Picture this: a fire breaks out in a massive warehouse. Instead of every sprinkler in the building drenching the entire facility, only the ones directly over the flames kick on. That’s Zone Selective Interlocking (ZSI) in a nutshell. It's a smart communication system between circuit breakers that pinpoints and isolates a problem with surgical precision.

This simple idea solves one of the biggest headaches in power system design.

Solving the Protection vs. Selectivity Puzzle

For years, electrical engineers have been stuck in a trade-off between protection speed and system reliability. To keep a small fault on a branch circuit from tripping the main breaker and killing power to everything—a practice called selective coordination—we've had to intentionally slow down our upstream breakers. We program in time delays to give the device closest to the fault the first chance to open.

It works, but it comes at a steep price. The longer that fault is allowed to cook, the more destructive energy it unleashes. This dramatically increases the danger of a catastrophic arc flash. So you're left with a terrible choice: accept a higher arc flash risk to keep the lights on, or sacrifice uptime for faster, safer fault clearing.

Zone Selective Interlocking completely rewrites the rules, getting rid of that compromise. It establishes a high-speed communication link between breakers.

With ZSI, the breaker closest to the fault still trips instantly. But at the same time, it sends a signal "upstream" to the other breakers telling them to hold off. That simple "wait" command prevents a cascading outage and keeps the problem contained to the smallest possible area.

How ZSI Gives You the Best of Both Worlds

By enabling this kind of intelligent, localized response, ZSI delivers both lightning-fast tripping and rock-solid coordination. In the real world, this translates to huge benefits:

- Massively Improved Safety: Clearing a fault in a few milliseconds instead of hundreds of them drastically cuts down the incident energy of an arc flash. This can be the difference between a minor event and a life-threatening one, often lowering the required level of Personal Protective Equipment (PPE).

- Maximum Uptime: Say goodbye to nuisance trips that take out an entire production line or data center floor. ZSI ensures only the single affected circuit goes down, which is a massive win for operational continuity.

- Less Equipment Damage: The faster you clear a fault, the less thermal and mechanical stress you put on your gear. That means less damage to cables, bus bars, and transformers, leading to faster repairs and lower replacement costs.

Essentially, ZSI transforms a rigid, pre-programmed protection scheme into a dynamic system that can think and react. It gives your power system the intelligence to know exactly where a fault is happening and to act only where needed. This capability has made ZSI a cornerstone technology for any modern industrial facility that values safety and reliability.

How Zone Selective Interlocking Actually Works

Let's stick with that fire sprinkler analogy. Now, imagine each sprinkler head couldn't just detect a fire, but could instantly text the main water valve: "Hold on, I see the flames here. I've got this." That’s pretty much the logic Zone Selective Interlocking (ZSI) brings to an electrical system.

At its heart, ZSI is a high-speed conversation between circuit breakers, all arranged in zones—from the main breaker all the way down to individual branch circuits. When a downstream breaker sees a fault, it doesn't just quietly prepare to trip. It simultaneously sends a tiny, instantaneous "blocking" signal to the breaker directly upstream.

This signal is a simple but powerful message: "I see the fault in my zone, and I am handling it." The local breaker then opens in milliseconds, clearing the fault with surgical precision. The upstream breaker, having received the signal, simply holds its position, maintaining its standard (and longer) time delay. It's now on standby, ready to act as a backup only if the first device fails to do its job.

The Communication Backbone

This intelligent conversation between breakers happens over dedicated wiring. The exact method really depends on the age and design of the switchgear you're looking at.

- Hardwired Pilot Wires: In a lot of traditional setups, this is handled by a simple pair of low-voltage wires running directly between the electronic trip units of the breakers. It’s a direct, no-fuss, and incredibly reliable connection.

- Internal Communication Buses: More modern "smart" switchgear often takes an integrated approach. Here, ZSI signals travel over an internal data bus—much like a small computer network—that connects all the breakers within the assembly.

This communication is the secret sauce. It’s what transforms a static, time-based protection scheme into a dynamic, responsive one.

The flowchart below shows just how simple and elegant this process is—a logical sequence that delivers both speed and selectivity.

Tracing the ZSI Signal Path

Let’s walk through a fault in a typical power distribution system to see ZSI in action. Imagine a dead short on a branch circuit feeding a large motor.

- Fault Detection: The branch circuit breaker (we'll call it Breaker C) immediately senses the massive rush of current.

