Think of a soft starter as a sophisticated dimmer switch for an industrial-grade AC motor. Instead of slamming the motor with full power from a dead stop—like flipping a light switch—it smoothly and gracefully brings it up to speed.

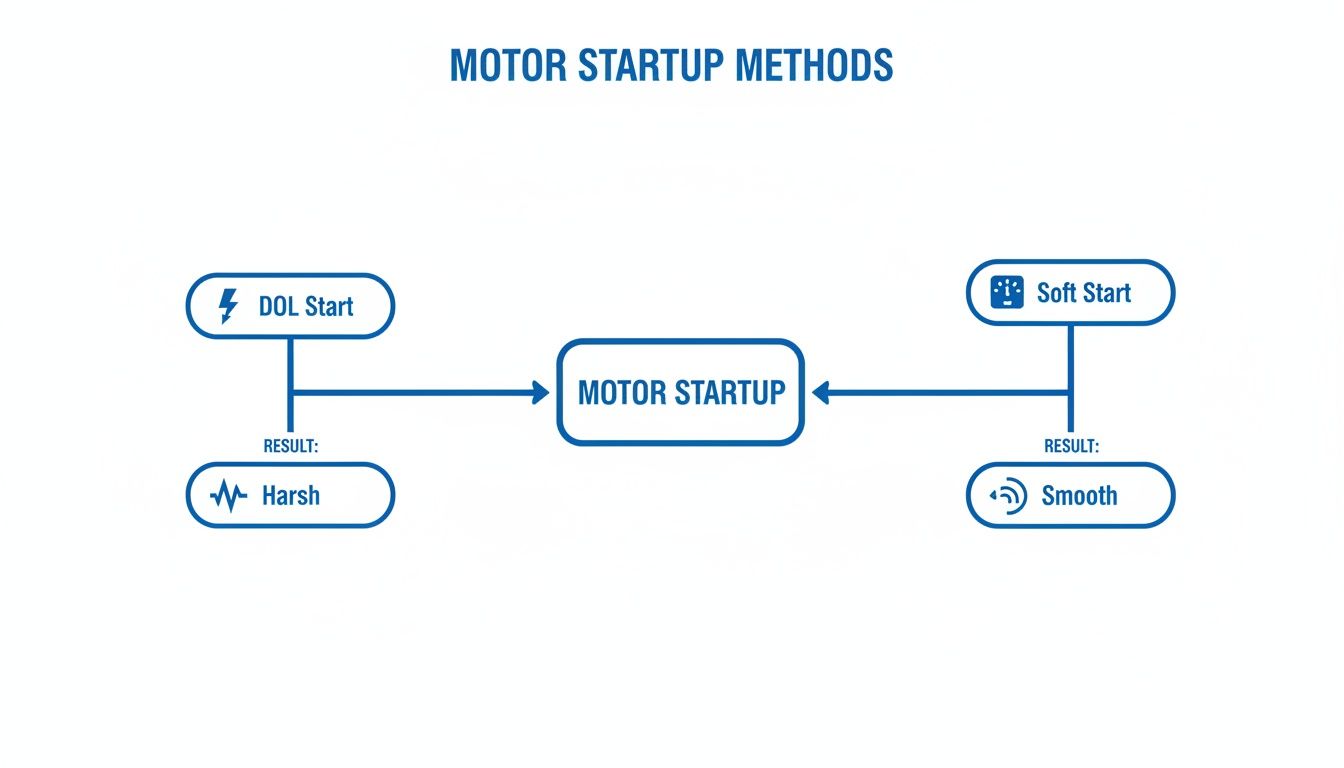

This is a massive departure from the old-school direct-on-line (DOL) start, which is about as gentle as a sledgehammer.

What Is a Soft Starter in Simple Terms

Imagine you’re about to turn on a massive fire hose. If you crank the valve open instantly, the hose will whip around violently from the sudden, immense pressure. It’s chaotic and destructive.

