Engineered maintenance services are all about getting ahead of the curve. It’s a smart, proactive strategy that blends deep engineering know-how with advanced data analysis to predict and stop equipment failures before they ever happen. This approach completely changes the game, moving maintenance from a reactive "break-fix" model to a strategic one that optimizes the entire lifecycle of your critical industrial assets, from electric motors to complex UL-listed control systems.

Beyond the Break-Fix Mentality

Think of a Formula 1 pit crew. They don't just wait for a tire to blow out. They use live telemetry to see engine stress in real-time and prevent a breakdown mid-race. That’s the exact mindset behind engineered maintenance services. It’s a conscious shift away from the old—and incredibly expensive—cycle of waiting for something to break and then scrambling to fix it.

Instead of seeing maintenance as just another line item on the budget, this approach turns it into a genuine strategic advantage. It weaves fundamental engineering principles into the day-to-day upkeep of your machinery, directly boosting the reliability, safety, and efficiency of your most important assets. For plant managers and original equipment manufacturers (OEMs), this is a powerful way to drive operational excellence.

From Reactive to Proactive

The traditional way of doing things is purely reactive. A motor burns out, a control panel shorts, and suddenly, your entire production line grinds to a halt. What follows is a frantic scramble to diagnose the issue, find the right parts, and get a technician on-site—all while the costs of downtime pile up. In fact, unplanned downtime costs industrial manufacturers an estimated $50 billion every single year.

