At its core, an automatic transfer switch (ATS) is the unsung hero that keeps the lights on. It’s the device that intelligently shifts your facility’s electrical load from the primary power source to a backup, like a generator, the moment an outage hits. Its whole job is to detect that power loss and automatically manage the transition, providing a seamless and safe handoff to maintain operations without anyone needing to flip a switch.

The Brain of Your Backup Power System

Think of an automatic transfer switch as the brain of your entire backup power system. It’s the smart device that ensures your critical operations—from manufacturing lines to data servers—never go dark. It acts like a high-speed, automated railroad switch for electricity.

The ATS is constantly watching the main power grid—what you could call the "main track." The second it senses a problem like a blackout or a brownout, it instantly reroutes power from your backup generator, the "secondary track." This happens in the blink of an eye, protecting you from costly downtime.

How an ATS Manages a Power Outage

When the power goes out, the ATS kicks into gear with a precise, three-step sequence that unfolds in seconds. Each step is absolutely critical for a safe and effective power transfer.

- Sensing the Outage: The ATS is always monitoring the utility power’s voltage and frequency. When these numbers drop below a preset, safe level for a specific amount of time, it officially recognizes an outage.

- Signaling the Generator: As soon as an outage is confirmed, the ATS sends a start signal to the backup generator. It then patiently waits for the generator to fire up and reach the correct operational voltage and frequency before it does anything else.

- Transferring the Load: Once the generator is stable and ready, the ATS safely disconnects your facility from the utility line. It then connects the building to the generator, bringing power back to your critical loads. This “break-before-make” process is fundamental to preventing dangerous back-feeding to the grid.

An ATS isn't just a simple switch; it's an intelligent controller that isolates your facility from the grid during an outage. This isolation is a critical safety feature that prevents backfeed, which could endanger utility workers trying to repair the lines.

Restoring Normal Power

Once the ATS senses that the main utility power has been restored and is stable, it simply reverses the process. It transfers the load back to the grid, signals the generator to cool down and shut off, and then goes back into its monitoring state, ready for the next event.

The entire operation is completely hands-free, which guarantees reliability when you need it most. This need for uninterrupted power is why many facilities pair their systems with reliable fuel sources, like emergency natural gas for critical infrastructure, to keep those backup generators running.

To get a better picture of how these components work together, it helps to understand what a disconnect switch is and how it fits into the larger electrical system. You can learn more here: https://eandisales.com/uncategorized/what-is-a-disconnect-switch/

Diving Into the Core Types of Automatic Transfer Switches

Not all transfer switches are created equal. The right ATS for a job really boils down to one simple question: how much of a power blip, even for a millisecond, can your facility really handle? That's the critical distinction that drives the different designs you'll find on the market today.