Now, what if you slowly opened the valve instead? The pressure would build in a controlled, predictable way. That’s exactly what a soft starter does for a motor. It tames the brutal mechanical shock and massive electrical surges that come with an abrupt startup.

This isn't just a minor tweak; it's a complete change in how we manage motors, directly protecting the health of your equipment and the stability of your entire facility. The core job of a soft starter is to solve two huge problems that plague traditional motor starting methods.

Protecting Your Mechanical Systems

When a motor lurches from zero to full speed instantly, it sends a shockwave of torque through every single connected component. Gears grind, belts stretch, couplings strain, and the machine itself shudders. This is what causes premature wear and tear, leading to those frustrating, costly, and completely unexpected breakdowns.

A soft starter acts as a buffer. It applies the mechanical load gently, preserving the life of the entire system.

By preventing the sudden mechanical jerk at startup, a soft starter significantly reduces the physical strain on your entire powertrain, which is a leading cause of maintenance headaches and unexpected breakdowns.

Stabilizing Your Electrical Network

Just as important is how a soft starter handles the massive electrical demand of a motor startup. It’s an electronic device that gradually increases the voltage supplied to the motor. This simple-sounding action slashes the enormous inrush current that DOL starters are famous for—often hitting 800% of the motor’s normal running current.

For common applications like industrial pumps and compressors, this technology cuts that peak current by 50-70%. The result? No more severe voltage dips that trip breakers, disrupt sensitive electronics, and cause chaos across your plant's electrical network. You can find more details on these applications and market trends in research from the IMARC Group.

Comparing Motor Startup Consequences

The difference between a "hard" start and a "soft" start is night and day. This table breaks down the immediate consequences of each method.

| Impact Area | Direct-On-Line (DOL) Start | Soft Start |

|---|---|---|

| Electrical Impact | Massive inrush current (600-800% of normal), causing voltage sag and potential network trips. | Controlled, limited inrush current, ensuring a stable electrical system without disruptions. |

| Mechanical Impact | Abrupt, high-torque jolt that stresses belts, gears, couplings, and machinery. | Smooth, gradual acceleration that eliminates mechanical shock and reduces component wear. |

| Operational Result | Increased risk of equipment failure, higher maintenance costs, and potential for facility-wide downtime. | Extended equipment lifespan, lower maintenance expenses, and enhanced operational reliability. |

As you can see, the choice has a direct and immediate impact on both your machinery and your bottom line. A soft start isn't just a feature; it's a foundational strategy for reliable, long-term operation.

How a Soft Starter Tames the Power

Think about opening a massive water valve. If you crank it open instantly, you get a violent surge of water—a water hammer—that slams into the whole system. But if you open it slowly and deliberately, the flow builds up smoothly. A soft starter does the exact same thing for a big industrial motor, but with electricity.

It’s all about preventing that initial electrical "slam" that comes with a direct-on-line start.

The real workhorses inside a soft starter are a set of solid-state devices called Silicon Controlled Rectifiers (SCRs), often just called thyristors. You can think of these as incredibly fast, heavy-duty electronic gates on each of the three power phases feeding the motor. Instead of just being open or closed, they can be controlled with surgical precision.

By telling these gates exactly when to open and close within each AC cycle, the soft starter effectively "chops" the electrical waveform. This technique, known as phase angle control, is the key. At the very start, the controller only opens the gates for a tiny fraction of a second, letting just a trickle of voltage through.

As the motor starts to spin, the controller progressively holds those SCR gates open a little longer with each cycle. This creates a smooth, steady ramp-up of voltage to the motor windings. The result? The motor accelerates gracefully, without the brutal torque jolt and massive inrush current that you get from hitting it with full power all at once.

The Brains Behind the Brawn

A soft starter isn’t just a dumb switch; it has a sophisticated control circuit that acts as its brain. This controller is constantly watching the motor's current and voltage, making lightning-fast adjustments based on the parameters you’ve programmed. It's all about fine-tuned management.

