Think of ground fault protection as your electrical system's personal bodyguard. It’s an incredibly fast safety switch that monitors your wiring for any sign of trouble. The moment it detects electricity straying from its intended path—a dangerous situation known as a ground fault—it snaps into action, shutting down the power in a fraction of a second to prevent a nasty electric shock.

That immediate, life-saving response is what makes it so indispensable in our homes, on job sites, and anywhere electricity is used.

What Is Ground Fault Protection and Why Is It Essential

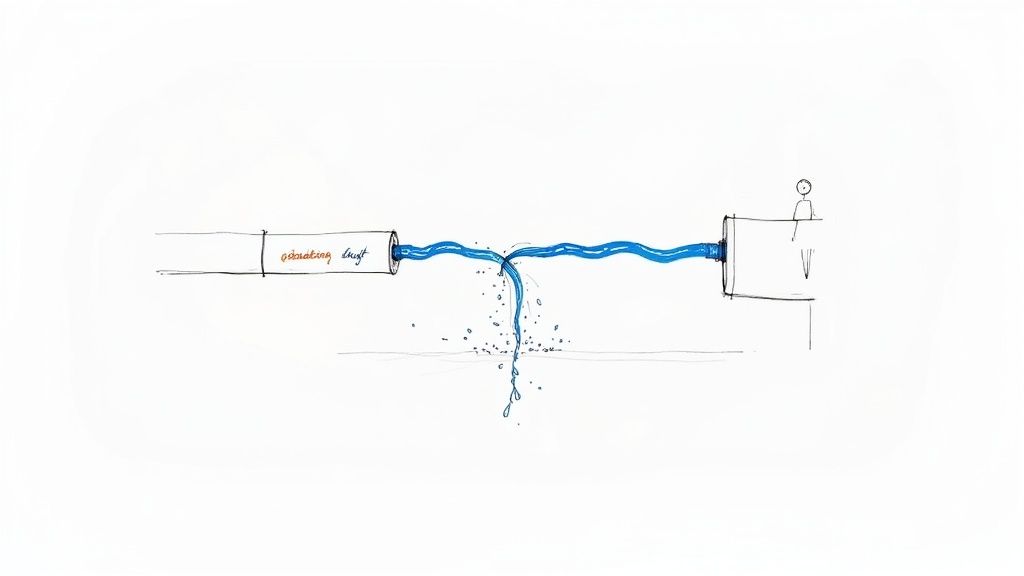

Let's use an analogy. Imagine your electrical circuit is a closed-loop plumbing system. The electricity is like water, flowing from the source, through your tools or appliances, and then returning to the source. Everything is contained.

A ground fault is what happens when that system springs a leak. The electricity escapes its intended path and finds a shortcut to the ground.

That leak can be incredibly dangerous. If a person accidentally becomes that shortcut—say, by touching a faulty piece of equipment while standing in a puddle—the resulting electric shock can be severe, or even fatal. This is precisely where ground fault protection proves its worth.

Protecting People First and Foremost

When we talk about ground fault protection, the number one priority is almost always people. It doesn't take much electrical current to cause serious harm, far less than what it takes to trip a standard circuit breaker. Those breakers are designed to protect equipment and wiring from overheating, not to save a person's life. They simply aren't sensitive enough for the job.

This brings us to the two distinct goals of electrical protection:

- Personnel Protection: This is all about preventing electrocution. These devices are fine-tuned to detect tiny, almost imperceptible current imbalances—as little as 4-6 milliamperes—and trip instantly.

- Equipment Protection: The focus here is on shielding expensive machinery like motors, generators, and transformers. These systems are designed to stop higher-level ground faults that could lead to fires or catastrophic equipment failure.

While both types of protection are critical, keeping people safe is the non-negotiable mission in nearly every setting.

A ground fault is an unintended electrical path between a power source and a grounded surface. Ground fault protection devices are designed to interrupt this dangerous flow of electricity before it can cause serious injury or death.

The widespread adoption of these systems has fundamentally changed electrical safety for the better. As experts at NK Technologies explain in their resources, a huge number of potential disasters are quietly prevented every day because these devices do their job.

