A vacuum circuit breaker, or VCB, is an electrical protection device that uses a perfect vacuum to extinguish an electrical arc. Think of it as an incredibly fast, ultra-reliable firefighter for your medium-voltage electrical system. It's designed to stop a destructive fault current in its tracks—in just milliseconds—to protect your most vital equipment.

This sealed, zero-maintenance design has made the VCB the undisputed gold standard for industrial power distribution today.

So, What Does a Vacuum Circuit Breaker Actually Do?

Picture your plant's power system as a network of superhighways, all carrying immense electrical current. A short circuit or overload is like a catastrophic, multi-car pile-up. It happens in an instant and brings everything to a grinding halt, causing widespread damage. The vacuum circuit breaker is your advanced, automated traffic controller and emergency response unit, all rolled into one.

Its main job is to act as a silent guardian for your most critical and expensive assets—think large motors, transformers, and switchgear. Under normal operating conditions, it just stays closed, letting power flow right through it without any interruption. But the second a fault is detected, it springs into action with unbelievable speed.

A Mission-Critical Fail-Safe

The VCB’s core purpose is to interrupt the flow of dangerous fault currents. This is absolutely critical for preventing a few key disasters:

- Catastrophic Equipment Damage: A short circuit can unleash thousands of amps of energy, enough to literally melt the windings in a motor or completely destroy a transformer. A VCB isolates that fault before the real damage is done.

- Widespread Outages: By tripping only the affected part of the system, it keeps a single fault from cascading into a facility-wide blackout.

- Serious Safety Hazards: Uncontrolled electrical arcs can cause violent explosions and fires, putting your personnel at severe risk. The VCB contains and extinguishes that arc energy safely within its sealed chamber.

The Power of Nothing

What makes a VCB so remarkably effective is its use of a vacuum. An electrical arc is essentially a superheated plasma that needs a medium—like air or gas—to keep burning. By separating its electrical contacts inside a perfectly sealed vacuum chamber, the VCB creates an environment where an arc simply can't survive.

A vacuum is the ultimate electrical insulator. Once the contacts inside a vacuum circuit breaker separate, the arc is starved of fuel and extinguishes almost instantly as the AC current passes through its natural zero point.

This simple principle is what allows the VCB to quench an arc with extreme speed and with minimal wear and tear on its internal parts. Unlike older technologies that relied on messy oil or complex compressed air systems, the vacuum interrupter is a "sealed for life" component. It requires practically no maintenance over its entire 20- to 30-year lifespan.

This unmatched reliability and low total cost of ownership is exactly why VCBs have become the go-to choice for modern industrial applications, from manufacturing plants to data centers and everything in between.

How a Vacuum Interrupter Works

At the very core of every vacuum circuit breaker, you'll find its most vital component: the vacuum interrupter. This is the sealed, maintenance-free chamber where the real magic happens—where electrical arcs are extinguished with incredible speed. To really get why VCBs are so dependable in tough industrial environments, you first have to understand what goes on inside this little chamber.

The concept is brilliantly simple but unbelievably effective. The interrupter has just three main parts: a fixed electrical contact, a moving electrical contact, and the hermetically sealed vacuum chamber that houses them. That vacuum is what makes all the difference.

The Power of an Empty Space

Think about what happens if you try to light a match in outer space. It fizzles out instantly. Why? No oxygen. An electrical arc is a lot like that flame; it’s a superheated plasma that needs a medium—like air or some other gas—to keep burning.

By creating an environment with practically no air molecules, the vacuum interrupter literally starves the arc of the fuel it needs to exist. This simple principle gives it a massive dielectric strength (its ability to insulate against voltage) that is far greater than air or even specialized gases like SF6 at normal pressure.

This flow diagram shows how a VCB acts as a gatekeeper, protecting a facility from grid-side problems.

You can see its role in isolating all the downstream equipment from upstream faults, which is critical for keeping operations safe and running smoothly.

The Arc Interruption Sequence Step-by-Step

When a fault hits the system, a precise, lightning-fast chain of events kicks off inside the interrupter. The whole show is over in a few milliseconds, usually within just 3 to 5 cycles of the AC waveform.

- Fault Detected, Trip Signal Sent: Protective relays sense the abnormal current from a short circuit or overload. They waste no time, sending a trip signal to the VCB's operating mechanism.