Here’s a look at what that controller is really doing:

- Voltage Ramp: This is its main job. You define how quickly the voltage climbs from its starting point to full line voltage. A longer ramp gives you a much gentler start, which is perfect for fragile loads or high-inertia systems that take a while to get moving.

- Current Limiting: You can tell the controller to never let the motor draw more than a specific amount of current. If the amps start to spike during the ramp, the soft starter holds the voltage right where it is until the current settles down. This is a lifesaver for the motor and for your facility's electrical network.

- Torque Control: At the end of the day, controlling voltage and current is really about controlling the motor's output torque. This prevents mechanical shock, which means less wear and tear on gearboxes, belts, and chains. For something like a conveyor line, it means your products don't get thrown around.

The difference is night and day. This simple graphic shows you just how jarring a direct start is compared to the smooth ride a soft starter provides.

It’s easy to see how one approach prevents the kind of damaging surges that have been a problem with older startup methods for decades.

Internal Bypass: The Key to Efficiency

Once the motor is up and running at full speed, the soft starter's main job is over. But if you kept running all that power through the SCRs, you’d just be generating heat and wasting electricity. That’s inefficient and bad for the electronics.

This is where a critical feature comes in: the internal bypass contactor.

Once the motor hits full speed, the bypass contactor closes, creating a direct path for power to flow straight to the motor. This effectively takes the SCRs out of the circuit, which maximizes efficiency and massively extends the life of the soft starter itself.

This technology has really matured. The first solid-state starters emerged from 1980s thyristor tech, and today it’s a global market hitting USD 953 million this year. For industrial OEMs, that evolution means specifying a modern soft starter from a trusted distributor gets you a reliable, code-compliant installation that can cut commissioning time by weeks. If you want to dig deeper into the numbers, you can discover more insights about the soft starter market on imarcgroup.com. It's proof that today's units are built for effective, efficient, and long-term industrial duty.

The Real-World Benefits of a Controlled Start

Knowing how a soft starter works is one thing, but seeing how that translates into real dollars and cents on the floor is what really matters. So, how does a smooth, gradual motor start actually help your business? The benefits go way beyond just a quieter startup—they create a ripple effect of savings, longer equipment life, and more reliable operations across your entire facility.

Think of a direct-on-line start as a sledgehammer blow to your equipment every single time you hit the "on" button. A soft starter swaps that jarring impact for a controlled, predictable event. It turns a major point of system stress into a managed process, and that's a huge win for asset protection.

Let’s break down the five biggest advantages you can expect.

Reduced Mechanical Stress and Extended Equipment Life

Every time a motor slams on with full, instant power, it sends a violent shockwave through the entire mechanical system. You can practically hear it—gears grind, conveyor belts stretch and slip, and couplings shudder under the immense strain. This repeated abuse is one of the top reasons expensive machinery fails long before it should.

A soft starter completely changes that story. By gently ramping up the torque, it allows everything to get up to speed smoothly. It's the difference between a shove and a gentle push.