Personnel vs Equipment Protection At a Glance

To really get a feel for these two functions, it helps to put them side-by-side. Think of one as a hyper-alert bodyguard for people and the other as a heavy-duty security guard for your expensive gear.

This table breaks down the key differences:

| Aspect | Personnel Protection (e.g., GFCI) | Equipment Protection (e.g., GFPE) |

|---|---|---|

| Primary Goal | Prevents electric shock and saves lives. | Prevents damage to electrical equipment and fires. |

| Sensitivity | Extremely high; trips at very low currents (4-6 mA). | Lower; trips at higher currents (e.g., 30 mA to several amps). |

| Response Time | Extremely fast, typically within 20-30 milliseconds. | Slower, may have an intentional time delay to avoid nuisance trips. |

| Common Location | Bathrooms, kitchens, outdoor outlets, and wet areas. | Main service panels, feeders, and large motors. |

Ultimately, both play a vital role in a safe, reliable electrical system. One keeps you safe, and the other keeps your operations running without burning down.

Understanding Different Ground Fault Protection Devices

While the goal of ground fault protection is always the same—stopping dangerous electrical currents in their tracks—the tools for the job aren't one-size-fits-all. Different devices are engineered for very different scales, from protecting a single person plugging in a hairdryer to safeguarding an entire industrial plant.

Think of it like securing a building. You’d use a simple lock on an interior office door, but a far more complex system for the main entrance and vault. Electrical safety is no different. It uses a whole range of devices to build a complete safety net, layer by layer. Let’s break down the most common players you'll run into.

Ground-Fault Circuit Interrupters (GFCIs)

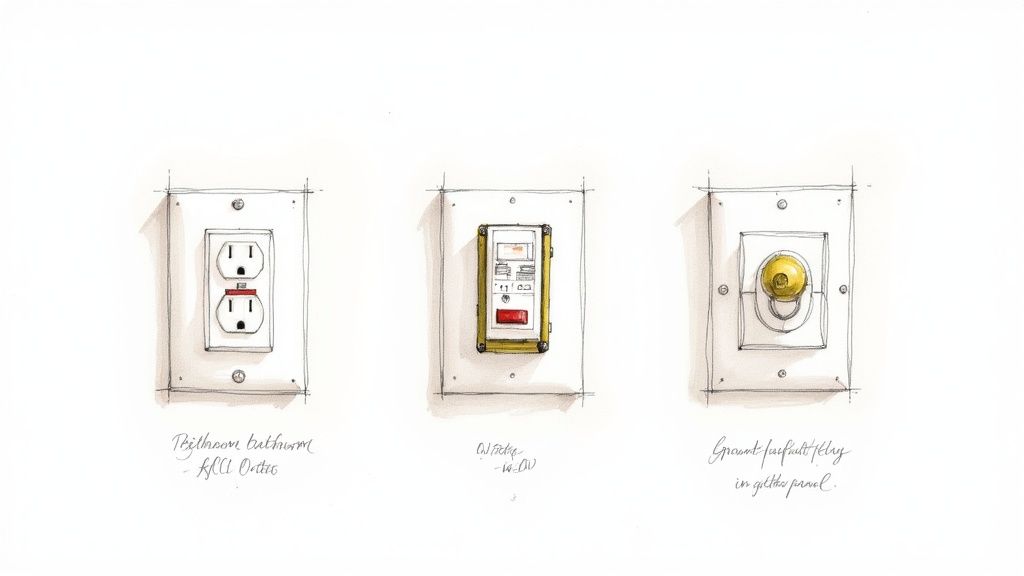

For most people, the GFCI is the face of ground fault protection. It’s that outlet with the little "TEST" and "RESET" buttons you see in kitchens, bathrooms, and garages. The GFCI is your personal bodyguard, standing watch right at the point of use.

How it works is both simple and brilliant. A GFCI constantly monitors the electricity flowing out on the "hot" wire and coming back on the "neutral" wire. In a healthy circuit, these two currents are perfectly balanced.