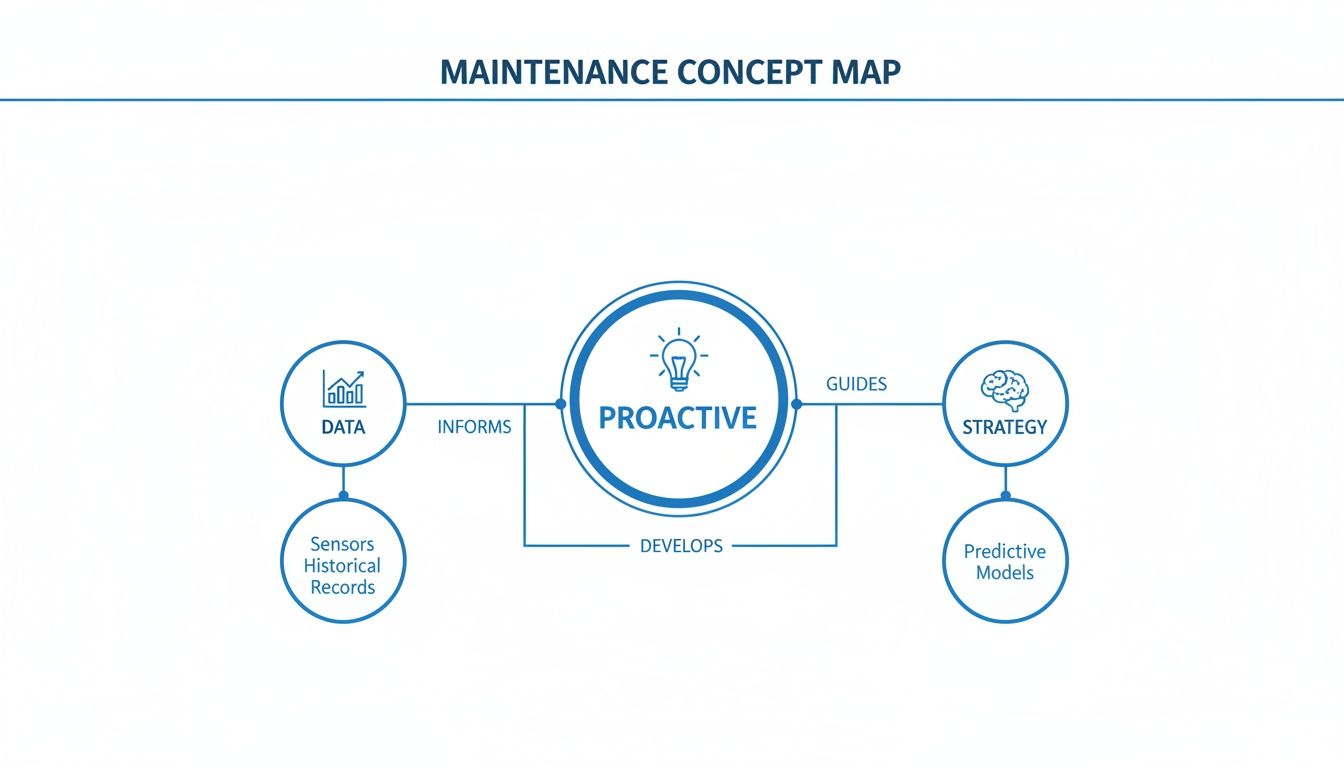

Engineered maintenance flips that script. It starts by asking a much better question: "How can we engineer failure right out of the system?" This forward-thinking strategy is built on a few key pillars:

- Data-Driven Decisions: Forget rigid schedules or waiting for an alarm to go off. This is about using real-time data from sensors and diagnostic tools to get a true picture of equipment health.

- Root Cause Analysis: When a problem does pop up, the goal isn't just a quick patch. It’s about digging deep to understand the underlying engineering cause so it never happens again.

- Lifecycle Optimization: We're looking at the entire lifespan of an asset—from its first day of commissioning to its final replacement—to make sure you get the absolute maximum value out of it.

- System-Level Thinking: This isn't just about one component. It’s about understanding how your motors, drives, and control systems all interact, letting you spot potential points of failure within the bigger picture.

By focusing on proactive, data-informed strategies, engineered maintenance services don't just fix problems—they systematically prevent them, turning upkeep into a predictable and value-driven activity.

This strategic pivot creates a clear path toward rock-solid reliability. By using real engineering expertise to make sense of complex data, your facility can move past simple preventive checklists and start tackling the fundamental reasons equipment fails in the first place. It’s all about creating an operation that is more resilient, predictable, and ultimately, more profitable.

So, what does an engineered maintenance services program actually look like on the ground, beyond the high-level strategy? Think of it less as a single service and more as a sophisticated diagnostic toolkit for your entire operation.

It’s a suite of specific, data-driven techniques and technologies all working in concert to give you an unprecedented look into the health of your most critical assets. Each component is designed to detect the subtle, almost invisible signs of wear and tear long before they spiral into catastrophic failures. The goal is to catch problems at their absolute earliest stage when they are cheapest and easiest to fix.

Predictive Diagnostics: Your Early Warning System

At the heart of any modern maintenance program, you'll find predictive diagnostics. This isn't just about following a schedule; it's about using advanced tools to listen for the earliest whispers of trouble, turning abstract data into real, actionable intelligence. It's like a doctor using an EKG to spot a heart issue before any outward symptoms ever appear.

This proactive stance is only possible thanks to a few key technologies:

- Vibration Analysis: Every rotating machine, whether it's a motor, pump, or fan, has a unique vibration signature when it's running smoothly. We use specialized equipment to measure this signature and detect tiny changes that signal developing problems like bearing wear, shaft misalignment, or imbalance.

- Thermal Imaging: Overheating is one of the most common and destructive signs of electrical and mechanical stress. Using infrared thermography, our technicians create a visual map of heat, allowing them to spot a faulty connection in a UL-listed control panel or an overworked motor long before it burns out.

This is what it means to be proactive—connecting real-world data with a clear strategy to stop failures before they ever start.

Specialized Motor and Control Panel Maintenance

While predictive tools are vital, they're only half the battle. They need to be paired with deep, hands-on expertise, especially when it comes to high-value assets like industrial motors and custom control panels. Maintenance for these complex systems goes way beyond a simple checklist.

For electric motors, this means targeted services like motor circuit analysis and advanced lubrication management. Just doing lubrication right can prevent over 50% of premature bearing failures. But an engineered approach takes it further by analyzing the lubricant itself for microscopic metal fragments that indicate internal wear.

