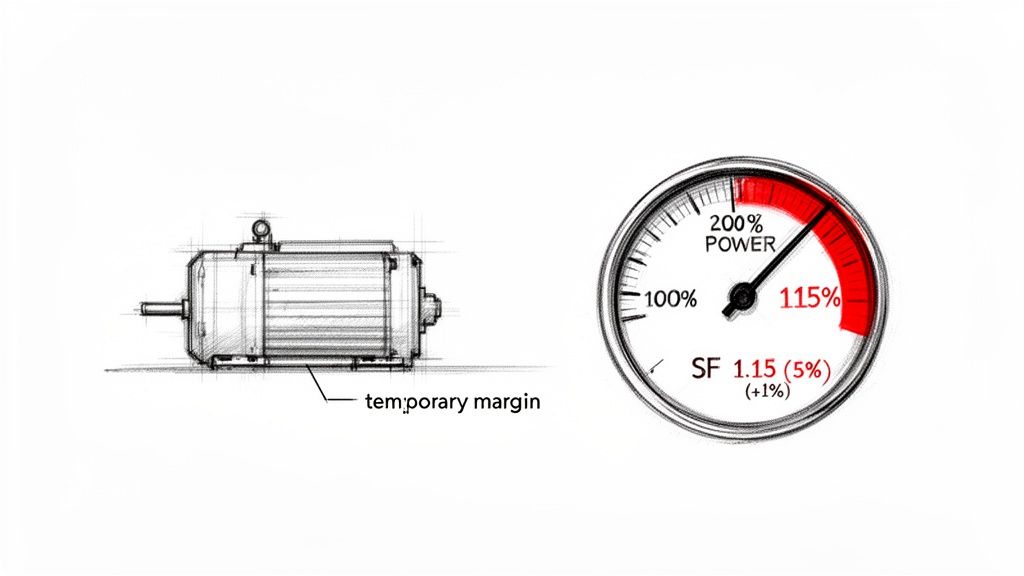

Put simply, a motor's service factor is a multiplier that tells you how much extra load it can handle for short bursts. It's essentially a built-in safety margin. For example, a motor with a 1.15 service factor can operate at 15% above its rated horsepower without immediately frying itself.

Decoding Motor Service Factor: The Built-In Power Margin

Think of it like driving a car. You wouldn't drive with the pedal floored and the engine screaming in the redline all day. But to get up a steep hill or pass another vehicle, you might push it for a few moments. The car is built to handle that brief, intense demand.

A motor's service factor is that engineered redline. It's not "free" horsepower—it's a carefully calculated reserve capacity designed to handle the unpredictable, real-world challenges that inevitably pop up.

The Official Definition And Its Practical Meaning

The National Electrical Manufacturers Association (NEMA) gives us the formal definition. According to the NEMA MG 1 standard, the service factor (SF) is "a multiplier which, when applied to rated power, indicates a permissible power loading that may be carried under the conditions specified for the service factor.”

In plain English, this means a 10 horsepower (HP) motor with a 1.15 SF is thermally designed to safely deliver 11.5 HP when needed. That 1.15 value has become an unofficial standard for general-purpose industrial motors for a reason.

This built-in cushion is absolutely critical for a few key reasons:

- Handling Unexpected Loads: It gives the motor the muscle to manage intermittent spikes in demand, like when a conveyor belt has to start moving under a particularly heavy load.

- Voltage Fluctuations: It provides a buffer against the minor voltage sags common in industrial plants, which could otherwise cause the motor to struggle or overheat.

- System Resiliency: It makes the whole operation more robust, preventing nuisance trips and production stoppages from brief, unusual operating conditions.

In essence, service factor provides a margin for error. It’s the difference between a system that runs smoothly despite minor hiccups and one that constantly trips offline, causing expensive downtime.

Getting a handle on this concept is about more than just numbers on a nameplate. It's about understanding how electrical power gets converted into the real-world mechanical work that gets the job done. For a closer look at that relationship, our guide on torque calculation for a motor is a great next step.