But if that balance is off by just a tiny amount—as little as 4 to 6 milliamperes—the GFCI assumes the missing current has found another path to ground. A dangerous path, possibly through you. It doesn't wait to find out. In a flash (20-30 milliseconds), it trips and cuts the power, stopping a potentially lethal shock before it can happen.

A GFCI's sole mission is personnel protection. Its speed and sensitivity are finely tuned to react long before an electrical current can cause serious harm to the human body.

Residual Current Devices (RCDs)

Think of a Residual Current Device (RCD), sometimes called a Residual Current Circuit Breaker (RCCB), as a GFCI for a whole circuit. While a GFCI outlet protects whatever is plugged into it, an RCD is installed back in the breaker panel to watch over an entire circuit branch.

It does the same life-saving job, just on a bigger scale. By monitoring the current balance for all the outlets and equipment on that circuit, it provides widespread protection. This is a really efficient way to cover areas with multiple potential hazards, like a whole workshop or a string of outdoor lights. While common in European systems, they work on the same core principle as the GFCIs we see every day. To get a better handle on the different safety devices out there, it’s worth understanding the distinction between AFCI and GFCI devices.

Ground-Fault Relays and Equipment Protection

Now we're moving from protecting people to protecting big, expensive equipment. This is where ground-fault relays come in. These are the heavy-duty guardians for industrial and commercial systems, working with large circuit breakers to protect things like motors, transformers, and switchgear.

Unlike a GFCI with its fixed, hair-trigger sensitivity, a ground-fault relay system is adjustable. This is crucial in a factory setting. A massive motor might cause tiny, harmless current imbalances when it kicks on, and you don't want that to cause a nuisance trip. An engineer can set the relay to ignore these normal operational quirks but trip instantly when a real, damaging fault occurs.

A typical system has three parts working in concert:

- Current Sensors: Usually large rings called current transformers (CTs) that fit around the main power conductors.

- Relay Logic: This is the brains of the operation. It analyzes the signals from the sensors and, based on its settings, decides if there's a problem.

- Tripping Mechanism: If the relay detects a fault, it sends a signal telling a massive circuit breaker to open up and kill the power.

This kind of setup is absolutely essential for keeping operations running and preventing catastrophic equipment failures. For a deeper dive, our guide on the protection of motors covers how to safeguard these critical assets in more detail. Each of these devices, from the humble GFCI to the sophisticated relay, plays a vital role in a complete safety strategy.

Decoding Key Electrical Codes and Safety Standards

Ever wonder why that special outlet with the little "reset" button is mandatory in your kitchen but not your living room? The answer isn't arbitrary. It comes from a carefully crafted set of rules, born from decades of experience and a deep understanding of where electrical dangers lurk.

This framework of regulations is what ensures ground fault protection is installed exactly where it's needed most. For anyone working with electricity in the United States—from electricians to facility managers—the primary rulebook is the National Electrical Code (NEC).

Think of the NEC as the definitive guide to safe electrical design and installation. It’s more than just a list of dos and don'ts; it explains the why behind each rule, connecting technical specs to real-world safety. Its mission is simple: to safeguard people and property from electrical hazards. The rules on ground fault protection are a perfect example of this mission in action.

The NEC Mandate: Where Protection Is Required

The NEC gets very specific about where ground fault protection for people (GFCIs) must be used. The logic is straightforward: wherever water is present, the risk of a deadly shock skyrockets. Water dramatically lowers the human body's resistance to electricity, turning a minor shock into a potentially fatal one.

That’s why you’ll find the NEC mandating GFCI protection in places like:

- Bathrooms: All 125-volt, single-phase, 15- and 20-ampere receptacles.

- Kitchens: All outlets serving countertop surfaces.

- Garages and Accessory Buildings: Receptacles in these areas are often exposed to moisture or are near grounded surfaces like concrete floors.

- Outdoors: Every single receptacle installed outside needs this protection.

- Crawl Spaces and Unfinished Basements: In these spots, people are often in direct contact with the earth or concrete.

- Laundry Areas: Any outlet within six feet of the outside edge of a sink.

