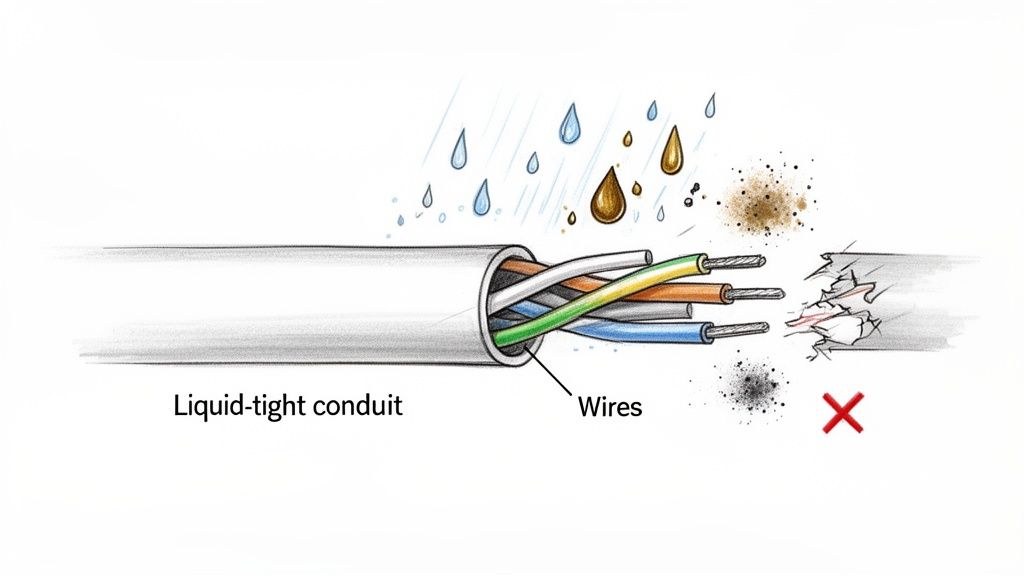

Think of liquid tight conduit as the ultimate armor for your electrical wiring. It's a flexible, completely sealed raceway designed to give your wires an impenetrable defense against moisture, chemicals, dust, and grime—all the things that lead to catastrophic failures in tough environments. This level of protection is simply non-negotiable in demanding industrial and commercial settings.

Your Wiring’s First Line of Defense

In any industrial plant, from a food packaging line to an outdoor OEM skid, electrical wiring is constantly under assault. Standard conduit might stop a bump or a scrape, but it offers almost no defense against the persistent enemies of moisture, corrosive washdowns, and fine particulates. This is exactly where liquid tight conduit proves its worth.

I like to compare it to a high-quality diver's wetsuit. The whole point is to keep water out, period. A single tiny leak in a seam or a faulty zipper makes the entire suit useless. Liquid tight conduit and its specialized fittings operate on the same all-or-nothing principle for your critical electrical systems.

A properly installed liquid tight system creates a fully sealed barrier, safeguarding conductors from the elements that cause short circuits, corrosion, and unexpected downtime. It’s not just a component; it’s an insurance policy against electrical failure.

Without this specialized protection, facilities are just asking for equipment damage, production halts, and serious safety hazards. The core problem that liquid tight conduit solves is environmental vulnerability, ensuring your systems stay reliable precisely where standard raceways would fail.

Understanding the Two Main Families

On the surface, this protective solution comes in two main flavors, each engineered for different challenges you'll face on the plant floor. Getting a handle on their basic makeup is the first step in picking the right defense for your application.

These two families are:

- Liquid-Tight Flexible Metal Conduit (LFMC): This is the heavy-hitter. It’s built with a strong, helically wound metal core for serious physical strength, which is then covered in a rugged, waterproof polymer jacket. It offers fantastic crush resistance, making it the go-to choice for protecting wiring on and around heavy machinery that moves or vibrates.

- Liquid-Tight Flexible Non-Metallic Conduit (LFNC): Made entirely from advanced polymers like PVC, this conduit is naturally immune to corrosion and is often much more flexible than its metal cousin. Its lightweight nature and chemical resistance make it perfect for washdown areas, chemical processing plants, or routing wires through complex, tight spaces.