Properly applying service factor ensures you're designing and maintaining reliable, resilient industrial systems that perform exactly as you expect them to.

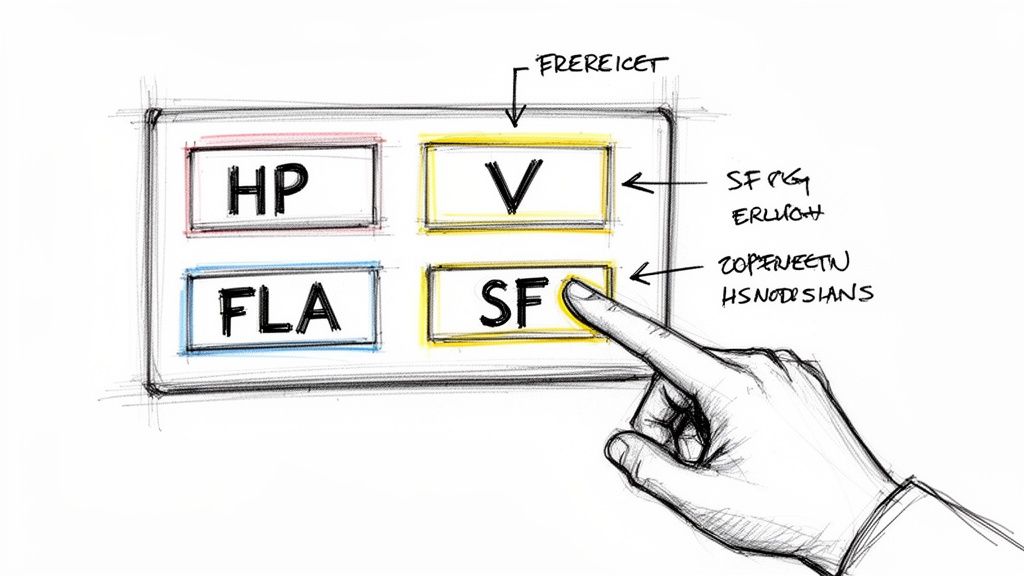

Finding and Reading the Service Factor on a Motor Nameplate

Think of a motor's nameplate as its birth certificate and resume rolled into one. It’s packed with every critical detail you need to know about what that motor can do, and learning to decipher it is a core skill for anyone in the field.

When you're looking for the service factor, you won't have to search too hard.

Most manufacturers make it pretty obvious. Just scan the nameplate for the abbreviations SF or S.F., or sometimes the full "Service Factor." It’s almost always a decimal, like 1.15 or 1.25, and you'll usually find it huddled up next to the other headliners like horsepower (HP), RPM, and voltage.

But just spotting the number is only half the battle. That little decimal doesn't mean much in isolation. To really understand what it's telling you, you have to see it as part of the bigger picture, especially in its relationship with the motor's horsepower and full-load amperage (FLA).

Putting The Numbers In Context

Here's the best way to think about it: the horsepower rating is the motor's day-in, day-out marathon pace. It's the load it was designed to handle continuously without breaking a sweat.

The service factor? That’s the motor’s sprint capability. It tells you exactly how much extra power you can pull from it for short bursts without causing immediate damage. These two numbers work as a team, defining the absolute peak power the motor can safely deliver under ideal conditions.

Take a look at this real-world example. On the nameplate below, the SF is clearly marked as 1.15. Notice where it’s located—right next to the 3 HP rating. That’s not a coincidence. Manufacturers put them side-by-side to emphasize their direct link.

Getting this connection right is absolutely crucial. It’s the key to sizing your equipment correctly and, just as importantly, setting up your protective devices to prevent a burnout.

