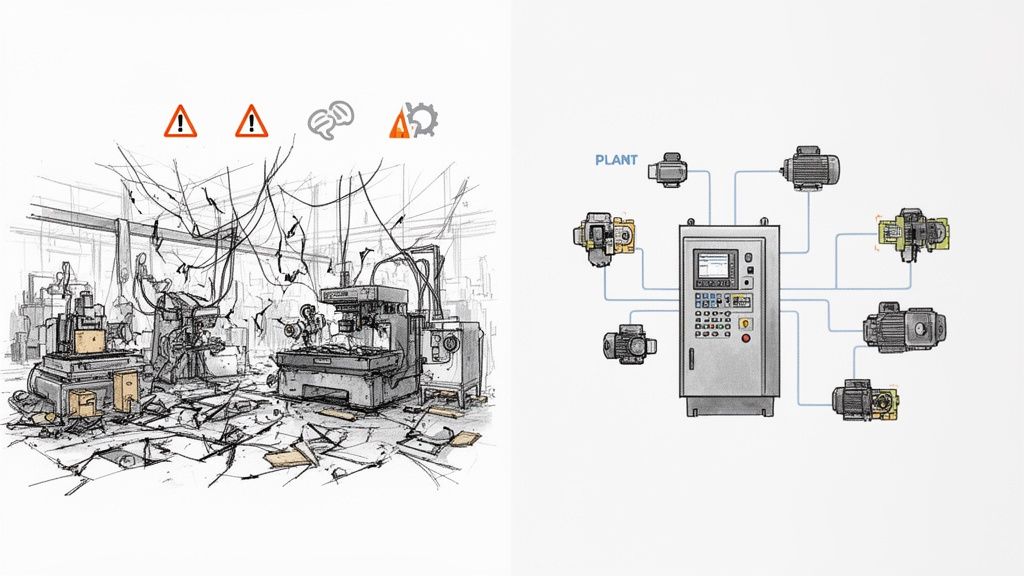

Picture this: your big plant expansion project is dead in the water. Why? Because the new VFDs from one vendor refuse to talk to the PLCs from another. It's not just a technical snag; it's a full-blown operational crisis, leading to downtime, safety concerns, and a budget that's spiraling out of control.

If that sounds familiar, you already know the truth: systems integration isn't just an IT problem, it's a core business strategy.

Why Strategic Systems Integration Is a Game-Changer

When done right, professional systems integration services take all those disparate pieces of equipment—motor controls, automation hardware, power distribution gear—and make them work together as a single, well-oiled machine. Too many project managers treat integration as an afterthought, something to bolt on at the end. That’s a mistake. The smart ones know it's the foundation of operational excellence. It’s what separates a random collection of machines from a truly unified production line.

This guide isn't about textbook definitions. It’s a practical roadmap for using integration to turn that potential chaos into a real competitive advantage. My goal here is to give you, the engineer or buyer on the ground, the tools you need to specify, select, and manage these critical services effectively.

The Business Case for Getting It Right

In an industrial plant, integration failures hit the bottom line—hard and fast. When a new variable frequency drive (VFD) can't communicate with the central PLC, or a motor control center (MCC) isn't properly tied into the SCADA system, the whole process can just stop. These aren't minor bugs; they're fundamental breakdowns.

This is where a good systems integrator proves their worth, delivering tangible results that you can see in your P&L. The real benefits are clear:

- Slash Operational Downtime: Systems built to work together are just more reliable. A unified control architecture means you can find and fix problems faster, getting equipment back online in minutes, not hours.

- See Everything, Control Everything: When all your components are speaking the same language, you finally get a complete picture of your operation. This is gold for making smarter decisions, implementing predictive maintenance, and optimizing your processes.

- Boost Safety and Compliance: A qualified integrator is your best defense against non-compliance. They ensure every part of the system, like UL 508A for control panels, meets the right standards and that safety circuits are rock-solid.

