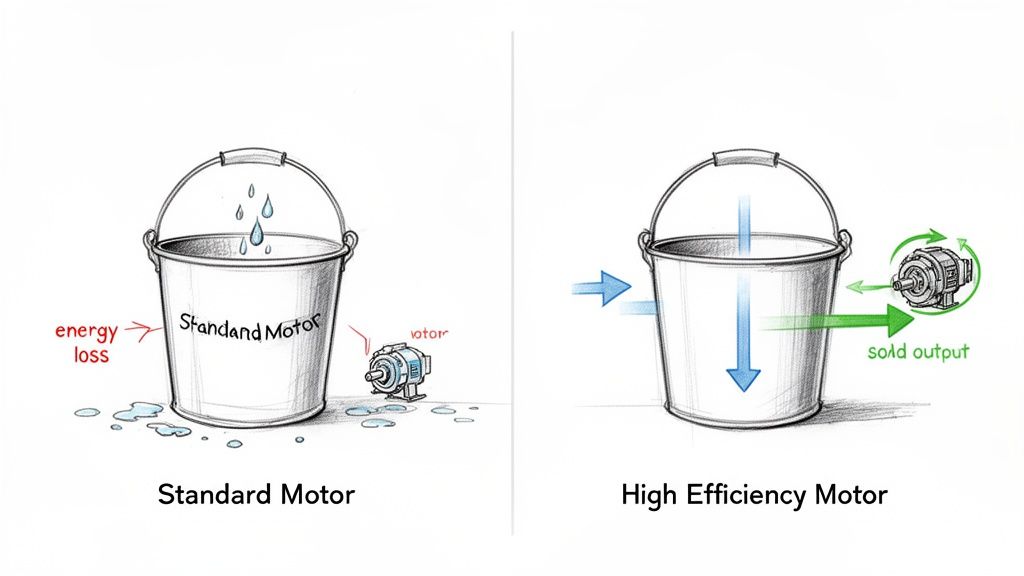

Think of a standard electric motor like a leaky bucket. You pour electricity in, but a good portion of it leaks out as wasted heat before it can do any real work. High-efficiency motors are the sealed bucket—they’re engineered to turn as much of that electricity as possible directly into the mechanical power your facility needs.

This guide isn't about a simple component swap. It's about a strategic shift in thinking that can drastically cut your operating costs and boost reliability across the board.

Why High-Efficiency Motors Are a Strategic Investment

In any industrial plant, whether it's manufacturing, food and beverage, or water treatment, electric motors are the workhorses. They're everywhere, running pumps, fans, conveyors, and compressors, and they are almost always one of the biggest line items on your utility bill. Even a small improvement in efficiency, when multiplied across dozens or hundreds of motors running 24/7, adds up to serious savings.

This is more than just an incremental upgrade. Moving to high-efficiency motors is a fundamental change in how plant engineers, procurement managers, and OEMs should approach equipment specs. It means looking past the initial price tag to see the far more important total cost of ownership.

The Real Cost of a "Cheaper" Motor

Believe it or not, the purchase price of an electric motor only accounts for about 2-5% of its total lifetime cost. The real expense—often over 95%—is the electricity it consumes over years of hard work.

A standard-efficiency motor is constantly wasting money by converting electricity into heat instead of torque. That excess heat doesn't just disappear; it actively works against you, causing premature wear on windings and bearings. This leads to higher maintenance bills and, worse, a greater risk of unplanned downtime.

High-efficiency models are designed to crush this problem. They use better materials, are built to tighter tolerances, and feature smarter designs that minimize those electrical and mechanical losses. This delivers a few key wins:

- Lower Energy Bills: This is the most obvious benefit. The savings often pay for the motor itself in under two years.

- Better Reliability: These motors run cooler. A cooler motor means longer life for its insulation and bearings, which translates to less maintenance and fewer breakdowns.

- Cooler Operations: A motor that isn't throwing off as much heat can also reduce the load on your facility's HVAC systems, creating secondary savings.

Building a Foundation for Modern Systems

Specifying high-efficiency electric motors is about more than just saving on a single machine; it's about building a smarter, more resilient operational foundation. Industry standards like NEMA Premium® and the IEC's IE classes give you a clear benchmark for performance, so you know you're getting the efficiency you paid for.

