At its most basic, an electric motor control system is the collection of hardware and software that tells a motor what to do. Think of it as the brains and nervous system that turns raw electrical power into precise, controlled work. It dictates everything from when a motor kicks on to how fast it spins.

The Brains Behind the Brawn

Electric motors are the undisputed workhorses of industry. In fact, they’re responsible for over 40% of global electricity consumption. But on their own, they're just brute force—little more than a simple on/off switch. A motor control system is what refines that raw power, giving it purpose, intelligence, and a crucial layer of safety. It's the conductor of an industrial orchestra, ensuring every motor plays its part perfectly.

Picture a massive conveyor system in a distribution center. Without a control system, every motor would slam on at once with a jarring jolt, which is a great way to damage products and put immense stress on the machinery. They'd also run at a single, constant speed, guzzling energy even when the workload is light.

Why Control Is Non-Negotiable

Proper motor control brings order to this potential chaos. Instead of a violent, abrupt start, a soft starter can gently ramp up the conveyor’s speed, saving the belts and gearboxes from unnecessary wear and tear. Even better, a Variable Frequency Drive (VFD) can adjust the speed based on the actual volume of packages, which can slash energy costs.

A well-designed electric motor control system does more than just start and stop a motor; it optimizes performance, protects expensive assets, and ensures the safety of personnel. It's the critical link between raw power and productive output.

This control goes way beyond just speed. These systems are absolutely essential for:

- Safety and Protection: They constantly monitor for overloads, short circuits, and overheating, ready to automatically shut down the motor before a catastrophic failure can happen.

- Operational Precision: For things like CNC machining or robotics, they deliver the exact speed and torque needed to perform incredibly intricate tasks with repeatable accuracy.

- Energy Efficiency: By matching the motor's output to the real-time load demand, control systems can cut electricity use by up to 50% in some applications.

Ultimately, these systems are what transform a simple motor from a dumb component into an intelligent, responsive, and efficient part of a much larger automated process.

Understanding The Core Components

To really get a handle on electric motor control systems, you need to peek inside the control panel. Think of it like the engine bay of a car—it's a collection of specialized parts all working together to turn a simple command into controlled, powerful motion. Each component has a specific job, whether it’s distributing power or fine-tuning speed with incredible precision.

Let’s break down the essential hardware that keeps modern industrial operations running. Getting to know these core elements is the first real step toward designing, maintaining, and getting the most out of any motor-driven process.

The visual below shows how a control system juggles a motor's three primary functions: speed, safety, and efficiency.

As you can see, motor control isn't just one single action. It's a balanced strategy to regulate performance while protecting the equipment and keeping energy costs down.

The Command Hub: Motor Control Centers

At the heart of many industrial facilities, you'll find the Motor Control Center (MCC). An MCC is the central nervous system for all the motors in a plant or a specific area. It consolidates starters, protective devices, and control wiring into a single, organized enclosure. Instead of having dozens of separate control boxes scattered across the floor, an MCC gives you one place for control and maintenance.

This centralization is a massive win for both safety and efficiency. It’s no surprise the global market for MCCs is growing so quickly—it's expected to jump from USD 6.73 billion in 2026 to a forecasted USD 11.94 billion by 2035. This growth is a direct result of the automation boom in industries where experts like E & I Sales deliver engineered UL panels and integrated motor control systems.

The Gatekeepers: Motor Starters

The most fundamental piece of the puzzle is the motor starter. Its main job is simple but absolutely critical: to safely energize and de-energize a motor. It acts as a gatekeeper, connecting the motor to the power source and—just as importantly—disconnecting it during an overload or fault to prevent costly damage.

There are a few different kinds of starters, but they all rely on two key parts:

- Contactor: This is an electrically-operated switch that physically opens and closes the power circuit to the motor. You can think of it as the muscle of the starter.

- Overload Relay: A smart protective device that senses when the motor is drawing too much current. It signals the contactor to open the circuit and shut the motor down before it can overheat.

When you're digging into control system hardware, it’s also important to understand the components they're controlling, like the various three and single phase electric motors that pair with different starter technologies.