- Build for the Future: A smart integration plan always looks ahead. A well-designed system makes it far easier to add capacity or upgrade technology later without having to rip everything out and start over.

People often think integration is just about connecting a few wires. The reality is, it’s about creating a seamless flow of data and control that directly supports your business goals, whether that’s boosting throughput or cutting energy costs.

Bridging the Physical and Digital Worlds

Modern plants are a complex dance between physical machinery (motors, pumps, conveyors) and the digital brains that run them. A systems integrator is the choreographer making sure that dance is perfectly synchronized.

This involves a lot more than just software. While many resources talk about connecting business apps—and for a deeper dive on that, you can check out this overview of software integration services—our world is different.

Here on the plant floor, the focus is on making heavy iron work together intelligently. In the sections that follow, I'll walk you through the nitty-gritty of managing these projects to make sure your investment pays off.

Defining Your Project Scope and Technical Needs

A vague project scope is the single biggest threat to your budget and timeline. I’ve seen it happen time and again—ambiguity leads to misunderstandings, costly change orders, and a lot of finger-pointing when things go sideways.

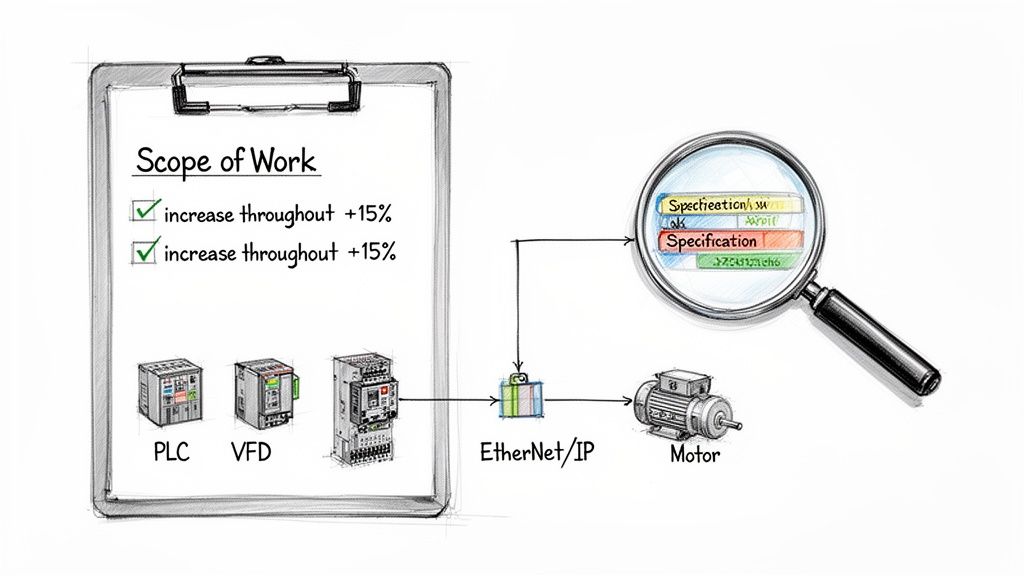

A successful project always starts with a crystal-clear Scope of Work (SOW). Think of this document as the definitive blueprint for everyone involved. It’s not just paperwork; it’s your first and best defense against scope creep.

When you hand a detailed SOW to potential systems integration services providers, you empower them to give you accurate, competitive bids. They can see exactly what you need, from hardware preferences to performance targets, which kills the guesswork. The result is a much smoother project, from design to commissioning, because you set clear expectations right from the start.

From Business Goals to Technical Specs

Your SOW has one primary job: translate high-level business objectives into concrete technical requirements an integrator can actually build from. It’s not enough to say you want a "more efficient system." You have to get specific and quantify what that means.

Start by defining your operational goals in measurable terms. Are you trying to boost production, cut down cycle times, or improve energy efficiency? A well-defined goal immediately gives the project direction.

