it all together, here’s a quick overview of what a control transformer brings to the table.

Control Transformer at a Glance

| Function | Key Characteristic | Primary Benefit |

|---|---|---|

| Voltage Regulation | Provides stable, stepped-down voltage (e.g., 480V to 120V) for control circuits. | Protects sensitive components and ensures consistent operation. |

| Inrush Management | Designed to handle high momentary inrush currents from inductive loads. | Prevents voltage sags that can cause device malfunction or failure. |

| Electrical Isolation | Creates a physical separation between the high-voltage power source and the control circuit. | Enhances safety for operators and protects electronics from power line noise. |

In short, this small but mighty component is the bedrock of any modern industrial control system, ensuring machinery operates safely, efficiently, and without interruption.

How Control Transformers Differ From Other Transformer Types

It's a lot easier to wrap your head around what a control transformer is when you see it side-by-side with its more common cousins. While all transformers play with voltage, what’s going on inside—their design—is what really matters. Picking the wrong one is like trying to haul a load of gravel with a sports car. Sure, it might move an inch, but it’s built for a totally different kind of stress and won’t last long.

The electrical world has a whole family of transformers, each with a specific job. To steer clear of costly mix-ups and keep your systems humming, you've got to understand what makes a control transformer the special tool it is. The key differences aren't just in what they do, but in how they're built to survive the chaotic demands of industrial control circuits.

Control Transformer vs. Power Transformer

The most frequent point of confusion is between control transformers and the standard power (or distribution) transformers you see everywhere. A power transformer is all about efficiency and steady, predictable loads. Its job is to deliver bulk power to a facility or a big machine with as little energy waste as possible. It’s happiest with a relatively constant, predictable current draw.

A control transformer, on the other hand, is a specialist built for chaos. It’s engineered to handle the massive, but very brief, inrush currents that come from energizing inductive components like solenoids, relays, and motor contactors. We're talking about a momentary surge that can be 5 to 15 times the component's normal operating current.

A standard power transformer would see that surge as an overload and its output voltage would plummet. That voltage sag would cause your control components to stutter or fail, bringing the whole system down.

Think of it this way: a power transformer is a marathon runner, built for steady, long-distance performance. A control transformer is a weightlifter, engineered to handle immense, explosive bursts of effort without even flinching.

This is because its windings have a lower impedance, which is the secret to maintaining stable voltage even when it gets hit with a sudden, heavy load.

The Role of Isolation Transformers

An isolation transformer is all about safety and cleaning up electrical noise. It almost always has a 1:1 turns ratio, which means the voltage you put in is the same as the voltage you get out (e.g., 480V in, 480V out). Its claim to fame is the complete electrical separation—often called galvanic isolation—between its primary and secondary windings.

This separation creates a brand-new, isolated power source on the secondary side. This is great for protecting sensitive electronics from electrical noise and creating a much safer environment for anyone working on the equipment.

Now, here's the key: all control transformers are technically isolation transformers (they separate the high-voltage primary from the low-voltage control circuit). But not all isolation transformers are control transformers. A standard isolation transformer just isn't built with the muscle needed to handle the brutal inrush demands of a control circuit.

Understanding the Autotransformer

An autotransformer is the odd one out. It uses just one winding that serves as both the primary and the secondary. By using different connection points, or "taps," along this single coil, it can step voltage up or down. Because of this clever design, they are often smaller, lighter, and cheaper than their two-winding relatives.

But that efficiency comes with a huge trade-off: autotransformers provide zero electrical isolation. There’s a direct physical connection between the input and output circuits. This complete lack of separation makes them totally unsuitable and dangerous for most control panel applications, where keeping operators safe and protecting delicate electronics is non-negotiable. You’ll usually find them in places like motor starting circuits where isolation isn’t a priority.

To really nail down these differences, let's put them all in one place.