- Contacts Separate: The mechanism yanks the moving contact away from the fixed one. As they part, current is forced to jump the widening gap, and an electrical arc is born.

- Metal Vapor Plasma Forms: The arc is intensely hot, instantly vaporizing a tiny amount of metal from the contact surfaces. This creates a temporary, conductive bridge of metal vapor plasma, which allows current to flow for just a moment longer.

- Current Zero Extinction: This is where the vacuum really flexes its muscle. The AC current waveform naturally drops to zero 120 times every second on a 60Hz system. The moment the current hits zero, the arc has no energy to sustain itself. And because there’s no gas in the chamber to help it reignite, it's extinguished for good.

The vacuum's ability to regain its full dielectric strength almost instantly after the current hits zero is the key. It prevents the arc from ever re-striking. This makes the interruption incredibly clean, fast, and efficient, which minimizes wear and tear on the contacts.

Why This Process Is Superior

The entire event is neatly contained inside the sealed interrupter. There are no external flames, no deafening bang, and no venting of hot gases, making the whole operation incredibly safe.

Better yet, because the arc is so short-lived, the contacts barely erode. This means a single vacuum interrupter can perform thousands of operations without ever needing to be serviced. It's this simple, elegant process that has cemented the VCB's reputation for unmatched speed, reliability, and safety—protecting critical industrial assets with near-perfect precision.

Demystifying VCB Ratings and Specifications

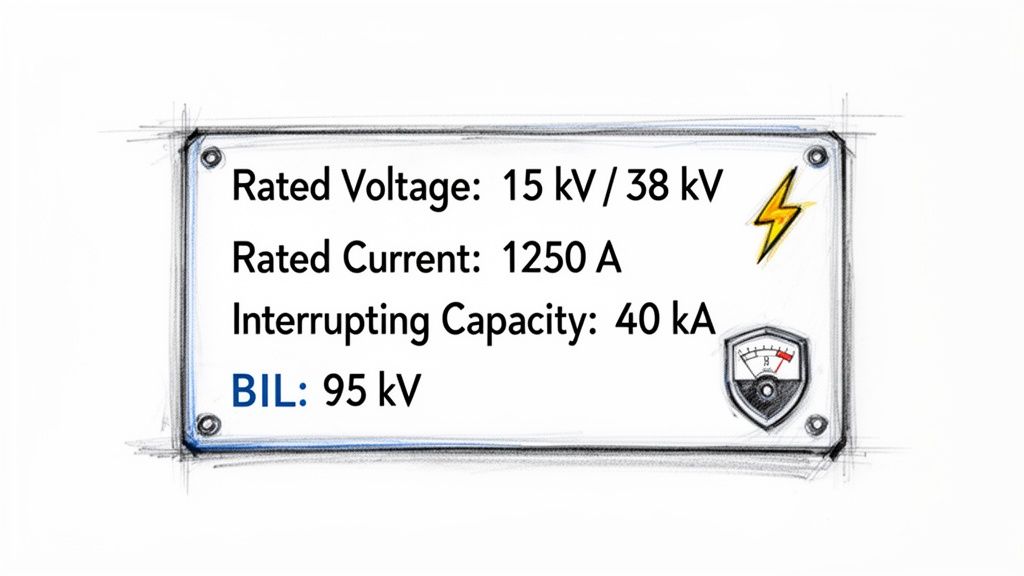

Choosing a vacuum circuit breaker isn’t like picking a part off a shelf. You're matching a critical safety device to the very specific electrical heartbeat of your facility. Think of a VCB's nameplate as its resume—it's packed with the technical specs that spell out exactly what it can and can't do. Getting this right is fundamental to protecting your people and your high-value assets.

These ratings aren't just arbitrary numbers. They are firm promises about the breaker's performance, guaranteeing it can handle not only the daily grind but also the worst-case fault scenarios without skipping a beat.

The Core Electrical Ratings You Can't Ignore

While a full data sheet can look intimidating, a few key specifications are absolutely non-negotiable. These are the cornerstones of any solid VCB selection.

- Rated Voltage (kV): This is the maximum voltage the breaker is built to handle safely. You'll see standard ratings like 15kV and 38kV, which line up with common medium-voltage distribution systems. Using an underrated breaker is a direct path to insulation failure.

- Continuous Current (Amps): This tells you how much current the breaker can carry day in and day out without overheating. This figure must be higher than the normal full-load current of the circuit it’s protecting. For a deeper dive, check out our guide on proper circuit breaker sizing.