For any industrial operation, the logic is simple: every kilowatt-hour saved drops directly to the bottom line. Upgrading to a premium-efficiency motor is one of the most reliable and predictable ways to boost profitability while making your facility more robust.

The full potential of these motors is really unlocked when they're paired with an expertly integrated UL control system. A well-designed control panel ensures the motor runs in its sweet spot, protecting your investment and maximizing performance from day one. This guide will walk you through how to make it happen.

Decoding Motor Efficiency Ratings: NEMA and IE Classes

Trying to make sense of electric motor specs can feel like learning a new language. You're hit with terms like NEMA Premium, IE3, and IE4, but what do those labels actually mean for your bottom line?

Think of these ratings as a simple ladder. Each step up represents a serious drop in wasted energy—the electricity that just turns into heat instead of productive work. For anyone responsible for specifying motors, climbing this ladder isn't just about efficiency; it's about making a smarter, more profitable choice for the long haul.

NEMA: The North American Standard

Here in North America, the National Electrical Manufacturers Association (NEMA) is the authority. For a long time, their NEMA Premium® efficiency rating has been the gold standard for high-performance motors. When you see that label, you know you're getting a motor that’s guaranteed to meet a high bar for performance, losing less electricity as useless heat.

The NEMA Premium standard was a huge step forward, pushing the entire industry away from old, energy-guzzling designs. Choosing a NEMA Premium motor sends a clear message: you're prioritizing long-term operational savings over a slightly lower price tag upfront.

IEC: The Global Efficiency Language

On the world stage, the International Electrotechnical Commission (IEC) provides a similar framework with its International Efficiency (IE) classes. This system creates a universal language for motor performance, which makes it much easier to compare products from different manufacturers around the globe.