Control Transformer vs. Other Transformer Types

This table breaks down the key distinctions between these common transformer types.

| Transformer Type | Primary Purpose | Inrush Current Handling | Typical Application |

|---|---|---|---|

| Control Transformer | Provide stable, low-voltage power for control circuits with high inductive loads. | Excellent. Specifically designed to handle high inrush without significant voltage drop. | Industrial control panels for PLCs, relays, contactors, and solenoids. |

| Power Transformer | Efficiently transfer bulk electrical power at a steady rate. | Poor. Not designed for sudden, high-demand surges; voltage will sag. | Utility distribution, building power, and supplying main machine power. |

| Isolation Transformer | Create electrical separation for safety and noise filtering. | Poor. Not typically designed for high inrush unless specified as a control type. | Medical equipment, sensitive laboratory instruments, and data centers. |

| Autotransformer | Step voltage up or down economically without isolation. | Poor. Lacks isolation and is not built for the demands of control circuits. | Motor starting circuits (reduced voltage starters) and some power grids. |

At the end of the day, a control transformer is a purpose-built beast. It gives you the safety of an isolation transformer combined with the raw strength needed to regulate voltage under the toughest industrial conditions, making it an absolutely essential part of modern automation.

Cracking the Code on Transformer Ratings and Specs

Picking the right control transformer isn't about grabbing the biggest one off the shelf. It’s a precision game. You’re matching its DNA—its specifications—to the exact needs of your control circuit. These ratings aren't just numbers on a label; they're the blueprint for a reliable, safe, and effective system. Get this right, and you prevent a world of headaches.

The first spec you'll run into is the VA (Volt-Amps) rating. Think of this as the transformer's total power budget. It tells you the apparent power it can handle. To figure out the maximum continuous current the secondary can supply, just divide the VA rating by the secondary voltage. For instance, a 500 VA transformer with a 120V secondary is good for a steady 4.17 amps. Simple enough, right?

But "steady" is a luxury in the industrial world. Control circuits are all about starts and stops, which brings us to the most critical part of sizing: understanding the two very different kinds of power demand.

Sealed VA vs. Inrush VA: The Two Sides of Power Demand

Imagine you're trying to push a heavy cart. That first shove to get it moving takes a huge, concentrated effort. But once it's rolling, keeping it going is way easier. That's a perfect picture of how control components use power.

- Sealed VA: This is the "keeping it rolling" power. It's the continuous, low-level energy your components need just to stay on—think energized relays, timers, and PLC processors.

- Inrush VA: This is that massive, initial shove. It’s the momentary surge of power needed to energize an inductive device like a motor contactor or a solenoid. This jolt can be 5 to 15 times higher than the sealed VA.

Your transformer has to be beefy enough for both. If you only size for the sealed VA, the transformer's voltage will tank the moment that inrush hits, and your control system will stumble right at startup.

As you can see, a control transformer is really a specialized type of isolation transformer, built from the ground up for the unique demands of industrial control circuits, setting it apart from its general-purpose power transformer cousins.

Voltage Ratings and Temperature Rise

Beyond VA, the voltage ratings are non-negotiable. The primary voltage has to match your incoming power (like 480V or 240V), and the secondary voltage needs to match what your control components are designed for (typically 120V or 24V). Thankfully, many control transformers come with multi-tap primaries, giving you some much-needed flexibility to handle different supply voltages on-site.

Another spec to watch is temperature rise. This tells you how much hotter the transformer's windings will get than the surrounding air when it's running at full tilt. A 115°C rise is pretty standard, meaning it can operate that much hotter than the ambient temperature without breaking down. But if you’re installing it in a hot environment, grabbing a transformer with a lower temperature rise (like 80°C) is a smart move that can seriously extend its working life.

UL and NEMA Compliance: Your Seal of Approval

Last but not least, always look for the UL (Underwriters Laboratories) and NEMA (National Electrical Manufacturers Association) marks. These aren't just stickers. They are your proof that the transformer has been put through the wringer and passed strict safety and performance tests. UL 508, for example, is the gold standard for industrial control gear.

Choosing a compliant transformer means you're getting a product built with quality insulation that can handle its rated load without becoming a fire or shock hazard. For anyone building UL-listed control panels, using certified components isn't just a good idea—it's a requirement.