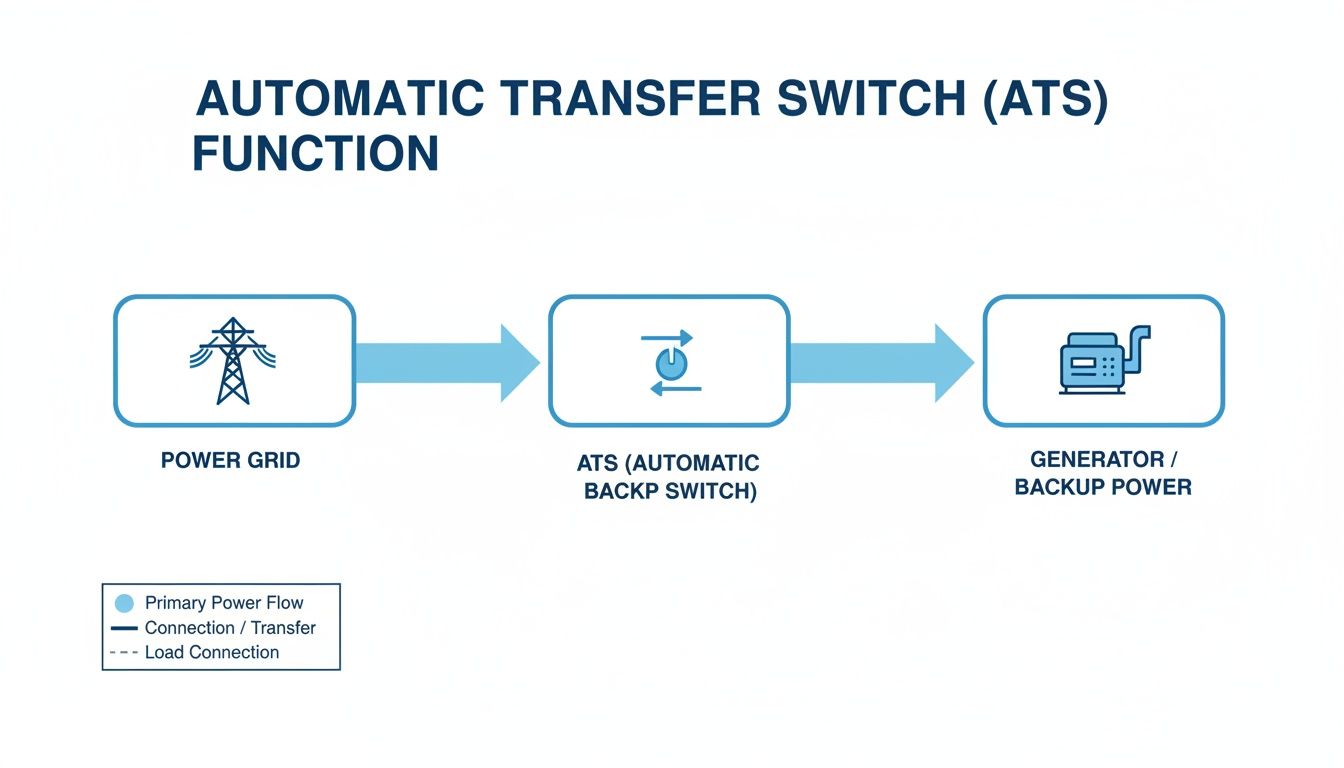

At its heart, an ATS is the gatekeeper of your power system. It stands between the utility grid and your backup generator, deciding which source feeds your facility at any given moment.

This diagram shows the ATS in its fundamental role—the central brain ensuring that when one source goes down, another is ready to take over, keeping the lights on.

Open-Transition Switches: The Standard Workhorse

The most common and straightforward design out there is the open-transition ATS. You'll often hear engineers call it a "break-before-make" switch, and that name tells you everything you need to know about how it works.

Think of it as a simple, rugged toggle switch for your building's power. First, it completely disconnects from the failing utility source (the break). Only then does it connect to the backup generator (the make). This sequence guarantees the two sources can never meet.

This action creates a very brief, but definite, interruption in power—usually less than a second. For most industrial loads like lighting, motors, and standard machinery, this momentary flicker is no big deal. It's the cost-effective, reliable standard for a reason.

Closed-Transition Switches: For Zero Interruption

What if even a split-second of downtime is a complete disaster for your operations? That’s where a closed-transition ATS comes in. These are the "make-before-break" switches, and they operate on a totally different principle.

Instead of breaking from the grid first, a closed-transition switch momentarily connects to the backup generator before it disconnects from the utility. For a very brief window—less than 100 milliseconds to keep the utility companies happy—both sources are running in parallel. The result? A perfectly seamless, bumpless transfer. No flicker, no reboots, no disruption.

You'll find these switches are non-negotiable in places like:

- Hospitals and Healthcare: Where they protect life-support systems and sensitive imaging equipment.

- Data Centers: Where a server reboot can mean catastrophic data loss and millions in lost revenue.

- Advanced Manufacturing: For continuous processes where a momentary stop could ruin an entire production batch.

This need for uninterrupted power is why closed-transition systems hold the largest product segment, with roughly 30% market share. It's a testament to how many modern industrial applications simply can't afford to go dark. You can dig deeper into the global ATS market trends to see how these segments stack up.

Static Transfer Switches: The Ultimate Protection

When you get to the absolute peak of performance, you’ll find the Static Transfer Switch (STS). An STS is a different beast entirely. It has no moving mechanical parts. Instead, it relies on powerful semiconductors—Silicon Controlled Rectifiers (SCRs)—to direct the flow of electricity.