How Using Service Factor Impacts Motor Lifespan

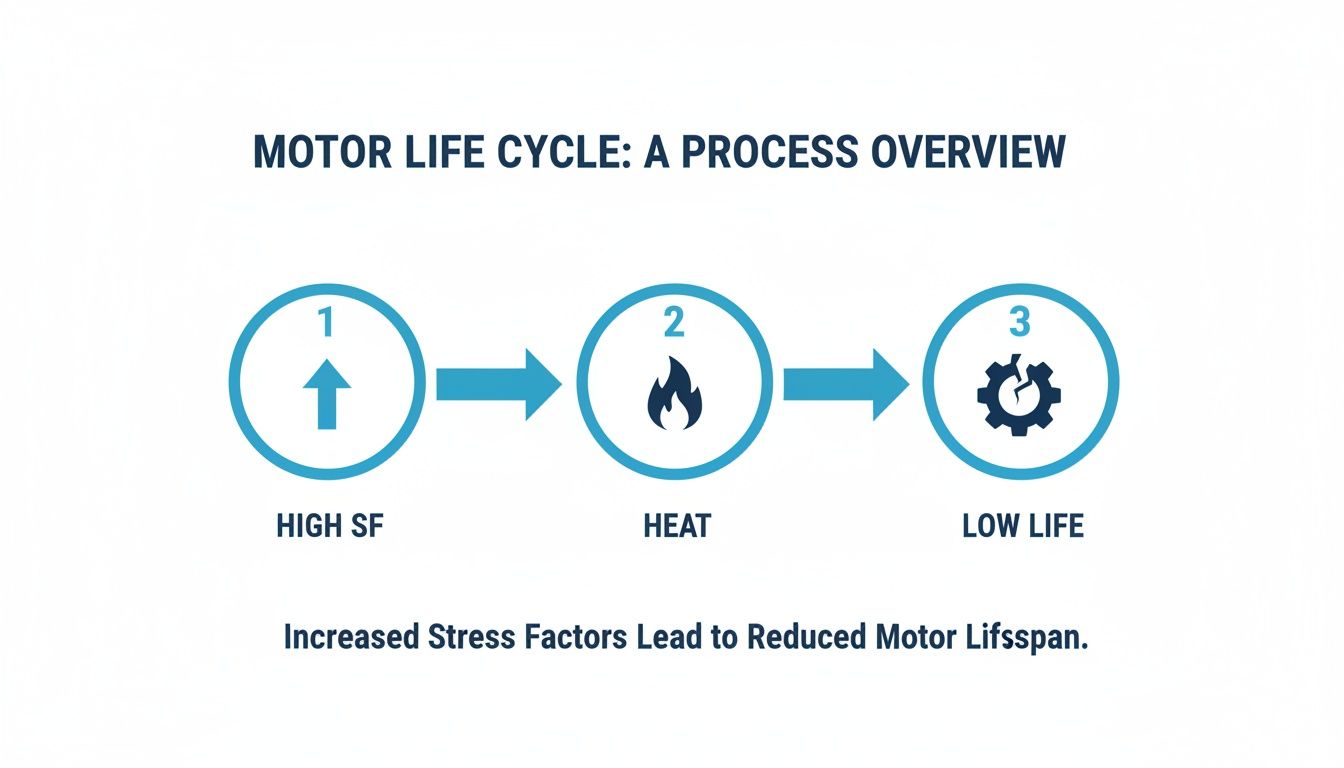

Pushing a motor into its service factor range might feel like getting a free power boost, but there's a steep price to pay: a shorter lifespan. There’s no such thing as free horsepower. The cost of tapping into that reserve margin is accelerated wear and tear, pure and simple.

The number one enemy of any electric motor is heat. Running continuously into the service factor generates a ton of it, and that heat directly attacks the motor's most vulnerable parts—the winding insulation and the bearings. When you push a motor past its rated horsepower, the current draw goes up, which in turn cooks the windings. This thermal stress is the single biggest reason motors fail before their time.

The 10-Degree Rule and Its Financial Impact

There's a well-known rule of thumb in motor maintenance called the "10-degree rule." It’s a harsh but accurate guideline: for every 10°C (18°F) you run a motor's windings above their rated temperature, you cut the insulation's life in half. It's an unforgiving penalty for running too hot.