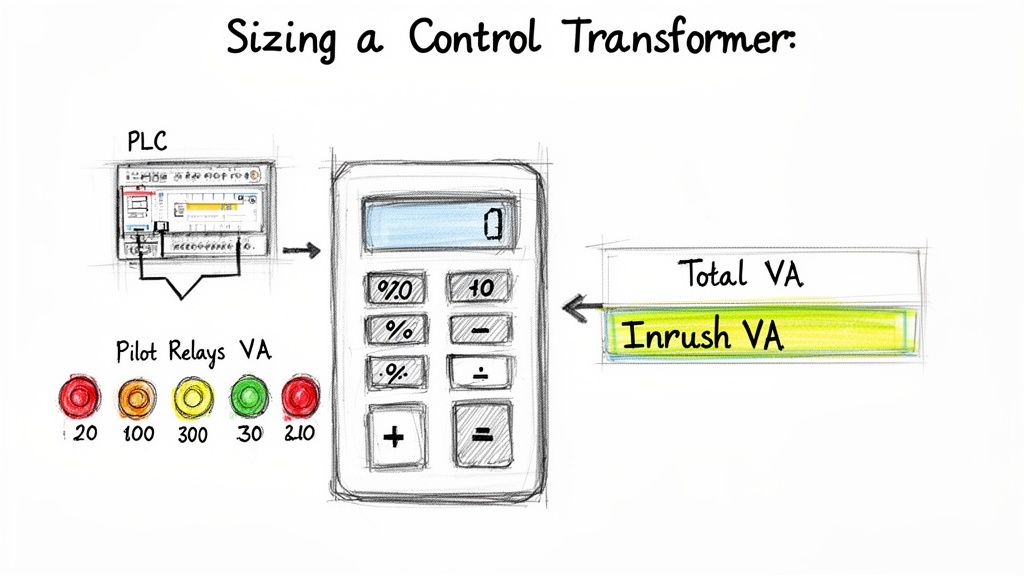

A Practical Guide to Sizing Your Control Transformer

Getting the size of your control transformer right is more of a science than a guessing game. If you go too small, you're signing up for frustrating voltage drops and mysterious system failures. Oversize it, and you're just wasting money and precious panel real estate.

The good news is there's a straightforward process to nail the sizing every single time. Let's walk through a real-world example to see how it's done, covering both the steady-state power draw and that all-important inrush surge.

Step 1: Tally Your Continuous Power Needs

First things first, we need to figure out the sealed VA. This is the continuous power your components need just to stay on and do their jobs. Think of it as the baseline power needed to keep the lights on inside your control circuit.

Start by making a list of every single device that will be powered by the transformer's secondary winding. This means PLCs, timers, relays, pilot lights, and the coils inside contactors and motor starters—everything.

Once you have your list, dig into the manufacturer datasheets to find the sealed VA rating for each component. Let’s put together a list for a typical motor control panel:

- Programmable Logic Controller (PLC): 30 VA

- Active Timers (2): 5 VA each (10 VA total)

- Control Relays (6): 4 VA each (24 VA total)

- Pilot Lights (4): 3 VA each (12 VA total)

- Motor Starter Coils (2): 15 VA each (30 VA total)

Now, just add it all up:

Total Sealed VA = 30 + 10 + 24 + 12 + 30 = 106 VA

That 106 VA is the constant, everyday load your transformer will be handling.

Step 2: Calculate the Critical Inrush VA

This next part is where a control transformer really earns its keep: handling the inrush current. This is that massive, split-second surge of power needed to energize inductive loads like contactors, solenoids, and relays.

For this calculation, you only need to worry about the components with a big inrush demand that could all kick on at the exact same moment. Looking at our list, the motor starter coils are the main culprits here. Go back to the datasheets and find their inrush VA rating.

Let's say each motor starter coil has an inrush rating of 150 VA. If there's any chance both could start simultaneously, you have to account for that combined surge.

Total Inrush VA = 150 VA + 150 VA = 300 VA

This is the peak load your transformer has to endure without letting its output voltage sag below a critical point, which is usually 85% of its nominal rating.