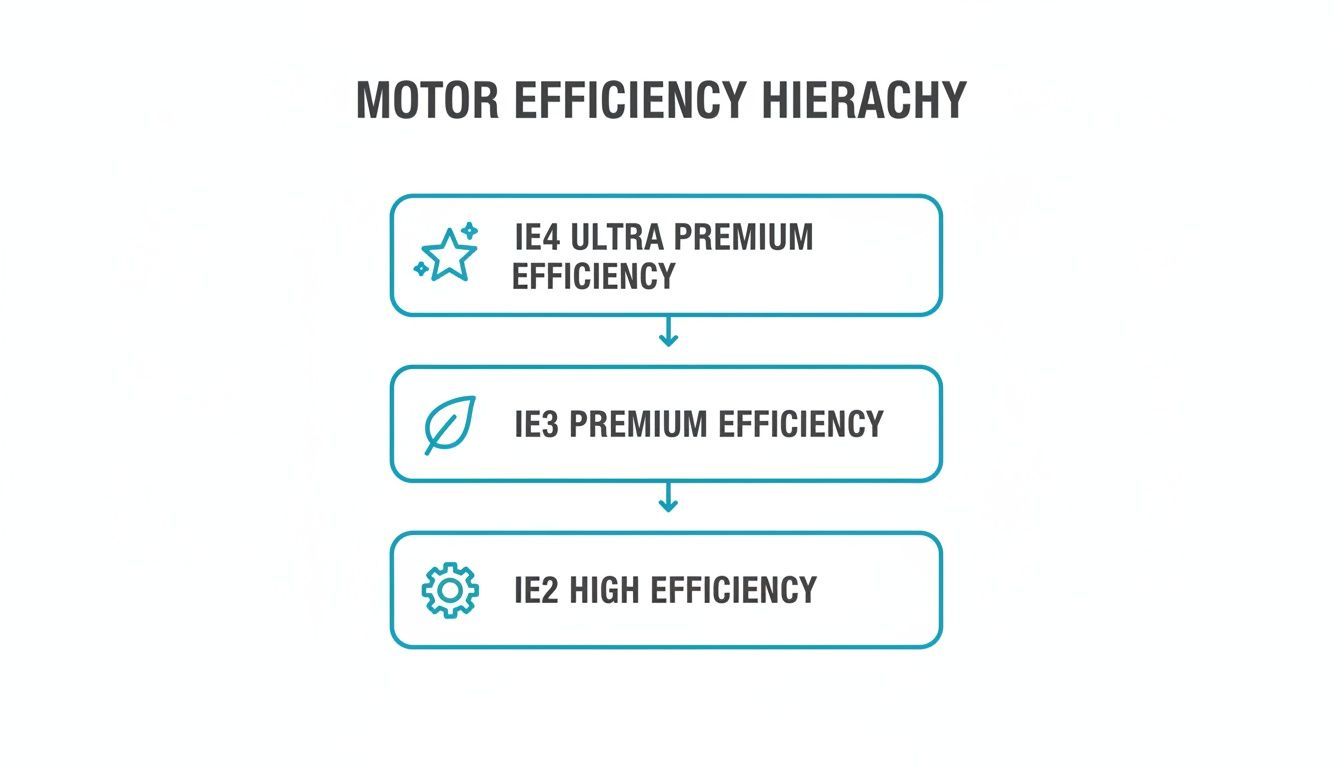

The IE classes are a simple, logical progression:

- IE1 (Standard Efficiency): The old baseline. You won't see these in new installations in most places anymore.

- IE2 (High Efficiency): A good step up, but in many markets, you'll need to pair these with a VFD for new applications.

- IE3 (Premium Efficiency): This is today's global standard and the direct counterpart to NEMA Premium. IE3 is where the energy savings really start to stack up.

- IE4 (Super Premium Efficiency): This class pushes the envelope of motor design, offering even bigger energy savings. These are perfect for continuous-duty jobs where even a small efficiency gain delivers a massive return over the motor's life.

The momentum is undeniable. In the US industrial sector alone, upgrading motor systems could save an incredible 37-79 billion kWh every year. While many facilities say that 47-77% of their new motor purchases are premium-efficiency, there's still a huge opportunity left on the table. You can dive deeper into these Department of Energy findings on motor market assessments.

Why IE3 Is The New Normal

For almost any new project, specifying an IE3 or NEMA Premium motor isn't just a good idea—it's often the law. Regulations across the United States and Europe have made these efficiency levels a mandatory minimum for most new motors sold. This has completely reshaped the market, making high-efficiency the default choice, not the exception.

Making IE3 your facility's baseline doesn't just keep you compliant; it future-proofs your entire operation. As energy costs climb and regulations inevitably get tighter, standardizing on premium-efficiency motors shields you from future headaches and locks in savings for years to come.

Understanding how these global standards relate is key to making the right choice, no matter where your project is. This quick table breaks down the common equivalents.

NEMA Premium vs IEC Efficiency Classes At A Glance

| IEC Class | Efficiency Level | Common NEMA Equivalent | Typical Application Use Case |

|---|---|---|---|

| IE2 | High | EPAct / High Efficiency | Often used in existing systems or where regulations allow; may require VFD pairing for new installations. |

| IE3 | Premium | NEMA Premium® | The standard for new pumps, fans, compressors, and conveyors in continuous or frequent-duty cycles. |

| IE4 | Super Premium | NEMA Super Premium (guideline) | Best for 24/7 applications like large-scale HVAC systems or critical process machinery where lifecycle costs are paramount. |

| IE5 | Ultra Premium | (No direct equivalent) | Emerging technology for specialized applications demanding the absolute peak of motor performance and energy reduction. |

Ultimately, whether the label says NEMA Premium or IE3, the goal is the same: to ensure you're installing a motor that works smarter, not harder, delivering performance you can count on while cutting down your energy bill.

Seeing Past the Sticker Price: The True Cost and ROI of High-Efficiency Motors

The initial price tag on a new electric motor is probably one of the most misleading numbers on any industrial budget. It feels like the main event, but in reality, it’s just the cost of admission. The real cost—the one that chips away at your bottom line for a decade or more—is the electricity that motor will guzzle down, day in and day out.

When you look at the total lifecycle cost, that upfront purchase price typically accounts for just 2-5% of the money you'll spend. The other 95%? Almost all of it is energy. This one simple fact should completely reframe how you approach motor procurement. That "cheaper" standard-efficiency motor isn't a smart buy; it's a long-term financial drain disguised as a deal.

Let's break down how to see past the initial price to calculate the Total Cost of Ownership (TCO) and Return on Investment (ROI). Once you see the numbers, the case for high-efficiency motors becomes impossible to ignore.