- Interrupting Current Capacity (kA): This is arguably the most critical safety rating on the entire nameplate. It's the absolute maximum fault current the VCB can extinguish safely. If your system can produce a 40kA fault and your breaker is only rated for 25kA, you’re looking at a potential explosion, not a clean trip.

A great way to think about the interrupting rating is to compare it to firefighting equipment. You wouldn't bring a small fire extinguisher to a five-alarm building fire. The interrupting capacity ensures your breaker has enough "firepower" to safely put out the most violent electrical fire your system could ever throw at it.

Digging Deeper: Specs That Define Reliability

Beyond the big three, a few other specifications paint a clearer picture of how a VCB will hold up in the real world. These details help you fine-tune your choice for specific applications, making sure the breaker doesn't just work on day one, but for years to come.

- Basic Insulation Level (BIL): Measured in kV, this rating signals the breaker's ability to survive a massive, lightning-fast voltage surge, like from a lightning strike. A higher BIL rating means tougher insulation and better protection against transient events.

- Operating Duty Cycle: This spec defines the breaker's ability to perform a sequence of reclosing operations. A standard duty cycle like "O – 0.3s – CO – 3min – CO" lays out the exact sequence of open (O) and close-open (CO) operations it can handle without sustaining damage.

The market for this technology underscores just how important these specs are. The medium-voltage outdoor vacuum circuit breaker market is already valued at USD 609.37 million and is expected to more than double to USD 1205.29 million by 2032. The 15kV to 27kV segment is the dominant force, holding a 40.24% market share—a perfect fit for the industrial motor control centers and manufacturing plants that rely on them. Understanding these ratings means you’re specifying the right gear for these critical, growing applications.

Comparing VCB and SF6 Circuit Breakers

When you're specifying a medium-voltage breaker, the choice often comes down to a head-to-head matchup between two heavyweights: the vacuum circuit breaker (VCB) and the SF6 (sulfur hexafluoride) circuit breaker.

While both are pros at snuffing out fault currents, they get the job done in fundamentally different ways. These differences have massive implications for your facility's environmental impact, maintenance schedule, and long-term operational costs. Getting this right is about future-proofing your plant.

At the heart of it all is the arc-quenching medium. A VCB uses a pure vacuum—literally, nothing—to extinguish the electrical arc. On the other hand, an SF6 breaker uses sulfur hexafluoride gas, a man-made compound with incredible dielectric properties. This single difference is the domino that sets off every other point of comparison.

Environmental Impact and Sustainability

The environmental report card for these two technologies couldn't be more different. Vacuum interrupters are completely benign. The sealed vacuum chamber contains zero harmful substances and poses no threat to the atmosphere. If a VCB’s interrupter ever fails, it simply loses its vacuum. No harm, no foul.

SF6, however, is a whole other story. It’s the most potent greenhouse gas on the planet, with a global warming potential 24,300 times higher than carbon dioxide. That's not a typo. Any leak from SF6-filled equipment releases this incredibly powerful gas straight into the atmosphere, directly contributing to climate change. This massive environmental risk has regulators scrambling, with the EU already implementing a phased ban on SF6 in new switchgear.

Maintenance and Operational Demands

When it comes to maintenance, the paths diverge significantly, hitting your total cost of ownership right where it counts. The vacuum circuit breaker is legendary for its hands-off, low-maintenance design.

-

VCB Maintenance: The vacuum interrupter is a "sealed for life" component. That means no gas monitoring, no refilling, and no special handling. Maintenance is all about the mechanicals—the operating system—which just needs routine cleaning, lubrication, and electrical testing.

-

SF6 Maintenance: SF6 breakers are much more demanding. They require constant vigilance, with periodic checks of the gas pressure to spot leaks and make sure insulation levels are correct. Handling the SF6 gas itself requires specially trained technicians and specific equipment to avoid releasing it into the atmosphere.

This stark contrast is a huge driver behind market trends. The global power distribution vacuum circuit breaker market, currently valued at USD 3.8 billion, is forecasted to skyrocket to USD 9.0 billion by 2035. Why the boom? It’s all about the VCB’s superior arc quenching, minimal maintenance needs, and eco-friendly profile, making it the clear successor to SF6 systems.

For plant managers, this is simple math. The VCB’s low-maintenance design means less downtime, lower labor costs, and better safety, since you completely eliminate the risks that come with handling pressurized gas systems.