Step 3: Determine the Total Design VA

Okay, we have our sealed VA and our inrush VA. Now we can figure out the total power requirement for the transformer. The formula is surprisingly simple:

Total Design VA = √( (Total Sealed VA)² + (Total Inrush VA)² )

Let’s plug in the numbers from our example:

Total Design VA = √( (106)² + (300)² )

Total Design VA = √( 11,236 + 90,000 )

Total Design VA = √( 101,236 )

Total Design VA ≈ 318 VA

This number represents the minimum VA rating you need to handle both the steady load and the momentary peak demand. When you're planning a project with many components, using a tool like electrical estimating software can seriously speed up the process of getting these specs right.

Step 4: Select a Transformer with a Safety Margin

Our math tells us we need a transformer rated for at least 318 VA. But in the real world, you never want to spec something that just barely meets the minimum. It's smart to build in a safety margin for future upgrades, unexpected loads, or even just a hot day in the plant.

A safety margin of 20-25% is a solid rule of thumb. This gives you breathing room for expansion and keeps the transformer from running at its max limit all day, which will definitely help it last longer.

Let's apply a 25% safety margin to our number:

Required VA Rating = 318 VA * 1.25 = 397.5 VA

With a final requirement of 397.5 VA, you'd look at standard transformer sizes and simply pick the next size up. In this case, a 500 VA control transformer is the perfect choice, giving you plenty of capacity for rock-solid reliability and any future needs.

Proper sizing is also your first line of defense against problems like excessive voltage drop; you can dive deeper into that topic by learning about voltage drop calculation formulas.

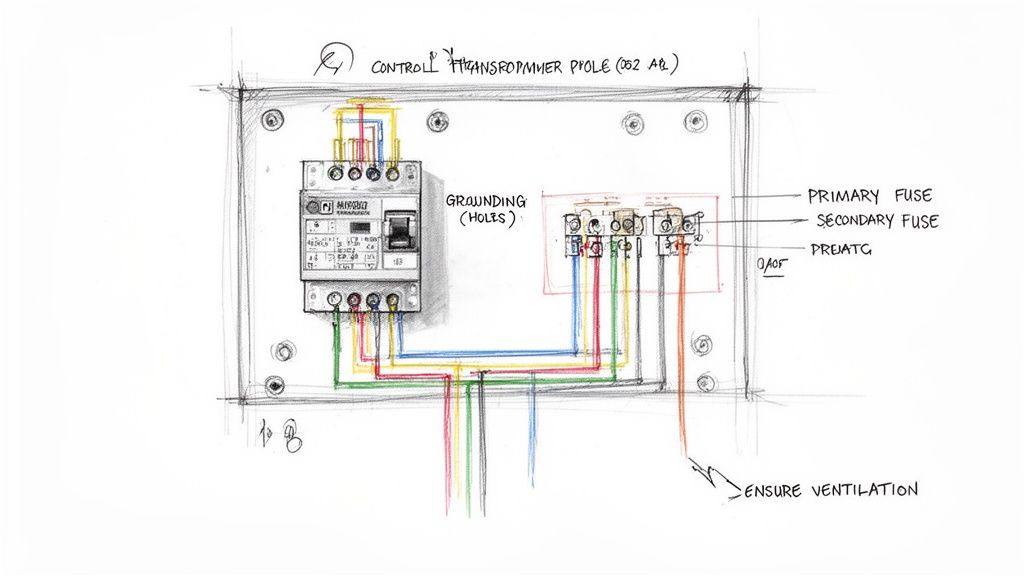

Getting the Installation Right: Safety and Performance Best Practices

You can pick the perfect control transformer for the job, but if the installation is sloppy, you've only done half the work. A rushed or incorrect setup is the fastest way to turn a well-designed circuit into a fire hazard or a source of constant headaches. It can lead to overheating, premature failure, and major safety risks.

Think of it this way: proper installation is what brings your careful planning to life. Following industry standards, like those outlined in UL 508A for industrial control panels, isn't just about ticking a box. It's about building a rock-solid, dependable machine that will run smoothly for years.