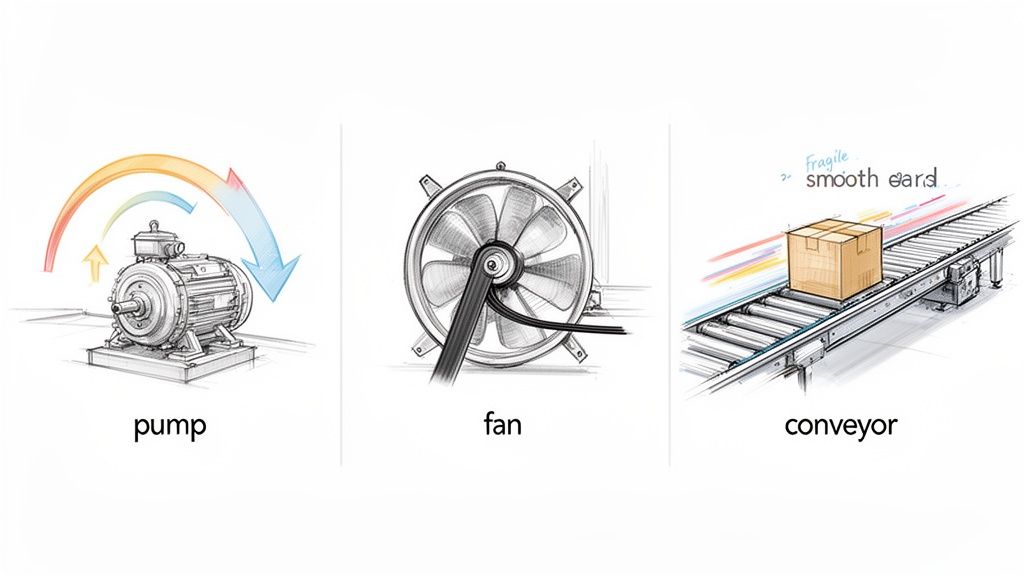

- Pumps and Fans: The sudden jolt on impellers and belts is gone, which means less slippage and a much longer service life.

- Conveyors: You get a jerk-free start that protects belts, rollers, and whatever products you're moving down the line.

- Gearboxes: It minimizes the shock loading on gear teeth, which is a leading cause of chipping and catastrophic failure.

Less physical stress directly translates to a longer, more reliable life for your most critical assets.

Lowered Electrical Strain on Your Entire System

That massive inrush of current from a direct-on-line start doesn't just hit the motor; it sends a tremor through your whole electrical network. This huge, sudden demand for power causes a significant voltage sag that can create chaos elsewhere in the plant.

Sensitive electronics like PLCs, sensors, and computers are especially vulnerable. Those voltage dips can cause them to fault, reset, or even fail completely. A soft starter acts as a much-needed buffer.

By choking back that inrush current—often by 50-70% compared to a DOL start—a soft starter prevents those disruptive voltage sags. This protects not just the motor but every other piece of equipment sharing the circuit, giving you far greater stability.

Improved Cost Efficiency and Lower Utility Bills

If you've ever looked closely at your power bill, you might have seen "peak demand charges." Your utility company bases these charges on the single highest spike of electricity you use during a billing period, even if it only lasted a few seconds. A plant full of large motors all starting across-the-line is a recipe for massive, costly demand spikes.

Because a soft starter controls and limits that peak current during startup, it flattens those spikes. This can lead to serious savings on your monthly energy bills, especially in facilities where motors are starting and stopping all day long.

Enhanced Operational and Process Control

A soft starter does more than just start a motor; it gives you a much finer degree of control over your process. A key feature you’ll find in many units is soft stop capability. This lets the motor ramp down in a controlled way instead of just coasting to a jarring halt.

This is a game-changer in a few key applications:

- Pumping Systems: A soft stop is the perfect solution for "water hammer." When a pump shuts off instantly, the abrupt stop in flow creates a hydraulic shockwave that can damage pipes, valves, and seals. Ramping the pump down gently makes this problem disappear.

- Conveyor Systems: A controlled stop prevents products from tipping over, shifting, or getting damaged, which means better product quality and less waste.

Decreased Maintenance and Unplanned Downtime

When you get right down to it, all these benefits point to one critical goal: keeping the plant running. By cutting down on both mechanical and electrical stress, a soft starter directly reduces how often equipment fails. That means fewer emergency repair calls, less time spent troubleshooting, and a massive reduction in the kind of unplanned downtime that kills profitability.

The numbers speak for themselves. Maintenance managers have seen motor failures drop by as much as 60% after implementing soft starts, saving millions in industries like oil and gas. The energy sector is also leaning in hard, using them to start up massive 10MW wind turbines without shocking the grid. For a deeper dive, you can read the full research about the soft starter market's growth. It’s clear a soft starter isn't just another component; it’s a smart investment in long-term reliability.

