Walk down any aisle in an electrical supply house, and you'll see a dizzying array of electrical boxes. They come in all shapes and sizes, from simple plastic junction boxes meant for tucking away wire splices to heavy-duty steel device boxes built to hold switches and outlets securely for decades.

But what do they all do? At their core, their job is to safely wrap up electrical connections. They’re the first line of defense, protecting wires from getting damaged and, just as importantly, protecting us from accidental contact that could lead to shocks or fires.

The Hidden Backbone of Safe Electrical Wiring

Think of electrical boxes as the silent, essential hubs of your building's entire nervous system. They’re not just simple containers; they're the critical junctions where the flow of electricity is safely managed and directed. You'll find them in every single electrical system, from the light switch in your living room to a massive industrial motor control center.

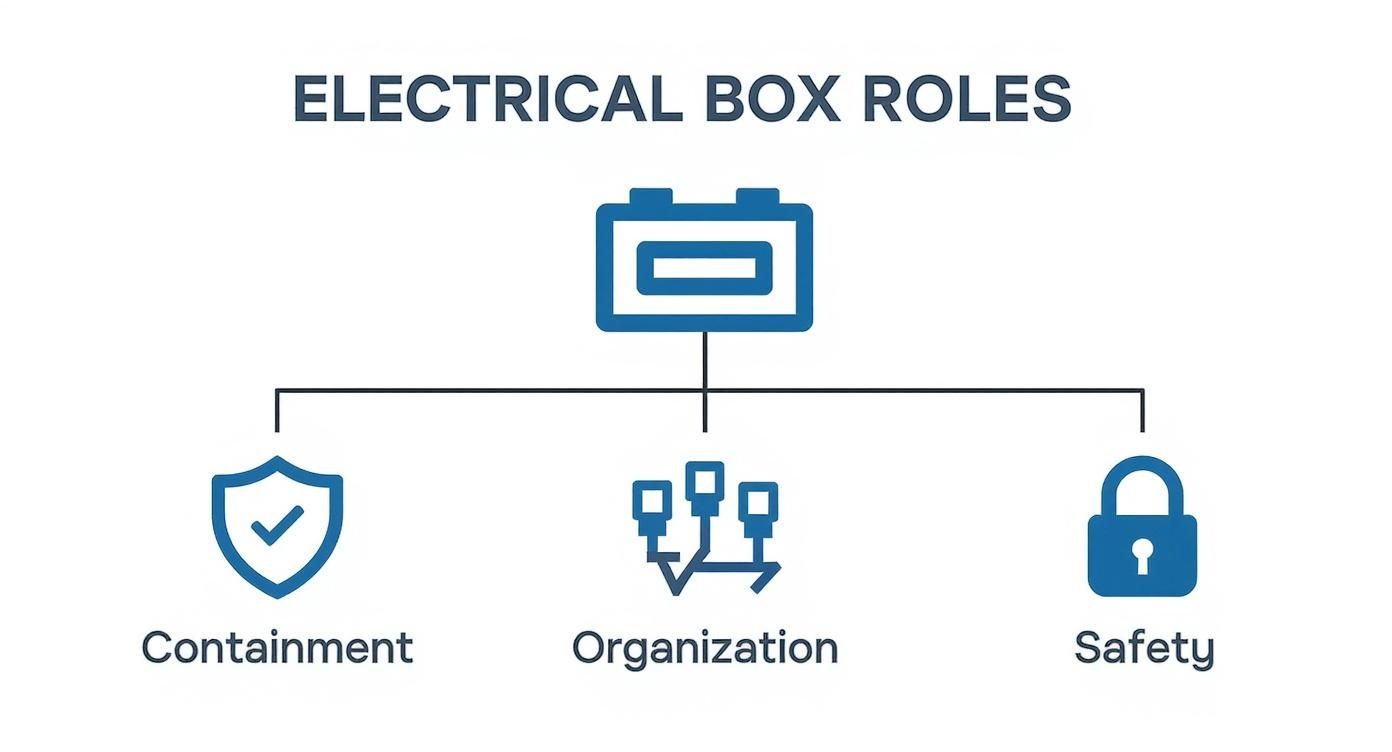

Every box, no matter its shape or material, serves three fundamental roles. It's this trifecta of duties that ensures a system is not only functional but also reliable and up to code.