Let's take a motor with a 1.15 service factor. When you operate it at that peak load, you're not just asking for 15% more power; you're generating a disproportionate amount of heat. According to guidance from both EASA and NEMA, this overload rapidly ages the insulation and bearings. While a 1.15 SF load increases the current by about 15%, the heat generated is a different story. Heat from resistance (known as I²R loss) scales with the square of the current, meaning the extra heat is actually closer to 32%. You can discover more insights about motor thermal limits on PlantEngineering.com.

This isn't just an abstract electrical principle; it has real, tangible financial consequences. An overheated motor leads directly to:

- Brittle Insulation: Over time, the heat makes the insulation on the copper windings fragile and prone to cracking. This leads to electrical shorts and catastrophic failure.

- Bearing Failure: That same excess heat breaks down the grease in the motor's bearings, causing more friction, seizing, and eventually, a total breakdown.

- Unexpected Downtime: A motor that dies prematurely grinds production to a halt, leading to expensive delays and emergency repair bills.

Think of a motor's service factor as a temporary reserve for unexpected peaks, not a continuous operating point. Leaning on it all the time is a surefire way to drive up maintenance costs, shorten your equipment's life, and deal with unplanned shutdowns.

Getting this relationship right is critical for building a reliable system. It’s not just about picking the right motor, but also setting up the proper safeguards. That’s why we also recommend you read our detailed guide on the protection of motors.

Smart Applications for Sizing Motors and Setting Overloads

Knowing what a motor service factor is on paper is one thing, but the real magic happens when you apply it intelligently out in the field. Seasoned pros don't look at a service factor as free horsepower; they see it for what it is—a strategic buffer. It’s a crucial safety margin for dealing with the messy, unpredictable reality of industrial work.

This built-in capacity is the perfect tool for handling those temporary, intermittent peak demands that can bring a lesser system to its knees. Think of a positive-displacement pump that has to work a little harder to push through a slug of thick fluid, or a conveyor belt groaning to a start under a heavy, lopsided load. These are precisely the moments a 1.15 SF is designed to absorb, preventing a costly system shutdown.

This isn't a new concept. Service factor has always been a design and reliability margin meant to cover real-world uncertainties, like minor voltage sags or the simple fact that it's tough to predict the exact horsepower an application will need. For system integrators building complex motor control centers, specifying motors with a 1.15 SF on critical drives is a time-tested strategy to slash nuisance trips and keep the line running. For a great technical breakdown on how this NEMA-defined margin adds reliability, check out this piece on Electrical Engineering Portal.

Setting Overload Protection Correctly

One of the most critical jobs for service factor is in setting a motor's overload protection. This is where theory directly impacts equipment safety and operational uptime. If you set the overload relay too low, you're signing up for frustrating nuisance trips. But set it too high, and you're leaving your expensive motor completely exposed to burnout.

Thankfully, the National Electrical Code (NEC) gives us clear, direct guidance. According to NEC 430.32, for any motor with a service factor of 1.15 or greater, you can set the overload device at up to 125% of the motor's Full Load Amps (FLA) listed on the nameplate. This setting gives the motor breathing room to safely use its service factor margin for short periods without tripping out.

On the other hand, if you're working with a motor with a service factor of 1.0, the rule changes. The maximum overload setting is capped at 115% of the FLA. That tighter tolerance is there for a reason—the motor has no built-in thermal capacity to handle overloads.

The bottom line is simple: your motor's service factor directly dictates how you configure its primary defense mechanism. Getting this setting right is fundamental to protecting your investment.

This relationship between running in the service factor, heat, and motor life is a straight line. The more you lean on that SF, the more heat you generate, and heat is the number one enemy of a motor's insulation and bearings.

As you can see, consistently relying on the service factor generates excess heat, which is the fast track to premature motor failure.

A Practical Step-by-Step Example

Let's walk through a quick, real-world scenario to lock this in.

- Check the Nameplate: You've got a 10 HP motor. The nameplate shows an FLA of 28 amps and an SF of 1.15.

- Apply the NEC Rule: Since the SF is 1.15, we know we can go up to 125% of the FLA for our overload setting.

