When you're dealing with electrical equipment, the enclosure is your first and most important line of defense. A NEMA enclosure rating chart is the go-to tool for figuring out exactly what kind of protection you're getting. It cuts through the jargon and helps you match the right enclosure—like a NEMA 4X or NEMA 12—to the specific hazards of your plant floor or outdoor installation.

So, What Are NEMA Ratings, Exactly?

Think of the National Electrical Manufacturers Association (NEMA) rating system as the North American standard for grading how tough an electrical enclosure is. The whole point is to keep sensitive electronics and wiring shielded from whatever the environment throws at them, ensuring everything runs safely and reliably for the long haul.

This isn't just a simple "indoor" vs. "outdoor" label. The system gets incredibly specific. It spells out an enclosure's ability to stand up to everything from a clumsy operator accidentally touching a live part to fine, circulating dust, dripping water, or even the harsh bite of corrosive salt spray. Each rating number corresponds to a strict set of performance tests an enclosure has to pass.

Why This Matters on the Plant Floor

For any plant engineer or equipment packager, getting the NEMA rating right is non-negotiable. It's a decision that affects the lifespan of a motor control center, the precision of an automated packaging line, and the safety of your team. The wrong choice leads to fried components, unplanned downtime, and serious safety hazards.

The NEMA rating system has been around since the organization was founded way back in 1926, and it's more critical now than ever. In the U.S. manufacturing world, downtime from industrial automation costs a staggering $50 billion every single year. But here’s the kicker: simply choosing the correct NEMA-rated enclosure can cut equipment failure rates by as much as 40%. You can learn more about how these ratings impact day-to-day industrial control panel design.

This guide is built to be your definitive reference, breaking down each NEMA type so you can specify enclosures with total confidence.

Key Takeaway: Using a NEMA enclosure rating chart isn't just about ticking a box on a spec sheet. It's a strategic move to protect your investment, keep your people safe, and sidestep the massive financial hit that comes with equipment failure.

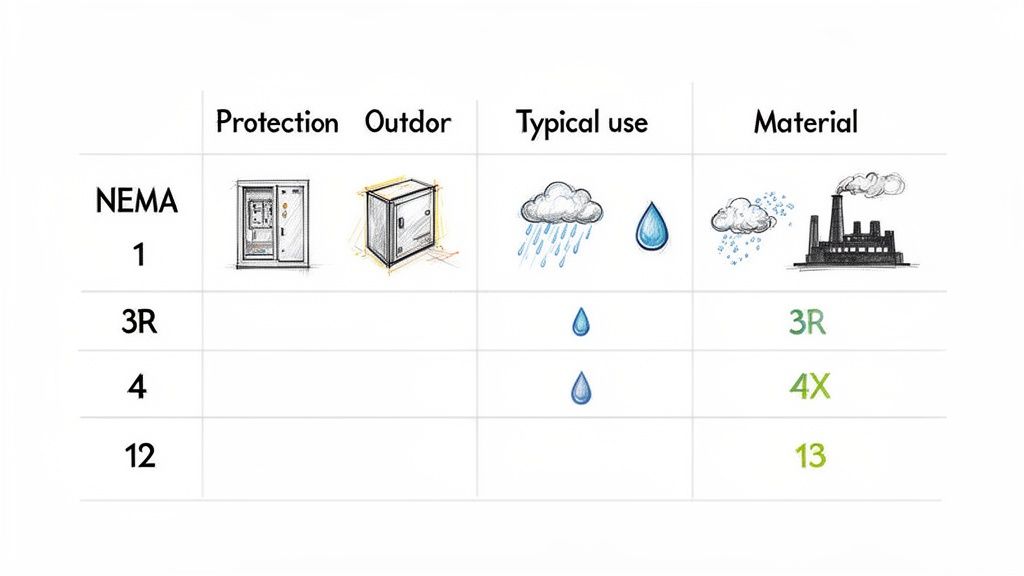

NEMA Enclosure Ratings Quick Reference Table

For a quick overview, this table breaks down the most common NEMA ratings. It’s a handy starting point for narrowing down your options before diving into the finer details.