For instance, a goal like "increase conveyor throughput by 15%" is infinitely more useful than just "make the conveyor faster." This specific target directly informs decisions about motor sizing, VFD programming, and PLC logic. These are the kinds of details any firm providing industrial controls and automation solutions needs to design the right system.

Make sure your SOW nails down these core elements to eliminate any confusion:

- Operational Objectives: State the business or production goals clearly. Use numbers and metrics whenever you can.

- Hardware and Software Specs: List any required or preferred manufacturers for PLCs, VFDs, HMIs, and other key components. If your plant has standardized on a particular platform, say it loud and clear.

- Communication Protocols: Define the network architecture. Does the system need to communicate over EtherNet/IP, PROFINET, Modbus TCP, or something else?

- Compliance and Standards: This is non-negotiable. List all required industry standards, like UL 508A for control panels, and include any of your own corporate safety or engineering standards.

Building a Comprehensive Scope of Work

A truly effective SOW leaves no room for interpretation. It’s a detailed document that covers every phase of the project, from the parts list to the final documentation you expect to receive. It's the ultimate checklist to ensure you get exactly what you paid for.

A strong SOW isn't about micromanaging your integrator. It’s about creating a shared understanding of success. When both parties know exactly what the finish line looks like, you’re far more likely to get there on time and on budget.

The table below breaks down the key components every industrial integration SOW should have. Use this as a guide to make sure you've covered all your bases before sending the project out for bid. This level of detail helps potential partners understand the full picture, which leads to better questions and more accurate proposals.

Key Components for a Systems Integration SOW

Use this checklist to ensure your Scope of Work is comprehensive, clear, and provides all the necessary details for accurate integrator bidding.

| Component | What to Include | Practical Example |

|---|---|---|

| Project Overview | A high-level summary of the project's purpose and the problem it solves. | "Upgrade the main packaging line's control system to increase throughput by 15% and replace obsolete PLC hardware." |

| Mechanical Scope | Details on physical equipment being controlled or installed. | "Integrator to provide controls for a new conveyor system (Model XYZ). All mechanical installation by others." |

| Electrical Scope | Power requirements, source of power, and panel specifications. | "The new control panel will be fed from MCC-04, breaker 22. Panel must be UL 508A certified and include a main disconnect." |

| Control Narrative | A detailed, step-by-step description of how the system should operate. | "When the start button is pressed, the conveyor motor will ramp up to 60 Hz over 5 seconds. A photo-eye will count boxes." |

| Deliverables | A list of all documentation to be provided upon completion. | "As-built electrical drawings in AutoCAD format, PLC and HMI source code, a complete Bill of Materials, and O&M manuals." |

Putting in the time to create a thorough SOW upfront is one of the best investments you can make. It sets the stage for a successful partnership and ensures the systems integration services you receive are perfectly aligned with your operational needs, preventing costly surprises down the road.

How to Select the Right Integration Partner

Choosing a partner for your systems integration services based on the lowest bid is one of the oldest, and most expensive, mistakes in the book. It’s a classic trap. That low initial quote often balloons with change orders, unexpected downtime, and non-existent support when you need it most.

The real goal isn't to find the cheapest contractor. It’s to find a true partner who delivers long-term value and reliability you can count on.

This means you need a solid evaluation process that goes way beyond the price tag. You’ve got to dig into a potential partner’s technical chops, their real-world industry experience, how they manage projects, and their safety culture. A slick proposal is one thing; proven execution is what actually matters.

Beyond the Bid Price: Technical Expertise

Your first filter should always be technical competence. It's non-negotiable. Does the integrator have deep, hands-on experience with the specific hardware and software platforms humming away in your facility? This is absolutely critical for core components like PLCs and VFDs.

When an integrator is a certified partner with brands like Rockwell Automation or Siemens, it's more than just a piece of paper. It means they have a direct line to technical support, specialized training, and product roadmaps that a generalist simply can't access. That inside track can be a lifesaver when you're troubleshooting a complex issue during commissioning.

