Let's be blunt—an arc flash isn't just a spark. It's a violent, catastrophic failure with devastating human and financial costs. A structured arc flash safety training program isn't just about checking a compliance box; it’s about building a safety culture that actively prevents injuries, sidesteps crippling fines, and protects your entire operation.

Why a Proactive Safety Culture Is Non-Negotiable

It’s easy to get lost in the textbook definitions, but the reality is much harsher. An arc flash is a brutal explosion of energy, capable of reaching temperatures hotter than the surface of the sun in a split second. The consequences are immediate and often horrific. That’s why a rock-solid safety program is an absolute necessity, not an optional line item in the budget.

The numbers don't lie. We see roughly 30,000 arc flash incidents in the U.S. every single year. These aren't minor events; they lead to around 7,000 burn injuries, 2,000 hospitalizations, and 400 fatalities annually. As these arc flash accident statistics from AllumiaX show, electrical hazards are a constant, lurking threat in any industrial setting.

The Real Price of an Incident

When an arc flash happens, the fallout goes way beyond the initial medical response. The financial gut punch to a business can be staggering, hitting you from all sides with both direct and indirect costs.

- Hefty OSHA Fines: We're not talking about a slap on the wrist. Non-compliance penalties can easily soar into the hundreds of thousands of dollars.

- Crushing Medical Bills: Treating severe, life-altering burns is incredibly expensive, often running into the millions for just one person.

- Destroyed Equipment: That explosive force can obliterate expensive switchgear, control panels, and other vital infrastructure in an instant.

- Crippling Downtime: While you’re dealing with the investigation and repairs, production grinds to a halt, and every minute is lost revenue.

A proactive safety culture, anchored by consistent and effective training, is your best—and really, your only—defense. It’s about shifting the entire company mindset from reactive damage control to proactive, intelligent prevention.

A truly effective safety culture is one where every employee, from the shop floor to the C-suite, understands not just what they need to do, but why it's so critical. It’s the difference between a checklist mentality and a shared commitment to keeping everyone safe.

The Core of an Effective Program

Building this kind of culture isn't magic; it's a structured approach. To get there, you need to focus on a few key pillars that work together. A great safety program isn't just one thing, but a combination of interlocking components.

Let's break down what that looks like.

Core Components of an Effective Arc Flash Safety Program

| Pillar | Objective | Key Activities |

|---|---|---|

| Realistic Risk Assessment | Identify and quantify hazards. | Incident energy analysis, defining arc flash boundaries, proper equipment labeling. |

| Clear Safety Procedures | Create unambiguous, actionable rules. | Lockout/Tagout (LOTO), energized work permits, proper tool selection and use. |

| Ongoing Education & Training | Ensure knowledge is current and practical. | Hands-on drills, regular refreshers, competency checks, PPE demonstrations. |

This table provides a high-level view, but the real work is in the details and the commitment to consistency.

A one-and-done training session just won't cut it. Real safety comes from continuous education that keeps knowledge fresh and skills sharp, especially as standards or equipment change. A smart move is to weave this training into your regular operations. For instance, you can formalize your commitment by integrating safety checks and training reminders right into a preventive maintenance schedule template.

Ultimately, putting money and effort into a comprehensive arc flash safety program is a direct investment in your people, your productivity, and your company's long-term health. It shows you're serious about safety as a core value, not just an obligation.

Getting to Grips with the Rules and Standards

When you first dive into electrical safety, the acronyms can feel like alphabet soup. OSHA, NFPA, NEC… what does it all mean? These aren't just bureaucratic hurdles; they're the bedrock of any serious arc flash safety training program. Understanding them is what keeps people from getting hurt.

The two big players you absolutely have to know are OSHA (Occupational Safety and Health Administration) and NFPA (National Fire Protection Association).

Think of it like this: OSHA writes the law. They set the legal requirement—the "what"—for providing a safe workplace. NFPA, especially through its NFPA 70E standard, gives you the "how." It's the industry's consensus on the best practices to actually achieve that safety.