Each type is designed to seal out contaminants, but they get there with different materials and bring different strengths to the table. In the next few sections, we'll dig a lot deeper into these differences.

Metallic vs. Non-Metallic: Choosing Your Conduit's Armor

When you get into the nitty-gritty of liquidtight conduit, you’ll find two main players ready for very different kinds of fights: metallic and non-metallic. They both create that crucial sealed raceway for your wiring, but how they're built completely changes the game. Figuring out their core differences is the first step to picking a solution that will not just work for now, but will hold up for years.

It’s a bit like choosing tires. You wouldn’t slap highway tires on a heavy-duty truck destined for rocky, off-road trails. In the same way, picking between Liquid-Tight Flexible Metal Conduit (LFMC) and Liquid-Tight Flexible Non-Metallic Conduit (LFNC) is all about matching the product to the environment and the kind of abuse it's going to face.

The Heavy-Duty Defender: Liquid-Tight Flexible Metal Conduit (LFMC)

Meet LFMC, the armored tank of the liquidtight family. Its design is a masterclass in layered defense.

At its core, you have a helically wound, flexible metal strip—usually galvanized steel or sometimes aluminum. This is what gives it incredible crush strength and impact resistance. For any application near heavy machinery that moves, vibrates, or poses a physical threat, LFMC is the undisputed champ.

But the metal core is only half the story. It's wrapped in a thick, flame-retardant PVC jacket. This outer layer is the "liquid-tight" part of the equation, creating a seal that keeps moisture, oils, coolants, and other nasty industrial fluids out. It’s the perfect marriage of raw strength and environmental sealing.

A huge, and often forgotten, benefit of LFMC is its built-in EMI/RFI shielding. That metal core acts as a natural shield, protecting sensitive control signals from the "noise" thrown off by motors and drives. In a busy plant, that’s a big deal.

The Corrosion-Proof Champion: Liquid-Tight Flexible Non-Metallic Conduit (LFNC)

On the other side, we have LFNC, or Liquid-Tight Flexible Non-Metallic Conduit. As you can guess from the name, this conduit is all-polymer, typically a tough PVC. This construction gives it a completely different set of superpowers.

With no metal core, LFNC is way lighter and often more flexible than its metal cousin. That makes it a dream for installers, especially on complex runs with tight bends and crowded pathways.

Its real claim to fame, though, is its total immunity to rust and corrosion. This makes it the go-to choice for outdoor installations, coastal areas with salt spray, wastewater plants, or food and beverage facilities with frequent chemical washdowns. Where metal conduit would eventually corrode and fail, LFNC just keeps on going.

If you want a broader look at how different systems protect wiring, this guide on raceways for cables offers a great overview of the different approaches used to safeguard network infrastructure.

LFMC vs LFNC Quick Comparison

To make the right call, it helps to see these two side-by-side. Each has a clear purpose and is designed to solve specific industrial headaches. This table breaks down the key differences at a glance.

| Attribute | LFMC (Metallic) | LFNC (Non-Metallic) |

|---|---|---|

| Primary Advantage | Superior physical protection and impact resistance. | Complete corrosion immunity and light weight. |

| Core Material | Helically wound steel or aluminum core. | All-polymer construction (typically PVC). |

| Best For | Heavy machinery, high-traffic areas, vibrating equipment. | Corrosive environments, outdoor use, chemical plants. |

| Weight | Heavier, more rigid. | Lighter, often more flexible. |

| EMI Shielding | Provides inherent electromagnetic shielding. | Does not provide EMI shielding on its own. |

| Grounding Path | Can serve as a grounding path in certain conditions (per NEC). | Requires a separate grounding conductor inside. |

In the end, this isn't about which one is "better." It's about which one is right for the job. By looking closely at the real-world threats—whether it's a forklift on the floor or corrosive chemicals in the air—you can pick the perfect armor to protect your critical wiring.