The Accelerator: Variable Frequency Drives

If a starter is a basic on/off switch, then a Variable Frequency Drive (VFD) is the system's accelerator pedal. A VFD gives you precise, continuous control over a motor's speed by adjusting the frequency of the electrical power it receives. This capability is a total game-changer for both process control and energy savings.

For example, on a pump or fan, a VFD can slow the motor down when demand is low instead of just running it at full blast all the time. That small adjustment can slash energy consumption by 50% or more, delivering a quick return on investment. If you want to dive deeper into how they work, check out our guide on the basics of Variable Frequency Drives.

A VFD transforms a fixed-speed motor into a variable-speed asset. This allows operations to perfectly match motor output to process demand, eliminating wasted energy and enabling a level of precision that a simple starter cannot achieve.

The Shock Absorber: Soft Starters

So, what if you don't need full speed control but want to avoid the mechanical shock of a motor slamming on at full power? That's where a soft starter comes into play. It provides a smooth, gradual ramp-up to full speed, acting like a shock absorber for both your mechanical and electrical systems.

A soft starter gently increases the voltage to the motor during startup. This reduces the massive inrush of current and lessens the physical jolt on belts, gears, and couplings. This is especially useful for equipment like conveyor belts or large pumps, where an abrupt start can cause serious wear and tear over time. By managing only the startup and shutdown, a soft starter offers a cost-effective way to extend equipment life without the full feature set (and cost) of a VFD.

The table below breaks down the key differences to help you decide which technology fits your needs.

Motor Starter Technology Comparison

| Control Method | Primary Function | Best Application | Key Benefit |

|---|---|---|---|

| Direct-On-Line (DOL) Starter | On/off control with overload protection. | Simple, fixed-speed applications like small pumps or fans where start-up torque isn't an issue. | Simple, reliable, and low-cost. |

| Soft Starter | Ramps motor voltage up/down for a smooth start and stop. | Conveyors, large fans, and pumps where reducing mechanical stress is the main goal. | Extends equipment life and reduces electrical strain during startup. |

| Variable Frequency Drive (VFD) | Full control over motor speed and torque at all times. | Complex processes requiring precise speed control, like HVAC systems, mixers, or machine tools. | Maximum energy efficiency and ultimate process control. |

Ultimately, choosing between a starter, soft starter, or VFD comes down to what your application truly demands. Do you need simple on/off, a gentle start, or complete control over the entire speed range? Answering that question is the key.

How to Design the Right Control System

Choosing the right electric motor control system isn’t like picking a part off a shelf. It’s more like drafting a blueprint for your plant's long-term success. A well-designed system goes far beyond matching horsepower ratings—it’s a strategic decision that touches everything from operational reliability and energy bills to employee safety.

The goal here is to build a solution that nails today's demands while being tough enough for whatever you throw at it tomorrow. That whole process starts with a serious look at the application itself. Before you even think about a single component, you have to understand the job the motor is being asked to do. Getting this right from the start saves you from costly headaches down the road.

Analyzing Your Application and Load

First things first: you need to get intimately familiar with the motor's workload, or what we call its load characteristics. Not all loads are created equal, and this analysis is what dictates the type of control you'll need.

Think of it like choosing an engine for a vehicle. A sports car and a dump truck both have engines, but they’re engineered for completely different jobs. You wouldn't put a Ferrari engine in a dump truck and expect it to haul gravel effectively.

Ask yourself these critical questions about your application:

- What's the torque demand? Does the load require a massive kick of starting torque, like a fully loaded conveyor belt? Or does the torque demand ramp up with speed, like with a centrifugal pump?

- Do I need speed control? Is the process something that needs to run at different speeds, or is a simple on/off, fixed-speed operation good enough?

- How often will it start and stop? A motor that cycles hundreds of times an hour needs a much different control strategy than one that runs continuously for days on end.

Answering these questions honestly prevents you from over-engineering with an expensive VFD when a simple starter would do the trick, or under-engineering a system that’s just going to burn out under pressure.

Defining Operational and Environmental Needs

Once you’ve got a handle on the load, the next step is to map out the operational requirements and the environment the system will live in. This is where you translate the real-world physical demands into concrete electrical and mechanical specs.

You’ll want to consider these factors:

- Speed and Torque Control Precision: How tight does the speed control need to be? A simple exhaust fan might be fine with a 5% variance, but a CNC machine or a robotic arm could require precision within a fraction of a percent.