Maintaining UL-listed control panels is even more critical because it directly impacts safety and compliance. A specialized program ensures every single component, from circuit breakers to variable frequency drives, is functioning exactly to specification. This isn't just about preventing downtime; it's about protecting your people and ensuring the entire system keeps its UL certification.

Let's take a look at the core services that make up a robust engineered maintenance program. The table below breaks down what each service does and where it's typically applied, giving you a clear picture of how these components fit together to protect your assets.

Key Services in an Engineered Maintenance Program

| Service Component | Primary Objective | Typical Application |

|---|---|---|

| Vibration Analysis | Detect early-stage mechanical faults in rotating equipment. | Motors, pumps, fans, gearboxes, compressors |

| Thermal Imaging | Identify overheating in electrical and mechanical systems. | Control panels, circuit breakers, motor casings, bearings |

| Motor Circuit Analysis | Assess the electrical health of a motor from the controller. | AC/DC motors, generators |

| Lubricant Analysis | Analyze oil and grease for contaminants and wear particles. | Bearings, gearboxes, hydraulic systems |

| Commissioning | Verify new or repaired equipment meets performance standards. | New production lines, upgraded motor controls, custom panels |

Each of these services provides a different piece of the puzzle. When combined, they give you a complete, 360-degree view of your equipment's health, allowing for truly intelligent and proactive maintenance decisions.

Why This Level of Expertise Is More Important Than Ever

Demand for these advanced services is surging as more industries finally recognize the crushing cost of unplanned downtime. It’s part of a massive market shift where businesses are investing heavily in technical expertise to stay competitive. In fact, the U.S. engineering services market hit USD 407.3 billion in 2024 and is projected to reach USD 581.0 billion by 2030.

That kind of growth points to a fundamental truth in modern industry: combining advanced diagnostic technology with deep engineering knowledge isn't a luxury anymore—it's a competitive necessity.

To get started organizing these efforts, you can see how it all fits into a broader plan with our guide on creating a preventive maintenance schedule template. By building a program around these core components, you can transform your maintenance department from a reactive cost center into a powerful driver of productivity and profit.

Calculating the ROI of Proactive Maintenance

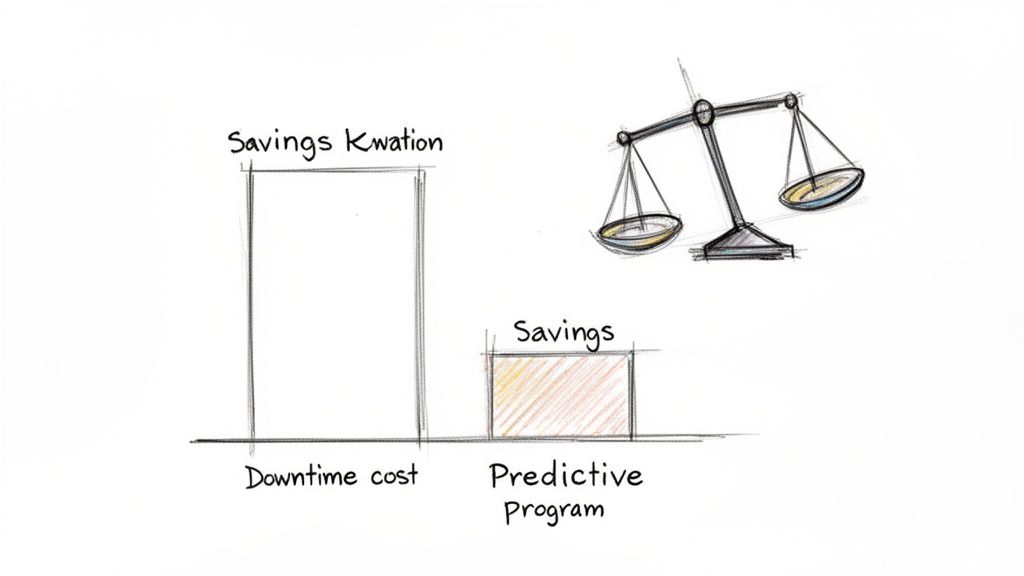

Getting buy-in for engineered maintenance services means translating the technical wins into the language everyone understands: dollars and cents. Sure, things like vibration analysis and thermal imaging are impressive, but their real magic is measured in saved costs and boosted productivity. This is where calculating the return on investment (ROI) becomes your most convincing tool.