| NEMA Rating | Protection Against | Environment Type | Common Application |

|---|---|---|---|

| 1 | Accidental contact, falling dirt | Indoor | General-purpose control panels, junction boxes |

| 3R | Rain, sleet, snow, external ice formation | Indoor/Outdoor | Outdoor lighting controls, utility boxes, metering equipment |

| 4 | Windblown dust, rain, splashing water, hose-directed water | Indoor/Outdoor | Washdown environments, exterior machine controls |

| 4X | Same as NEMA 4, plus corrosion | Indoor/Outdoor (Corrosive) | Food processing plants, marine applications, wastewater |

| 6P | Water ingress during prolonged submersion | Indoor/Outdoor (Submersible) | Manholes, pits, deck-mounted shipboard equipment |

| 12 | Circulating dust, falling dirt, dripping non-corrosive liquids | Indoor | Machine tool environments, packaging lines, assembly plants |

| 13 | Same as NEMA 12, plus spraying of oil and coolants | Indoor | CNC machines, presses, and other industrial machinery |

This table is great for at-a-glance comparisons, but always refer to the detailed descriptions for each NEMA type to ensure your selection fully meets the demands of your specific application.

A Detailed Look at Common NEMA Enclosure Ratings

While a quick-reference NEMA chart is great for a high-level overview, you can't confidently spec the right enclosure without knowing what each rating really means on the plant floor. Let's move beyond the summary and dig into the specific protections, typical materials, and real-world applications for the most common non-hazardous NEMA ratings you’ll run into.

Each one of these ratings was designed to solve a very specific set of environmental problems, from basic indoor protection all the way up to withstanding corrosive washdowns. Let's break them down.

NEMA 1: The General-Purpose Indoor Standard

A NEMA 1 enclosure is your most basic option, designed strictly for indoor use in clean, dry spaces. Its main job is simple: keep fingers away from energized parts and stop falling dirt from getting inside.

Don't expect any protection from liquids. Not even a light drip. Think of it as a fundamental safety barrier, not an environmental shield.

- Primary Protection: Guards against someone accidentally touching internal equipment and shields from falling solid debris.

- Typical Materials: You'll almost always find these made from painted carbon steel because they're meant for non-corrosive environments.

- Common Applications: Perfect for junction boxes, switch enclosures, and control panels tucked away in office spaces, clean control rooms, or protected utility closets where moisture and heavy dust are non-issues.

NEMA 3R: Outdoor Weather Resistance

When you need to mount equipment outside, NEMA 3R is often the go-to, cost-effective choice. This rating is built to handle falling rain, sleet, and snow, and it will prevent external ice from forming on the enclosure.

One of the key features of a NEMA 3R enclosure is its drainage holes. This design is smart because it prevents water and condensation from building up inside, but it also means the enclosure is not dust-tight. Windblown dust and other debris can, and will, find their way in.

Practical Scenario: A NEMA 3R enclosure is the perfect fit for an outdoor disconnect switch or a metering cabinet. It does a great job of shielding components from the rain, but since it's not sealed against dust, you wouldn't want to put a sensitive control panel in one if it's in a dusty part of the yard.

NEMA 4 and 4X: Washdown and Corrosion Protection

The NEMA 4 rating is a major leap in protection. It’s designed for both indoor and outdoor use and is completely sealed against windblown dust, rain, splashing water, and even high-pressure hose-downs. This makes it a true workhorse in any environment that needs frequent, heavy cleaning.

A NEMA 4X enclosure gives you everything a NEMA 4 does, but with one critical addition noted by the "X": corrosion resistance.

- NEMA 4: Provides a dust-tight and water-tight seal that stands up to hose-directed water. It’s usually made from painted carbon steel.

- NEMA 4X: Delivers the exact same dust and water protection but is built from corrosion-resistant materials like 304 or 316 stainless steel or even polycarbonate.

These are absolutely essential in places like food processing plants, wastewater treatment facilities, and marine applications. In these settings, chemical exposure or salt spray would chew through a standard painted steel box in no time. Upgrading to NEMA 4X isn't a luxury; it's a critical investment in keeping your equipment alive.