An OSHA inspector won't write you a ticket for an NFPA 70E violation directly. But they will cite you under their General Duty Clause for failing to protect employees from known hazards. And guess what they use as the yardstick for what's considered "safe"? You guessed it: NFPA 70E.

Putting the Core Concepts to Work

To make these standards work on the plant floor, you need to speak the language. The regulations are built on a few critical ideas that have to be baked into your training and your everyday work.

-

Qualified Person: This isn't just a job title. A "qualified person" is someone who has been specifically trained on the equipment, its operation, and the hazards involved. Crucially, they have to demonstrate they have the skills to work safely near live parts.

-

Arc Flash Boundary: This is a non-negotiable safety perimeter. Inside this boundary, an unprotected worker could get a second-degree burn if an arc flash kicks off. Your training has to hammer this home: crossing that line without the right PPE is a hard stop. No exceptions.

-

Incident Energy: This is the raw power of an arc flash, measured in calories per square centimeter (cal/cm²). It's the amount of heat your body would take at a set distance. That number, right there on your equipment labels, tells you exactly what level of arc-rated PPE is required to do the job.

I remember a case at a facility where an experienced electrician—a great mechanic, but not formally "qualified" by OSHA's definition—was troubleshooting a 480V panel. He triggered an arc flash and got badly burned because he wasn't wearing PPE rated for the calculated incident energy. The investigation found that his training was never documented and the arc flash boundary was ignored. It was a painful, expensive lesson in why these definitions matter.

The standards aren't just rules to memorize; they are life-saving tools. When your team understands that 'incident energy' isn't an abstract number but a direct measure of potential harm, their entire approach to safety changes.

The Big Picture: Global Standards and Why They Matter

This focus on rock-solid training isn't just a U.S. thing. The global market for arc flash protection is driven by these kinds of regulatory frameworks. North America was the biggest market in 2023, mostly because of strict standards from agencies like OSHA and Canada's CSA that demand comprehensive safety programs, including worker training. You can dig into the numbers yourself and check out these arc flash protection market trends from Grand View Research.

This worldwide push proves a simple truth: strong standards and consistent enforcement create demand for better equipment and more thorough training. It also circles back to how your facility's systems are designed in the first place. For instance, a smart industrial control panel design can engineer out some of the arc flash risks from the get-go, making it much easier to stay compliant and keep everyone safe.

At the end of the day, truly understanding these regulations turns your safety program from a chore into a strategy. It gives your team the power to not just follow rules, but to take ownership of their safety because they get the physics and the real-world risks behind every single task. That knowledge is the real foundation of a safety culture that actually works.

Mastering Arc Flash Risk Assessments and Labeling

Think of an arc flash risk assessment as the foundation of your entire electrical safety program. This isn't just about checking a box on a compliance form; it's the detailed engineering study that turns abstract electrical hazards into concrete, life-saving information for your team on the floor. It’s what quantifies the specific dangers lurking inside every panel and piece of equipment.

To do this right, you have to conduct a meticulous data collection process—basically an electrical census of your entire facility. Engineers need to dig into the details of every component, from the main utility feed all the way down to the individual circuit breakers. This means gathering precise data on fault current levels, conductor sizes and lengths, and, most importantly, the trip times of all your protective devices.

In-House Team Versus Third-Party Experts

So, who tackles this critical analysis? That's one of the first big decisions you'll make.

You might be tempted to use your in-house engineering team to save some money, but it's often not that simple. These studies require highly specialized software and a deep, nuanced understanding of standards that can be a real hurdle for a team that doesn't live and breathe this stuff every day.

This is where third-party engineering firms really shine. They perform these studies day in and day out, bringing an unbiased, expert perspective to the table. They’ve seen it all across countless facilities and can often spot potential issues your internal team might miss. Their entire focus is on the accuracy and compliance of the study, making sure it aligns perfectly with NFPA 70E and OSHA. That independent verification is worth its weight in gold, especially if an auditor comes knocking.