When you're vetting potential partners, ask specific, probing questions about their experience:

- Platform Proficiency: Get them to talk about recent projects using the exact PLC family you plan to use (e.g., ControlLogix, S7-1500).

- Network Knowledge: How much experience do they have with the industrial protocols in your scope, like EtherNet/IP or PROFINET? Ask how they guarantee network reliability.

- In-House Capabilities: Find out what work they do themselves versus what they subcontract. Do they have an in-house UL 508A panel shop? Keeping programming and engineering in-house almost always leads to better quality control and a more cohesive final product.

The real value of a top-tier integration partner isn't just their ability to follow a scope of work. It's their capacity to spot potential problems you haven't thought of and recommend better, more reliable solutions based on their deep product knowledge.

Evaluating Industry Experience and Past Performance

General automation experience is good. But direct experience in your industry is a whole lot better.

An integrator who understands the unique headaches of a food and beverage plant—like clean-in-place requirements and traceability—will deliver a far better result than one who has only ever worked in automotive manufacturing. Relevant experience means they already speak your language and won't be learning on your dime.

Checking references is a step you cannot skip. And don't just ask for a list of happy clients. Ask specifically for contacts from projects that were similar in scope and complexity to yours.

When you call those references, ask the tough questions:

- How did the integrator handle unexpected curveballs or scope changes?

- Was the project documentation—drawings, code, manuals—thorough and accurate?

- Would you hire them again for another critical project? The answer to that last one tells you everything you need to know.

A site visit can also be incredibly revealing. Ask to tour their facility, and more importantly, their panel shop. A clean, organized shop with clear quality control processes is a huge indicator of a disciplined, professional organization. A messy, chaotic shop is a major red flag. If you want to dive deeper, you can learn more about the key characteristics of an effective industrial automation system integrator on our blog.

The Value-Based Decision

Ultimately, your decision has to come down to value, not just cost. A slightly more expensive partner with deep expertise, a proven track record, and robust support systems will almost always deliver a lower total cost of ownership. Their systems are simply more reliable, easier to maintain, and are backed by a team you can count on.

Create a simple evaluation matrix to score potential partners objectively across your key criteria. This is a great way to move the conversation away from a single price point and toward a more balanced, value-focused decision.

Your future self will thank you when the system is running flawlessly years from now.

Managing the Project from Kickoff to Commissioning

You’ve signed the contract and selected your integration partner. Great. Now the real work starts.

Signing that dotted line isn't the finish line; it’s the starting gun. If you want this project to land on time and on budget, you have to stay actively engaged. A hands-off approach is a recipe for missed deadlines, scope creep, and a final product that doesn’t quite hit the mark.