NEMA 12 and 13: Indoor Industrial Protection

Inside the factory, NEMA 12 enclosures are the standard. They're built to protect equipment from circulating dust, falling dirt, and dripping non-corrosive liquids. This rating is specifically made for factory floors where airborne particles from manufacturing are a constant headache.

They feature sealed doors and gaskets, but don't make the mistake of thinking you can hit them with a pressure washer—they are not designed for the kind of washdown a NEMA 4 can handle.

A NEMA 13 enclosure has all the protection of a NEMA 12 but adds a crucial defense against oil and non-corrosive coolants. You'll specify this rating for anything near machining, stamping, or other industrial processes where oils and lubricants are being sprayed or splashed. The gaskets in NEMA 13 enclosures are made from special materials that won't break down when exposed to these fluids.

Example Comparison

| Feature | NEMA 12 | NEMA 13 |

|---|---|---|

| Environment | Indoor, industrial factory floors | Indoor, machine shops, metalworking facilities |

| Liquid Protection | Dripping non-corrosive liquids | Spraying oil and non-corrosive coolants |

| Primary Use Case | Protecting controls on packaging lines | Housing electronics on CNC machines or presses |

Getting these distinctions right is vital. If you put a NEMA 12 enclosure on a CNC machine, the coolant will eventually destroy the gasket, leading to equipment failure. This is exactly why a detailed grasp of each rating is so important for any plant engineer.

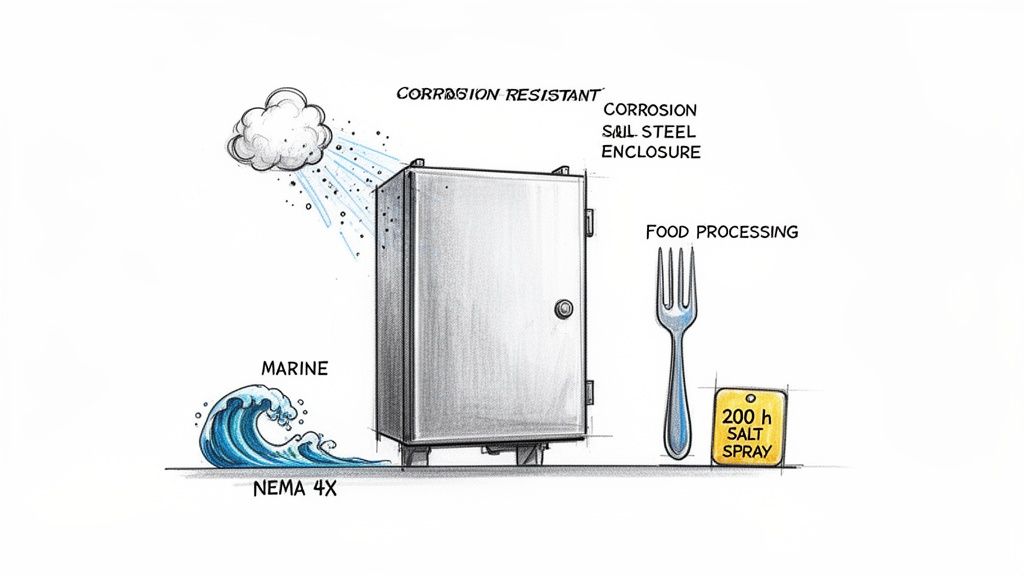

Breaking Down NEMA 4X for Corrosive Environments

When you're dealing with an industrial setting that's not just wet but also chemically harsh, a standard NEMA 4 enclosure just won't survive. This is precisely where the NEMA 4X rating comes in, setting the gold standard for protection in the toughest places you can imagine. That little 'X' in its name is the game-changer—it means serious corrosion resistance.

Sure, it gives you all the same great protection against hose-directed water, splashing, and windblown dust as a regular NEMA 4. The real difference, though, is in the materials. We're talking 304 or 316 stainless steel or beefy, high-grade polycarbonates that are built to take a beating from caustic chemicals, salt spray, and constant washdowns with aggressive cleaning agents.