The Critical Roles of an Electrical Box

Let's break down what these enclosures are really doing behind the scenes:

- Containment and Protection: First and foremost, a box houses wire connections. If a connection ever arcs or sparks—and it can happen—the box contains it. This simple act prevents those sparks from reaching flammable materials like wood studs or insulation, which is a massive factor in fire prevention.

- Organization and Accessibility: Wires need a clean, logical place to terminate or be spliced. Boxes provide that structure. For any electrician coming in later to troubleshoot a problem or add a new circuit, this organization is a lifesaver. It makes the job faster, safer, and a whole lot less frustrating.

- Safety and Grounding: This is a big one. When you're working with metal boxes and metal conduit, the box itself becomes a key part of the grounding system. If a hot wire somehow makes contact with the metal box, this ground path provides a direct route for the fault current, instantly tripping the circuit breaker and shutting down the danger.

An improperly installed or undersized electrical box is a ticking time bomb. When you cram too many wires into a small space, you get heat buildup. That heat breaks down wire insulation over time, creating the perfect recipe for a short circuit and an electrical fire.

Quick Guide to Common Electrical Box Types and Uses

To get a clearer picture, it helps to see how different boxes are used in the real world. This table gives a quick rundown of the most common types you'll encounter and where they typically fit in.

| Box Type | Primary Use | Common Material |

|---|---|---|

| Junction Box | Enclosing wire splices and connections | Steel, PVC, Fiberglass |

| Switch/Device Box | Mounting switches, outlets, and dimmers | Steel, PVC |

| Octagon/Round Box | Mounting ceiling lights and smoke detectors | Steel, PVC |

| Conduit Body | Providing pull points and turns in conduit runs | Aluminum, Steel |

| Weatherproof Box | Outdoor outlets, switches, and lighting | Die-cast Aluminum |

This is just a starting point, of course. The specific needs of a residential, commercial, or heavy industrial project will dictate the best choice, but knowing the basics is the first step.

Ensuring a Safe Work Environment

Before you even think about touching a wire, your first priority is always safety. No exceptions. Shut off the power at the main circuit breaker that controls the circuit you're working on. Then, double-check that the power is actually off.

You can't trust that a switch is off just because it's in the down position. Always verify with a tester. Tools like non-contact voltage detectors are perfect for this—they'll tell you instantly if there's any live current present without you having to touch a single wire.

This guide will be your roadmap to navigating the world of electrical boxes. We’ll cover everything from the standard boxes in your walls to the rugged, specialized enclosures that keep critical industrial systems running, giving you the practical knowledge you need for your next project.

Diving Into the Most Common Electrical Boxes for Any Job

Once you get past the high-level theory, the world of electrical boxes opens up into a whole cast of specialized players, each built for a very specific role. Think of it like a mechanic's toolbox; you don't use a sledgehammer to tighten a small bolt. In the same way, an electrician picks the right box for the job to make sure every connection, switch, and fixture is housed correctly and safely.

Getting to know these common workhorses is the first step to making smart, code-compliant choices on any project. Each box has a specific purpose, whether it's just protecting a few spliced wires or providing a rock-solid anchor for a heavy ceiling fan.

This diagram breaks down the fundamental jobs of any electrical box, showing how it provides containment, organization, and safety all at once.

As you can see, a box isn't just a simple container. It's an active safety component that provides structure, protection, and a hub for keeping everything up to code.

Junction Boxes: The Unsung Heroes

The junction box is probably the most essential type of electrical box out there. Its job is straightforward but absolutely critical: to house and protect wire splices. Any time you need to connect wires together—whether to extend a circuit, branch off in a new direction, or join different types of cable—those connections have to be made inside a junction box.

Think of it as a secure meeting point for electrical conductors. The wires come in, get safely connected with wire nuts, and the box is sealed up with a blank cover. This simple setup prevents anyone from accidentally touching a live wire, keeps dust and debris away from the delicate connections, and even contains potential sparks. The National Electrical Code (NEC) is very clear that every splice must remain accessible, which means you can never bury a junction box behind drywall or plaster.