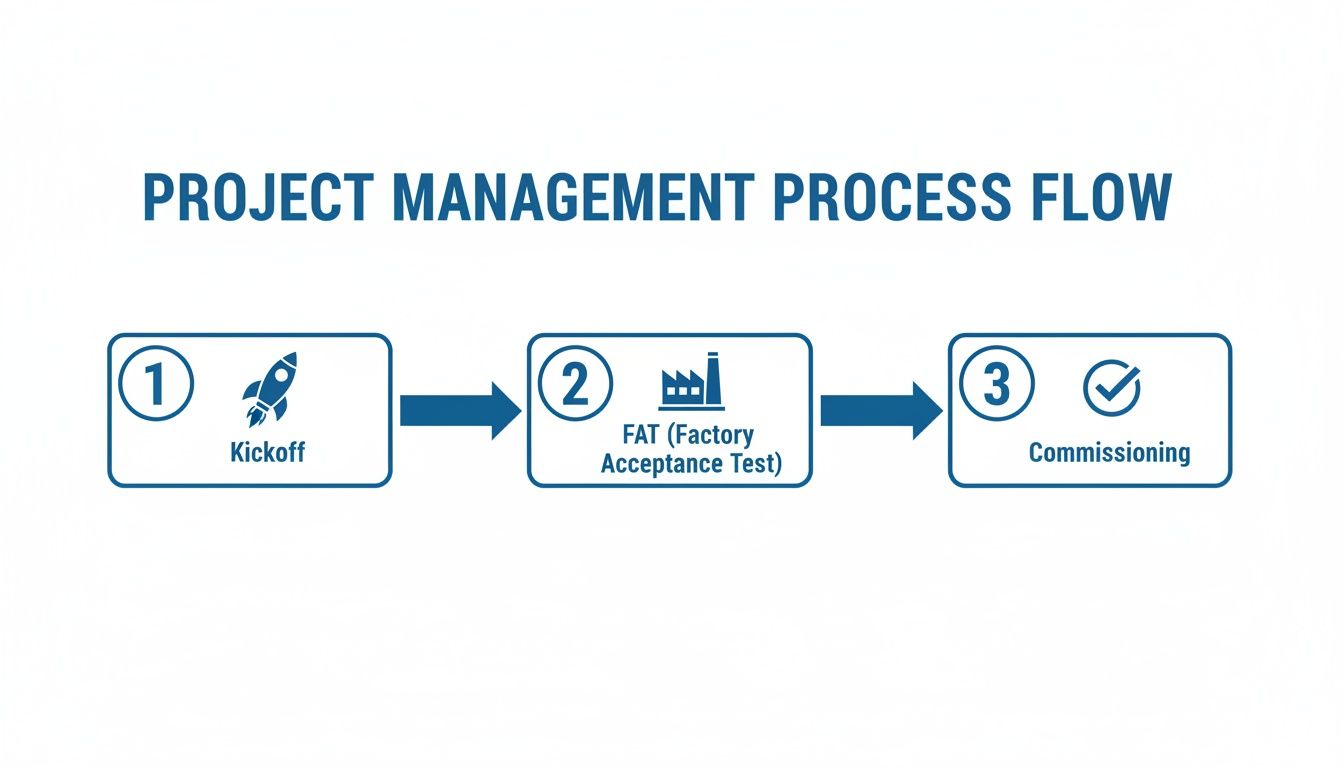

Think of yourself as the project's co-builder. Your integrator handles the technical heavy lifting, but your job is to provide clear direction, fast feedback, and firm approvals. We can break this entire process down into a few key phases, each with its own critical milestones.

Setting the Stage with a Strong Kickoff

The project kickoff meeting is more than just a formality—it’s your first and best chance to set the tone for the entire engagement. This is where you get both teams in a room and translate that written Scope of Work into a shared game plan.

During this meeting, you need to lock down a few non-negotiable processes. Getting these things right from day one will save you a world of headaches later.

- Establish a Single Point of Contact: Designate one person on your team and one on the integrator’s to be the official communication channel. This prevents crucial information from getting lost in a flurry of emails between different engineers and managers.

- Nail Down the Change Order Process: Let's be realistic—scope creep happens. But it doesn't have to create chaos. Define a formal, written process for how any changes are requested, quoted, approved, and tracked. No "oh, by the way" additions.

- Confirm the Project Schedule: Go through the timeline milestone by milestone. Pay special attention to the critical path and identify anything that depends on your team, like getting the integrator access to the facility or digging up old electrical drawings.

The Design and Submittal Phase

With the ground rules set, the integrator’s engineering team gets to work turning your operational needs into detailed electrical designs. This stage ends with the delivery of the design submittal package. This is a huge milestone. Your sign-off here gives them the green light to start ordering parts and building panels.

This package is your first tangible look at the system. It’ll include things like electrical schematics, panel layout drawings, and a detailed Bill of Materials (BOM). Don't just skim it. Scrutinize every single page. A change on paper costs next to nothing. A change after a control panel has been wired can cost thousands and delay the project for weeks.

Treat the design submittal like the final blueprint for a house. Once you sign off, you’re saying, "Yes, this is what I want you to build." You are confirming that the design will meet your operational and technical needs.