- Signal Transmission: Instantly, Breaker C sends a "restrain" signal up to its feeder breaker (Breaker B). Breaker B gets the message and, in turn, passes a restrain signal up to the main (Breaker A).

- Localized Trip: With its upstream neighbors now waiting patiently, Breaker C trips almost instantaneously—typically within 50 milliseconds—and isolates the fault right where it happened.

- System Stability: Breakers A and B, having received their "hold" instructions, stay closed. Power to every other healthy circuit remains on, completely unaffected. That’s maximum uptime.

Now, what if Breaker C failed to trip for some reason? The restraining signal would stop. Breaker B would then see the fault, its own time delay would expire (say, at 200 milliseconds), and it would open as the next line of defense. This built-in backup function ensures the system stays protected, no matter what.

The "interlocking" logic is what makes the whole thing work so well. The upstream device’s action is literally locked based on the status of the downstream device. It’s a cooperative strategy that prevents cascading, widespread outages.

This coordination technique has been around for about four decades, but it really became a cornerstone of modern industrial safety as digital microprocessor breakers became the norm. Modern ZSI uses incredibly fast electronic signaling, which turns a traditional, slow time-graded system into something dynamic that dramatically cuts down on the thermal and mechanical stress equipment sees during a fault. For system designers, this means you can get incredible selectivity without having to compromise on speed or safety. You can learn more about how ZSI fits into modern power system studies on ETAP's product page.

Faster Tripping and Slashed Arc Flash Hazards

The engineering behind Zone Selective Interlocking is clever, but its real-world value is where things get exciting. It’s about safety and reliability. By turning a rigid, pre-programmed protection scheme into one that thinks and reacts, ZSI gets right to the heart of the biggest risks in power distribution.

The single most critical benefit? A massive reduction in arc flash energy.

The destructive force of an arc flash boils down to a simple formula: energy equals current squared times time (I²t). You can't change the massive fault current available from the utility, but you absolutely can control the time component. That's ZSI's superpower—it allows the breaker closest to the fault to open almost instantly, dramatically cutting down the time the arc can burn.

A Tale of Two Clearing Times

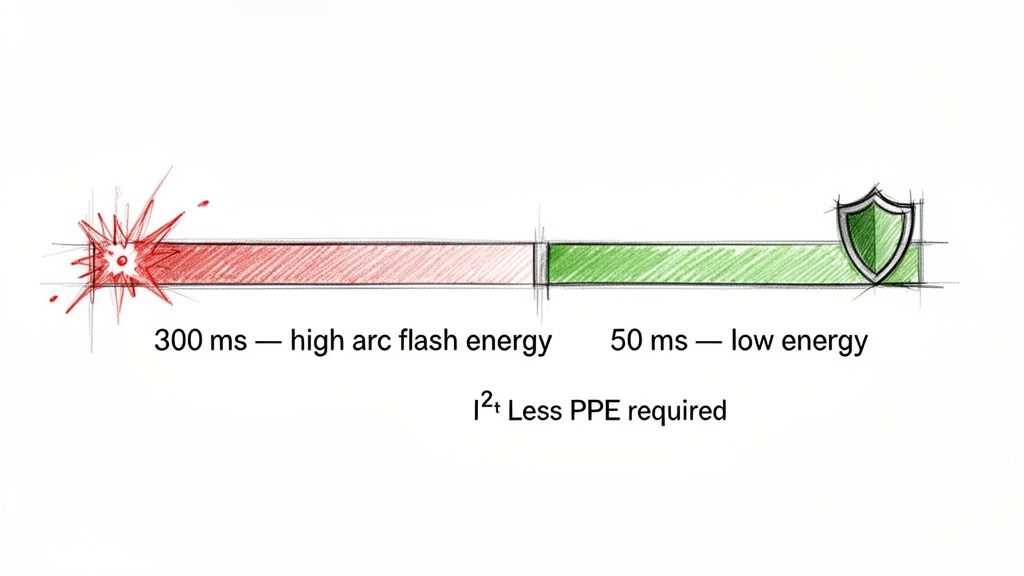

Let's put some numbers on it. Picture a fault deep within a system that relies on traditional time-delay coordination. To avoid a nuisance trip, the main upstream breaker is intentionally set to wait, maybe for 300 milliseconds. That’s a long time for thousands of amps to be wreaking havoc.

Now, let's run the same scenario with ZSI enabled. The local breaker sees the fault, instantly signals the upstream breaker to hold off, and clears the fault itself—all in about 50 milliseconds.