- Do the Math: 28 Amps (FLA) x 1.25 = 35 Amps.

- Set the Overload Relay: You'll dial in your overload relay to trip if the current draws more than 35 amps for a sustained period.

This simple calculation gives you a system that's both tough and safe. Getting these protective devices configured correctly is a core skill in motor control. For those who want to go deeper, we have a complete guide on how to size a motor starter that unpacks all these components in much more detail.

When You Should Avoid Using the Service Factor

While a motor’s service factor gives you a nice little power margin, it’s a tool with strict limitations, not a get-out-of-jail-free card. Knowing when not to use it is just as important as knowing when you can. In certain environments, leaning on that built-in buffer isn't just a bad idea—it can be downright dangerous.

Think of the service factor as a thermal savings account. In some situations, external conditions have already spent that entire savings for you, leaving zero margin for error.

High Ambient Temperatures and High Altitudes

A motor's standard ratings, including its service factor, are based on a very specific set of ideal conditions: operating at or below 40°C (104°F) and at an altitude of no more than 1,000 meters (3,300 feet). The moment you step outside those boundaries, the motor's ability to keep itself cool starts to plummet.

- High Temperatures: In a hot factory or outdoors in the summer sun, the motor is already struggling to shed its own heat. Pushing it into the service factor range generates even more heat, which can cook the winding insulation and lead to a catastrophic failure.

- High Altitudes: The air gets thinner the higher you go. Thinner air means the cooling fan can't move as much heat away from the motor's body, making it run hotter even under a normal load.

In both of these scenarios, the environment itself effectively "uses up" the thermal cushion that the service factor is meant to provide. To operate safely, you have to derate the motor and treat its service factor as 1.0.

Hazardous and Explosive Environments

When you're dealing with a location classified as hazardous—think refineries, grain elevators, or chemical plants—any extra heat can become an ignition source for flammable dust or vapors. It’s no surprise, then, that motors built for these environments are held to a much higher safety standard.

In hazardous locations, the motor's surface temperature is a critical safety parameter. Operating in the service factor range raises this temperature, creating an unacceptable risk. For this reason, all hazardous-duty motors are rated with a 1.0 service factor and must never be operated above their nameplate horsepower.

When Using a Variable Frequency Drive (VFD)

Heads up: pairing a standard, general-purpose motor with a Variable Frequency Drive (VFD) almost always means you forfeit the service factor. A VFD controls the motor's speed by manipulating the power waveform, a process that inherently introduces extra heat into the motor windings. This heating effect is especially bad at low speeds when the motor's own cooling fan is barely spinning.

That added heat from the VFD eats up the motor's thermal reserve, making it totally unsafe to push the load beyond its nameplate rating. Unless you're using a specialized inverter-duty motor that is explicitly designed with a service factor for VFD operation, you must assume the SF is 1.0.

The table below summarizes the key conditions where you need to back off and treat the service factor as 1.0.

Service Factor Derating Guide

This table outlines common operating conditions that require derating a motor's service factor to 1.0 to ensure safe, reliable operation and prevent premature failure.

| Operating Condition | Recommended Service Factor | Reason for Derating |

|---|---|---|

| Ambient Temp > 40°C (104°F) | 1.0 | Reduced cooling capacity prevents the motor from dissipating the extra heat of an overload. |

| Altitude > 1,000 m (3,300 ft) | 1.0 | Thinner air makes the cooling fan less effective, increasing operating temperature. |

| Hazardous/Explosive Locations | 1.0 | Prevents surface temperatures from exceeding safety limits and becoming an ignition source. |

| Used with a Standard VFD | 1.0 | The VFD introduces additional heat, consuming the motor's thermal margin. |

| Frequent Starting/Stopping | 1.0 | High inrush currents during startup generate significant heat, leaving no room for overload. |

Remember, these are not just suggestions; they are critical guidelines for protecting your equipment, your facility, and your personnel. When in doubt, always derate to a service factor of 1.0.