Breaking Down the Lifecycle Cost

Total Cost of Ownership isn't just a corporate buzzword; it's the complete financial story of a piece of equipment. For a motor, the formula is refreshingly simple and shines a bright light on where the money really goes.

- Initial Purchase Price: This is the upfront capital outlay. It's what everyone focuses on, but it's the smallest piece of the pie.

- Installation & Commissioning: The labor and materials needed to get the motor bolted down and wired up.

- Energy Consumption: This is the heavyweight champion of motor expenses, dictated by runtime, load, and, most importantly, efficiency.

- Maintenance & Repairs: All the scheduled servicing, replacement parts, and the painful costs of unplanned downtime.

- Disposal Costs: The expense of decommissioning the motor when it finally reaches the end of its operational life.

Out of all these, energy consumption absolutely dwarfs everything else. Every single percentage point you gain in efficiency is a direct, recurring reduction in this massive operating expense.

Each step up this ladder, like moving from a workhorse IE2 motor to a modern IE3 premium model, locks in a significant and guaranteed cut in energy waste.

A Real-World ROI Calculation

Let's get practical. Say you're looking at a 100 HP motor running 8,000 hours a year where you pay $0.10/kWh for electricity. A standard motor with 82.5% efficiency will burn through a staggering $723,394 in electricity over a 10-year life.

Now, what happens if you upgrade to a 94.5% efficient IE3 premium motor? The energy bill for that same period drops to $615,534. That’s a $107,860 savings on a single motor. This isn't just theory; it's the kind of math we do every day for plant managers and EPC firms, pairing the right motors with VFDs and UL control panels to deliver rapid paybacks.

This kind of saving isn't a rounding error—it's a massive operational win hiding in plain sight. When you can walk into a budget meeting with this kind of detailed financial analysis, the decision to invest in efficiency becomes incredibly straightforward. To dig even deeper into the numbers, check out our guide on how to calculate electric motor efficiency. And while it's from a different industry, this pricing guide and cost breakdown shows just how powerful a detailed financial analysis can be for any major investment.

The Key Takeaway: The premium you pay for a high-efficiency motor isn't a cost. It’s an investment. In almost any industrial application, that investment pays for itself with energy savings, often in less than two years.

The Rebate Accelerator: Getting Paid to Upgrade

The financial picture gets even brighter. Many utility companies offer substantial rebates for businesses that install energy-efficient equipment, and high-efficiency motors are often at the top of their list. These programs can directly chip away at the initial purchase price, sometimes covering the entire cost difference between a standard and a premium model.

Why would they pay you to use less of their product? It’s simple economics. It is far cheaper for a utility to help you save a kilowatt of power than it is for them to build the infrastructure to generate a new one.

It’s a true win-win:

- Your Facility: You get a top-tier, reliable motor with a drastically shorter payback period.

- The Utility: They reduce demand on the grid and hit their energy conservation targets.

By taking advantage of these programs, you can turn a multi-year ROI into a matter of months, making the upgrade a no-brainer for even the most risk-averse financial teams.

How to Properly Size a Motor for Peak Performance

In any industrial plant, one of the most common and expensive mistakes we see is motor oversizing. It usually comes from a good place—a well-intentioned but misguided effort to build in a "safety factor." What you end up with is a powerful motor running at a tiny fraction of its capacity. It's like using a sledgehammer to crack a nut. Sure, the job gets done, but it’s incredibly wasteful.

When an oversized motor runs at a partial load, you force it way outside its peak efficiency zone. This mistake completely wipes out the benefits of choosing electric motors high efficiency to begin with, burning through the very energy you paid a premium to save. Real-world performance comes from a perfect match between the motor’s capability and what the application actually demands.

The Problem with Partial Loads

Electric motors are designed to hit their efficiency sweet spot when operating between 75% and 100% of their rated load. When the actual workload dips below this range, especially under 50%, the motor's efficiency doesn't just dip—it plummets. This isn't a small drop; the energy losses are significant, leading directly to higher electricity bills and a lot more heat.

That excess heat isn't just wasted energy; it's a direct threat to the motor itself. It cooks the windings and bearings, accelerating their breakdown, which means more maintenance and a higher risk of unexpected failure. Oversizing a motor doesn't make it more reliable; in many cases, it does the exact opposite.