How to Select the Right Liquid Tight Conduit

Picking the right liquid tight conduit is one of those decisions that can make or break an electrical installation. It’s not just a tube for your wires—it's the first line of defense, a critical component for a safe, reliable, and compliant system that has to survive in its environment for the long haul. Get it wrong, and you’re looking at premature failures, expensive downtime, and some serious safety hazards.

To nail the choice every time, you need a solid framework. I like to think of it as a four-point inspection for your application. By walking through the real-world conditions the conduit will face, you can move from a gut feeling to a decision you can stand behind.

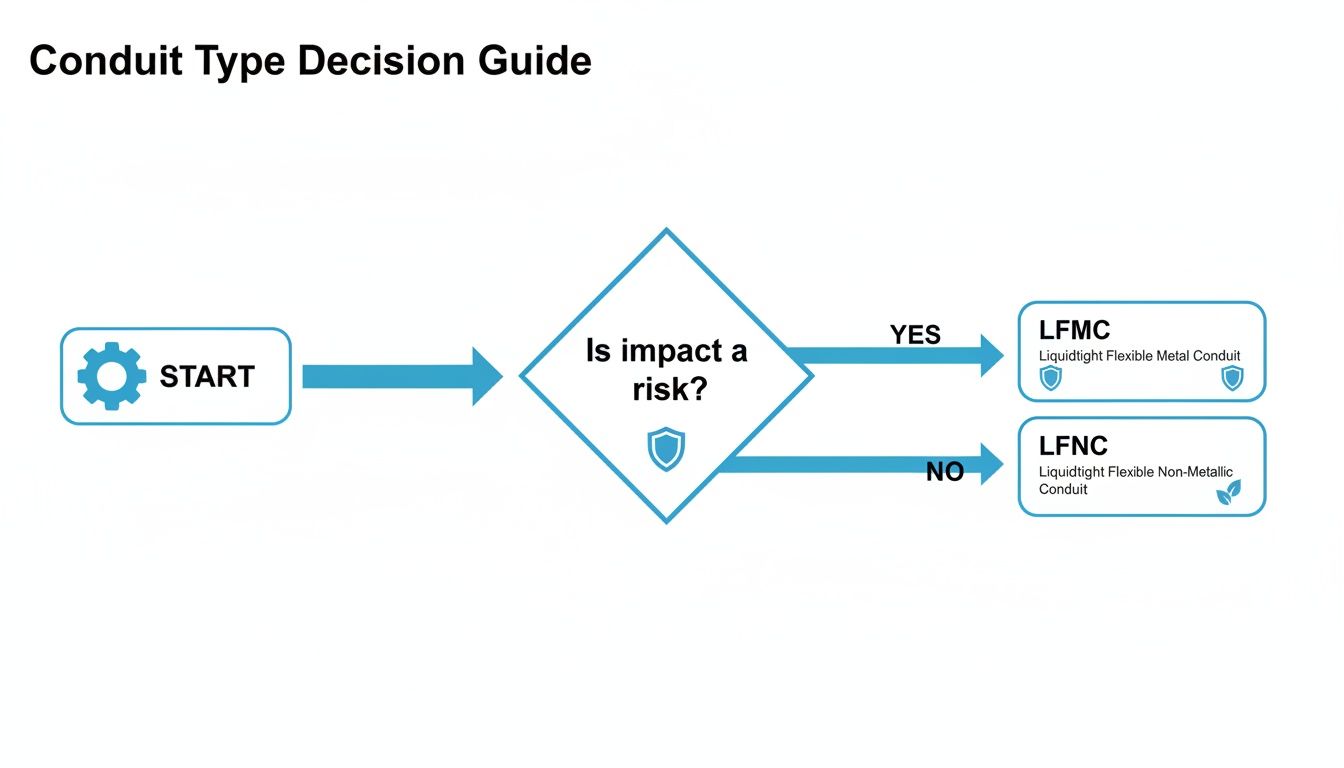

This flowchart is a great starting point for that first big decision: metal or non-metallic?

As you can see, the moment you introduce the risk of impact, you're immediately pointed toward the heavy-duty protection of LFMC. If that's not a concern, the corrosion-fighting power of LFNC starts looking pretty good.