Knowing these locations is step one, but it’s also critical to remember that the code is a living document. For example, the 2020 NEC update brought in more nuanced requirements for marinas and boat docks, reflecting a better understanding of shock hazards around water. It specifies distinct thresholds: 30 mA for shore power receptacles, the familiar 4-6 mA for personnel protection via GFCI on 15–20 amp receptacles, and a maximum of 100 mA for feeder circuits supplying docks.

To give you a quick reference, here’s a breakdown of some of the most common NEC requirements for ground fault protection.

Common NEC Ground Fault Protection Requirements

A summary of mandatory GFCI and GFPE locations as specified by the National Electrical Code to provide a quick reference for compliance.

| Location / Application | Required Protection Type | Typical NEC Article |

|---|---|---|

| Bathrooms | GFCI | 210.8(A)(1) |

| Garages & Accessory Buildings | GFCI | 210.8(A)(2) |

| Outdoors | GFCI | 210.8(A)(3) |

| Crawl Spaces & Basements | GFCI | 210.8(A)(4) & (5) |

| Kitchens (Countertops) | GFCI | 210.8(A)(6) |

| Sinks (within 6 ft.) | GFCI | 210.8(A)(7) |

| Boathouses & Marinas | GFCI | 210.8(A)(8), 555.33 |

| Electrically Heated Floors | GFCI | 424.44(G) |

| Service Disconnects >1000A | GFPE | 230.95 |

| Feeder Disconnects >1000A | GFPE | 215.10 |

This table is just a starting point, but it clearly illustrates how the NEC targets high-risk areas to maximize safety.

Beyond the NEC: A Landscape of Safety Organizations

While the NEC dictates the rules of the road for installation, it’s backed by a whole ecosystem of organizations that ensure the equipment itself is safe and reliable. They all work together to create a multi-layered shield of protection.

The NEC sets the rules for the game (installation), while organizations like UL and IEEE help design the players and equipment (the devices themselves) to ensure they are safe and effective.

A few of the key players you should know are:

- Underwriters Laboratories (UL): UL is a global safety certification company. When you see that familiar UL mark on a GFCI outlet, it means that device has survived a gauntlet of tests to meet specific standards like UL 943. That little logo is your assurance that the device will actually do its job when you need it most.

- Institute of Electrical and Electronics Engineers (IEEE): The IEEE is a professional organization that develops standards used across countless industries. Their work often provides the core engineering principles and testing methods that inform both product design and the complex ground fault protection schemes required by the NEC in industrial settings.

These standards, working hand-in-hand with code requirements like the NEC tap rule, create a truly comprehensive safety net. Of course, knowing the technical rules is only half the battle; teaching them effectively is just as important. For anyone tasked with this, resources on creating a high-impact health safety course can be invaluable. Ultimately, it’s this powerful partnership between codes and standards that connects life-saving technology with enforceable rules to protect us all.

How Ground Fault Protection Is Implemented

Knowing the individual devices is one thing, but the real engineering magic happens when you see how they all come together to create a cohesive safety net. Implementing ground fault protection isn't as simple as plugging in a GFCI outlet. It's about designing a smart, layered defense for your most critical assets—motors, feeders, and even entire distribution panels.

This is where things get tricky. You need a system that’s sensitive enough to catch a genuinely dangerous fault but not so touchy that it causes constant, unnecessary shutdowns. A factory simply can’t afford to have a massive motor trip every time it starts up because of a tiny, harmless current imbalance. That’s why a thought-out, strategic approach is non-negotiable.

Protecting Critical Industrial Assets

Once you step into an industrial facility, the focus of ground fault protection shifts. It's not just about protecting people anymore; it’s about safeguarding high-dollar equipment. A ground fault in a giant motor or a main feeder can be catastrophic, leading to fires, destroyed machinery, and crippling downtime.

Here’s a quick look at how we apply protection to these key players:

- Motors: Big motors are prone to ground faults if the insulation in their windings starts to break down. We use a ground-fault relay set just right—it ignores the normal inrush current when the motor kicks on but trips instantly if a real fault occurs, preventing a meltdown.

- Feeders: Think of these as the main electrical arteries of your facility. Protecting them is vital to isolating a problem in one area without plunging the entire plant into darkness.