Why That 'X' Matters So Much

That 'X' isn't just for show; it means the enclosure has been put through some serious corrosion-resistance testing. The most common trial by fire is the 200-hour salt spray test, which mimics years of exposure to highly corrosive marine or chemical environments. This is what separates a simple painted steel box from a truly battle-hardened NEMA 4X solution.

In industries where uptime is everything, picking the wrong enclosure can lead straight to disaster. In the U.S. alone, it's estimated that improper enclosure selection is behind 25% of electrical failures in corrosive settings. Switching to NEMA 4X can slash those incidents, saving companies millions in downtime and repairs. You can learn more about the critical role of NEMA-rated enclosures and how they protect your most valuable assets.

Bottom line: for certain sectors, NEMA 4X isn't just a good idea—it's an absolute must for equipment longevity and safety.

Where You'll See NEMA 4X in Action

The unique guts of a NEMA 4X enclosure make it the go-to choice in several key industrial environments. In each case, the rating's ability to fight off degradation is what keeps the enclosure—and the critical gear inside—alive and kicking.

- Food and Beverage Processing: These plants are all about daily high-pressure washdowns with sanitizing chemicals. A NEMA 4X stainless steel enclosure is really the only way to go to stop rust and contamination, keeping everything in line with tough hygiene standards.

- Wastewater Treatment Plants: Think corrosive gases like hydrogen sulfide and constant dampness. A NEMA 4X box is what stands between sensitive control systems and a swift death from chemical attacks and atmospheric corrosion.

- Marine and Coastal Installations: Equipment on docks, ships, or anywhere near the ocean gets blasted with salt spray 24/7. Here, a NEMA 4X enclosure, usually made of 316 stainless steel for top-tier chloride resistance, is essential to stop rapid rust and failure.

- Pharmaceutical and Chemical Plants: In these facilities, enclosures have to stand up to spills and vapors from a whole cocktail of aggressive chemicals. The solid construction of a NEMA 4X enclosure ensures control panels and junction boxes stay sealed and fully operational.

Expert Insight: Let's be clear: specifying a NEMA 4X UL-listed control panel isn't just following best practices; it's a smart business move. You're directly extending the life of your equipment, preventing incredibly expensive unplanned downtime, and making the plant safer for your team in places that would eat lesser-rated enclosures for lunch.

So, when you're looking at a NEMA enclosure rating chart, just remember that the 'X' in 4X signifies a whole other level of toughness. For any packager or plant engineer working in a corrosive environment, getting this distinction right is the key to building a system that's reliable and built to last.

NEMA Ratings vs. IP Equivalents: What's the Real Difference?

If you're specifying electrical enclosures, you're going to run into two main standards: NEMA and IP. Here in North America, a good NEMA enclosure rating chart is the bible. But for international projects, it's all about the Ingress Protection (IP) code. Knowing how the two relate is essential, but it’s definitely not a simple one-to-one conversion.

While both systems are designed to measure how well an enclosure protects what's inside, they don't use the same playbook. Their testing methods and what they cover are just different enough that you can't just swap one for the other. Trying to substitute a NEMA rating with what looks like its IP twin can cause some serious headaches, from failed inspections to fried equipment.

The Core Difference: NEMA vs. IP

The IP rating system is refreshingly straightforward. It focuses on just two things: how well it keeps out solid objects (that's the first digit) and how well it keeps out liquids (the second digit). The higher the number, the better the protection. Simple. For example, an IP67 rating tells you the box is completely sealed against dust (the "6") and can be dunked in water for a short time (the "7").

But the NEMA system goes deeper. Beyond just keeping stuff out, NEMA standards bake in tests for other real-world conditions you'll find on the plant floor. These extra layers of protection are exactly why a direct NEMA-to-IP conversion just doesn't work.

- Corrosion Resistance: A rating like NEMA 4X has to prove it can stand up to corrosive agents, often by surviving a grueling 200-hour salt spray test. The IP system has no specific test for corrosion.