Environmental Conditions and Exposure

First things first, look at the environment. What is this conduit going to be up against every single day? A product that works perfectly in a clean, dry factory might give up the ghost in a matter of months when it’s getting blasted with salt spray or harsh washdown chemicals.

Start by asking the right questions:

- Is it going outside? If the answer is yes, you absolutely need a jacket rated for sunlight (UV) resistance. Standard PVC will get brittle and crack under constant UV exposure, and there goes your liquid-tight seal.

- What chemicals are in the air or on the floor? Think food processing plants, chemical facilities, or wastewater treatment. Here, you’re dealing with acids, alkalis, and all sorts of aggressive cleaners. This is where non-metallic (LFNC) conduit really shines, as it’s completely immune to corrosion.

- What’s the temperature range? Extreme heat and cold will mess with a conduit's flexibility and overall integrity. Always check that the product is rated for both the ambient and operating temperatures it will have to endure.

For example, if an OEM is building machinery destined for a coastal port, LFNC is the clear winner. It laughs off the salt-induced corrosion that would eat a metallic system for breakfast.

Physical Stress and Movement

Next up, let's talk about physical abuse. On industrial equipment, electrical raceways are rarely just sitting still. They’re dealing with vibration, constant movement, and the ever-present risk of getting hit by something. This is where the actual construction of the conduit matters—a lot.

You need to evaluate:

- Vibration: Is the conduit hooked up to a motor, a pump, or a stamping press? That constant shaking demands a flexible conduit that can absorb the motion without fatiguing or working its connections loose. Both LFMC and LFNC are great at this.

- Impact and Crushing: Is the conduit run along the floor where a forklift might clip it? Or on a machine where a heavy tool could get dropped? In these scenarios, the steel or aluminum core of LFMC provides non-negotiable crush protection that an all-polymer conduit just can't offer.

- Flexibility Needs: How tight of a bend do you need to make? While both types are flexible, some LFNC products have a tighter bend radius. That can be a lifesaver in a cramped control cabinet or a machine with a spaghetti-like wiring layout.

A classic case is wiring up a large industrial press. You've got intense vibration and a high risk of impact. That combination makes LFMC the only sensible—and safe—choice.

Key Takeaway: The selection process is a balancing act. You have to weigh the need for raw physical toughness (LFMC's strong suit) against the need for total immunity to chemicals and corrosion (where LFNC is the champion).

Electrical Needs and Grounding

The third piece of the puzzle is the electrical circuit itself. Remember, the conduit is more than a protective skin; it’s a functional part of the system's safety infrastructure.

Here are the key electrical points to consider:

- Voltage and Circuit Size: Most standard liquid tight conduit is good for circuits up to 600V, but you should always double-check the manufacturer's specs. Don't assume. High-voltage jobs might require a specialized solution.

- Grounding Requirements: This is a big one. According to the National Electrical Code (NEC), the metal core of a listed LFMC can serve as the equipment ground—but typically only in sizes up to 1.25 inches and on runs of 6 feet or less. On the other hand, LFNC is non-metallic, so it always requires a separate ground wire to be pulled inside. Frankly, it’s best practice to run an internal ground wire even in LFMC just to guarantee a rock-solid ground path.

- Voltage Drop: For longer runs, you also need to think about the total circuit length to avoid equipment performance problems. If you need a quick refresher, our team put together a handy guide on the essential voltage drop calculation formulas to help make sure your gear gets all the power it needs.

Code Compliance and Certifications

Finally, you have to square your choice with the rulebook. Using a non-compliant product is a recipe for failed inspections, expensive rework, and massive safety liabilities.

Always look for:

- UL Listings: Make sure the conduit and the fittings are UL listed. This is your proof that they've been tested and meet industry-recognized safety and performance standards.

- NEC Compliance: The whole installation has to follow the latest NEC articles for flexible conduits. This covers everything from how it's supported and terminated to where it can be used.

- Hazardous Location Ratings: If you're working in a Class I, Div 2 area (where flammable gases might show up), you must use conduit and fittings specifically listed for that environment. Standard liquid tight won't cut it.