Because the switch is entirely electronic, the transfer is almost instantaneous. We're talking about a transfer completed in a quarter of a single electrical cycle, or about 4-5 milliseconds. This incredible speed makes an STS the ultimate line of defense for the most sensitive electronic loads imaginable—servers, network hubs, and high-tech process controls that can't tolerate even the slightest power quality disturbance.

ATS Transition Types At a Glance

To make sense of these options, it helps to see them side-by-side. Each type has a distinct mechanism and timing, making it suitable for very different applications.

| Feature | Open-Transition ATS | Closed-Transition ATS | Static Transfer Switch (STS) |

|---|---|---|---|

| Mechanism | Break-before-make (electromechanical) | Make-before-break (electromechanical) | Solid-state (semiconductors/SCRs) |

| Typical Transfer Time | < 1 second | < 100 milliseconds | 4-5 milliseconds (nearly instantaneous) |

| Best-Fit Applications | General industrial loads, lighting, motors, HVAC systems. | Hospitals, data centers, telecom, critical manufacturing. | Mission-critical IT loads, sensitive process control, server farms. |

Ultimately, the choice comes down to a simple trade-off: cost versus continuity. While an open-transition switch is a reliable and economical choice for many, the seamless power offered by closed-transition and static switches is an absolute necessity for today's high-tech, always-on world.

Decoding Key ATS Ratings and Specifications

Choosing an automatic transfer switch goes way beyond just matching up the voltage and amperage. When you look at a spec sheet, you’re seeing a whole list of technical ratings that are your guarantee of safety and performance, especially when things go sideways. Getting these numbers right is crucial for picking a switch that won’t quit on you when you need it most.

Think of an ATS as a critical safety valve in your power system. Sure, it handles routine power transfers, but its real job is to stand its ground during a catastrophic failure, like a dead short. This is where one of the most important—and often misunderstood—specs comes into play.

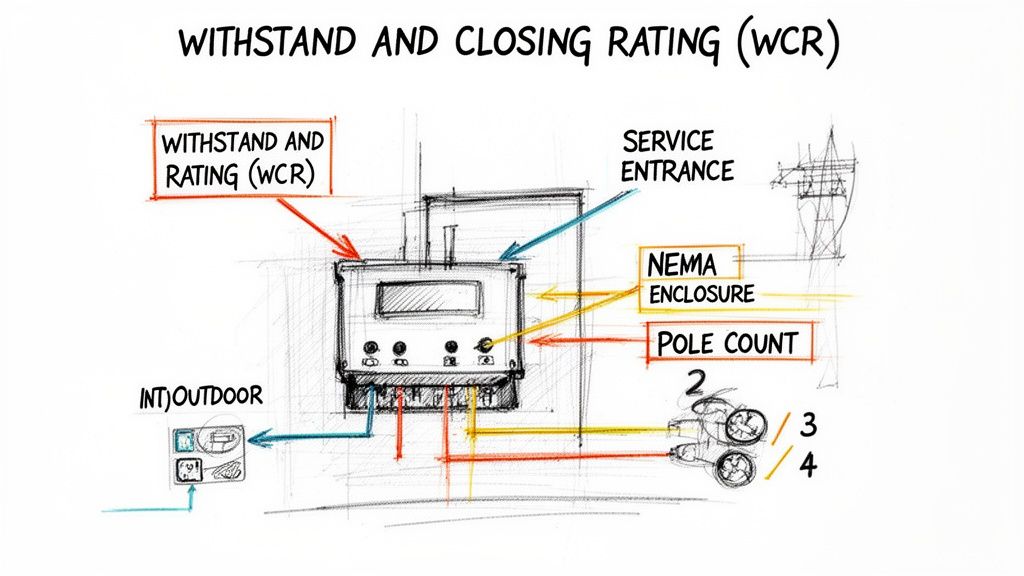

Surviving the Surge: Withstand and Closing Rating

The single most critical safety rating on any ATS is its Withstand and Closing Rating (WCR). This number tells you if the switch can survive the immense physical and electrical forces of a major fault without blowing apart. A solid WCR means the switch can be closed onto a short circuit and stay in one piece, without its contacts welding themselves together.