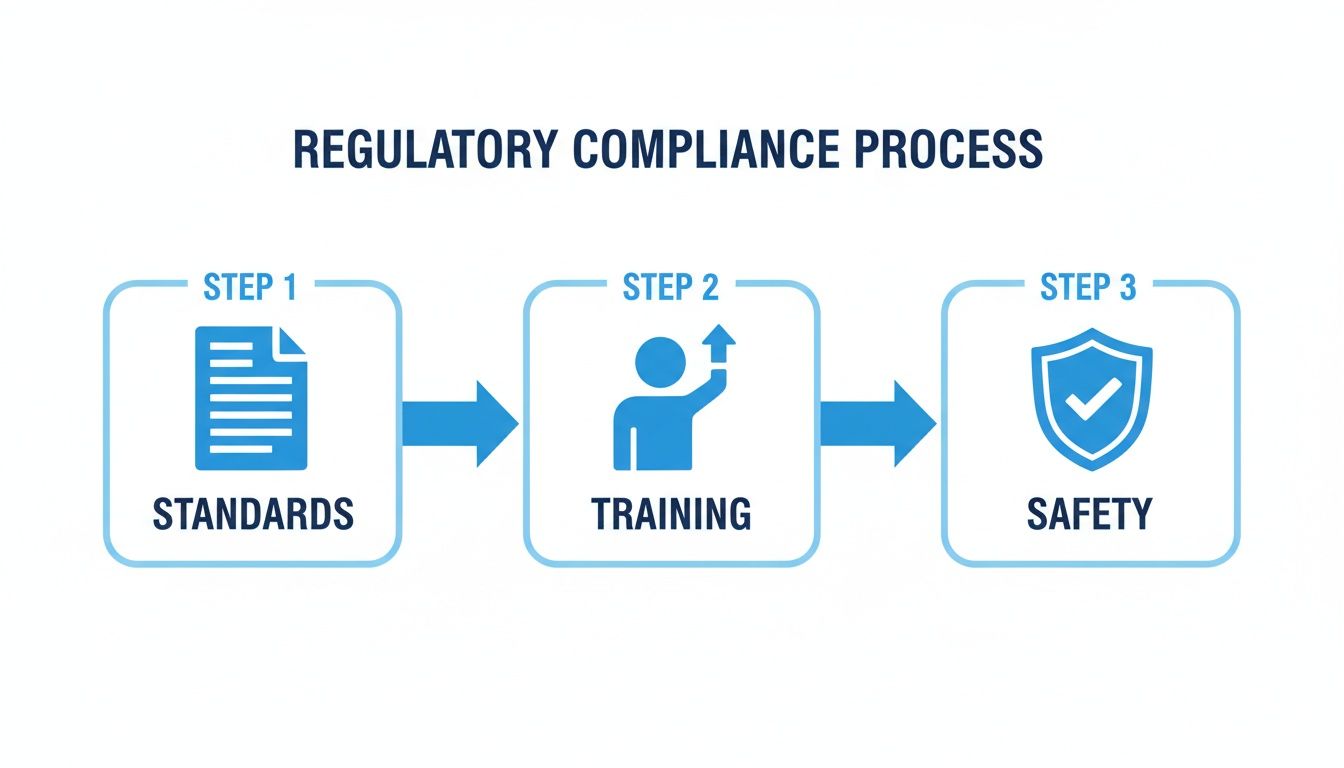

Getting this right involves a clear path: you start with the standards, build out your training based on them, and then you achieve a true state of operational safety.

This visual really drives home how each step builds on the last. You can't have real safety without proper training, and you can't have proper training without first understanding the standards. It's a chain of compliance you can't break.

From Technical Data to Actionable Labels

All that complex engineering work boils down to one thing: the arc flash label. This is arguably the most important piece of safety communication you can have on your plant floor. It’s not just a warning sticker; it's a data-driven instruction manual for anyone interacting with that equipment. A solid arc flash safety training program has to teach every qualified worker how to read, understand, and act on these labels in a split second.