By working through these four areas—environment, physical stress, electrical needs, and compliance—you can stop guessing and start selecting the perfect liquid tight conduit for any job with total confidence.

Best Practices for Conduit Installation

Even the best liquid tight conduit on the market is useless if it's not installed correctly. A single small mistake during setup can sabotage the whole system, leaving a tiny gap that’s an open invitation for moisture and grit. Following tried-and-true installation practices isn't just about getting the job done—it's about locking in the long-term safety and reliability of your entire electrical system.

The end goal is a raceway that's completely sealed, from one end to the other. This process starts with careful prep work and demands attention at every step, from bending the conduit to tightening that last fitting. Nailing these details is what separates a truly tough, long-lasting installation from one that’s just a failure waiting to happen.

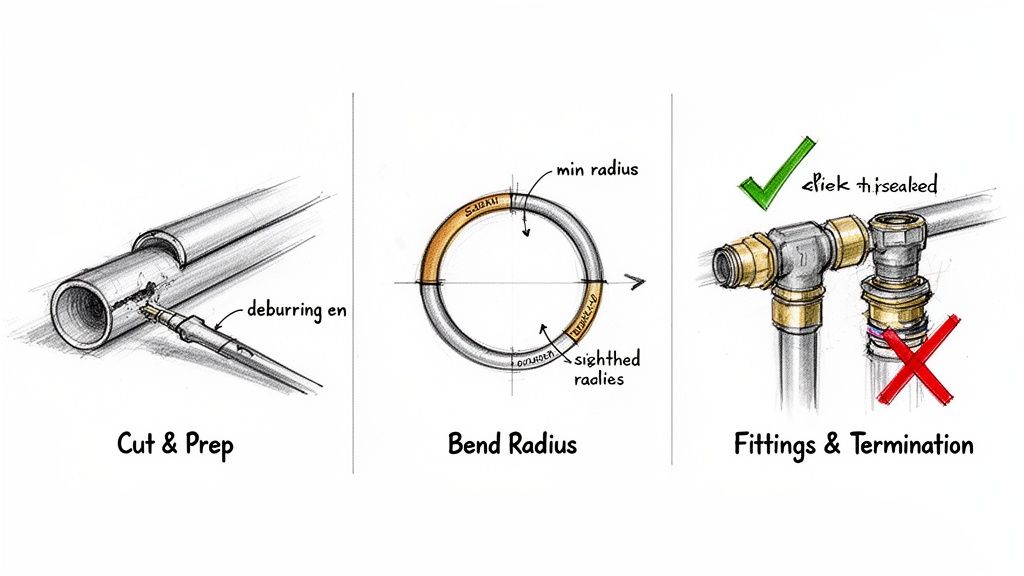

Proper Cutting and Preparation Techniques

It all starts with a clean cut. A jagged, sloppy edge makes it impossible for the fitting to seat properly, creating a guaranteed leak point right where you need protection most. The right tool for the job really depends on the type of conduit you’re wrestling with.

- For LFMC (Metallic): Grab a fine-toothed hacksaw or, even better, a rotary conduit cutter. You want to make your cut between the metal convolutions to get a perfectly square edge. After the cut, you absolutely have to deburr the inside of the metal core. Skip this step, and you’re leaving sharp edges that will slice into your wire insulation during the pull.

- For LFNC (Non-Metallic): A standard PVC cutter or even a sharp utility knife will do the trick. The objective is the same: a clean, 90-degree cut with no burrs or ragged bits. You don't have a metal core to worry about, but getting that cut perfectly straight is crucial for the fitting to create a tight seal.

We see it all the time—someone grabs a coarse saw to save a few seconds. That shortcut can easily deform the conduit or leave a rough surface. This one little mistake can compromise the entire seal, proving that an extra minute for a clean cut is always time well spent.

Respecting the Minimum Bend Radius

Yes, liquidtight conduit is flexible, but it's not a spaghetti noodle. Every conduit has a specified minimum bend radius, which is the tightest corner it can take without kinking up or collapsing on itself. Forcing a sharper bend is a rookie mistake with serious consequences.