A properly sized motor isn't just about efficiency; it's a cornerstone of operational reliability. By matching the motor to the true workload, you ensure it operates in its sweet spot, maximizing both energy savings and its service life.

Mastering the Art of Load Analysis

To sidestep the oversizing trap, you have to get past the theoretical maximums and focus on the actual load profile of your application. This means doing a bit of homework to understand the system's needs throughout its entire operational cycle.

A solid load analysis involves a few key steps:

- Measure the Actual Load: Don't guess. Use a power analyzer to measure the real power consumption of the existing motor under its normal working conditions. This gives you hard data on what the machine truly needs.

- Account for Load Variations: Is the load constant, or does it bounce around? Applications like pumps and fans often have variable demands, which require a totally different sizing strategy than a constant-torque conveyor belt.

- Calculate Required Torque: For many machines, knowing the torque requirements is critical for picking the right motor. If this is new territory, a good torque calculation for motor guide can give you a strong foundation to build on.

- Consider Starting Torque: Some equipment, like heavily loaded conveyors or positive displacement pumps, needs a big kick to get going. Make sure the motor you choose can handle that initial demand without being way too big for its normal running state.

Using VFDs for Variable Load Applications

For any system where the demand fluctuates, a Variable Frequency Drive (VFD) is an absolute game-changer. Think of a VFD as a smart throttle for your motor, perfectly matching its speed and power output to the load's real-time needs. This lets you size the motor for the peak load while still running efficiently during those times of lower demand.

While many manufacturer datasheets boast efficiencies over 95%, real-world conditions often tell a different story. One study that analyzed performance data from 48 different electric motors found the average maximum efficiency was just 77.64%, with the best performer hitting 97.61%. This shows just how much factors like load variations impact what you see in the field, making systems like VFDs even more critical.

By pairing a correctly sized motor with a VFD, you can achieve peak performance across the entire operating range, delivering maximum savings and extending the life of your equipment.

Tying It All Together: Motors, Drives, and UL Control Panels

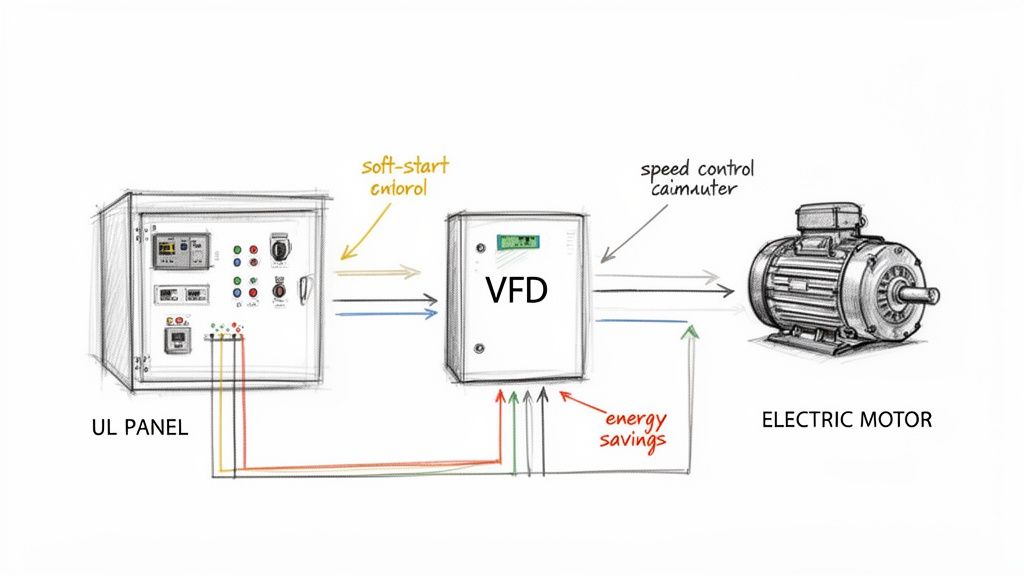

A high-performance motor on its own is like a world-class sprinter without a starting block—it has all the potential in the world but lacks the system to launch it into action. The true power of high-efficiency electric motors is only unlocked when you pair them with intelligent control systems. This is where premium motors, Variable Frequency Drives (VFDs), and custom UL-listed control panels come together to create a powerful, synergistic system that delivers peak performance and safety.