- Main Distribution Panels: The NEC often requires Ground Fault Protection for Equipment (GFPE) at the main service entrance for large systems. This acts as the final line of defense against arcing ground faults that are notorious for starting electrical fires.

This hierarchy of protection is a perfect example of how electrical codes and standards translate from paper to the real world, flowing from the highest authority down to a specific piece of equipment.

This visual just hammers it home: safety rules start with a governing body (like the NEC), get baked into a standard (like UL 943), and are then applied right where they're needed, like that outlet in your kitchen.

The Challenge of Nuisance Tripping

One of the biggest headaches in this field is nuisance tripping. This is when a protective device trips out during perfectly normal operation, not because of a real hazard. It's a constant battle, especially in plants filled with equipment like variable frequency drives (VFDs) or servo amplifiers, which generate a ton of electrical "noise" that can fool a sensitive GFCI into thinking there's a problem.

Tempting as it may be, you can't just disable the protection. Instead, good engineers use a mix of strategies:

- Use GFPE Devices: These equipment protectors are less sensitive than their personnel-protecting cousins (GFCIs) and often have adjustable time delays, letting them ignore momentary current blips.

- Proper Shielding and Grounding: Simply making sure motor cables and control wiring are correctly shielded and grounded can slash electrical noise and solve a lot of problems.

- Isolation Transformers: For really sensitive gear, an isolation transformer can create a clean, dedicated power source, completely separating it from the noise on the main system.

Wrestling these issues requires a deep, hands-on understanding of both the equipment and the electrical environment it lives in.

Selective coordination is the art of making sure the breaker closest to a problem opens first. It’s what stops a small, localized issue from turning into a full-blown, plant-wide outage.

Achieving Selective Coordination

Picture this: a small fault happens in one machine out on the factory floor. In a poorly designed system, that tiny hiccup could trip the main breaker for the entire building, bringing everything to a screeching halt. That’s exactly what selective coordination is designed to prevent. It’s an absolutely critical concept for building a reliable ground fault protection system.

The idea is to create a clear pecking order. The device right next to the fault—say, a small branch-circuit breaker—should trip first and fastest. The next breaker upstream, maybe for a larger feeder, is set with a slightly longer time delay. The main breaker? It has the longest delay of all. This tiered system guarantees that only the affected part of the circuit goes offline.

Pulling this off takes careful engineering and a lot of math to get the trip settings of every device just right. But when it's done correctly, you get the best of both worlds: enhanced safety and maximum uptime. For anyone diving into this process, getting a solid grasp of industrial control panel design is invaluable, as it shows you exactly how these protection schemes are woven into the heart of a control system.

The Long Road to Modern Electrical Safety

That little GFCI outlet in your kitchen, the one with the "TEST" and "RESET" buttons, is the result of more than a century of hard-won innovation. The idea of ground fault protection wasn’t a single brilliant idea that appeared overnight. Instead, it was painstakingly built, piece by piece, by engineers grappling with the new and often deadly challenges of a world powered by electricity.

To really get a feel for how far we've come, you have to go back to the turn of the 20th century. As power grids began stretching across the country, engineers ran into a huge problem: how do you shut down one faulty power line without plunging an entire city into darkness? The first attempts were clumsy, often just simple fuses that couldn't tell the difference between a momentary overload and a catastrophic fault.

The First Breakthroughs in Protective Relays

The first real leaps forward happened out of necessity, driven by the need to protect the massive new power plants of the era. One of the earliest game-changing moments was around 1899 at the Niagara power plants. Engineers there devised a clever way to achieve selective line protection for their 11 kV network, using a directional element to create a reverse current protection scheme. Many see this as the true birth of selective protection, a concept that's still at the heart of electrical safety today. You can dive deeper into the history of protection engineering and how these ideas came to be.

Right on the heels of that innovation came another critical development. In 1908, an engineer named Nicholson came up with the summation current circuit for detecting earth faults. It was a brilliantly simple concept: measure the current going out and compare it to the current coming back. If they don't match, you have a leak. This fundamental principle is still the basis for every GFCI and ground fault relay in use today.