Mounting and Ventilation: Your Transformer's Biggest Ally

Heat is public enemy number one for any transformer. As it works, its windings generate heat, and if that heat has nowhere to go, the component’s lifespan will plummet. This is why proper mounting and giving it room to breathe are so critical.

When you’re placing a transformer inside a control panel, treat the manufacturer's clearance specs as law, not suggestions. They spell out the bare minimum space needed for air to circulate. One of the most common mistakes we see is cramming wires or other components right up against the transformer, effectively suffocating it.

Here are a few pro tips for mounting:

- Go with the Flow: Mount the transformer where it can take advantage of natural convection. Usually, this means placing it lower in the cabinet, so cool air can be drawn in from the bottom and hot air can rise and escape out the top.

- Keep It Away from Other Hotspots: Never mount a control transformer right above another heat-generating device like a VFD or a beefy power supply. Their combined heat will cook the transformer in no time.

- Lock It Down Tight: Use the right mounting hardware and make sure it’s fastened securely to the backplane. Industrial environments are full of vibration, and a loose transformer can easily lead to failed connections down the road.

A transformer's life is cut in half for every 10°C increase above its maximum rated operating temperature. Proper ventilation isn't just a best practice—it's the single most important factor for ensuring longevity.

Wiring, Grounding, and Fusing

With the transformer securely in place, it’s time to focus on clean, safe electrical connections. This isn't the place to cut corners. Messy wiring is a major safety risk and a frequent cause of mysterious system faults.

Always use the right wire gauge for your primary and secondary circuits, based on the current draw and local electrical codes. Make sure every terminal is torqued down to the manufacturer's spec—a loose connection is a ticking time bomb that can cause arcing and heat buildup.

Grounding is completely non-negotiable. The transformer’s core and frame absolutely must be tied to the panel's main ground point. This creates a safe escape route for fault currents, preventing the enclosure from becoming live and protecting operators from a nasty shock. A solid ground also helps quiet down electrical noise that can mess with sensitive control components.

Finally, fusing is your first line of defense against disaster.

- Primary Fusing: A fuse on the high-voltage side protects the transformer itself from surges and overcurrent events coming from your main power source.

- Secondary Fusing: A fuse on the low-voltage side protects your control circuit wiring and all the expensive components connected to it, like relays and PLCs.

Choosing the right type and size of fuse is crucial. We typically recommend time-delay fuses on the primary side to handle that momentary inrush current without popping unnecessarily. For a deeper dive into the whole process, check out our complete guide to a control panel build.

What to Do When Your Control Transformer Acts Up

Even the most dependable hardware can have a bad day. When a control transformer starts giving you grief, the good news is that a little logical troubleshooting can almost always get to the bottom of it fast. Knowing what to look for keeps your downtime to a minimum and your machines running safely.

The classic complaint is an unusual humming or buzzing sound. Now, all transformers hum a bit—that’s just physics at work (a phenomenon called magnetostriction). But if that quiet hum suddenly turns into an angry buzz, you’ve likely got loose core laminations or mounting bolts that have rattled loose from vibration.

Another huge red flag is overheating. If the transformer is too hot to comfortably touch, something is seriously wrong. Nine times out of ten, this means the transformer is overloaded; the components in your control circuit are trying to pull more power than the transformer was ever designed to give.

And of course, there's the obvious one: constantly blowing fuses. Whether on the primary or secondary side, this is a dead giveaway that you've got a fault. It could be a short circuit somewhere in your control wiring, or it might mean the transformer itself has an internal failure.

A Step-by-Step Diagnostic Plan

Instead of guessing, let's walk through it systematically. This simple checklist will help you nail down the most common issues you'll run into.

- Check Your Input Voltage: Grab your multimeter and make sure the primary voltage is what the transformer's nameplate says it should be. Too much or too little voltage is a recipe for poor performance and a short lifespan.