A proper WCR isn't just a nice-to-have; it's a non-negotiable safety feature. An underrated switch is a ticking time bomb—a catastrophic point of failure that risks equipment fires and serious injury. This rating is the ultimate measure of the switch's toughness.

You’ll typically see this rating expressed in symmetrical amps at a specific voltage, like 100,000A at 480V. It’s absolutely essential that this rating is coordinated with the upstream circuit breaker or fuse. This coordination ensures your entire system plays as a team to safely clear a fault before the ATS itself gets destroyed.

Simplifying Installation with a Service Entrance Rating

Another spec that can make your life a lot easier is the service entrance rating. If an ATS has this rating, it’s been approved to act as the main disconnect for the entire facility. This can dramatically simplify your electrical design and cut down on installation costs.

Instead of installing a separate main breaker before the ATS, a service entrance-rated switch bundles it all into one box. It saves a ton of wall space and means less wiring and labor to get the job done.

Matching the ATS to Its Environment

Finally, you have to look at the physical and electrical makeup of the switch itself to make sure it’s the right fit for the job site.

Here are the key details to double-check:

- Number of Poles: A 3-pole ATS is the standard for most commercial and industrial systems, switching the three main power phases (A, B, C). You’ll need a 4-pole ATS when you also have to switch the neutral, which is common in systems with separately derived sources where proper ground-fault protection is critical.

- NEMA Enclosure Type: This rating tells you how well the box protects the guts of the switch from its surroundings. A NEMA 1 enclosure is fine for a clean, dry electrical room, but if the switch is going into a food processing plant or a coastal area, you’ll need a corrosion-resistant NEMA 4X enclosure to handle washdowns and salty air.

Navigating the Critical ATS Codes and Standards

When you're dealing with industrial power, compliance isn't just about checking a box—it's the very foundation of safety and reliability. An automatic transfer switch has to meet some incredibly strict codes to ensure it works without a hitch when the lights go out. Getting a handle on these standards is the first step to designing a system that’s not just effective, but built to code.

The big one you need to know in North America is UL 1008. Think of it as the ultimate safety seal of approval for an ATS. A UL 1008 listing tells you that the switch has been through the wringer—tested to prove it can handle its rated current day-in and day-out and, more critically, withstand a massive fault current without blowing apart. Skimping on this by using non-listed gear is just asking for trouble, from catastrophic failures to voided insurance claims.

Cracking the NEC Classifications

Beyond the switch itself, the National Electrical Code (NEC) lays down the law on how and where an ATS can be used. The NEC breaks down backup power systems based on how critical the loads are, and that classification directly shapes the kind of ATS you'll need.

You'll run into three key classifications:

- Article 700 Emergency Systems: This is for the heavy-hitters—systems legally required to protect human life. We're talking fire pumps, emergency lighting in stairwells, and critical ventilation in hospitals. These applications face the toughest rules, often requiring features like bypass-isolation so you can service the ATS without ever dropping power.

- Article 701 Legally Required Standby Systems: These are mandated by government agencies for things like communications systems, sewage disposal, or public safety operations. They're still critical, but the requirements are a notch less stringent than for Article 700.

- Article 702 Optional Standby Systems: This bucket catches everything else. These are systems installed to prevent financial loss or simply for convenience, like keeping a manufacturing line running or a data center online during an outage.

Figuring out which NEC article your application falls under is the absolute first step in choosing the right ATS. If you get this wrong, you could end up with a non-compliant switch, leading to failed inspections, expensive project delays, and an unsafe system.

For instance, you'd never specify a standard open-transition ATS for a hospital's life-safety branch—that's a major code violation. An application like that absolutely demands a more sophisticated switch built for zero interruption. By making sure your ATS selection lines up with the right NEC article and carries that crucial UL 1008 certification, you’re building your backup power system on solid, approved ground.

How to Correctly Size and Select Your ATS

Choosing the right automatic transfer switch is one of those decisions that can make or break your entire backup power system. Get it wrong, and the ATS quickly becomes the weakest link, waiting to fail when you need it most. This isn't just about matching a few specs on a data sheet; it's about making sure your facility stays online.