Device Boxes: The Interactive Hub

Next up are device boxes, which you probably know better as switch boxes. These are the rectangular boxes you see every day holding light switches, dimmers, and electrical outlets. They're designed specifically to mount these devices securely, with threaded holes for screws and enough internal space for both the device and all the wiring behind it.

Device boxes come in a few common configurations, often described by "gangs."

- Single-Gang Box: The standard size, built to hold just one device, like a single light switch or outlet.

- 2-Gang Box (or Multi-Gang): These are wider boxes made to hold two or more devices right next to each other—perfect for a switch and an outlet combo or a bank of light switches.

- 4-Square Box: A versatile 4×4 inch metal box that can act as a large junction box or be fitted with a special cover (called a mud ring) to mount one or two devices.

One of the biggest mistakes people make is cramming too many wires into a device box. You always have to calculate your "box fill" to make sure you have enough cubic-inch capacity. Overcrowding can lead to dangerous heat buildup and is a major fire hazard.

Octagon and Round Boxes: The Overhead Mounts

Look up at your ceiling, and you're probably looking at the handiwork of an octagon box or its sibling, the round box. These uniquely shaped enclosures are the go-to choice for mounting ceiling fixtures like lights, smoke detectors, and ceiling fans. Their shape gives you plenty of angles to secure the fixture's mounting bracket.

While a standard octagon box works great for a lightweight light fixture, you need something much tougher for a ceiling fan or a heavy chandelier. For those jobs, you must use a box that is specifically fan-rated. These are usually made of steel and are designed to mount directly to a ceiling joist or a heavy-duty brace, giving them the strength to handle the weight and dynamic forces of a spinning fan.

You'll also find a super-shallow version called a "pancake box." These are thin, round boxes used for light fixtures when there's no room inside the wall or ceiling for a standard box. They provide just enough space for the connections while sitting almost flush against the surface. Each of these box types has a clear-cut role, making your selection process a lot easier once you know what you're trying to accomplish.

Choosing the Right Materials and Construction

Ever wondered why some electrical boxes are metal and others are plastic? It’s not just about what’s cheapest. The material you choose is a critical decision based on the job site, the kind of wire you're running, and the safety codes you have to meet.

Think of it like picking the right gear for the job. What works perfectly in a wood-framed house would be a total liability in an industrial plant. Getting a handle on the differences between metallic and non-metallic boxes is the first step toward a safe, solid, and up-to-code electrical system.

Metallic Boxes: Steel and Aluminum

For as long as anyone can remember, metal boxes have been the go-to for commercial and industrial work. There's a good reason for that. Their natural toughness and ability to conduct electricity make them non-negotiable for certain installations.

Steel boxes are the undisputed heavyweights. Their biggest advantage is brute strength and the fact that they don't burn. This rugged build is a must-have in places where a box might take a hit. More importantly, when you're working with metal-sheathed cable (like MC) or running wires through metal conduit, a steel box is a key part of the grounding system. The box itself completes the ground path, which is a massive safety feature.

Aluminum boxes are the lighter-weight cousin to steel, which makes them a bit easier to wrangle. You'll often see them as die-cast conduit bodies or those familiar weatherproof boxes for outdoor outlets, where their built-in resistance to corrosion really shines.

Non-Metallic Boxes: PVC and Fiberglass

Lately, plastic boxes have taken over, especially in residential construction. They're just plain easier and more cost-effective for a lot of jobs.

PVC (Polyvinyl Chloride) boxes are what you'll find in most new homes today. They're cheap, light, and a breeze to install—a quick tap with a screwdriver is all it takes to pop out a knockout. Since PVC doesn't conduct electricity, the box itself doesn't need to be grounded. This makes wiring with standard non-metallic (NM) cable much simpler.

This choice between metal and plastic isn't just a job-site debate; it's big business. The global market for electrical boxes is currently valued at USD 6,992.4 million and is expected to climb to USD 10,682.4 million by 2033. PVC boxes are the clear leader, holding over 59.84% of the market thanks to their low cost and perfect fit for residential wiring.