A Head-to-Head Comparison

To make the decision clearer, let's break down the key differences in a simple table.

| Attribute | Vacuum Circuit Breaker (VCB) | SF6 Circuit Breaker |

|---|---|---|

| Arc Quenching Medium | Pure vacuum (environmentally neutral) | Sulfur Hexafluoride (SF6) gas |

| Environmental Impact | None. Considered a green technology. | Extremely high. SF6 has a GWP of 24,300x CO2. |

| Maintenance | Minimal. "Sealed for life" interrupter. | Requires gas pressure monitoring and specialized handling. |

| Reliability | Very high, especially in frequent switching operations. | High, but depends on maintaining gas integrity. |

| Regulatory Risk | Low. Future-proof and compliant. | High. Facing increasing restrictions and phase-outs. |

| Upfront Cost | Can be slightly higher in some ratings. | Often lower initial cost, but higher lifetime cost. |

| Size | Compact, especially for medium-voltage applications. | Very compact, particularly in high-voltage GIS. |

| Safety | High. No risk of gas leaks or high-pressure systems. | Potential risks from gas leaks and handling procedures. |

Ultimately, while SF6 has been a reliable workhorse, the VCB's combination of low maintenance, environmental safety, and robust performance makes it the smarter long-term investment for nearly all medium-voltage industrial applications.

Performance and Application Suitability

Both VCB and SF6 breakers are top performers, but their sweet spots are different. VCBs are the undisputed champions of frequent switching operations. Think arc furnaces, motor starting circuits, or capacitor bank switching—anywhere the breaker has to work hard, and often. The minimal contact erosion inside the vacuum interrupter allows them to perform tens of thousands of operations without breaking a sweat.

Historically, SF6 has dominated the high-voltage and extra-high-voltage world, where its exceptional dielectric strength allows for incredibly compact gas-insulated switchgear (GIS). You can learn more in our complete overview of how gas-insulated switchgear works. However, vacuum technology isn't standing still. Advances are constantly pushing VCBs into higher voltage classes, chipping away at SF6’s old territory.

For most industrial medium-voltage systems, the performance of a modern vacuum circuit breaker is more than enough to handle the job, making its environmental and maintenance advantages the real deciding factors.

Essential VCB Maintenance and Testing Procedures

It’s a common myth in the plant: the vacuum circuit breaker is so reliable you can just set it and forget it. While VCBs are incredibly low-maintenance compared to their older cousins, they are absolutely not zero-maintenance. If you want your VCB to hit its full 20 to 30-year lifespan without a hitch, you need a proactive, scheduled maintenance program.

Think of it like the engine in a heavy-duty truck. You wouldn’t dream of running it for years without an oil change or inspection, and the same logic applies here. For a VCB, this means a smart mix of visual checks, mechanical servicing, and a few critical electrical tests to get a real look under the hood.

Foundational Inspection and Mechanical Tasks

Most of the hands-on work for a VCB happens outside the sealed vacuum interrupter. You’re really focusing on the mechanical systems that do the physical work of opening and closing the breaker. Keeping them in prime condition is job one.