- Oil and Coolant Protection: A NEMA 13 enclosure is built to handle the oils and coolants common in machine shops, something no standard IP rating even considers.

- Dealing with Ice: Ever had an outdoor enclosure freeze over? NEMA ratings like 3R and 3S are specifically tested to ensure they work even when coated in ice, another blind spot for the IP system.

I've seen this mistake made a few times: someone assumes an IP68-rated enclosure is the same as a NEMA 6P. They both handle being submerged, sure. But the NEMA 6P rating also requires more intensive testing for corrosion and material aging, giving you an extra level of confidence the IP standard simply doesn't provide.

NEMA to IP Rating Conversion and Comparison Chart

So, how do you compare them? Think of this chart as a solid reference for finding the closest IP equivalent, not a direct translation. You always have to account for the extra protections that a NEMA rating brings to the table, especially when you're dealing with UL-listed applications here in North America.

| NEMA Rating | Closest IP Equivalent | IP First Digit (Solids) | IP Second Digit (Liquids) | Key Differences and Additional NEMA Protections |

|---|---|---|---|---|

| 1 | IP20 | 2 | 0 | NEMA 1 protects against falling dirt; IP20 protects against fingers/large objects. |

| 3R | IP24 | 2 | 4 | NEMA 3R specifically tests against rain, sleet, and external ice formation. |

| 4 & 12 | IP66 | 6 | 6 | NEMA 4 is for hose-downs; NEMA 12 protects from dripping liquids and circulating dust. |

| 4X | IP66 | 6 | 6 | Crucial Difference: NEMA 4X adds mandatory corrosion resistance testing. |

| 6 | IP67 | 6 | 7 | NEMA 6 protects during temporary submersion at a limited depth. |

| 6P | IP68 | 6 | 8 | NEMA 6P is for prolonged submersion and includes a corrosion resistance test. |

| 13 | IP65 | 6 | 5 | NEMA 13 specifically adds protection against spraying oil and non-corrosive coolants. |

At the end of the day, for any job in the U.S. or Canada, getting the NEMA rating right is non-negotiable. It's about safety, code compliance, and getting that all-important UL listing. While an IP rating is a useful point of comparison, the NEMA enclosure rating chart is, and will remain, the gold standard for any industrial application here.