Fiberglass boxes are a definite upgrade from standard PVC. They're tougher and won't get brittle or flex in extreme hot or cold, making them a great pick for demanding spots like unfinished basements, workshops, or even some light industrial areas where you still want a non-conductive box. When you're dealing with more advanced systems, material selection becomes even more critical, as we cover in our guide to industrial control panel design.

Making the Right Choice for Your Project

So, metal or plastic? The decision really comes down to a few straightforward factors.

- Your Wiring Method: This is the golden rule. If you're running wire in metal conduit or using metal-clad cable, you must use a metal box. No exceptions. It's essential for proper grounding. For standard non-metallic (Romex) cable, a plastic box is usually the path of least resistance.

- The Environment: Think about where the box will live. Is it going to be exposed to rain or moisture? You'll need a weatherproof box made of PVC, fiberglass, or die-cast aluminum. Is it in a garage or workshop where it might get bumped? A tough steel box is the way to go.

- Cost and Labor: On a large residential build, the savings from using inexpensive PVC boxes and the speed of installing them really add up. But for a commercial job, the priority shifts to long-term durability, making steel the smarter investment, even if it takes a bit longer to install.

Going Beyond the Basics: A Look at Specialized Electrical Enclosures

While the standard junction boxes and device boxes are the bread and butter of most wiring jobs, some situations call for something much tougher. When you’re taking a project outdoors, running conduit underground, or trying to wrangle massive conductors, you need an enclosure that was built for the job.

Think of it like the difference between your daily driver and a purpose-built off-road truck. Both will get you from A to B, but only one is engineered to handle mud, rough terrain, and brutal weather. Specialized electrical enclosures are the heavy-duty off-roaders of the electrical world, built to protect critical connections where ordinary boxes would quickly fail.

Weatherproof Boxes: Your First Line of Defense Against the Elements

Any electrical connection outside is in a constant fight with moisture, dust, and wild temperature swings. That's where weatherproof boxes step in. These aren't just regular boxes with a slightly better cover; they're complete systems engineered from the ground up to create an impenetrable seal against the environment.

Usually made from die-cast aluminum or heavy-duty, non-corrosive PVC, their design hinges on a few key features that keep moisture out:

- Gasketed Covers: A thick rubber or foam gasket gets compressed between the box and the cover plate, forming a watertight seal that blocks rain, sleet, and snow.

- Sealed Hubs: Threaded hubs combined with watertight connectors ensure that any point where conduit enters the box is completely sealed off from moisture.

- Durable Construction: The materials themselves are chosen for their ability to resist corrosion and stand up to years of UV exposure without turning brittle.

These features make weatherproof boxes non-negotiable for outdoor outlets, landscape lighting systems, and mounting security cameras, ensuring those connections stay safe and reliable for years to come.

The demand for these rugged solutions is growing fast. The North American market for plastic electrical boxes is projected to grow at a compound annual rate of 6.3% between 2025 and 2030, hitting an estimated USD 10.34 billion. The weatherproof and outdoor segment is a major part of that story, expected to expand at an even faster 6.8% CAGR. This trend highlights a clear shift toward more robust, specialized enclosures, as detailed in this Grand View Research industry analysis.

Pull Boxes: Making Big Conductor Jobs Manageable

On large-scale commercial and industrial jobs, electricians are often tasked with pulling incredibly thick and heavy conductors through hundreds of feet of conduit. Trying to pull those massive cables through multiple bends or over extremely long distances in one go is a recipe for frustration and failure. This is exactly what pull boxes were invented to solve.

At its core, a pull box is a strategically placed junction box that gives you an access point in the middle of a long conduit run. It provides a straight shot for pulling, letting the crew pull one section of cable, neatly coil it inside the box, and then start the next pull from that point. It turns an overwhelming task into a series of smaller, manageable steps.

The National Electrical Code (NEC) actually mandates pull boxes in conduit runs with more than 360 degrees of bends between access points. The code also strictly governs their size to make sure there's enough room to work with the cables without kinking them or damaging their insulation.

Floor Boxes: Discreet Power Where You Need It

In today's open-concept offices, sprawling conference centers, and even high-end custom homes, getting power and data access right where it's needed—without a mess of cords—is a huge design challenge. Floor boxes are the elegant solution, putting outlets and data ports directly into the floor.