The whole process kicks off with a detailed calculation of your facility’s total electrical load. And I don’t mean just adding up the amperage of your equipment. You have to dig deeper. A proper load calculation accounts for the massive inrush currents from large motors kicking on and the harmonic distortions that things like variable frequency drives (VFDs) throw into the mix. Forgetting these factors is a classic misstep that leads to nuisance tripping or, even worse, a total failure to transfer power during an outage.

Matching ATS Features to Your Real-World Needs

Once you've got a solid handle on your load profile, the next step is to match the ATS features to what your facility actually does day-in and day-out. A one-size-fits-all approach is a recipe for disaster in critical power applications.

Think about the difference between a manufacturing plant and a hospital. The plant can probably handle a brief flicker in power, making a standard open-transition ATS a perfectly good, cost-effective choice. A hospital operating room? That's a completely different story. They can't afford a single millisecond of downtime.

For facilities that absolutely cannot go dark, a bypass-isolation switch isn't a luxury—it's a requirement. This feature is what allows technicians to perform maintenance, run tests, or even repair the ATS itself without cutting power to the critical loads it's there to protect.

Picking an ATS is just as much about planning for the future as it is about meeting today's needs. A bypass-isolation switch is a direct investment in uptime. It ensures the very device meant to save you from one outage doesn't become the cause of another during routine service.

Don't Forget Environmental and Enclosure Specs

The physical environment where the ATS will live is just as important as the electrical load it will handle. A transfer switch sitting in a clean, climate-controlled electrical room has a much easier life than one installed in a corrosive, wet, or dusty environment.

- Ambient Temperature: Seriously high temperatures can actually reduce the amount of current an ATS can safely handle. You have to pick a unit rated to perform flawlessly at the hottest temperature it will ever experience.

- Corrosive Atmospheres: In places like wastewater treatment plants or coastal areas with salt spray, you need an enclosure built to last. That means corrosion-resistant materials, like a NEMA 4X stainless steel box, are a must to prevent it from rusting away.

- Hazardous Locations: If your ATS is going into an area with flammable gases or dust, it absolutely must be in a properly rated explosion-proof enclosure. Safety is non-negotiable here.

Getting these details right is becoming more important every day. The global market for automatic transfer switches is expected to climb from USD 664.24 million in 2024 to USD 716.67 million in 2025, which just goes to show how much businesses are focusing on power reliability.

Of course, a key part of this whole process is making sure your protective devices are sized correctly from the start. For a closer look at that, check out our guide on properly sizing circuit breakers.

Best Practices for ATS Maintenance and Testing

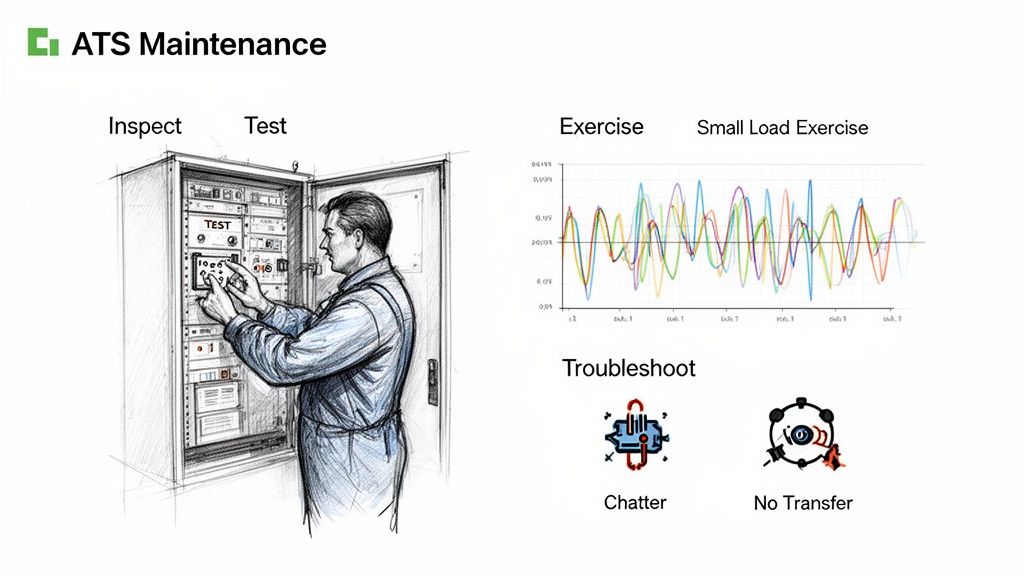

Think of your automatic transfer switch (ATS) as the silent guardian of your facility's power. It stands ready 24/7. But like any guardian, its readiness depends entirely on how well it's maintained. Simply having an ATS isn't enough; it has to work flawlessly the moment the lights go out. A proactive maintenance plan isn't just a good idea—it’s the only way to guarantee this critical asset does its job when it matters most.