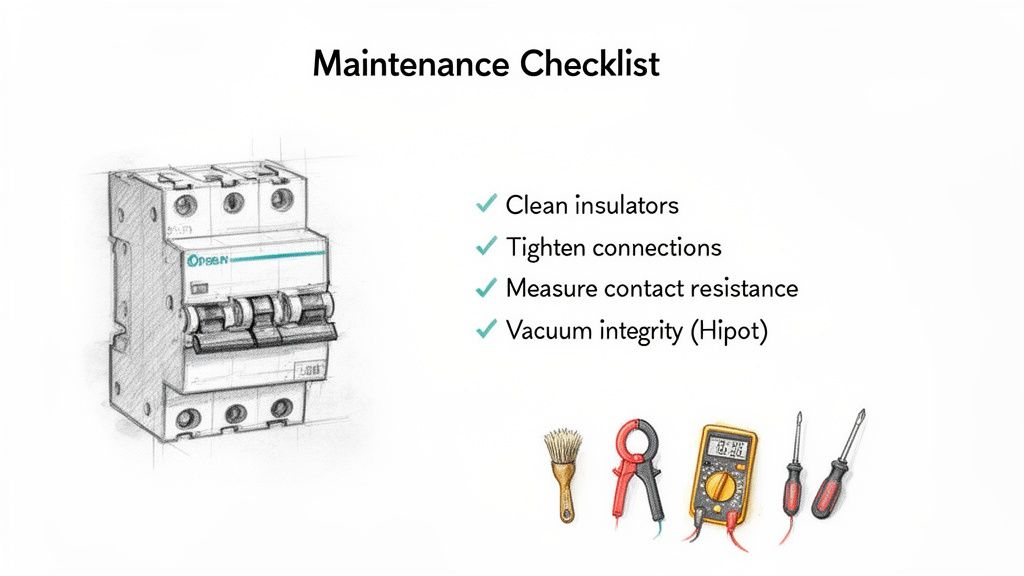

A solid annual inspection should always hit these points:

- Cleaning Insulators: Over time, dust and grime can build up on the insulators. Add a little moisture, and you've created a perfect path for current to track to the ground. A simple wipe-down with an approved solvent is all it takes to prevent a flashover.

- Checking Connections: Heat cycles make things expand and contract, and this can slowly loosen bolted electrical connections. A loose connection is a high-resistance hot spot waiting to happen. Technicians need to put a torque wrench on every primary and control connection to be sure.

- Lubricating Linkages: The operating mechanism is a collection of pivots, rollers, and latches that need to move without a hint of resistance. A dab of the right lubricant ensures the breaker trips smoothly and instantly when it’s called on.

Key Diagnostic Electrical Tests

Mechanical checks are great, but the only way to know what's really going on inside is through electrical testing. These tests give you hard data on the health of the breaker’s most critical components.

A proactive testing schedule is non-negotiable. It turns maintenance from a reactive, break-fix headache into a predictive strategy that spots trouble long before it can shut you down.

There are three diagnostic tests that are absolute must-dos for any VCB:

- Contact Resistance Measurement (CRM): Often called a "Ductor" test, this involves pushing a high DC current through the closed contacts and measuring the resistance in micro-ohms. If that number starts to creep up, it’s a huge red flag for problems like contact pitting or a failing connection that will overheat under load.

- Insulation Resistance Test (Megger): Using a high-voltage DC source, this test checks the integrity of the breaker’s insulation. It’s fantastic at sniffing out contamination or moisture that could compromise the breaker’s ability to withstand system voltage. A low megohm reading tells you there's a problem that needs immediate attention.

- Vacuum Integrity Test (Hipot): This is the moment of truth for the vacuum interrupter. You apply a high AC or DC voltage across the open contacts. A healthy vacuum is a near-perfect insulator and will hold the voltage easily. If the vacuum has been lost, the current will flash over, telling you the interrupter has failed and needs to be replaced.

Finally, don’t forget the simplest check of all: the contact wear indicator. This little mechanical gauge gives you a direct visual on how much life is left in the contacts. Keeping an eye on it lets you plan for the interrupter's replacement at the end of its life, ensuring your breaker is always ready to do its job.

How to Select the Right VCB for Your Application

Choosing the right vacuum circuit breaker isn't as simple as matching a few numbers on a spec sheet. It's a critical decision that hits right at the heart of your system's safety, reliability, and long-term performance. Think of it like picking an engine: you wouldn't put a sports car engine in a heavy-duty truck just because the horsepower looks good on paper. You have to consider the terrain and the job it needs to do.

To get it right, you need to look past the basic ratings and really dig into the specific demands of your application. A VCB tucked away in a clean, climate-controlled switchgear room faces a completely different set of challenges than one sitting in an outdoor substation, exposed to the elements year-round.

Analyzing Application-Specific Factors

The environment a VCB lives in plays a massive role in its performance and how long it will last. You have to account for all the ambient conditions that can put stress on its mechanical and electrical components.

Here are a few key environmental factors to nail down:

- Installation Location: Is this breaker going indoors or outdoors? Outdoor models need much more robust, weatherproof enclosures and insulation systems built to handle everything from driving rain and snow to constant UV exposure.

- Altitude and Humidity: Air gets thinner at high altitudes, which reduces its ability to insulate. For installations well above sea level, you’ll likely need a VCB with a higher insulation rating (BIL) to compensate. High humidity is another enemy, as it can cause condensation and lead to insulation breakdown if not managed.

- Corrosive Atmospheres: If you're in a chemical plant, a paper mill, or a coastal area with salt spray, corrosion can eat away at enclosures and mechanical parts. In these spots, it's smart to specify upgraded materials like stainless steel or special protective coatings.