When a conduit kinks, it creates a choke point that can damage the wires and weaken the raceway's structure. Just as critically, it distorts the conduit's round shape, making it impossible for the fitting to clamp down and form a proper seal. Always check the manufacturer’s spec sheet for that minimum bend radius and stick to smooth, gradual sweeps when routing your runs.

Selecting and Terminating Fittings Correctly

The connection point—where the conduit meets an enclosure—is ground zero for failures in a liquidtight system. The success of the entire run boils down to choosing the right fitting and installing it perfectly. Use the wrong part or do it sloppily, and you’ve basically installed a drain.

First things first: always use fittings designed specifically for your conduit type. An LFMC fitting will not seal properly on LFNC conduit, period. They are engineered completely differently to grip and seal their specific materials.

The termination process itself is just as critical:

- Slide the gland nut over the conduit first. Don't forget this step!

- Seat the ferrule or gripper firmly onto the prepped end of the conduit. Make sure it’s pushed all the way on.

- Push the conduit (with the ferrule) into the main fitting body until it bottoms out.

- Tighten the gland nut. Get it snug and secure, but do not overtighten it. Cranking down too hard can crack the fitting or damage the conduit's jacket, destroying the very seal you’re trying to create.

This procedure ensures the fitting compresses evenly around the conduit, creating that 360-degree seal that keeps everything nasty out. A perfectly terminated fitting should be securely seated inside one of the many types of electrical boxes found on the factory floor, completing the protected pathway your wiring deserves.

Maintenance and Troubleshooting Common Failures

Getting an electrical system up and running is just the start. The real test is its reliability over time, and even the toughest liquid tight conduit needs a little attention to go the distance.

Learning to spot the early warning signs of trouble is key. A proactive inspection plan lets you fix small issues before they snowball into major system failures, protecting your equipment and keeping everything safe.

A Proactive Inspection Checklist

Think of regular inspections as your first line of defense. A quick walkthrough isn't enough; you need a systematic check of the entire conduit run, especially in areas that take the most abuse from the environment.

We've found that integrating these checks into a routine schedule is the best way to build an early-warning system. If you need a good starting point, we've put together a guide on creating a preventive maintenance schedule template you can adapt for your facility.

Keep an eye out for these specific signs of wear and tear:

- Jacket Discoloration: If the jacket is fading or turning yellow, that’s a classic sign of chemical attack or serious UV damage.

- Cracks and Brittleness: Look closely for tiny cracks, especially around bends or in direct sunlight. A brittle jacket has lost its flex and can't maintain a liquid-tight seal anymore.

- Physical Damage: Any sign of crushing, kinking, or abrasion is a red flag. These are obvious weak points where moisture can get in.

- Loose or Corroded Fittings: Give the fittings a little wiggle. They should be rock solid. If you see any rust or corrosion on metal fittings, it’s a sure sign the seal has already failed.

Proactive maintenance isn’t just about fixing what’s broken; it’s about preserving the integrity of the entire system. A $50 fitting replacement caught during an inspection can prevent thousands in downtime from a shorted-out motor.

Troubleshooting Common Failures

When you find a problem, like moisture inside a control panel, don't just patch the symptom. You need to dig in and find the root cause, or you’ll be fixing it again next month.

Start by running through a few diagnostic questions:

- Is the Fitting Loose? Constant vibration is notorious for loosening fittings over time. First thing to check: Is the compression nut tight? Is the fitting secure?

- Is the Conduit Jacket Breached? Follow the conduit run back from the failure point. A small, almost invisible puncture or crack is often the real culprit.

- Was the Correct Conduit Type Used? Step back and look at the environment. Did someone use a standard conduit in an area with harsh chemical washdowns? A material mismatch is a recipe for premature failure.

- Was the Termination Done Correctly? This is a big one. Open up the fitting and look at how the conduit was cut and seated. A crooked cut or an improperly installed ferrule will never create a reliable seal.

By methodically working through these steps, you shift from a reactive, "break-fix" cycle to a proactive maintenance strategy. This approach doesn't just make your liquid tight conduit last longer—it makes your entire operation safer and more reliable.