A compliant label needs to spell out a few critical pieces of information:

- Incident Energy: This is the big one, shown in cal/cm². It tells you the minimum Arc Thermal Performance Value (ATPV) your PPE needs. If the label says 8.5 cal/cm², your gear better be rated higher than that.

- Arc Flash Boundary: This is the "stay-out" zone. It’s the closest an unprotected worker can get before risking a second-degree burn. No one crosses that line without the right PPE on.

- Required PPE Category: While modern labels often list specific gear, you'll still see the category method (1, 2, 3, or 4). Each number corresponds to a pre-defined kit of protective clothing and equipment.

- Shock Risk Information: This includes the nominal system voltage and the approach boundaries (limited and restricted), which are absolutely critical for preventing shock.

The arc flash label is the final translation of complex engineering into a simple, non-negotiable set of instructions. When a worker sees that label, they should know in seconds exactly what it takes to work on that piece of equipment without getting hurt.

Let’s make this real. Say you have a 480V motor control center with a label showing 12 cal/cm² incident energy and a 48-inch arc flash boundary. A properly trained employee knows instantly they need, at minimum, a 12-cal arc-rated suit, balaclava, and gloves before they can even think about crossing that four-foot perimeter. It completely removes the guesswork.

When you're sourcing PPE based on these assessments, you have to consider every single component. Even smaller items, like a Leather Cut Resistant Driver Glove With Arc Flash Rating, must meet the required protection levels.

All this label data comes from analyzing how your protective devices will operate during a fault. The faster a circuit breaker clears the fault, the lower the incident energy. That's why understanding the specific performance of your components is so vital. Knowing the details of an ABB circuit breaker, for instance, is just as important for the engineers running the study as it is for the technicians who maintain it.

Designing a Training Curriculum That Sticks

Let's be honest. A stale PowerPoint presentation and a box of donuts isn't an arc flash safety program. To really protect your team, you need a curriculum that builds active, life-saving skills—not one that just encourages passive listening. The end goal is to create muscle memory, making safe practices an automatic reflex, not just another item on a checklist.

A truly effective program is built from the ground up. It starts with the basics and layers on more complex, hands-on tasks. It's all about making sure every "qualified" worker understands the why behind the what, turning compliance rules into ingrained, safe work habits.

Foundational Knowledge Modules

Before anyone even thinks about touching a tool, they need a healthy respect for the invisible dangers they face. Your training has to start by demystifying the physics of electrical hazards in a way that actually connects with your team. This isn't about memorizing complex formulas; it's about building a deep-seated respect for the energy they work with every single day.

Your core modules have to cover these non-negotiables:

- The Physics of Shock and Arc Flash: Clearly explain how a shock occurs—the path current takes through the body—and just how little amperage it takes to be fatal. For arc flash, break down the violent chain reaction: the short circuit through the air, the intense heat, the pressure wave, the molten shrapnel, and the blinding light.

- Decoding Regulations and Labels: This is where the classroom meets the plant floor. Your team needs to know exactly how to read and interpret the arc flash labels on your equipment. They must understand what incident energy, boundaries, and specific PPE requirements mean for them right at that spot.

- Recognizing Hazard Conditions: You need to train your team to be vigilant detectives. Teach them how to spot abnormal equipment conditions—subtle signs of arcing, overheating, corrosion, or physical damage—that can dramatically increase the risk of an incident.

Hands-On Skills and Practical Application

This is where the rubber really meets the road. Reading about safety is one thing, but practicing it is something else entirely. Interactive, hands-on sessions are absolutely essential for building the confidence and skills needed to work safely when the pressure is on.

Your curriculum has to include practical components. A fantastic example is a Lockout/Tagout (LOTO) simulation. Don't just show a slide; set up a training board with actual disconnects, breakers, and valves. Have your employees physically walk through the entire process of isolating, locking, and verifying a zero-energy state. This muscle memory is infinitely more valuable than just reading a procedure.