Choosing Between a Soft Starter and a VFD

When you're mapping out a motor control system, you'll inevitably hit a fork in the road. It’s a decision that trips up even seasoned engineers: should you go with a soft starter or its more sophisticated cousin, the Variable Frequency Drive (VFD)?

While they both manage how power gets to your motor, they play fundamentally different roles.

The choice really hinges on one simple question: do you need to control the motor’s speed during operation? Your answer to that single question will almost always point you straight to the most practical and cost-effective solution for your job.

Think of a soft starter as a specialist in one thing: managing the motor’s startup and shutdown. If your application just needs to run at one steady speed—like a simple conveyor belt or a pump maintaining a constant flow—a soft starter is nearly always the better, smarter choice. It gives you that smooth, controlled acceleration to protect your equipment and then gets out of the way.

A VFD, on the other hand, is a true speed control master. It does everything a soft starter can, but its real talent is letting you precisely adjust the motor’s speed at any point. This is non-negotiable for applications needing dynamic control, like an HVAC fan that has to vary its airflow or a pump that must maintain constant pressure as system demand fluctuates.

Core Functional Differences

The real divide is in what they do after the motor is running. A soft starter is a "start and stop" device. A VFD is a "start, stop, and run" device. Once the motor hits full speed, a soft starter with a bypass contactor basically becomes invisible to the circuit, letting the motor run at maximum efficiency.

A VFD is always in the loop. It’s constantly reshaping the AC power waveform to tell the motor exactly how fast to spin, whether that’s 10% or 100% of its rated RPM. This continuous command is what unlocks massive energy savings in variable-load scenarios. To really get a grip on the tech, you can dive deeper into our guide on variable frequency drive basics.

The simplest way to frame it is this: A soft starter is for applications that run at one speed. A VFD is for applications that need to run at multiple speeds. Using a VFD where a soft starter would do is often just burning money.

While a soft starter is focused on the launch sequence, VFDs are what make advanced applications like variable speed heat pumps possible, where adjusting motor speed is key to maximizing both comfort and energy savings.

A Head-to-Head Comparison

To make the right call, you need to weigh the factors that set these two technologies apart. Each has its place, and picking the wrong one can lead to wasted capital, unnecessary complexity, and a system that’s just not right for the task.

Here’s a practical breakdown to help guide your choice.

Decision Guide: Soft Starter vs. Variable Frequency Drive (VFD)

Choosing between a soft starter and a VFD isn’t just a technical decision; it's a financial and operational one. The right choice depends entirely on the demands of your application. This table breaks down the key differences to help you invest wisely.

| Criterion | Soft Starter | Variable Frequency Drive (VFD) |

|---|---|---|

| Primary Function | Smoothly starts and stops the motor at a fixed speed. | Starts, stops, and controls the motor's speed throughout operation. |

| Cost | Significantly lower initial cost, often 2 to 3 times less expensive. | Higher upfront investment due to more complex power electronics. |

| Physical Size | Compact and lightweight, requiring less panel space. | Larger and heavier, generating more heat that requires ventilation. |

| Energy Savings | Reduces peak demand charges during startup but offers minimal running savings. | Delivers substantial energy savings on variable-torque loads like pumps and fans. |

| Complexity | Simple to install, configure, and troubleshoot with fewer parameters. | More complex installation and programming, requiring specialized knowledge. |

Ultimately, if your only goal is a smooth, controlled start for a fixed-speed application, a soft starter is the clear winner. It delivers the crucial mechanical and electrical protection you need without the added cost and complexity of a VFD.

But if continuous speed control is a must-have for process optimization or energy efficiency, then a VFD is the only tool that will get the job done.

Where Soft Starters Make the Biggest Impact

This is where the rubber meets the road—or more accurately, where the theory of motor control hits the factory floor. In certain industrial applications, a soft starter isn't just a nice-to-have piece of kit. It's a critical component that protects expensive machinery, keeps processes stable, and prevents spectacular failures.