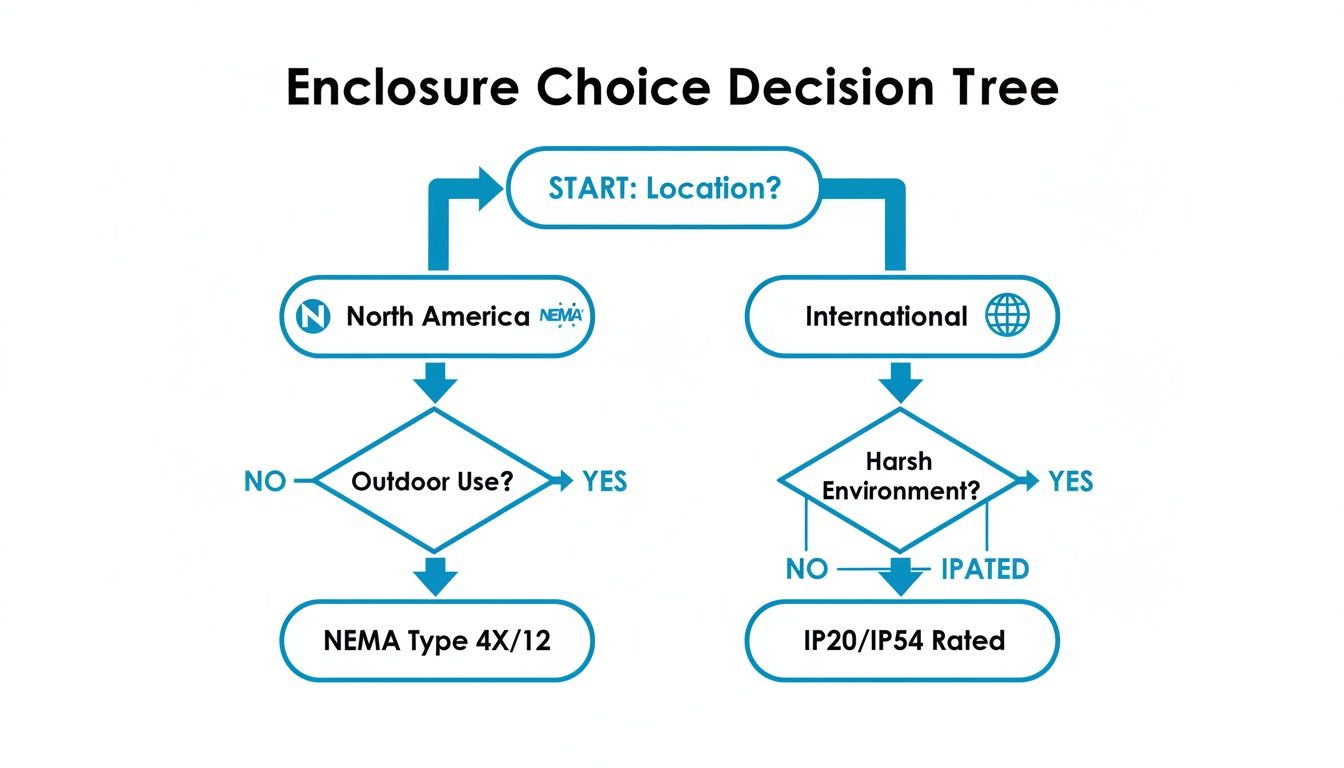

How to Select the Right NEMA Enclosure

Knowing your way around a NEMA enclosure rating chart is one thing, but actually picking the right box for the job? That takes a deeper dive into your specific environment. It's less about just reading a chart and more about a consultative process—thinking through the entire lifecycle of the equipment, from the day it's installed to its long-term maintenance needs.

This approach is what ensures you land on a solution that hits the perfect balance of performance, cost, and rock-solid reliability.

A smart selection process always starts with the right questions. It’s not enough to know if an enclosure is going indoors or outdoors; you have to get granular about the challenges it will face day in and day out. A few minutes of thoughtful analysis upfront can prevent a world of hurt later, like over-specifying and blowing the budget, or worse, watching expensive equipment fail because its housing wasn't up to the task.

Key Questions to Guide Your Selection

Before you even think about settling on a NEMA rating, every plant engineer and packager needs to run through a quick mental checklist. Getting clear answers here will point you directly to the non-negotiables for your application.

- What are the exact environmental hazards? Get specific. Is it just dripping water (NEMA 12), or are we talking high-pressure hose-downs (NEMA 4)? Is corrosive salt spray in the air (NEMA 4X)? You need to account for every potential threat, from fine dust and fibers to oil and chemical coolants.

- What's going inside the box? Think about the heat your components will generate. Power-hungry gear like VFDs can turn an enclosure into an oven, which might mean you need a larger box, or even one with active cooling, to keep things from frying. This decision impacts both size and material.

- How often do you need to get inside? Consider your maintenance crew. How frequently will they need to access the components? Enclosures with hinged doors, easy-to-use latches, or even clear windows can make a massive difference in maintenance time and operator safety.

- Are there specific material requirements? A NEMA 4X rating requires corrosion resistance, but other factors come into play. Do you need lightweight aluminum? High-impact polycarbonate? Or is budget-friendly carbon steel good enough? The material has to match the environment and the project budget.

This decision tree gives you a great visual starting point for the selection process, helping you map out your needs based on the location and standards you're working with.

As the graphic shows, the first fork in the road is a big one: are you operating under North American (NEMA) standards, or do you need to meet international (IEC/IP) requirements?

Balancing Performance and Project Cost

At the end of the day, picking the right enclosure is all about finding that sweet spot between bulletproof protection and real-world project economics. Sure, a NEMA 4X stainless steel enclosure is the only real choice for a harsh marine environment, but it’s complete overkill for a clean, dry control room where a simple NEMA 1 box would do just fine.