Think of engineered maintenance not as an expense, but as a strategic investment in your plant's profitability. The ROI calculation proves this by putting the cost of doing nothing—unplanned downtime—head-to-head against the cost of a smart, proactive program. For anyone in procurement or project engineering, this gives you a clear, data-driven case to make.

The True Cost of Unplanned Downtime

First things first: you need to figure out what an unexpected failure actually costs your business. It’s almost always way more than just the price of a replacement part. An equipment failure creates a domino effect of expenses that can ripple through your entire operation.

To get a real number, you have to add up a few key factors:

- Lost Production: This one’s the biggie. How much revenue do you lose for every hour a line is down?

- Labor Costs: Think about the wages for idle operators just standing around, plus the overtime you’ll pay your maintenance crew for the emergency fix.

- Repair and Replacement: This covers the new parts—often at a premium for rush delivery—and any outside contractors you have to call in.

- Secondary Damage: A catastrophic motor failure can easily take out other components with it, turning a small problem into a massive, expensive repair.

Add all that up, and you get a clear cost-per-hour of downtime for your most critical assets. That number is the bedrock of your entire ROI calculation.

Building a Hypothetical ROI Scenario

Let's walk through an example. Imagine a critical conveyor system in a manufacturing plant, all run by a large electric motor. The plant has done its homework and knows that every hour this conveyor is down costs them $20,000 in lost production and other expenses.

Over the last year, this conveyor failed out of the blue three times, leading to a total of 15 hours of downtime.

The Cost of Inaction:

15 hours of downtime × $20,000 per hour = $300,000 in lost revenue

Now, let's say the plant decides to invest $50,000 a year in an engineered maintenance services program for its critical motors. This program includes quarterly vibration and thermal scans, which catch two of the three potential failures before they can happen. The team addresses these issues during scheduled maintenance, so there’s zero unplanned downtime from them.

One minor, unpredictable failure still slips through, but because the system is being monitored, they catch it much faster. It only leads to 3 hours of downtime instead of the usual 5.

Calculating the Financial Return

With a proactive program in place, the plant’s financial picture looks a whole lot better. The annual cost of downtime plummets to just $60,000 (3 hours × $20,000). To find the net savings, we just subtract the new downtime cost and the program's cost from the original loss.

- Net Savings: $300,000 (original loss) – $60,000 (new downtime cost) – $50,000 (program cost) = $190,000

Now for the ROI. The formula is simple:

(Net Savings / Program Cost) × 100 = ROI

In our scenario, that looks like this: ($190,000 / $50,000) × 100 = 380% ROI

That’s a powerful number. It means that for every dollar the company put into the maintenance program, it got $3.80 back in saved revenue. This completely changes the conversation from "How much does it cost?" to "How much will it save us?" To dig deeper, check out our guide on the benefits of predictive maintenance for manufacturing.

This shift toward financial returns and reliability is why the maintenance services market is booming. The global market, which covers everything from electric motor controls to automation, was valued at USD 81.86 billion in 2025 and is projected to hit USD 122.09 billion by 2029. That's a compound annual growth rate of 10.5%, all driven by the need for smarter upkeep and sustainable tech.

Defining Success with KPIs and Service Agreements

Any good partnership for engineered maintenance services has to be built on a foundation of clarity and trust. You can't just cross your fingers and hope for the best. To make the relationship work, you need to agree on what "success" actually looks like from the very beginning. This is where Key Performance Indicators (KPIs) and a well-defined Service Level Agreement (SLA) come into play.

Think of KPIs as the scoreboard for your entire maintenance program. They’re the hard numbers that tell you if your strategy is paying off. Vague goals like “improving reliability” won't cut it; you need real data to measure progress and prove the value of your investment.