That 250-millisecond difference is everything. It's the gap between a contained event and a catastrophic explosion that destroys switchgear and puts lives at severe risk.

The table below breaks down just how significant this time reduction is. By slashing the clearing time, ZSI directly lowers the incident energy a worker could be exposed to.

ZSI Impact on Fault Clearing Time and Arc Flash Energy

| Scenario | Fault Location | Clearing Time (ms) | Incident Energy (cal/cm²) | Resulting PPE Category |

|---|---|---|---|---|

| Traditional Coordination | Motor Control Center Bus | 300 ms | 12.5 cal/cm² | Category 3 |

| With ZSI Enabled | Motor Control Center Bus | 50 ms | 2.1 cal/cm² | Category 1 |

As you can see, dropping the trip time from 300ms to 50ms can easily reduce the required PPE from heavy, cumbersome suits to much lighter gear, making work safer and more efficient.

Keeping the Lights On and the Business Running

Safety is priority one, but ZSI also delivers a huge boost to the bottom line by maximizing uptime. In a conventionally coordinated system, a fault on a single motor feeder might be just slow enough to trip the main breaker for the entire MCC. Suddenly, an entire production line grinds to a halt over a localized problem.

ZSI stops these cascading outages cold. It makes sure only the device right next to the fault opens, leaving the rest of the facility online and productive.

For any plant manager or facility operator, uptime is money. Zone Selective Interlocking is a direct investment in operational continuity, protecting your revenue-generating processes from unnecessary and costly shutdowns.

This kind of surgical precision is priceless in factories, data centers, and hospitals, where every second of downtime costs a fortune. It elevates your protection scheme from a blunt instrument to a finely-tuned tool. Of course, technology is only one piece of the puzzle. The best-designed system still needs people who know how to work safely, which is why comprehensive https://eandisales.com/uncategorized/arc-flash-safety-training/ is non-negotiable.

This double-win of world-class safety and bulletproof reliability makes zone selective interlocking a must-have for any modern power system. It's not just about ticking a box for code compliance—it's about building an operation that is fundamentally safer, more resilient, and more profitable.

Alright, let's take that section on designing a ZSI system and give it a more hands-on, expert feel. Moving from the theoretical "what is ZSI" to actually building one that works is where the rubber really meets the road.

Designing and Implementing a ZSI System

Moving from a drawing board concept to a real-world, reliable Zone Selective Interlocking system is all about sweating the details. It really boils down to three make-or-break pillars: picking the right hardware, getting the settings dialed in perfectly, and making sure the wiring is flawless. Get these right, and you've built a powerful safety net. Get them wrong, and you've just got a diagram and a false sense of security.

The whole thing starts with the protective devices themselves. You can't just grab any old breaker off the shelf; they need to be built for this. Specifically, their electronic trip units must have the dedicated input and output terminals to send and receive those critical "hold off" signals.

Selecting Compatible Hardware

When you're putting together a bill of materials, you have to be certain that every device in the chain—from the main service entrance down to the feeder breakers—can speak the same ZSI language.

- Breaker and Relay Compatibility: Make sure every single breaker and protective relay you specify is ZSI-enabled. It's sometimes possible to mix and match brands, but that means you'll be spending a lot of time buried in technical manuals to confirm they'll actually talk to each other. For anything complex, sticking with a single manufacturer's product family is often the path of least resistance.

- Trip Unit Smarts: The electronic trip unit is the brain of this whole operation. You need to confirm it allows you to adjust the short-time pickup (Isd) and, most importantly, the short-time delay (tsd). These are the very settings ZSI manipulates.

- Zone Limits: Dig into the manufacturer's spec sheets to see how many ZSI zones a single breaker can handle. Trying to make a device manage more zones than it was designed for is a recipe for unreliable performance.

If you're looking to spec a new system or upgrade an old one, it’s always a good idea to see what the established brands are offering. You can get a good sense of modern capabilities by checking out guides on specific gear, like a detailed overview of an ABB circuit breaker.

Configuring Settings and Coordination

With your hardware picked out, the real engineering begins: programming the settings. This is driven by a coordination study, and your Time-Current Curves (TCCs) are your best friend here. TCCs let you see exactly how your breakers will behave and interact when a fault hits.

The trick is to set up your short-time delays for proper coordination as if ZSI didn't exist. Think of it as your failsafe. For instance, a downstream breaker might get a 100 ms delay, while its upstream parent gets a 300 ms delay. With ZSI active, the system bypasses that built-in delay for the breaker closest to the fault, letting it trip in, say, 50 ms, while telling the upstream breaker to hold back.