Expert Tip: Don't just look at the sticker price—think about the total cost of ownership. A slightly pricier NEMA 4X enclosure that lasts for 15 years in a corrosive plant is a much smarter investment than replacing a cheaper NEMA 4 painted steel box every three years. Likewise, understanding the nuances between UL Listed vs. UL Recognized components can be critical for overall compliance and safety. By weighing these factors carefully, you can confidently choose an enclosure that will protect your critical assets for years to come.

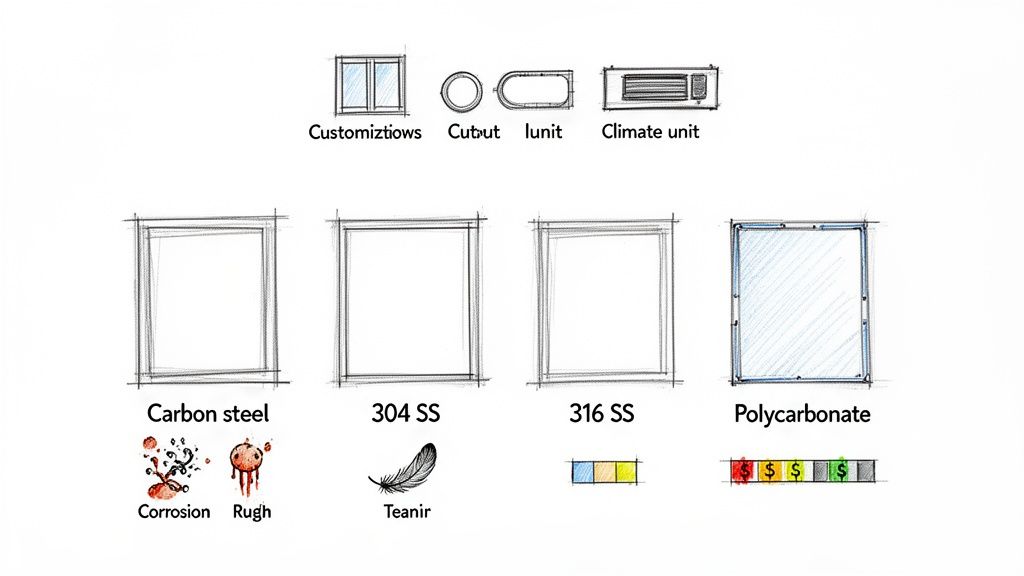

Getting Materials and Customizations Right

A NEMA rating is only half the story. The material an enclosure is made from is just as critical to its long-term performance, especially out on the plant floor. Making the right choice here is the difference between an enclosure that does its job for years and one that fails prematurely.

Each option presents a unique trade-off between corrosion resistance, weight, and of course, cost. Think about it: a standard painted steel box might be fine in a climate-controlled room, but it won’t last a week in a washdown environment where a stainless steel unit is designed to thrive.

Common Enclosure Materials

Understanding the pros and cons of each material is the key to matching the enclosure to the job. These are the most common options you’ll run into:

- Painted Carbon Steel: This is your workhorse for general-purpose indoor ratings like NEMA 1 and NEMA 12. It’s budget-friendly and the paint gives it a decent layer of protection. Just be aware that any scratch or ding can expose the steel underneath to rust.

- Stainless Steel (304 & 316): When you see NEMA 4X, you should be thinking stainless. 304 stainless is the standard for food and beverage processing where washdowns are constant. For anything involving harsh chemicals or salt spray, you’ll want to step up to 316 stainless for its superior chloride resistance.

- Aluminum: Lighter than steel and naturally resistant to corrosion, aluminum is a great middle-ground choice. It’s perfect for outdoor applications where you need durability without the weight of steel.

- Polycarbonate: This high-impact plastic is a fantastic problem-solver. It’s lightweight, completely rust-proof, and easy to drill on-site. As a bonus, it’s transparent to radio waves, making it the go-to for housing Wi-Fi routers, VFDs, and other wireless gear.