This process really starts the second the switch is bolted to the wall. Solid commissioning sets the foundation for a lifetime of reliability. This isn't just a quick power-up. It's a meticulous process of verifying every single control wire, triple-checking that all settings match the original engineering specs, and then running the whole system through its paces to simulate a real power failure. You have to prove the entire sequence—from the generator start signal to the final load transfer—works exactly as designed.

Building a Routine Maintenance Checklist

Once commissioning is complete, the real work begins. A routine inspection and testing schedule, guided by standards like NFPA 110, is what keeps the system sharp. A good program catches the most common failures long before they have a chance to bring you down.

Your maintenance checklist should be practical and consistent:

- Visual Inspections: Get your eyes on the equipment regularly. Look for tell-tale signs of trouble like moisture, discoloration from overheating, or excessive dust building up on contacts and connections.

- Cleaning: It sounds simple, but keeping the enclosure and internal components free of dirt and debris is critical. Grime can jam up mechanical parts or even cause dangerous short circuits.

- Exercising the Switch: You have to operate the ATS from time to time, and doing it under load is best. This keeps the mechanical parts moving freely and, just as importantly, helps burn off the oxidation that naturally builds up on the electrical contacts.

A classic troubleshooting headache is 'switch chattering,' where you can hear the contacts slapping open and closed rapidly. This is a huge red flag, often pointing to low control voltage or a faulty sensing circuit. It needs immediate attention to prevent the switch mechanism from destroying itself.

By putting a clear, repeatable routine in place, you’re building a much more resilient power system. If you need a starting point, a comprehensive preventive maintenance schedule template can help you organize and track these essential tasks. Stick to these practices, and you can be confident your automatic transfer switch ats will be ready when you need it most.

A Few Common Questions We Hear About Automatic Transfer Switches

When you get down to the brass tacks of designing or maintaining a power system, the details around the automatic transfer switch (ATS) can get a little fuzzy. It's totally normal. Here are some of the most common questions our engineers get from folks in the field.

What's the Real Difference Between a 3-Pole and 4-Pole ATS?

This one comes up all the time. A 3-pole ATS is pretty straightforward—it switches the three main "hot" conductors (or phases) but leaves the neutral wire connected straight through. You'll typically see this setup when the utility service and your backup generator share a common ground reference, often called a bonded neutral.

A 4-pole ATS, on the other hand, is built to switch everything: all three phases and the neutral conductor. This is a must-have for what the code calls "separately derived systems." In these setups, you have to completely isolate the neutral between the two power sources. Why? It's critical for making sure ground-fault protection works correctly and keeps you in line with NEC standards.

Choosing between a 3-pole and 4-pole ATS isn't just a design preference; it's a code compliance and safety issue. The right choice depends entirely on how your system's neutral is grounded.

When Do I Actually Need a Bypass-Isolation ATS?

You bring in a bypass-isolation ATS when there is absolutely zero room for downtime—not even for a few minutes of planned maintenance. Think of it as a built-in detour for your power. These switches are absolutely essential for places like:

- Hospitals and Healthcare Facilities: Where life-support systems and critical patient care equipment can never lose power.

- Data Centers: An outage, even a scheduled one, can mean millions in lost revenue and data.

- Critical Industrial Processes: For any continuous manufacturing line where a sudden stop would be catastrophic to production.

This design lets a technician safely route power around the main transfer switch. The load stays on, and the ATS itself can be inspected, tested, or even repaired without anyone breaking a sweat.

At E & I Sales, we live and breathe this stuff. We specialize in getting you the right power control components for the toughest industrial jobs out there. For some expert guidance on picking and integrating the perfect ATS for your project, come see us at https://eandisales.com.