A core philosophy in ZSI design is to first build a solid, traditional time-based coordination scheme. ZSI then acts as an intelligent accelerator, giving you incredible speed without sacrificing the fundamental backup protection of your staggered delay settings.

Critical Wiring and Verification

The physical wires connecting your devices are the nervous system of your ZSI scheme. The best breakers and the most brilliant settings mean absolutely nothing if the signal can't get through cleanly. Honestly, this is where most implementations go sideways.

Key Wiring Considerations:

- Dedicated Cabling: ZSI signals need their own dedicated, twisted-pair shielded wire. This is non-negotiable. You have to shield the signal from the electrical noise and interference blasting off nearby power cables, which could easily corrupt it.

- Correct Polarity: The ZSI input and output terminals are polarized. Getting them backward is a classic, easy-to-make mistake that completely defeats the system because the restraining signal will never be recognized. Double- and triple-check the polarity against the manufacturer's diagrams.

- Current Transformer (CT) Selection: The breaker's trip unit is only as smart as the information it receives. That information comes from the CTs. Make sure your CTs are sized correctly for both the normal load and the potential fault currents. And just like the signal wires, their polarity has to be right, or the breaker could completely misinterpret what's happening during a fault.

By locking down these three areas—hardware, settings, and wiring—you can build a Zone Selective Interlocking system that you can truly count on. It’s this disciplined approach that ensures the system will do its job when the worst happens, protecting both people and equipment.

Testing and Troubleshooting Your ZSI Scheme

A perfectly designed Zone Selective Interlocking scheme on paper means nothing until it's proven in the field. Commissioning and testing aren't just a final checkbox; they are the critical steps that turn a safety blueprint into a real-world, reliable asset. This is where you validate that every wire, setting, and signal will do its job when a fault finally happens.

Think of it like inspecting a parachute. You trust the engineering, but you still meticulously check every strap and cord before the jump. For ZSI, this means running through static checks before power-up and then dynamic functional tests to confirm the whole system talks to each other correctly. Cutting corners here is simply not an option.

Pre-Energization Checks and Verification

Before you even think about energizing the system, a few methodical checks can catch over 90% of the most common installation mistakes. These are the basics, but getting them right prevents a world of headaches later.

- Wiring Continuity and Polarity: This is ground zero for ZSI issues. Grab a multimeter and verify point-to-point continuity on all ZSI control wiring. More importantly, double-check the polarity of the ZSI input and output terminals against the manufacturer's drawings. Reversed polarity is an incredibly easy mistake to make, and it completely disables the interlocking logic.

- Settings Verification: Get the coordination study in hand and physically walk down every breaker. You need to verify that the short-time pickup and delay settings on each trip unit match the engineered values to the letter. A single digit off can throw the entire coordination scheme out the window.

- Insulation Resistance Testing: A quick "Megger" test on the ZSI control wiring is a must. This will tell you if there are any nicks or breaks in the insulation that could cause shorts or grounds, leading to phantom signals or a complete loss of communication.