Choosing the Right Partner for Your Conduit Needs

Picking the right liquid tight conduit feels like navigating a maze. You're juggling materials, compliance codes, and some pretty harsh environmental factors. Get it right, and your electrical system is safe, reliable, and built to last. Get it wrong, and you're looking at potential failures and downtime.

This decision is way more than just picking a part number from a catalog. It’s a critical engineering call. From specifying a jacket material that can stand up to chemical exposure to making sure every single fitting is UL-listed for the job, the small details have a huge impact. A minor oversight can snowball into premature failure, costly repairs, and serious safety risks.

This is exactly why finding a true expert partner isn't just a nice-to-have; it's a strategic move to get the job done right from day one.

Beyond the Part Number: Engineering Expertise on Your Side

Anyone can sell you parts. A true partner, on the other hand, delivers solutions. That’s where E & I Sales comes in. We bring deep engineering expertise to the table that cuts through the complexity of the whole specification process. We don't just take your order; we help you build it correctly from the ground up.

Here’s how we make a difference:

- Hands-On Specification Help: We’ll dig in with your team, analyzing everything from environmental conditions to physical stresses, to make sure you land on the perfect LFMC or LFNC solution for your application.

- High-Performance Components: We've built a portfolio of top-tier liquid tight conduit and fittings specifically for the tough demands of industrial environments.

- A Big-Picture Approach: We see how the conduit fits into your entire system—from the control panel all the way to the motor—ensuring every component plays well together.

Partnering with E & I Sales means you're plugging into decades of real-world, field-tested experience. We help you head off risks, speed up your project timelines, and build electrical systems designed for maximum uptime and safety.

When you're bringing suppliers or contractors on board for your projects, using solid vendor management best practices is key to ensuring you get the quality and reliability you expect. Let our team be the expert in your corner.

Your Liquid Tight Conduit Questions, Answered

Once you get the basics down, the real questions start popping up during project design and on the job site. Let's tackle some of the most common things we hear from engineers and installers to clear up any confusion.

Can I Use Liquid Tight Conduit in Hazardous Locations?

Yes, but you absolutely have to pay attention to the details. You can't just use any off-the-shelf liquid tight conduit. The entire system—both the liquid tight conduit and every single fitting—must be specifically listed and rated for that exact hazardous environment.

Think about a Class I, Division 2 location, where flammable gases could show up if something goes wrong. The National Electrical Code (NEC) has incredibly strict rules for these areas. You have to check the UL listings on every component to make sure it meets the Class, Division, and Group ratings your specific application needs. When it comes to safety and compliance, there are no shortcuts.

What’s the Main Difference Between LFMC and Armored Cable?

It really boils down to what the outer layer is designed to do. With Liquid-Tight Flexible Metal Conduit (LFMC), you have a tough PVC jacket wrapped around a metal core. That jacket has one job: to create a completely sealed, waterproof barrier that keeps out moisture, oils, and other chemicals.

On the other hand, armored cable (AC or MC) has a metal shell that's all about physical protection—it’s built to resist getting crushed or impacted. It’s not designed to be liquid-tight. While you can find some MC cable with a PVC jacket, LFMC and its fittings are engineered from the ground up as a complete system designed for wet, messy, and corrosive places.

Do I Need a Separate Grounding Conductor with LFMC?

This is a big one, and the answer is: it depends. The NEC says the metal core inside a listed LFMC can be your equipment grounding conductor (EGC), but only if you meet a very specific set of conditions:

- The trade size is 1.25 inches or smaller.

- The circuit protection is 20 amps or less.

- The total length of the conduit in the ground-fault path is 6 feet or less.

If your run exceeds any of these limits, you must pull a separate EGC wire inside the conduit. The same goes for any non-metallic (LFNC) installation. Honestly, the best practice is to just include an internal ground wire in all your flexible conduit runs. It guarantees you have a solid, reliable safety ground every single time.

Getting these details right is what separates a good installation from a great one. When you need help with specifications or want to source high-performance components, the engineering team at E & I Sales is here to make sure you build a safe and compliant system. Find out more at https://eandisales.com.