Another crucial hands-on session is PPE selection, inspection, and use. Get the gear out and have them practice:

- Donning and Doffing: Walk them through the correct sequence for putting on and taking off a full arc flash suit, stressing how to avoid cross-contamination.

- Glove Inspection: Teach them the proper technique for visually inspecting and air-testing their rubber insulating gloves before every single use.

- Tool Selection: Show them the physical difference between standard and correctly rated insulated tools. Explain why that distinction is a matter of life and death.

A worker who has physically practiced the LOTO sequence and inflated their own gloves to check for pinholes is infinitely better prepared than one who has only watched a video. These hands-on drills are where safety theory becomes lifesaving reality.

Verifying a De-Energized State

If there's one skill that is the absolute most critical in any arc flash training program, it's learning how to properly use test instruments to verify an electrically safe work condition. This isn't a single step; it's a multi-step process that must be taught, demonstrated, and drilled until it's second nature.

The mantra is simple: Live-Dead-Live.

- First, test your multimeter on a known live source to make sure it's working.

- Second, test the target circuit phase-to-phase and phase-to-ground to verify zero voltage.

- Finally, test your meter again on that same known live source to confirm it didn't fail mid-test.

This three-step procedure removes all doubt. It is the final, definitive confirmation that a circuit is safe to touch. Skipping any part of this sequence introduces a lethal amount of risk.

We know that improving these training programs relies on good data, but that data is often incomplete. Research from Johns Hopkins University highlighted a major gap between reported and actual electrical incidents. This underreporting makes it harder to refine safety protocols, underscoring the need for better data collection to create more effective training.

Making sure your team is ready for any electrical hazard means going beyond the basics. Comprehensive essential electrical safety training reinforces these crucial, hands-on verification techniques. A curriculum that sticks is one that creates a team that doesn't just know the rules, but has the practical skills to apply them every single day.

Keeping Your Safety Program Effective and Audit-Ready

Getting your arc flash safety training program off the ground is a major accomplishment. But the real work—the part that builds a lasting safety culture—starts the moment that first training session ends.

A program that’s just a binder on a shelf is useless when sparks fly, and it will absolutely fall apart under the microscope of an audit. We need to move away from a "one-and-done" mindset. Instead, think of it as a continuous cycle of reinforcement, skill verification, and obsessive record-keeping. This is about creating a living, breathing program that evolves with new standards, equipment changes, and your workforce.

Proving Competency Beyond the Classroom

So, did the training actually stick? You can't just assume that because someone sat through a PowerPoint, they absorbed the critical, life-saving details. You have to prove it.

A written exam is a decent first step. It’s great for checking their grasp of concepts like arc flash boundaries, incident energy, and the theory behind establishing an electrically safe work condition. But that only tells you what they know, not what they can do.

That’s where hands-on skill demonstrations are absolutely non-negotiable.

- LOTO in Action: Can the employee walk up to a piece of machinery, correctly identify every single energy source, and properly apply their lock and tag?

- Glove Inspection: Hand them a pair of rubber insulating gloves and ask for a pre-use inspection. Are they doing a proper air test? Can they spot the subtle signs of ozone damage, cuts, or pinholes?

- The Live-Dead-Live Test: On a training panel, can they flawlessly execute the three-point check with a voltmeter to verify de-energization? This isn't just a step; it's a life-saving ritual.

This is the only way to be certain that head knowledge has become muscle memory.

Maintaining Defensible Documentation

Let's be blunt: in the eyes of an OSHA auditor, if you didn't document it, it never happened. Your records need to be clean, organized, and immediately accessible. A dusty sign-in sheet from a training three years ago isn't going to cut it. Your paperwork is your first and best line of defense.

For every qualified person on your team, you need an audit-ready file containing:

- Training History: Dates, course topics covered, and the instructor's name.

- Competency Proof: The actual written tests (with scores!) and the signed-off checklists from their hands-on skill demos.

- Official Authorization: A formal document, signed by a manager, that officially designates them as a "qualified person" for specific electrical tasks.

An organized documentation system is more than just busy work; it's a clear, defensible narrative of your company's ongoing commitment to safety. It proves you not only train your people but also verify their skills and authorize their work responsibly.