This isn't just a matter of connecting a few wires; it's about building a unified "nervous system" for your equipment. Think of it this way: the motor is the muscle, the VFD is the brain, and the UL control panel is the protective backbone ensuring everything operates safely and reliably. For industrial OEMs and system integrators, mastering this integration is the key to building turnkey solutions that win in the real world.

The VFD: Your Key to Dynamic Efficiency

A VFD is the ultimate efficiency multiplier for your motor. Instead of just running full-blast all the time, a VFD fine-tunes the motor's speed to perfectly match the real-time needs of the application. It’s like a smart gas pedal for your motor, giving it precisely the right amount of power at any given moment—and not a drop more.

This is a game-changer for any application with variable loads, like pumps, fans, and blowers. Old-school methods relied on inefficient mechanical dampers or valves to restrict flow. A VFD simply slows the motor down, a change that can lead to dramatic energy savings, often exceeding 50%.

But the benefits go way beyond the electric bill. VFDs also bring a level of control that protects your entire mechanical system. Their "soft-start" capability gently ramps the motor up to speed, which drastically cuts down on the mechanical shock and electrical inrush current that hammers equipment during a traditional startup. That simple function extends the life of everything from belts and gears to the motor itself.

The UL Control Panel: Your Guarantee of Safety and Compliance

If the motor and VFD are the heart of your system, the UL control panel is the armor that protects it. A professionally engineered, UL-listed control panel is so much more than a metal box with switches. It's a fully integrated system designed from the ground up for safety, reliability, and strict compliance with national electrical codes.

A UL 508A certification isn't just a sticker. It's an independent guarantee that the entire assembly has been designed and built to the highest safety standards. It confirms every component, from circuit breakers to wiring, has been properly selected, installed, and tested to work together safely.

This third-party verification is absolutely critical. It smooths the path for getting equipment signed off by local inspectors, gives your end-users confidence, and provides a clear line of defense against electrical hazards. Skipping this certification is a huge gamble that can lead to costly project delays, failed inspections, and serious safety liabilities.

Bringing It All Together for Peak Performance

The synergy between these three components creates a system that is far greater than the sum of its parts. A high-efficiency motor provides the efficient foundation, the VFD optimizes its performance in real time, and the UL control panel ensures it all operates safely and within code.

For industrial OEMs and system integrators, this integrated approach delivers some powerful advantages:

- Single-Source Responsibility: Partnering with someone who can engineer and build the complete motor and control package simplifies your procurement and guarantees everything is compatible from day one.

- Faster Commissioning: A pre-engineered, pre-tested UL panel arrives on-site ready to go. That slashes your installation and startup time.

- Enhanced Reliability: When you know all the components are designed to work together, you drastically reduce the risk of integration headaches and premature failures down the road.

Ultimately, integrating high-efficiency electric motors with the right control system transforms them from standalone parts into a cohesive, high-performance asset. You can explore our expert insights to learn more about the benefits of variable speed AC motor control and how it can be applied to your specific needs.

Putting It All Together: Your High-Efficiency Motor Strategy

Alright, we’ve covered the why and the what. Now it's time to build a real-world action plan. The single most important takeaway from this guide should be this: thinking about high-efficiency electric motors as a simple expense is a mistake. It’s a strategic investment, one that pays for itself surprisingly quickly through lower energy bills and fewer breakdowns.

Let's move from theory to the shop floor. The whole point is to create a simple, repeatable process for your team to follow for procurement and project management. When you have a solid strategy in place, every single motor purchase—whether it’s a planned upgrade or a middle-of-the-night replacement—becomes a calculated move toward a more profitable operation.

Your Action Plan Checklist

A winning motor strategy isn't about reinventing the wheel every time. It’s about consistency and making decisions based on data, not just habit. Instead of treating each purchase like a one-off emergency, use a standardized checklist to make sure you’re squeezing every drop of value out of high-efficiency technology.

Here are the essential steps to build right into your process:

- Audit Your Existing Motor Fleet: Start by walking the floor. Pinpoint those old, power-hungry motors, the ones that fail too often, or the ones that are clearly too big for the job. Your biggest and fastest ROI will come from replacing oversized or continuously running motors first.

- Specify the Right Efficiency Class: Draw a line in the sand. From now on, IE3 (NEMA Premium) is the absolute minimum standard for any new or replacement motor in your facility. For those critical 24/7 applications? It's time to run the numbers on an IE4 motor and see how much more you could be saving.