- Stopping Method: Does the motor need to coast to a stop, brake hard (dynamic braking), or hold its position firmly once it’s stopped?

- Environmental Conditions: Where is this control panel going to live? A hot, dusty factory? A corrosive chemical processing area? Or a clean, climate-controlled room? The enclosure rating (like NEMA 12 or 4X) has to match the environment to protect the sensitive electronics inside.

Ignoring the operating environment is a common—and expensive—mistake. A control panel built for an office setting won't last long on a factory floor exposed to washdowns and metal dust. That's a direct path to premature failure and unplanned downtime.

Proper system design isn't just about day-one performance; it's about endurance. Factoring in environmental stressors and operational demands ensures your investment is protected and your process stays reliable for years.

The push for smarter, more robust motor controllers is accelerating, driven by everything from industrial automation to the EV revolution. The global market was valued at USD 37.99 billion in 2026 and is projected to skyrocket to USD 181.29 billion by 2035, growing at an incredible 18.8% CAGR.

Ensuring Compliance and Future-Proofing

Finally, a truly great design has to meet safety standards and be easy to maintain for years to come. This is where compliance and good documentation become absolutely non-negotiable.

UL 508A certification for industrial control panels is the gold standard here. It’s a sign that the panel has been designed and built to meet strict, nationally recognized safety standards. This isn't just a sticker on a box; it’s peace of mind for inspectors, insurers, and your own team that the system is safe to operate.

Just as critical is solid documentation. This should always include:

- Electrical Schematics: The detailed wiring diagrams that show how every single component is connected.

- Bill of Materials (BOM): A complete parts list, including manufacturer and model numbers.

- Panel Layout Drawings: A visual map showing the physical arrangement of components inside the cabinet.

This packet of documents is your roadmap for any future troubleshooting, maintenance, or upgrades. Without it, a simple component replacement can turn into a painful, time-consuming investigation.

By centralizing components in a well-documented assembly like a Motor Control Center, you make managing and upgrading your systems way easier. For a deeper dive, check out our guide on what a Motor Control Center is and see how it can streamline your operations.

Integrating Controls with Plant-Wide Automation

An electric motor control system is powerful on its own, but its real value is unlocked when it stops being an isolated island of technology. Modern industrial plants thrive on data and connectivity. Tying your motor controls into the bigger automation network is what turns a bunch of individual components into a single, intelligent system that works together.

Think of it this way: a standalone motor starter is like a single musician playing an instrument. They might be skilled, but they have no idea what the rest of the orchestra is doing. Integrating that starter into a Programmable Logic Controller (PLC) network is like giving the musician a headset to hear the conductor and the whole symphony. Suddenly, timing is perfect and everything is in harmony.

This integration connects your motors to the facility's central brain, creating a single source of truth for your entire process. It’s how you get to the next level of efficiency, visibility, and control.