Matching the Breaker to the Load

Not all electrical loads are the same. The kind of equipment your VCB is protecting dramatically changes the type of stress it will see during switching. A breaker on a transformer feeder has a very different life than one switching a massive motor on and off.

The single most important step in selection is performing a system study to figure out the available fault current. This number dictates the breaker's required interrupting capacity. Undersizing this rating is a recipe for disaster—the VCB simply won't be able to extinguish a powerful short circuit.

Think about these common load types:

- Motor Loads: Kicking on a large motor creates a huge inrush of current. The VCB has to be built to handle these repeated high-current events without breaking a sweat.

- Capacitor Banks: Switching capacitor banks is known for generating high-frequency transient voltages that are incredibly tough on equipment. Breakers designed for this duty have special features to handle that stress.

- Frequent Switching: Some applications, like arc furnaces, demand thousands of operations every single year. For that kind of duty, a VCB with a high mechanical endurance rating—say, 30,000 operations—is an absolute must.

This focus on detail is why the VCB market is booming. It recently hit USD 5.80 billion and is on track to reach USD 10.57 billion by 2034, all thanks to grid modernization projects and the demand for reliable, low-maintenance gear.

Ultimately, the goal is to build a detailed specification that you can use as a procurement checklist. By thinking through the operating environment, the load type, and the fault duty, you can be confident that the VCB you choose is a perfect match for your system. For specific models that meet these tough industrial requirements, you can learn more about options from the ABB circuit breaker line.

Got Questions About VCBs? We’ve Got Answers.

Even after you get the hang of vacuum circuit breakers, a few practical questions always pop up when it's time to put them to work. It’s one thing to know the theory, but another to confidently manage these critical assets in the field.

Let’s tackle some of the most common questions our engineers hear. Getting these real-world concerns sorted out is the key to making sure your electrical infrastructure is as safe and reliable as it can possibly be.

How Can You Tell If a Vacuum Interrupter Is Failing?

This is a tricky one because a failing vacuum interrupter looks exactly like a healthy one from the outside. There are absolutely no visual cues, which is why periodic electrical testing is so critical.

The gold standard for checking the internal integrity is a DC high-potential (Hipot) test. When you apply a specific test voltage across the open contacts, a healthy interrupter will hold it without any issue, proving the vacuum is solid. If current flashes over, that’s a dead giveaway—the vacuum is gone, and the interrupter needs to be replaced, pronto.

Another thing to keep an eye on is the built-in contact wear indicator. It’s a simple mechanical guide that gives you a visual heads-up when the internal contacts have eroded past their usable life after thousands of operations.

What Is the Typical Lifespan of a Vacuum Circuit Breaker?

You have to look at two things: its mechanical life and its electrical life. Mechanically, a modern VCB is a beast, built to handle anywhere from 10,000 to 30,000 open-close cycles. That means the mechanism itself is set for a long, long time.

The electrical life is a bit different; it really depends on how many faults it has to clear and how severe they are. That said, the sealed vacuum interrupter at its heart is designed for a service life of 20 to 30 years under normal conditions. In the end, how long your VCB actually lasts comes down to the environment it lives in and whether you stick to a proper maintenance schedule.

The real beauty of a vacuum circuit breaker's design is its longevity. With minimal contact erosion and a sealed, zero-maintenance interrupter, it delivers a predictable and extended service life that older technologies just can't touch.

Are VCBs Good for Frequent Switching Applications?

Absolutely. In fact, they’re the best choice for jobs that demand constant switching—think arc furnaces, heavy-duty motor starting circuits, or capacitor bank switching.

Here’s why: the arc is contained and snuffed out so quickly and cleanly inside the vacuum that the contacts barely wear down with each operation. This incredible mechanical endurance, combined with their ability to regain dielectric strength almost instantly, makes them the go-to for these high-demand scenarios. They handle the stress beautifully, reducing the wear and tear on both the breaker and your system over thousands of cycles where other breaker types would quickly burn out.

At E & I Sales, we live and breathe this stuff. We specialize in sourcing the right VCBs and building integrated solutions for the toughest industrial jobs out there. Our experts are here to help you specify, procure, and commission the perfect equipment to guarantee your facility’s safety and uptime.

See how our turnkey integration services can make your next project a whole lot simpler.