Key Performance Indicators That Matter

When you're trying to gauge the impact of an engineered maintenance program, you want to focus on metrics that truly reflect the health of your equipment and the efficiency of your operations. Instead of drowning in a sea of data points, it's better to zero in on a handful of KPIs that tell a compelling story.

Here are a few of the most critical ones we see making a real difference:

- Mean Time Between Failures (MTBF): This is the average time your equipment runs without a hitch between breakdowns. If your MTBF is trending upward, it’s a fantastic sign that your proactive maintenance is working, preventing failures before they happen.

- Overall Equipment Effectiveness (OEE): OEE is the gold standard for measuring just how productive your manufacturing time really is. It combines availability (uptime), performance (speed), and quality (defects) into one powerful metric. A rising OEE score means your maintenance efforts are directly contributing to your bottom line.

- Maintenance Cost per Unit: This KPI connects your maintenance spend directly to your output. If this number starts to drop, it’s proof that you're getting more efficient and your maintenance program is delivering a stronger return on investment.

These aren't just numbers on a spreadsheet. They turn maintenance from a reactive, "gut-feel" chore into a data-driven strategy, giving you the proof you need to show real improvements in uptime and profitability.

Table: Reactive Maintenance vs Engineered Maintenance

It’s one thing to talk about proactive maintenance, but seeing the difference side-by-side really drives the point home. The old "if it ain't broke, don't fix it" model is a recipe for surprise downtime and spiraling costs. An engineered approach, on the other hand, is about getting ahead of the curve.

Here's a quick comparison:

| Aspect | Reactive Maintenance (Break-Fix) | Engineered Maintenance (Predictive) |

|---|---|---|

| Philosophy | "Wait for it to fail, then fix it." | "Predict and prevent failure before it happens." |

| Downtime | Unplanned and often extensive. | Minimal and scheduled. |

| Costs | High, unpredictable emergency repair costs. | Lower, predictable, and budgeted. |

| Asset Lifespan | Shortened due to repeated failures. | Extended through proactive care. |

| Safety | Higher risk from unexpected equipment failure. | Improved safety through well-maintained equipment. |

The takeaway is clear: Engineered maintenance is a strategic investment in reliability, while reactive maintenance is a constant, costly firefighting exercise.

Crafting a Strong Service Level Agreement

Once you’ve nailed down your KPIs, the next step is to cement them into a formal Service Level Agreement (SLA). An SLA is so much more than a contract; it’s a shared playbook that outlines expectations, responsibilities, and performance goals. It ensures you and your service provider are always on the same page.

A well-structured SLA is the bedrock of a transparent and accountable partnership. It puts expectations in writing, defines performance targets, and clarifies what happens if those commitments aren't met, protecting everyone involved.

A solid SLA has to be specific and realistic. It should clearly define the scope of services and the exact performance targets your provider is committing to. For any engineered maintenance program, your SLA should always include:

- Guaranteed Response Times: How fast will a technician be on-site? This should be clearly defined for different levels of urgency, from a routine check to a critical failure.

- Uptime Commitments: Set a clear target for equipment availability, like 99.5% uptime for your most critical assets. This ties your provider’s performance directly to your operational stability.

- KPI Reporting Standards: Agree on how often you'll get performance reports and what they'll look like. This should include monthly dashboards tracking trends in MTBF, OEE, and your other key metrics.

- Scheduled Maintenance Windows: A clear, agreed-upon schedule for all preventive and predictive work ensures tasks get done on time without causing unnecessary production delays.

By setting these benchmarks before you even start, you're building a framework for success. It transforms your maintenance program from a simple list of tasks into a strategic initiative with measurable outcomes that deliver genuine business value.

How to Choose the Right Maintenance Partner

Picking a partner for engineered maintenance services is a huge decision, one that goes way beyond signing a simple vendor contract. You're not just hiring a crew to fix broken equipment; you're handing them the keys to the operational heart of your entire facility. The right partner acts like an extension of your own team, bringing in deep engineering know-how to proactively keep your most critical assets humming.