The Power of Factory Acceptance Testing

Before a single piece of equipment ships to your site, it needs to be put through its paces at the integrator's shop. This is called the Factory Acceptance Test (FAT), and it is arguably the single most important risk-mitigation step in the entire project.

The FAT is your chance to see the system run in a controlled environment. You can find software bugs, test the HMI screens, and request changes before that panel ever leaves their facility. A well-run FAT can catch and fix up to 90% of potential issues before they have a chance to cause massive delays during on-site commissioning.

You should see the panel fully powered up, connected to simulators that mimic your real-world devices. You'll get to watch the PLC logic execute and make sure the operator interface is intuitive. To make sure you cover all your bases, a solid checklist is a must. You can use our Factory Acceptance Test checklist as a starting point to build your own.

From Installation to Final Acceptance

Once the FAT is successfully in the rearview mirror, the system is shipped to your facility for installation. The integrator will handle the physical work of mounting panels and pulling wires, but your role is to clear the path for them. That means coordinating with other trades, ensuring site access, and making sure everyone follows your plant’s safety rules.

After the hardware is in place, the Site Acceptance Test (SAT) begins. This is the moment of truth. While the FAT tested the system in isolation, the SAT proves it works with your actual machinery. It's the final validation that the integrator has delivered on their promises, leading to the final project sign-off and official handover.

Mitigating Common Risks and Measuring True ROI

Let's be realistic: every industrial project has potential landmines. Even with the best planning, things can go sideways. While bringing in professional systems integration services is a huge step in the right direction, you can't just set it and forget it. You need to be aware of the common pitfalls to manage them proactively instead of just reacting when things catch fire.

Two of the biggest project-killers I see time and again are scope creep and interoperability failures.

Scope creep is that slow, insidious addition of "just one more thing" that wasn't in the original plan. It'll quietly bleed your budget dry. Your best defense is a rock-solid change order process you establish right at kickoff. Then there are the interoperability nightmares, where expensive gear from different vendors simply refuses to talk to each other. This is where a detailed design review and a comprehensive Factory Acceptance Test (FAT) become your most valuable assets.

Proper risk management is non-negotiable for getting these projects over the line on time and on budget. For those of us dealing with the software side of automation, the principles of software project risk management offer a really solid framework for spotting trouble before it gets out of hand.

Practical Strategies for Risk Mitigation

Anticipating problems is half the battle won. A proactive approach isn't about creating hundred-page risk registers; it's about practical, on-the-ground tactics that keep the project from veering off course.

Here are a few strategies that have proven their worth in the field:

- Implement a RACI Chart: A Responsibility Assignment Matrix (RACI) chart is a simple but powerful tool. It makes it crystal clear who is Responsible, Accountable, Consulted, and Informed for every critical task. This eliminates confusion and prevents things from falling through the cracks because everyone thought someone else was handling it.

- Plan Phased Rollouts: If you're upgrading a system that touches multiple production lines, a "big bang" go-live is just asking for trouble. A phased rollout, where you tackle one area at a time, is much smarter. It minimizes disruption to operations and lets your team learn and adapt in a more controlled environment.

- Prioritize Communication: Get regular, mandatory project meetings on the calendar and stick to them. A fixed agenda creates a predictable rhythm and ensures that small issues get aired out and solved before they fester into major roadblocks.

The point of risk management isn't to create a perfect, problem-free project. That's a fantasy. The goal is to reduce uncertainty so that when issues inevitably pop up, you have a plan ready to go, minimizing the hit to your schedule and budget.

This diagram shows a typical high-level project flow, highlighting the key checkpoints where you should be assessing risk.

Each of these stages—from the initial kickoff to the final commissioning—is a crucial chance to identify and squash risks before you move on.

Calculating the True Return on Investment

Okay, the project is done, the system is humming along, and now the front office wants to talk numbers. Specifically, Return on Investment (ROI). Too often, people only look at the initial project cost versus the immediate labor savings. This view is incredibly shortsighted and completely misses the real value of a well-integrated system.