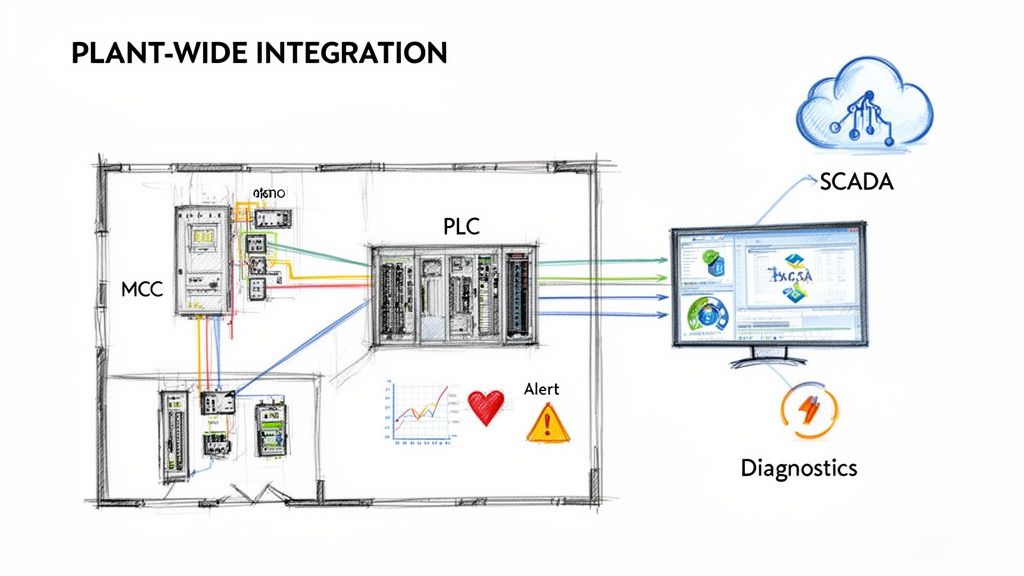

Connecting to PLCs and SCADA Systems

The most common way to do this is by linking your Motor Control Centers (MCCs) and Variable Frequency Drives (VFDs) straight to a PLC. This connection usually happens over standard industrial communication protocols.

- EtherNet/IP: This is a popular one because it uses standard Ethernet technology, so most IT and engineering teams are already comfortable with it.

- Modbus TCP/IP: An open protocol known for being simple and reliable. You see it a lot when connecting all sorts of different industrial electronics.

- PROFIBUS/PROFINET: A really robust standard, especially common in manufacturing and process automation, particularly in facilities running Siemens gear.

Once they're connected, the PLC can send start/stop commands, tell a VFD what speed to run at, and—most importantly—get a constant stream of data back from the motor controls. That information usually gets displayed on a Supervisory Control and Data Acquisition (SCADA) system, giving operators a live dashboard of the entire plant's health.

The Power of Diagnostic Data

This is where the real magic happens. A modern "smart" MCC or VFD does a lot more than just report if it's on or off. It feeds back a ton of diagnostic info that you can use to spot trouble and prevent failures before they bring a line down.

By integrating motor controls with automation platforms, you shift from a reactive maintenance model ("fix it when it breaks") to a proactive, predictive one ("fix it before it fails"). This single change can drastically reduce unplanned downtime and maintenance costs.

Instead of guessing, your team gets hard data on things like:

- Current Draw: Is a motor working harder than it should? That could point to a mechanical problem, like a bearing that’s about to fail.

- Operating Temperature: A motor running hot might mean a ventilation issue or that a winding failure is on the horizon.

- Run-Time Hours: You can schedule maintenance based on how much a motor has actually been used, not just based on a date on the calendar.

- Fault Codes: When something does trip, you get a specific code explaining why. This lets technicians find the root cause in minutes instead of hours.

For facilities in logistics and manufacturing, this data-driven approach is essential. It's the foundation for more advanced systems, like fully integrated Automated Storage And Retrieval Systems (ASRS), which depend on this level of connectivity to work.

The demand for these integrated systems is plain to see in the market's growth. The global electric motor market was valued at USD 212.96 billion in 2025 and is projected to hit USD 405.67 billion by 2033. A huge part of that growth is driven by the push for smarter automation and better efficiency. It really just highlights how critical intelligent motor control has become for any operation trying to stay competitive.

Best Practices for Maintenance and Troubleshooting

Getting a state-of-the-art electric motor control system installed is really just the starting line. If you want to get the most out of that investment, you need a solid plan to keep it running reliably for its entire lifespan. This means ditching the old "fix it when it breaks" mentality and embracing a proactive strategy for commissioning, maintenance, and troubleshooting.

A smart approach to the system's lifecycle does more than just prevent headaches. It minimizes costly unplanned downtime, extends the life of your most critical components, and keeps your whole operation humming at peak efficiency. It turns your control panels from mysterious black boxes into predictable, manageable assets. This journey begins the second the installation is finished, starting with a meticulous commissioning process.

The Commissioning Checklist: Your Guarantee for a Smooth Start

Think of commissioning as a systematic shakedown of your new system. It's the process of verifying that everything was installed correctly and performs exactly as designed before you put it into full production. Skipping steps here is a recipe for disaster down the road. A comprehensive commissioning plan is your final, non-negotiable quality check.