Get this choice wrong, and you're staring down the barrel of recurring failures, surprise downtime, and serious safety risks. But a truly great partner can flip that script, turning maintenance from a reactive, money-pit of a department into a predictable, value-adding part of your operation. That requires a vetting process that cuts through the sales fluff and zeroes in on what they can actually do and what they've already done.

Vetting Technical Expertise and Field Experience

First things first, you have to dig into their technical chops. Any potential partner needs to prove they have a profound understanding of your specific equipment and the environment it runs in. This is absolutely critical when you’re dealing with specialized gear like UL-listed control panels or intricate motor control centers, where safety and compliance aren't just suggestions—they're the law.

Start asking sharp questions about their real-world, hands-on experience. A qualified team should be able to walk you through their process without stumbling.

- Diagnostic Tooling: Do they own and use modern diagnostic tools like thermal imagers and vibration analyzers, or are they just going to farm that work out to someone else? Having this tech in-house usually means a stronger commitment and quicker response when things go sideways.

- Engineering Resources: Are there actual professional engineers on staff who can dig into a root cause failure analysis? You want a team that recommends system improvements, not just one that knows how to swap out a part.

- System Integration Knowledge: How well do they play with your existing automation and control architecture? Their ability to plug in without causing chaos is a massive factor. We talk more about what separates the good from the great in our guide on choosing an industrial automation system integrator.

A partner’s value isn't just in the fancy tools they bring to the job. It's in the engineering brainpower that can actually interpret the data. The best in the business can look at a subtle vibration reading, connect it to a specific mechanical fault, and then engineer a solution that makes sure it never happens again.

Assessing Safety Protocols and Proven Track Record

Beyond the technical skills, you need to see a rock-solid commitment to safety and a documented history of getting the job done right. A strong safety culture is about protecting your people and your plant. A solid track record gives you the peace of mind that they can actually deliver on what they promise.

When you’re checking out potential providers, really dig into their operational history and safety standards. This is how you separate the seasoned pros from the rest of the pack.

Critical Evaluation Checklist

Use this checklist to keep your conversations focused and make it easier to compare your options:

- Safety Record: Ask to see their formal safety program and hard numbers, like their Experience Modification Rate (EMR). A low EMR is a clear sign they take safety seriously and perform consistently.

- Case Studies and References: Don't just take their word for it. Ask for real-world case studies that are relevant to your industry and equipment. More importantly, insist on talking to a few of their current clients who are facing the same challenges you are.

- Reporting and Communication: How are you going to know what’s going on? A professional partner will provide detailed reports that are easy to understand and clearly connect their maintenance work to your business goals.

- Training and Certifications: What kind of training are their techs getting? Look for certifications that matter, like NFPA 70E for electrical safety, credentials in predictive tech, and any OEM-specific training.

At the end of the day, choosing the right partner for engineered maintenance is about finding a team that's on the same page as you. You need a group with the technical depth, the proven experience, and an unwavering focus on safety to not just fix your assets, but to actively make them more reliable and high-performing for the long haul.

Engineered Maintenance in Action

All the theory and technical talk is great, but let's be honest—what really matters is how this stuff works in the real world. Seeing engineered maintenance services solve messy, high-stakes problems is where the true value clicks. It’s how the concept goes from a line item on a budget to a genuine game-changer for your entire operation.

This isn't just a niche service, either. The industrial maintenance market, which covers specialized work on things like motor control centers, was a USD 57.6 billion industry in 2024. It's on track to hit a staggering USD 108.24 billion by 2035.

What’s fueling that growth? A massive shift toward predictive maintenance. In fact, a whopping 91% of companies using it report they’re seeing fewer breakdowns and faster repair times. You can dig into more of these industrial maintenance market trends if you're curious.

Eliminating Delays for a Packaging OEM

Picture a food packaging OEM. Their entire business model hinges on hitting tight shipping deadlines, day in and day out. The problem was, their main conveyor system kept shutting down at random, creating massive production bottlenecks. Every failure put shipments on hold and soured relationships with their biggest clients.