Expert Guidance for Motor and Control Panel Design

Really getting a handle on motor service factor is a game-changer when you're designing systems that need to be both tough and cost-effective. It’s what lets you turn those abstract numbers on a nameplate into smart engineering calls, making sure your equipment can actually handle what the real world throws at it. This is how you nail the balance between performance and a long, reliable service life.

But you can't just stop at the motor. To apply these principles right, you have to look at the whole electrical system. The motor is just one piece of the puzzle—the control panel protecting it is just as crucial. This is where teaming up with an expert who gets the entire picture, from the motor spec all the way to the UL-listed control panel integration, really pays off.

Aligning Components for Optimal Performance

A single-source partner is your best bet for making sure your motor, overload protection, and system controls are all singing from the same song sheet. This kind of integrated approach helps you sidestep the usual traps, like mismatched parts or badly configured safety devices, which are a fast track to premature failures and expensive downtime.

By treating the motor and its controls as one unified system, you're optimizing the entire operation for safety, reliability, and peak performance right out of the gate. It's about preventing problems before they even have a chance to start.

This holistic way of thinking takes the guesswork out of the equation and guarantees every component is working together smoothly. For instance, an expert can pinpoint a motor with the perfect service factor for your specific load, then build a control panel with overload relays calibrated precisely to that motor’s unique FLA and SF ratings.

When you get down to it, this level of detailed engineering gives you a system that isn't just up to code—it's built to last. It’s about creating a dependable operational backbone that supports your production goals without cutting corners, making sure your investment is protected by smart, forward-thinking design.

Got Questions About Motor Service Factor?

Once you get the hang of motor service factor, you start running into those tricky real-world situations. It’s one thing to understand the theory, but it’s another to apply it when you’re standing in front of a control panel. Let’s clear up a few of the most common questions that pop up.

Can I Use a VFD to Squeeze More Horsepower Out of the Service Factor?

This is a big one, and the answer is a hard no. It's a common and frankly dangerous assumption. The moment you connect a standard motor to a Variable Frequency Drive (VFD), its service factor is automatically reduced to 1.0. You should never try to push the motor beyond its nameplate horsepower rating when using a VFD.

Why? It all comes down to heat. A VFD introduces extra heat into the motor windings, a problem that gets worse at lower speeds when the motor's own cooling fan isn't spinning fast enough to be effective. That extra heat eats up the very thermal safety margin the service factor was meant to provide. Unless you have a specific inverter-duty motor that is explicitly rated for VFD use with a service factor above 1.0, the rule is absolute: SF is 1.0.

Is a Motor with a 1.25 SF Just Flat-Out Better Than One with a 1.15 SF?

Not at all. "Better" is completely relative to the job at hand. A higher service factor like 1.25 definitely gives you a bigger cushion for short-term overloads, but it doesn't make the motor superior across the board.

For instance, you’ll often see a 1.25 SF on Open Drip-Proof (ODP) motors, where there's plenty of airflow to help with cooling. On the flip side, a heavy-duty, Totally Enclosed Fan-Cooled (TEFC) motor built for a gritty, tough environment might be designed with a more conservative 1.15 SF. The best motor is the one that's a perfect match for its load, environment, and duty cycle. A high SF is great for unpredictable loads, but a 1.0 SF motor sized perfectly for a steady, continuous load might even be the more efficient choice.

How Does Running in the Service Factor Range Affect My Warranty?

Running a motor in its service factor range (above its rated horsepower) won't automatically void your warranty. After all, the motor was designed with that capability for intermittent use.

But here’s the catch: consistently running in that SF range dramatically shortens the life of the motor's insulation and bearings, making a premature failure much more likely. If the motor burns out from overheating because it was running in its SF range plus dealing with other stressors like high ambient heat, a manufacturer could easily challenge or deny a warranty claim. They expect you to use the service factor as a safety net for occasional spikes, not as a permanent horsepower boost.

At E & I Sales, we know that peak performance comes from the whole system, not just one part. Our experts are here to help you select the right motor and design a custom, UL-listed control panel that delivers the protection, reliability, and longevity your operation demands. Learn more about our comprehensive motor and control solutions.