To build a compelling business case, you have to look at the full picture. The capital outlay is just one piece of the puzzle. The true value is what you unlock over the long haul through better performance across the board.

Think about these less-obvious, but hugely impactful, metrics when you're calculating your real ROI:

- Reduced Unscheduled Downtime: Do the math on what an hour of downtime costs on that production line. A 10% reduction in unplanned stops can easily translate into hundreds of thousands of dollars saved over a year.

- Improved Energy Efficiency: Modern VFDs and integrated motor controls can slash energy consumption. Pull the utility bills from before and after the upgrade—the numbers will speak for themselves.

- Lower Long-Term Maintenance Costs: When you have a standardized system with quality parts and complete documentation, your maintenance team can troubleshoot issues faster. That's a direct reduction in maintenance labor costs, year after year.

When you start quantifying these tangible benefits, you can clearly show how a strategic investment in quality systems integration services pays for itself many times over. It stops being an "expense" and becomes what it truly is: a powerful engine for long-term profitability.

When you're diving into the world of systems integration services, a lot of questions come up. It's only natural. Getting straight answers is the key to making a good decision and keeping your project on track. Let's tackle some of the most common things people ask when they're looking to hire an integration partner.

What's the Difference Between a Systems Integrator and an EPC Firm?

This is a big one, and it’s all about project roles.

Think of a Systems Integrator (SI) as the specialist who handles the "brains" of the operation. Their entire world revolves around making the machinery do what it's supposed to do. We're talking PLC programming, SCADA systems, HMI development, and the networks that tie it all together. They are the control system experts.

An Engineering, Procurement, and Construction (EPC) firm, on the other hand, is the general contractor for the entire project. They have a much wider focus, managing everything from pouring the concrete and erecting the steel to the mechanical and structural engineering. In nearly every major project, the EPC firm will hire a specialized SI as a subcontractor to handle the automation and controls scope.

How Should We Decide Between Proprietary and Open-Source Technology?

This is a strategic fork in the road, and the choice you make will stick with you long after the integrator has packed up their tools.

Proprietary systems from a major vendor like Rockwell or Siemens offer a very streamlined experience. Everything is designed to work together, and you have a single number to call for support. The flip side? You can get locked into their ecosystem, which might limit your options and negotiating power down the road.

An open-source or multi-vendor approach gives you a ton of flexibility and often lets you shop around for more competitive pricing on individual components. The trade-off is that it can demand more heavy lifting during integration to make sure all the different pieces play nicely together. The right answer really depends on your team's in-house skills and how you plan to handle maintenance long-term. A good integrator won’t just tell you what to do; they’ll walk you through the pros and cons for your specific situation.

The decision between proprietary and open technology isn't just technical; it's a business decision. It directly impacts your future flexibility, your team's training needs, and the total cost of ownership for the life of the system.

What Level of Post-Project Support Should We Expect?

Don't ever let post-project support be an afterthought. This needs to be spelled out clearly in your contract before any work begins, because vague promises of "we'll be there for you" are a major red flag.

At the bare minimum, your agreement should specify a warranty period—typically one year—that covers any defects in the workmanship.

But a good contract goes further. It needs to detail specific response times for support calls and lay out the exact process for getting help. It’s also smart to talk about ongoing support options before you sign, like preventative maintenance contracts or remote monitoring services.

Finally, the project isn't truly done until you have the complete documentation package in hand. This is non-negotiable and must include:

- Complete as-built electrical drawings

- All PLC, HMI, and SCADA source code

- Thorough training for your maintenance and operations staff

This is how you ensure your team is fully equipped to own, operate, and maintain the system for years to come without being totally dependent on the integrator.

At E & I Sales, we don’t just build systems; we build systems that last. We believe that providing the right documentation and support is just as important as the code we write. We combine deep product expertise with turnkey integration services to deliver reliable, code-compliant solutions that set your team up for long-term success.

Explore our systems integration and UL control panel capabilities at eandisales.com