- Tighten Everything Down: Industrial environments are shaky places. Go through and check every single connection—primary terminals, secondary terminals, and the main mounting bolts holding the unit in place. A loose wire can cause arcing and all sorts of unpredictable problems.

- Do the Math Again: Re-calculate the total VA demand of your control circuit, both sealed and inrush. It’s incredibly common for new components (like a new relay or contactor) to get added to a panel over the years, slowly pushing the original transformer past its limits. This is a classic cause of overheating.

- Hunt for Shorts: If you’re popping fuses, start by disconnecting the entire load from the secondary side. Power up the transformer again. If the new fuse holds, your problem is somewhere in your control circuit's wiring or components. If the fuse still blows with nothing connected, the transformer itself has likely failed and needs to be replaced.

It's worth remembering that a control transformer getting warm during operation is completely normal. But if it's scorching hot or making a racket, it’s telling you something needs your immediate attention before it takes the rest of the control system down with it.

Even with a solid grasp of the basics, a few common questions always seem to surface when you're in the thick of it. Let's tackle some of the most frequent ones we hear from the engineers and techs on the shop floor.

Can I Just Use a Regular Power Transformer for My Control Circuit?

You might be tempted to swap in a standard power transformer to save a few bucks, but it's a move you'll likely regret. Here's why: power transformers are built for steady, predictable loads. They just aren't designed with the low-impedance windings needed to handle the massive, split-second inrush currents you get from slamming a contactor or firing a solenoid.

Try it, and you’ll almost certainly see a major voltage sag the second things kick on. That sag causes relay chatter, contactor coils to burn out, and sensitive electronics to go haywire. It's a recipe for unreliable—and unsafe—machine operation. A control transformer, on the other hand, is purpose-built to hold that voltage steady through the most demanding cycles.

What Does the VA Rating on the Nameplate Actually Mean?

The VA (Volt-Amps) rating is the transformer's power capacity, plain and simple. Think of it as the total punch it can pack. It’s the single most important number for figuring out if it can handle your circuit's demands without breaking a sweat.

There's a quick way to see what that means in practical terms. To find the maximum continuous current the secondary can supply, just divide the VA rating by your secondary voltage.

For example: A 500 VA transformer with a 120V secondary can safely deliver 4.17 amps (500 VA / 120V) continuously. When you're picking a transformer, you have to make sure that VA rating is big enough to cover both the steady-state (sealed) load and those big, momentary (inrush) hits from all your components combined.

Why Is Fusing Such a Big Deal?

Proper fusing isn't just a good idea; it's your first and best line of defense against fried components and dangerous electrical faults. It does two very different, but equally critical, jobs:

- Primary Fusing: The fuse on the high-voltage input side is there to protect the transformer itself. If there's a major overcurrent or a fault from the main power line, this fuse blows to save the transformer from becoming a casualty.

- Secondary Fusing: Fuses on the low-voltage output side are the guardians of your entire control circuit. They protect the wiring, PLCs, pilot lights, and everything else downstream from a short circuit.

Using the right size time-delay fuses is key. They're smart enough to ignore the normal inrush current spike, so you don't get nuisance trips, but they'll pop instantly if a real short circuit occurs. This helps isolate the problem, making troubleshooting a whole lot easier and protecting your expensive equipment.

Do These Things Need a Lot of Maintenance?

Honestly, control transformers are workhorses. They’re known for being incredibly reliable and pretty low-maintenance. Still, it's smart to add them to your regular preventative maintenance checklist. A quick check-in now and then can prevent a lot of headaches later.

- Give it a once-over: Look for any signs of overheating, like discolored windings or burn marks on the housing.

- Check the connections: Industrial environments have a lot of vibration, which can loosen terminal connections over time. Make sure everything is still tight.

- Let it breathe: Dust and grime can build up and block airflow, causing the transformer to run hot. Ensure the vents on the transformer and its enclosure are clear.

For over 50 years, E & I Sales has been the trusted partner for engineers building tough, high-performance industrial control systems. Whether it's specifying the perfect control transformer or engineering a complete UL-listed panel, we've got the expertise and the components to get it done right. Explore our solutions at https://eandisales.com.