Professional Modifications and How to Keep Your Rating

Let's be realistic—a stock enclosure straight out of the box rarely fits a project perfectly. You almost always need holes for conduit, cutouts for HMIs, or openings for pushbuttons. The catch? One bad drill hole can completely void an enclosure's NEMA rating.

Critical Point: Every single hole you add can break the seal. To keep a NEMA 4X rating intact, for example, every conduit hub, window, and latch you install must also be NEMA 4X rated and installed to spec.

This is exactly why certified UL panel shops are so valuable. These guys have the specialized tools and the know-how to make precise modifications without compromising the enclosure's integrity.

A good shop can handle things like:

- Precision Cutouts: Using CNC machines to get perfectly sized holes and openings.

- Component Installation: Professionally mounting everything from touch screens and windows to fans and air conditioners.

- Custom Finishes: Applying special powder coats for extra protection or to match company branding.

Partnering with a certified expert is your best guarantee that a customized box will perform exactly as you need it to, keeping your equipment safe and your plant in compliance. For a deeper dive into the different types of electrical boxes available, our other guides can help you make an informed choice for both standard and custom projects.

Your Top NEMA Rating Questions, Answered

Working with NEMA enclosures day in and day out, we get a lot of great questions. When you're dealing with specifics like comparing two similar ratings or planning on-site modifications, it's easy to get tripped up.

This section tackles some of the most common questions we hear from plant engineers and packaging specialists. We want you to have the confidence to apply this knowledge correctly, ensuring everything you install is compliant, safe, and built to last.

NEMA 3R vs. NEMA 4: What’s the Real Difference?

The biggest difference boils down to how they handle dust and high-pressure water. Think of a NEMA 3R enclosure as your go-to for general outdoor use. It’s designed to keep out rain, sleet, and ice, but it’s not dust-tight. You’ll often find drainage holes in these to let condensation escape.

A NEMA 4 enclosure, on the other hand, is a completely sealed box. It’s fully dust-tight and can take a direct blast from a high-pressure hose, no problem. This makes it perfect for places that need regular washdowns or are exposed to a ton of windblown dust.

Can I Drill Into a NEMA Enclosure and Keep the Rating?

You can, but it absolutely must be done by a qualified professional if you want to maintain that rating. It's incredibly easy to compromise the enclosure's seal when you start drilling holes for conduit or cutting out a space for an HMI.

To do it right, any component you add—like fittings, buttons, or windows—has to meet or exceed the enclosure's original NEMA rating. So, if you have a NEMA 4X box, you need to use NEMA 4X fittings, and they must be installed and sealed perfectly.

Pro Tip: Your safest bet is always to work with a certified UL panel shop. They have the expertise to make sure every modification follows strict guidelines. This not only protects the NEMA rating and keeps your UL compliance intact but also prevents a simple mistake from causing a catastrophic equipment failure down the road.

Is It Okay to Use a NEMA 12 Enclosure Outside?

Absolutely not. A NEMA 12 enclosure is strictly for indoor industrial settings. It's a workhorse on the factory floor, offering solid protection against circulating dust, falling debris, and light drips of non-corrosive liquids.

But it has none of the seals or weather-resistant construction needed to survive outdoors. Rain, snow, sleet, and UV rays will destroy it. For any outdoor job, you have to step up to a rating built for the elements, like NEMA 3R, NEMA 4, or NEMA 4X.

When Is Stainless Steel Worth the Extra Cost?

You should always opt for stainless steel whenever corrosion is a potential issue. This is a no-brainer for environments with chemical exposure, salt spray (think coastal areas), or facilities that rely on frequent washdowns with harsh sanitizers. This is the world where NEMA 4X lives.

For general-purpose indoor spots or non-corrosive outdoor applications, painted carbon steel is a solid, cost-effective choice (think NEMA 12 or NEMA 3R). The paint does a good job protecting the steel, but if it gets scratched, rust will find a way in and eventually compromise the enclosure.

At E & I Sales, we're experts in helping you find and customize the right NEMA-rated enclosure for any job, making sure your critical systems stay protected. Get in touch with our team today to talk through your project needs.