The Critical Retraining Cycle

NFPA 70E is very clear on this: retraining on safe work practices must happen at intervals not to exceed three years. That’s not a random number. It’s a built-in recognition that skills get rusty, knowledge fades, and bad habits creep in.

Think about how much can change in three years—new equipment, updated standards, maybe even a few close calls. This refresher is your chance to close any gaps that have appeared. It's also the perfect opportunity to review recent near-misses (anonymously, of course) to drive the lessons home with real-world examples from your own facility.

Don't wait until the last minute. Get this on the calendar and into the budget now. A proactive refresh cycle ensures your arc flash safety training remains a dynamic part of your culture, not a forgotten event. This continuous loop—train, assess, document, repeat—is what keeps your people safe and your program ready for any scrutiny.

Common Questions About Arc Flash Training

Even with a solid plan, a few questions always seem to come up when you're dialing in an arc flash safety training program. We hear these all the time from safety managers and facility engineers. Here are the most common ones, with some practical answers to get you on the right track.

Who Really Needs This Training?

The short answer? Anyone who could be exposed to an electrical hazard. But it's not a one-size-fits-all deal. The kind of training they need depends entirely on what they do day-to-day.

OSHA and NFPA 70E split this into two clear groups:

-

Unqualified Persons: Think machine operators or janitorial staff. These folks work near electrical gear but not on it. Their training is all about hazard recognition—knowing what an arc flash label means, what the approach boundaries are, and who to call if something goes wrong. It's about empowering them to stay out of harm's way.

-

Qualified Persons: These are your electricians, maintenance techs, and engineers—the people diagnosing, troubleshooting, or working on equipment. Their training has to be deep and comprehensive, covering everything from risk assessment and LOTO to picking the right PPE and performing live-dead-live tests. They must be able to prove they have the hands-on skills to do the job safely.

What Does It Take to Be a "Qualified Person"?

This is a big one. A "qualified person" isn't just a title you give to someone with 20 years of experience. The standards are very clear: qualification is a formal designation given by the employer.

To be officially "qualified," a worker has to be trained on the specific hazards they'll face at your facility and must have demonstrated the skills and knowledge needed to protect themselves. This isn't a handshake agreement; it's a documented process.

That means you can't just hire a seasoned electrician and assume they're good to go. You are responsible for training them on your specific equipment, your documented safety procedures, and the findings from your facility's arc flash risk assessment. Qualification is always task-specific and has to be on the books.

How Often Do We Need to Retrain?

Skills get rusty, and it's easy for bad habits to sneak back in. That’s why NFPA 70E sets a hard deadline for retraining on safe work practices: at least every three years.

But think of that as a final safety net, not the goal. You'll want to retrain much sooner if you see unsafe practices during an audit, when an employee's job duties change, or whenever you bring in new equipment or technology. The three-year rule is the absolute maximum, not the recommended pace.

Can We Just Do All Our Training Online?

Online courses and a good Learning Management System (LMS) are fantastic for building foundational knowledge in arc flash safety training. But they can't do the whole job.

The "book smarts"—the physics of an arc flash, the details of the regulations, how to read an equipment label—are perfect for an e-learning format. It’s an incredibly efficient way to get consistent, baseline information out to your whole team.

The problem is, you can't verify the most important skills through a computer screen. There's just no way to know if a worker can properly inspect a pair of insulated gloves, execute a complex LOTO, or safely use a voltmeter without seeing them do it.

The best approach is a blended one. Use online modules for the theory, then bring everyone in for mandatory, in-person sessions to assess and verify their hands-on skills. You get the efficiency of digital learning paired with the proven competence of a real-world demonstration.

At E & I Sales, we know a truly safe workplace starts with a reliable, well-documented electrical system. From custom UL-listed control panels to integrated motor control centers, our solutions are engineered with safety and compliance built in from the ground up. Let us help you design a safer, more efficient facility. Learn more at https://eandisales.com.