The core idea behind modern ground fault protection is over 100 years old. It's based on a simple principle: what goes out must come back. If it doesn't, the electricity has leaked somewhere it shouldn't, and the circuit must be shut down instantly.

From Protecting the Grid to Protecting People

For decades, this kind of technology was strictly the domain of big utilities and massive industrial sites. The relays were huge, clunky mechanical devices—far too complex and expensive for the average home. The focus finally shifted toward personal safety in the 1950s and 60s, as a growing number of electrocutions were linked to faulty consumer appliances.

This is when engineers started playing with solid-state electronics to shrink the technology down and make it affordable. Professor Charles Dalziel of UC Berkeley, a pioneer in understanding how electricity affects the human body, was a key figure here. He developed a transistorized relay that would become the prototype for the modern Ground-Fault Circuit Interrupter (GFCI).

His work was the final piece of the puzzle. It proved you could build a device sensitive enough to detect the tiny, lethal currents that can stop a human heart, yet tough enough for daily use in a home. That breakthrough opened the door for the NEC to start requiring GFCIs in kitchens, bathrooms, and outdoor areas—a change that has saved countless lives and fundamentally reshaped our relationship with electricity.

Testing and Troubleshooting Your Protection System

A ground fault protection device is a lot like a silent guardian; you really only know it’s working when it suddenly springs into action. But how can you be sure it will actually do its job when the time comes? The only way is through regular, methodical testing and having a clear game plan for when things go wrong.

Putting a protection system in place is just the first step. The real work—verification, commissioning, and routine maintenance—is what turns a piece of hardware into a safety shield you can actually rely on. These procedures aren't just best practices; they're non-negotiable for keeping your electrical environment safe and running.

Essential Testing Procedures for Every System

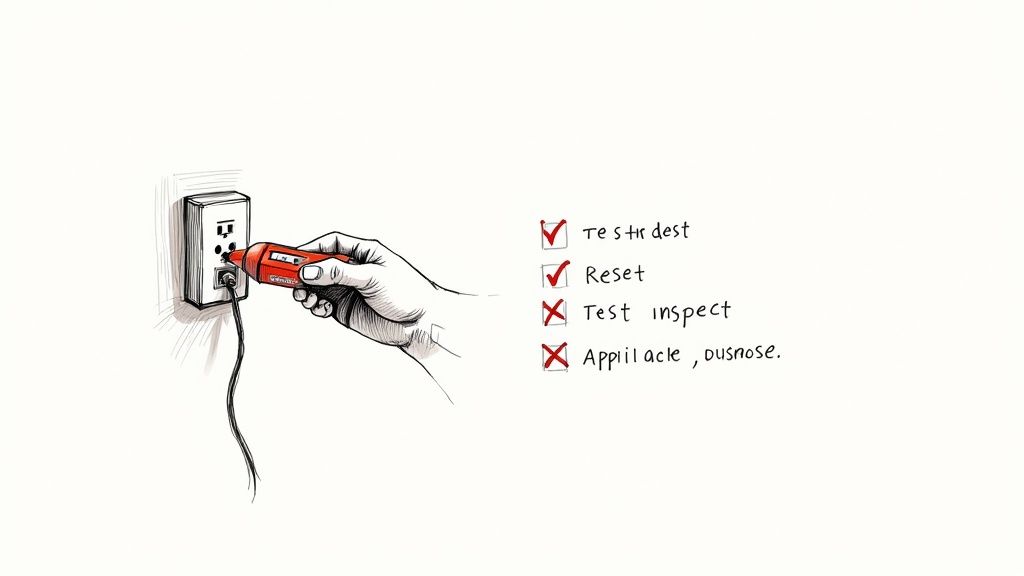

Making sure your ground fault protection is ready to go is a simple but vital habit. For the GFCIs in your home or office, it's a quick monthly check.

- Push the Button: Press the "TEST" button on the GFCI outlet or breaker. You should hear a solid click as it cuts the power.

- Double-Check: Plug in a lamp or phone charger to make sure the outlet is truly dead. No light, no power.

- Bring it Back: Press the "RESET" button. The power should pop back on, and your test device should light up again.