Your process should always hit these fundamental stages:

Pre-Power Checks: Before a single volt goes through the system, get hands-on. Physically confirm that all the wiring matches the electrical schematics. Check that every terminal connection is torqued to the manufacturer's spec. Make absolutely sure all grounding and bonding is buttoned up correctly. This is your best and easiest chance to catch simple mistakes that could cause major damage.

Initial Power-Up and Configuration: Once the physical checks are done, it's time to energize the system. Go through it methodically—verify control power, check input voltages, and carefully program the essential parameters into devices like VFDs and overload relays. This includes inputting motor nameplate data and dialing in the right protection settings.

Performance and Safety Validation: With the system live, you need to test its functionality under controlled conditions. "Bump" the motors to confirm they're spinning in the right direction. Test every I/O signal to make sure it's communicating correctly. Critically, verify that all safety circuits, especially emergency stops, function flawlessly. Finally, run the system through its operational sequences to ensure it meets all performance requirements.

Building a Proactive Preventive Maintenance Schedule

Once your system is up and running, the focus shifts to preventive maintenance (PM). A good PM schedule is all about catching small issues before they snowball into major, production-stopping failures. It’s the difference between a scheduled check-up and emergency surgery.

Preventive maintenance is the single most cost-effective strategy for maximizing the reliability and lifespan of electric motor control systems. It turns maintenance from an unpredictable expense into a manageable operational cost.

Your PM schedule should be built around routine inspections and data collection, focusing on the most common points of failure. Key activities should include:

- Thermal Imaging: Use an infrared camera to scan your control panels. You're looking for hot spots on connections, contactors, and circuit breakers. An unusually high temperature is a classic early warning sign of a loose connection or a component on its way out.

- Connection Integrity: Periodically re-torque all your power and control wire terminations. The constant vibration and temperature swings in an industrial plant can cause connections to loosen over time, creating resistance and dangerous heat.

- Environmental Cleaning: Keep the inside of your panels clean and free of dust and grime. Dust can act as an insulator, preventing proper cooling, and if it's conductive, it can lead to short circuits. Make sure all ventilation fans and filters are clean and working properly.

- Component Inspection: Do a visual check of contactors for any signs of pitting or wear on the contacts. Listen for any unusual humming or buzzing from transformers and relays—these sounds can often signal an impending failure.

A Practical Troubleshooting Guide for Common Issues

Even with the best maintenance plan, problems will pop up. When they do, a logical, step-by-step approach to troubleshooting is your best friend for minimizing downtime. Instead of random guessing, arm your team with a structured plan to quickly diagnose and fix the usual suspects.

Here’s a quick-and-dirty guide for tackling common problems:

| Problem | Potential Cause | Troubleshooting Steps |

|---|---|---|

| Nuisance Tripping | Overload setting is too low, voltage is fluctuating, or a mechanical issue is causing a high motor current. | Check the overload settings against the motor's nameplate data. Monitor incoming voltage for sags or spikes. Inspect the mechanical load for any binding or obstructions. |

| Motor Overheating | Poor ventilation, incorrect VFD parameters (like the V/Hz pattern), or it's simply being overloaded for too long. | Make sure the motor's cooling fans are clean and clear. Review the VFD settings to ensure they match the motor and application. Measure the motor current to confirm it's within its rated limits. |

| VFD Fault Code | Could be anything from overvoltage and undervoltage to an external fault signal. | Grab the VFD manual and look up the specific fault code. Check the input power quality. Inspect all motor and control wiring for loose connections or shorts. |

By combining a meticulous commissioning process with a disciplined maintenance schedule and a logical troubleshooting framework, you ensure your electric motor control systems remain the reliable backbone of your operations.

Finding the Right Partner for Your Project

Let's be honest, navigating the world of electric motor control systems is a huge undertaking. From picking the right components and designing the architecture to satisfying UL inspectors and integrating everything into your plant, it's a lot to handle. The success of any project—whether it’s swapping out a single control panel or building a new facility from the ground up—really boils down to the expertise of the team you've got in your corner.

This is where having a single, dedicated partner really shines.

Instead of trying to be the ringmaster for a circus of different vendors for motors, controls, and engineering, you get one unified team focused on your outcome. It simplifies communication and gets rid of the logistical nightmares that come from juggling multiple contacts and purchase orders.