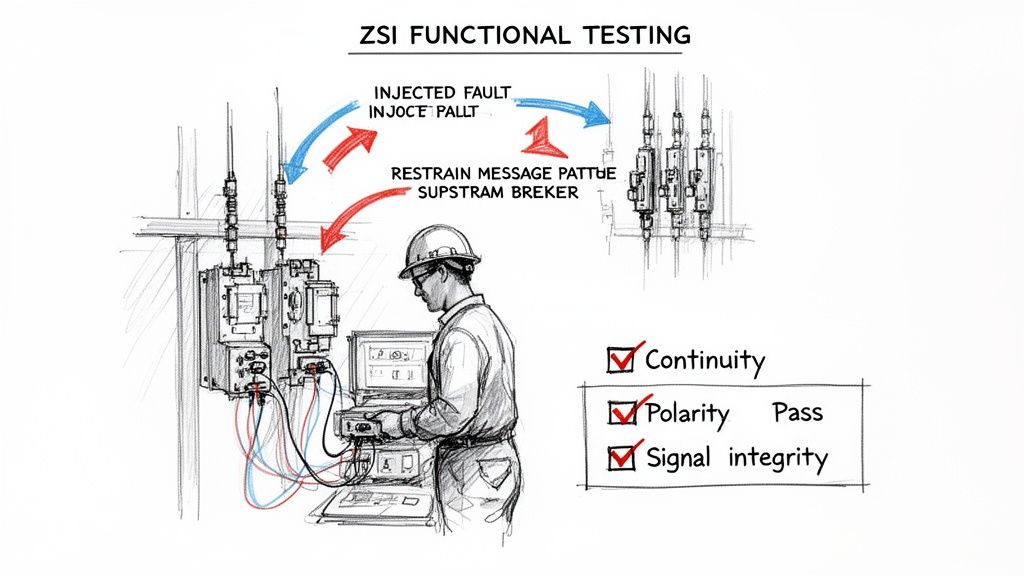

Functional Testing with Injection Sets

Once the static checks are done, it's time to make the system prove itself. We do this safely with a secondary current injection test set. This nifty tool essentially tricks the breaker's brain into thinking it sees a massive fault current, all without putting the actual power system at risk.

The whole point here is to trace the "restraining" signal's journey from start to finish. You'll inject a simulated fault current into a downstream breaker and watch for two things:

- The downstream breaker trips instantly (or on its own short-time setting), just as it should.

- The upstream breaker gets the restraining signal and successfully holds for its full coordinated time delay, proving the ZSI logic is working.

This functional test is the moment of truth. It goes beyond checking individual components and confirms that the entire ZSI system—breakers, wiring, and settings—operates as one cohesive, intelligent unit.

Common Troubleshooting Scenarios

Even the most carefully planned installations can hit a snag. When a functional test doesn't go as expected, the problem almost always boils down to just a handful of common issues. A methodical approach is your best friend here. If you need a refresher on the basics, understanding what can cause a breaker to trip provides some great foundational context.

To help you get straight to the root cause, here’s a quick-hit checklist for troubleshooting common ZSI symptoms.

Common ZSI Troubleshooting Checklist

| Symptom | Potential Cause | Diagnostic Step | Solution |

|---|---|---|---|

| Upstream breaker trips instantly (doesn't hold) | Lost restraining signal due to wiring issue | Verify continuity and polarity of ZSI control wiring between the downstream and upstream breakers. | Correct wiring error (e.g., re-land terminated wire, fix reversed polarity). |

| Upstream breaker trips instantly (doesn't hold) | Incorrect settings on the upstream breaker | Physically verify the ZSI function is enabled and the short-time delay is set per the coordination study. | Adjust trip unit settings to match the engineered values. |

| Upstream breaker holds, but downstream breaker doesn't trip | Test current is below downstream breaker's pickup setting | Confirm the injected current from the test set is high enough to exceed the downstream breaker's short-time or instantaneous pickup threshold. | Increase the injected test current to the proper level. |

| All breakers trip simultaneously (no selectivity) | ZSI function is disabled on all breakers | Check the trip unit settings on each breaker involved in the scheme to ensure ZSI is turned on. | Enable the ZSI feature in the trip unit's programming menu. |

| Intermittent or unreliable restraining | Damaged control wiring or loose connection | Perform an insulation resistance test (Megger) on the ZSI wiring and physically inspect all terminal block connections for tightness. | Replace damaged wiring or re-torque loose terminal screws. |

If an upstream breaker is tripping too fast, it's a clear sign the restraining signal isn't getting through. Start with the simplest and most likely culprits—the wiring—before you start digging into more complex device settings. This structured approach will save you time and lead to a more reliable fix every time.

ZSI on the Factory Floor: Real-World Applications

Theory is one thing, but putting it to work on the factory floor is where Zone Selective Interlocking (ZSI) really shines. It's a clever concept, for sure, but its real power is in solving tangible safety and uptime problems, especially in the systems that drive heavy industrial machinery.

You see this most clearly in Motor Control Centers (MCCs). Think of an MCC as the nerve center for an entire production line. A single fault on one motor feeder can easily bring everything to a grinding halt. Let's walk through a common scenario: a manufacturing plant is installing a brand new, UL-listed 480V MCC.

Without ZSI, if a big motor feeder shorts out, the main breaker for the whole MCC has to sit and wait. It's programmed with a long delay to try and coordinate with the downstream breakers. That delay might stop the whole plant from going dark, but it also allows a huge amount of dangerous arc flash energy to build up, often forcing anyone nearby into bulky Category 3 or 4 PPE.

A Case Study in Smarter Safety and Uptime

Now, let's say the engineers on this project decided to implement ZSI in their new MCC. This simple decision completely changes the outcome.

When a fault happens on a motor starter, the feeder breaker trips almost instantly—we're talking under 50 milliseconds. At the exact same moment, it fires a restraining signal up to the main MCC breaker, telling it, "Stand down, I've got this."