Let's look at a few real-world scenarios where a soft starter solves problems that a brute-force, direct-on-line start would create.

Imagine the massive forces at play in a municipal water treatment plant. When a huge pump motor slams on at full power, it sends a violent pressure wave—known as water hammer—ripping through the system. This hydraulic shockwave batters pipelines, stresses joints, and destroys valves, leading to premature failure of essential infrastructure.

A soft starter elegantly solves this. By gently ramping the pump up to speed, the water flow builds gradually and predictably.

This controlled acceleration completely neutralizes the hydraulic shock that causes water hammer. A properly configured soft start can eliminate 100% of these damaging effects, potentially saving a facility over $100,000 a year in pipeline repairs and component replacements.

Taming High-Inertia Loads

Now, picture the giant fans and blowers in an industrial HVAC system or the heavy drums in a rock crusher. These are high-inertia loads, meaning they put up a serious fight when you try to get them moving from a standstill. A direct-on-line start hits these systems with a brutal, instantaneous jolt of torque, triggering a whole host of mechanical issues.

- Belt Slippage and Wear: On belt-driven fans, that sudden torque makes belts squeal, slip, and stretch, dramatically shortening their lifespan.

- Mechanical Shock: The jarring start sends a shockwave through bearings, shafts, and motor windings, paving the way for early mechanical failure.

By applying torque smoothly, a soft starter lets these heavy systems overcome inertia without the damaging impact. Belts grip properly, and the mechanical load is applied in a controlled, manageable way. This principle is fundamental to the overall protection of motors in demanding jobs, extending the life of every connected component.

Protecting Products and Processes

In manufacturing and material handling, the game changes. Here, the focus shifts from protecting the equipment to protecting the product itself. A conveyor belt that lurches to life can topple fragile items like glass bottles, damage sensitive electronics, or knock products out of alignment for automated packaging. This leads to costly waste, production delays, and quality control headaches.

A soft starter delivers the smooth, jerk-free acceleration needed to gently move products down the line. It ensures the conveyor starts and stops predictably, preserving product integrity and keeping the whole production process flowing. That kind of finesse is simply impossible with a traditional motor starter.

How to Select and Integrate the Right Soft Starter

Picking the right soft starter isn’t just about grabbing a part off the shelf. It’s about designing a bulletproof system. If you get this step right, your motor is protected, and your operation hums along without a hitch. The whole process really boils down to knowing your motor and the job it’s been given.

First things first: you have to match the starter to your motor's specs. Don't eyeball it—the motor's nameplate is your source of truth. Find the Full Load Amps (FLA), which tells you exactly how much current the motor pulls when it’s working at its rated horsepower. Any soft starter you consider must be rated to handle that current, period.

But the FLA is just the starting line. You've got to think about the application's unique demands. A simple pump has a completely different personality at startup than a massive, high-inertia rock crusher.

Key Selection Criteria

Properly sizing a starter means looking past the motor's base rating. The kind of work it does is just as critical because that's what dictates the stress on both the motor and the starter during that all-important startup phase. If you overlook these details, you're just asking for an early failure.

A NEMA motor starter sizing chart is a great tool for this, giving you a solid framework for making these calls.

Here are the essential factors you absolutely have to consider:

- Application Type: Are you dealing with a high-inertia load like a huge ventilation fan, or is it a simple, low-inertia load like a centrifugal pump? Loads with high inertia need a beefier starter that can handle a longer, more demanding ramp-up time without breaking a sweat.

- Starting Duty Cycle: Think about how often the motor actually starts. A motor that fires up twice a day is a walk in the park compared to one that cycles ten times an hour. Those frequent starts build up a lot of heat in the starter's SCRs, so a higher duty cycle rating is a must.