They finally put a predictive maintenance plan in place, zeroing in on the conveyor's motor controls. Technicians started running regular vibration analysis, and it wasn't long before they spotted the early signs of wear on a critical bearing in one of the primary drive motors.

Instead of waiting for a catastrophic failure, they swapped out the bearing during a planned maintenance window. The result? Zero unplanned downtime for the next fiscal year. No more late shipments, and client confidence was fully restored.

This is a perfect example of how engineered maintenance directly protects your revenue. It shifted their entire mindset from reactive firefighting to a smart, proactive defense against costly downtime.

Boosting Compliance at a Water Treatment Facility

Here's another great example from a municipal water treatment facility. They were stuck with old, clunky control panels that were not only sucking down way too much power but also making it nearly impossible to keep up with changing regulatory standards.

The fix was a complete upgrade to custom-engineered, UL-listed control panels. This move didn't just solve one problem—it delivered two huge wins. The new system came with energy-efficient variable frequency drives (VFDs) built-in.

The outcome was a night-and-day difference:

- Compliance Assured: That UL listing gave them documented proof that their systems met the latest industry requirements, making audits a breeze.

- Energy Costs Slashed: The new VFDs adjusted motor speeds based on real-time demand, cutting the plant's energy bill by over 20%.

These stories drive home a key point. Engineered maintenance is so much more than just preventing breakdowns. It’s a powerful strategy that tackles complex business challenges, from logistics and customer satisfaction to regulatory compliance and cost control.

Your Questions, Answered

Making the switch to a smarter maintenance strategy always brings up a few questions. Let's tackle some of the most common ones we hear from plant managers and facility operators who are considering engineered maintenance services.

Is This Just for Massive Industrial Plants?

Not at all. While the big players definitely see huge returns, the core ideas of engineered maintenance scale beautifully to fit operations of any size. It’s all about applying the effort where it has the most impact.

For a small or mid-sized facility, the first step is usually a criticality analysis. A good partner will sit down with you to pinpoint that handful of machines where an unexpected shutdown would really hurt. By aiming predictive tools and engineering know-how at just those critical systems, you can get a serious ROI without a massive initial spend.

How Long Until We See Results?

This isn't a year-long waiting game. The rollout is almost always done in phases, specifically so you can start seeing value right away.

The initial discovery phase—auditing assets, setting up sensors, and getting baseline data—usually takes just a few weeks. After that, we can launch a pilot program on your most critical equipment within the first couple of months. This gives you early wins and proves the concept. A full, facility-wide implementation might stretch over six to twelve months, but the program is designed to pay for itself long before it’s fully complete.

The whole point is to generate tangible value, and fast. A phased approach lets you knock out the highest-risk problems first, delivering a clear ROI that builds a rock-solid case for expanding the program.

Isn't This Just a Fancy Name for Predictive Maintenance?

That's a common misconception, but the difference is pretty significant. The easiest way to think about it is that Predictive Maintenance (PdM) is one of the tools in the toolbox, while Engineered Maintenance is the entire strategic game plan.

Predictive Maintenance (PdM): This is all about using technology like vibration analysis and thermal imaging to forecast a failure. It answers the question, "When is this motor bearing likely to give out?"

Engineered Maintenance Services: This is the bigger picture. It uses PdM but adds a crucial layer of deep-dive problem-solving. We’re talking root cause failure analysis, system design improvements, and managing the asset's entire lifecycle. It doesn't just predict the failure; it works to engineer it out of the system for good by asking, "Why did the bearing fail in the first place, and what can we redesign to make sure it never happens again?"

In short, predictive maintenance is a tactic. Engineered maintenance is the complete strategy for winning the war against downtime.

Ready to turn your maintenance department from a cost center into a competitive advantage? The team at E & I Sales brings the deep engineering expertise and advanced diagnostic tools you need to keep your most critical systems running flawlessly. Start building a more reliable operation today.