- Conduct a Lifecycle Cost Analysis (LCA): Stop looking at just the sticker price. It's the least important number. Grab a calculator and figure out the ten-year energy cost of that new motor. This simple step builds an undeniable business case for the premium efficiency option every single time.

- Verify Proper Sizing and Application: Don't just replace like-for-like. Make sure the new motor is sized for the actual load it will see, not just what the nameplate on the old clunker says. If the load changes, it’s a perfect candidate for a VFD.

- Standardize and Consolidate: Talk to your supplier and start standardizing on a few specific motor brands and models. This is a huge, often-overlooked win. It simplifies maintenance, shrinks your spare parts inventory, and makes ordering a breeze.

Adopting a formal motor strategy is the difference between reactive maintenance and proactive management. It ensures that every dollar spent on motor assets is an investment in long-term efficiency, reliability, and profitability.

At the end of the day, a winning strategy is about more than just buying better parts; it’s about finding the right partners. Working with experts who can actually audit your facility, specify the right motor and control package, and deliver a reliable, code-compliant UL-listed system is the fastest way to guarantee you see the best possible return on your investment.

Got Questions About High-Efficiency Motors? We've Got Answers.

Even when you've got a solid plan, a few questions always pop up before pulling the trigger on a motor upgrade. Here are some of the most common ones we hear from plant engineers, maintenance managers, and procurement teams, along with some straight-to-the-point answers.

Do High-Efficiency Motors Need Special Maintenance?

Nope. In fact, it's often the opposite. High-efficiency motors follow the same maintenance playbook you're already using for standard motors—think regular lubrication, vibration checks, and keeping them clean.

But here’s the kicker: because they run cooler, the stress on critical components like bearings and winding insulation is significantly lower. This often means a high-efficiency motor will actually need less attention over its long life, which chips away at your total cost of ownership.

The real key is consistency. A proper installation and a proactive maintenance schedule will unlock the full reliability of any motor, efficient or not.

There's a myth that premium motors are somehow more delicate. The reality is their better build quality and cooler operating temps make them tougher and more forgiving in demanding environments, often leading to greater reliability and longer service intervals.

Can I Just Swap a Standard Motor for a High-Efficiency One?

For the most part, yes. Manufacturers design high-efficiency motors to be "drop-in" replacements. They almost always share the same NEMA frame sizes, mounting dimensions, and shaft heights, making the physical swap-out a breeze.

Still, there are two small details you'll want to double-check:

- Full Load Amps (FLA): Premium motors are more efficient, so they draw a little less current. That’s a good thing, but it means you might need to adjust your existing motor protection and overloads to match the new, lower rating.

- Speed (RPM): Due to lower "slip," high-efficiency motors tend to run a few RPM faster than their standard-efficiency cousins. This difference is tiny and won't matter for most pumps, fans, and conveyors, but if you're working with a precision timing application, it's something to be aware of.

Are These Motors Okay to Use with a VFD?

Absolutely, but you have to use the right kind. You need to specify a motor that is explicitly inverter-duty rated. These motors have a beefed-up insulation system designed to handle the unique voltage spikes created by a Variable Frequency Drive (VFD).

If you run a standard, non-inverter-duty motor on a VFD, you're asking for trouble. It can cause the insulation to break down prematurely, leading to a fried motor and unexpected downtime. Always look for "inverter-duty," "inverter-rated," or a similar label on the motor's nameplate to protect your investment.

What's the Real Difference Between IE3 and NEMA Premium?

They're essentially two different names for the same level of high efficiency. IE3 is the classification used by the International Electrotechnical Commission (IEC), which is common globally. NEMA Premium is the standard used here in North America.

Think of it as saying the same thing in a different language. When you're sourcing motors in the U.S., specifying NEMA Premium ensures you’re getting a motor that meets the globally recognized IE3-equivalent benchmark. It keeps procurement simple and guarantees you're installing a motor built for modern performance and energy savings.

Ready to build a motor strategy that delivers a guaranteed ROI? The experts at E & I Sales provide premium motors, custom UL control packages, and turnkey system integration to make sure your projects are efficient, reliable, and done right. Contact us today to start your upgrade.