The result? A massive reduction in incident energy on the main bus. The arc flash danger is completely contained to the specific faulted bucket. The calculated energy level plummets, often making it safe enough for technicians to work with much less restrictive PPE. It’s a win-win: safety gets a huge boost, and you avoid tripping the entire MCC offline for a localized problem.

This kind of intelligent protection goes hand-in-hand with a facility's overall safety strategy, complementing things like comprehensive industrial site security measures.

This shift from a slow, time-based coordination scheme to a fast, communication-based one isn't just an abstract concept. It's a practical, real-world solution that proves ZSI is a critical tool for modern industrial safety and reliability.

Taming Those Big Motor Inrush Currents

Here’s another place ZSI is a game-changer: dealing with large motors. When a big motor kicks on, the massive inrush current it draws can look a lot like a short circuit to a standard breaker, causing nuisance trips. To get around this, engineers sometimes have to dial back the protection settings to let the motor get through its startup phase, which unfortunately compromises safety.

ZSI provides a much more elegant answer. You can tune the system to intelligently ignore the predictable, brief surge of an inrush current but still react instantaneously to a genuine short circuit. This gives you bulletproof protection when the motor is most vulnerable, all without the headache of costly false trips that shut down production.

Even after getting the hang of Zone Selective Interlocking, you're bound to have some practical questions when it's time to put it to work. We see it all the time—engineers, maintenance managers, and facility operators need to balance the big safety wins with the real-world headaches of getting it done.

This section cuts straight to the chase, answering the most common questions we hear about cost, compatibility, and what happens when things go wrong. Let's clear up any confusion so you can feel confident about using ZSI to make your electrical system safer and more reliable.

Can I Retrofit ZSI Into My Existing Switchgear?

That’s the million-dollar question, isn't it? The answer is a solid "it depends." Retrofitting zone selective interlocking is definitely possible, but it all comes down to what kind of circuit breakers you're working with. The one non-negotiable is that your breakers need electronic trip units with dedicated ZSI input and output terminals.

If your switchgear is packed with old-school thermal-magnetic breakers or even basic electronic ones, this isn't a simple wiring project. You’d be looking at a full-blown replacement of the breakers with modern, ZSI-ready models. But if your gear already has compatible breakers, just adding the control wiring is a relatively simple upgrade that delivers a huge jump in safety.

What Happens If a ZSI Signal Wire Fails?

This is one of the most important things to understand from a safety perspective. Any properly designed ZSI system is built to be fail-safe. If a signal wire gets cut, comes loose, or shorts out, that communication link between breakers is broken. When that happens, your system doesn't just go dark—it automatically reverts to its standard, time-delayed coordination.

The upstream breaker simply never gets the "hold off" signal from the downstream device that saw the fault. So, it does what it's programmed to do: it trips based on its own short-time delay settings, ensuring you still have reliable backup protection. The system defaults to being slower, but it never defaults to being unsafe.

This built-in safety net means a simple wiring problem won't leave your people or equipment exposed. The worst-case scenario is that you lose the speed of ZSI, not the protection itself.

How Does ZSI Compare to Other Arc Flash Methods?

ZSI is a fantastic tool, but it's just one tool in the arc flash mitigation kit. It’s important to know where it shines compared to the other options out there.

- Arc-Resistant Switchgear: Think of this as a brute-force solution. It’s designed to physically contain and redirect the explosive energy of an arc blast. It's incredibly effective at protecting people standing in front of the gear, but it's a major capital investment and does nothing to reduce the actual incident energy.

- Maintenance Mode Switches: These are temporary overrides that let a technician manually set a breaker to trip faster while they work. They work well, but they are 100% dependent on someone remembering to flip the switch on and off. Human error is a real risk.

- Optical Arc Detection Systems: Using light sensors, these systems can spot an arc flash and send a trip signal in just a few milliseconds. They are the absolute fastest solution available, but they are also the most complex and expensive to install.

Zone selective interlocking hits that sweet spot right in the middle. It's an active, full-time system that slashes incident energy without the high cost and complexity of optical systems, making it one of the most practical and cost-effective arc flash reduction strategies you can implement.

At E & I Sales, we live and breathe this stuff. We design and build custom UL-listed control panels and motor control centers with advanced protection like ZSI baked in from day one. We’re here to help you sort through the technical details and make sure your systems are safe, dependable, and up to code. Ready to talk about your next project? Contact us today and see what our expertise can do for you.