For bigger industrial systems with ground-fault relays, the process is a bit more involved and is usually part of a scheduled maintenance program. This often means bringing in specialized gear to inject a simulated fault current, making sure the relay logic and breaker trip mechanisms work exactly as they were designed.

An untested protection device is just a hopeful assumption. Regular verification turns that assumption into a documented certainty, ensuring your safety net is ready to perform when a real fault occurs.

Diagnosing and Solving Nuisance Tripping

One of the biggest headaches you'll run into is nuisance tripping—when a GFCI or relay trips for no obvious reason. This can bring work to a screeching halt and make you lose faith in your system. The trick is to systematically hunt down the root cause instead of just mashing the reset button and hoping for the best.

Troubleshooting Steps for Nuisance Tripping:

- Step 1: Isolate the Circuit: Unplug everything. If the GFCI resets and holds, you know the problem is with one of your devices, not the wiring itself.

- Step 2: Find the Culprit: Start plugging things back in, one by one. The device that makes it trip is your source. Old motors, failing heating elements, or even a little moisture in an appliance can create tiny current leaks that a sensitive GFCI will pick up on.

- Step 3: Inspect the Wiring: If the GFCI trips with nothing plugged in, the problem is likely in the wiring. Look for moisture in an outdoor junction box, worn-out insulation, or even a loose connection.

In industrial settings, things like servo amplifiers can generate enough electrical noise to cause nuisance trips, leading to jerky motor behavior or sudden shutdowns. In these cases, checking for properly shielded cables and a solid single-point grounding scheme often solves the problem without sacrificing safety.

Remember, a persistent trip isn't an annoyance—it's a signal that something needs a closer look.

Common Questions About Ground Fault Protection

Even with a solid understanding of the basics, a few common questions always seem to pop up when we're talking about ground fault protection. Let's tackle them head-on, because getting these details right is what makes these systems work in the real world.

What’s the Difference Between a Circuit Breaker and a GFCI?

Think of it this way: a standard circuit breaker is like a security guard for your building’s electrical system. Its job is to watch for huge problems, like a massive overload or a dead short, that could cause a fire. When it sees way too much current trying to flow, it shuts everything down.

A GFCI, on the other hand, is a personal bodyguard for you. It’s not looking for system-wide overloads. Instead, it’s watching for tiny, almost undetectable leaks of electricity—the kind that happen when current finds a path through a person. If it senses an imbalance as small as 4-6 milliamperes, it knows something is wrong and cuts the power in an instant.

Why Does My GFCI Outlet Keep Tripping?

We hear this one all the time. It’s often called "nuisance tripping," but it’s rarely a nuisance for no reason. The culprit can be something as simple as moisture getting inside an outdoor outlet box or even just a bit of accumulated dust creating a path for current.

Older appliances, especially those with motors or heating elements, can also develop tiny, harmless current leaks that are still just enough to make a sensitive GFCI do its job.

If you're trying to figure it out, here’s a quick process of elimination:

- First, unplug everything from the GFCI circuit and hit the reset button.

- If it stays on, start plugging your devices back in, one by one. When it trips, you’ve found the problem appliance.

- If it trips immediately with nothing plugged in, the issue is likely in the wiring or the GFCI outlet itself. That's a job for a professional.

A GFCI that keeps tripping isn't just being annoying; it's sending you a signal. It's telling you there's a potential problem that needs attention, whether it's in a faulty appliance or the circuit itself.

Can I Install a GFCI on a Circuit Without a Ground Wire?

Yes, you can, and it's a common safety upgrade recognized by the National Electrical Code for older homes with two-wire circuits. A GFCI works by constantly monitoring the balance between the hot and neutral wires. If there's a difference, it trips—a function that doesn't need a ground wire to work.

There's a catch, though. You are required to label the outlet with a sticker that clearly says "No Equipment Ground" and "GFCI Protected." This lets everyone know that while the outlet offers excellent shock protection, it can't provide the grounding path that some electronics rely on for things like surge protection.

At E & I Sales, we live and breathe this stuff. We specialize in designing and building reliable, code-compliant UL-listed control panels that have exactly the right ground fault protection for your equipment and personnel. If you want to make sure your systems are both safe and efficient, contact us today.