- Required Features: Do you need a soft stop feature to prevent that nasty water hammer effect in a pump system? Or does this starter need to talk to the rest of your factory on an automation network? Keep an eye out for units with built-in perks like an internal bypass contactor (a huge plus for efficiency) and communication protocols like EtherNet/IP or Modbus for seamless integration.

Integration and Wiring Best Practices

Once you’ve got the right unit in hand, making it work reliably comes down to proper installation and protection. Remember, a soft starter is just one component in the motor circuit. It needs to be installed correctly inside a well-designed control panel to do its job.

A soft starter is not a substitute for overcurrent protection. You must have properly sized fuses or a circuit breaker installed upstream of the starter. This protects against short circuits and catastrophic failures, and it's a non-negotiable safety and code requirement.

The final piece of the puzzle is wiring the control logic. This is where you connect the start/stop signals from your control system—whether it’s a simple pushbutton on a panel door or a signal from a PLC—to the right terminals on the soft starter. Always, and I mean always, follow the manufacturer's wiring diagram down to the letter. It’s the only way to guarantee a safe and dependable setup.

Got Questions About Soft Starters? We've Got Answers.

Even after you get the basic idea of what a soft starter does, the practical questions always start popping up when it's time to actually put one into a system. Let's walk through some of the most common things people ask to clear up any confusion and help you make a smarter choice.

Getting these details right is more important than ever. The global market for soft starters is expected to climb to an impressive USD 15.92 billion by 2035, growing at a 9.89% CAGR. That boom is happening for a reason—modern industry needs smarter, more reliable motor control. You can dig into the market data over at Market Research Future.

Can a Soft Starter Really Save Me Money on Energy?

This is a big one, and the answer is yes, but with a catch. A soft starter's main energy-saving trick is to kill those massive inrush currents when a motor kicks on. By smoothing out that initial power draw, it keeps you from getting hit with painful peak demand charges from the utility company.

But what about when the motor is just humming along? That's where it gets different. Most good soft starters have a built-in bypass contactor, so they're incredibly efficient once the motor is up to speed. However, unlike a VFD, a soft starter can't adjust the motor's speed during operation to save energy. Think of it as a specialist for smooth takeoffs, not an all-day energy manager.

Do I Still Need an Overload Relay?

Absolutely, you do. It's not optional. While many modern soft starters come with some fancy built-in electronic overload protection, a separate overload relay is still a non-negotiable, and often legally required, piece of safety equipment.

Here's the key difference: a soft starter is focused on protecting the motor during the stress of startup. An overload relay's entire job is to watch for sustained overcurrents during normal operation—the kind that can slowly cook a motor from the inside out. You need both for complete protection.

How Does a Soft Stop Actually Work?

A soft stop is just what it sounds like: the startup process running in reverse. Instead of just cutting power and letting the motor coast to a jarring halt, the soft starter gradually ramps the voltage down. This gives you a controlled, gentle deceleration.

This feature is a lifesaver in a few key situations:

- Pumping Systems: It's the ultimate weapon against "water hammer"—that destructive hydraulic shockwave that can wreck pipes and valves when a pump stops suddenly.

- Conveyor Lines: It prevents products from tipping, jostling, or getting damaged from an abrupt stop. No more fallen boxes or shattered goods.

Can I Slap a Soft Starter on Any AC Motor?

Nope, definitely not. A soft starter is a specialized tool built for one primary job: starting standard three-phase AC induction motors. These are the rugged workhorses you find all over the industrial world.

They're generally not the right fit for single-phase motors or more exotic types like synchronous or wound-rotor motors. Always, always double-check that the motor is compatible before you even think about buying a soft starter.

At E & I Sales, we don't just ship boxes; we engineer complete solutions. From picking the perfect soft starter for your application to building it into a custom, UL-listed control panel, our team is here to make sure your motor control systems are reliable, compliant, and ready for whatever you throw at them. Let's get your next project moving with confidence. Explore our system integration and distribution services at eandisales.com.