The Value of a Single-Source Expert

A true partner does more than just ship boxes. They take ownership of the entire project, from concept to commissioning. It’s a holistic approach that ensures every piece of the puzzle—the VFD, the motor, the PLC, the wiring—all fits together exactly as it should.

Here’s what that looks like in the real world:

- Guaranteed Compliance: A good partner knows the code inside and out. They make sure every panel is designed and built to strict standards like UL 508A, giving you certified equipment you can trust. No more worrying about failed inspections.

- Seamless Integration: They have the deep-seated knowledge to get your motor controls talking flawlessly with your existing PLCs, SCADA systems, and even the main power distribution gear. It just works.

- Standardized Solutions: By bringing a consistent design philosophy to your facility, they make life easier for your maintenance team. Think simplified troubleshooting, a smaller spare parts inventory, and less downtime.

This strategy dramatically cuts down on project risk. You catch potential problems on the drawing board, not during a high-pressure startup with everyone watching.

Choosing a single-source partner turns a project from a bunch of separate purchases into a cohesive, engineered solution. It’s the difference between buying parts and investing in a system built for long-term performance.

At the end of the day, the right partner becomes an extension of your own team. They bring years of practical, in-the-field experience to the table, making sure your system isn't just designed well, but is also tough, easy to maintain, and ready for whatever you throw at it next.

With decades of experience, a dedicated industrial automation system integrator can help you tackle every challenge, from the initial spec sheet to flipping the switch. When you put your project in the hands of one accountable expert, you're building on a foundation of quality that will pay you back for years.

A Few Common Questions We Hear

When you're knee-deep in planning a new system or trying to troubleshoot an old one, a few practical questions always seem to pop up. Let's tackle some of the most common ones we hear from engineers and plant managers in the field.

What's the Real Difference Between a Soft Starter and a VFD?

The easiest way to think about it is specialization versus versatility.

A soft starter is a specialist. Its one and only job is to give a motor a gentle, smooth ramp-up to full speed, kind of like an electrical shock absorber. This is a lifesaver for reducing mechanical stress on equipment like conveyor belts or pump systems during startup.

A Variable Frequency Drive (VFD), on the other hand, is the multi-tool of motor control. Yes, it can also provide a smooth start, but its real superpower is continuous speed control throughout the motor's entire run time. This gives you the power to fine-tune your process on the fly and can lead to some serious energy savings, especially in applications with changing loads.

Why Should I Care About UL 508A Certification for a Control Panel?

That little UL 508A sticker is way more than just a label—it's your independent proof of safety and quality. It confirms that the industrial control panel was built and designed to meet the strict safety standards set by Underwriters Laboratories.

Basically, it's a third-party guarantee that the panel is wired correctly, its components are rated properly for the job, and it meets the National Electrical Code (NEC). For any facility manager, this certification is a must-have for passing inspections and, more importantly, for the peace of mind that your people and your facility are safe.

When Does It Make Sense to Go with an MCC Instead of Individual Starters?

A Motor Control Center (MCC) is your best bet whenever you have a group of motors clustered in the same general area of your plant. Instead of having a bunch of separate starter boxes bolted to walls and columns all over the place, an MCC pulls all that power distribution, control, and protection into one clean, organized cabinet.

This centralized approach makes a huge difference. It simplifies the initial install, makes routine maintenance far more efficient, and takes the guesswork out of troubleshooting. If you're managing more than just a handful of motors, an MCC gives you a standardized, scalable, and safer foundation to build on.

Can I Actually Upgrade My Old Motor Controls to Something Modern?

You absolutely can. In fact, retrofitting older or obsolete motor control systems is one of the most effective upgrades you can make. Swapping out old components for modern intelligent overload relays, soft starters, or VFDs can deliver a surprisingly fast and substantial return on your investment.

These kinds of upgrades don't just improve energy efficiency. They give you much tighter control over your process and unlock a ton of diagnostic data you can use for predictive maintenance. A good systems integrator can take a look at your current setup, pinpoint the best opportunities, and map out an upgrade path that fits your goals and your budget.

Ready to modernize your system or design a new one from scratch? The experts at E & I Sales provide engineered UL-listed control panels and turnkey integration services, ensuring your project is reliable, compliant, and efficient right from the start. https://eandisales.com