These aren't your average boxes. They have to be incredibly tough to withstand constant foot traffic and the weight of heavy furniture. They usually feature a solid metal construction with a heavy-duty cover that sits perfectly flush with the flooring. Many models have recessed connections and pop-up lids, allowing you to plug in cords while keeping the cover mostly closed to minimize tripping hazards.

From industrial control panels to specialized instrument housings, the world of enclosures extends far beyond the common boxes. Here's a quick look at how different types are deployed in demanding settings.

Specialized Electrical Enclosures and Their Industrial Applications

| Enclosure Type | Key Feature | Typical NEMA Rating | Industrial Application Example |

|---|---|---|---|

| Hazardous-Location | Explosion-proof or intrinsically safe construction | NEMA 7, 8, 9, 10 | Protecting controls in an oil refinery or chemical processing plant. |

| Conduit Body | Provides access for pulling conductors around bends | NEMA 3R (outdoor) | Connecting rigid conduit runs at a 90-degree angle on an exterior wall. |

| Meter Box | Houses and secures the utility power meter | NEMA 3R | Standard residential and commercial utility service entrance. |

| UL-Listed Control Enclosure | Pre-certified to house complex automation systems | NEMA 12, 4, 4X | Housing a PLC, VFDs, and motor starters for an automated conveyor system. |

Each of these enclosures solves a specific set of challenges, proving that in the electrical world, having the right box for the job is critical for safety, reliability, and code compliance.

Decoding NEMA Ratings and UL Safety Listings

When you're looking at different types of electrical boxes, you'll see a string of codes and symbols stamped right on them. These aren't just random characters; they're a critical language telling you exactly what that enclosure can handle and how safe it is.

Getting fluent in this language is non-negotiable. It's how you ensure a system is reliable, up to code, and most importantly, safe for everyone involved.

The two names you absolutely need to know are the National Electrical Manufacturers Association (NEMA) and Underwriters Laboratories (UL). Think of NEMA ratings as a toughness score, defining an enclosure's ability to protect what's inside from the outside world. A UL Listing, on the other hand, is the ultimate seal of approval, confirming the product passed a battery of independent safety tests.

Understanding NEMA Ratings

NEMA ratings are a straightforward way to classify how well an enclosure protects its contents from environmental hazards like dust, water, and corrosion. In the industrial world, this is huge. Electrical boxes face everything from fine airborne particles to high-pressure chemical washdowns.

Here’s a quick look at some of the most common ratings you'll run into:

- NEMA 1: This is your basic indoor-use rating. It’s designed to keep fingers and tools from touching live parts but doesn't offer much protection against dust or water.

- NEMA 3R: Built for the great outdoors, this rating protects against rain, sleet, and ice. You’ll see these everywhere, from utility meter housings to outdoor junction boxes.

- NEMA 4X: Now we’re talking serious protection. This rating is watertight against direct hose spray (like a NEMA 4) but adds a critical layer of corrosion resistance. That makes it the go-to choice for punishing environments like wastewater treatment plants, food processing facilities, and marine applications.

- NEMA 12: Back indoors, a NEMA 12 enclosure is perfect for the factory floor. It’s built to keep out dripping liquids (non-corrosive ones), circulating dust, and falling dirt.

If you want to go deeper into how these ratings play out in the real world, check out our detailed guide covering NEMA standards. Knowing these inside and out is the key to picking the right box for the job, every time.

The Importance of a UL Listing

While a NEMA rating tells you what an enclosure is designed to do, a UL Listing is your guarantee that it's been independently tested and proven to do it safely. Underwriters Laboratories is a world-renowned safety science organization, and they don't mess around.

A UL Listing is so much more than a sticker—it’s a mark of trust. It means that an electrical box has been rigorously evaluated for potential fire, electric shock, and other hazards. For OEMs and system integrators, specifying UL-listed components is absolutely critical for ensuring the entire system is safe and compliant.

The demand for certified enclosures is exploding. The global market is on track to grow from USD 54.2 billion to a massive USD 87.4 billion by 2035. Junction boxes, which often need specific NEMA and UL ratings, are leading the charge, making up 38.2% of the market thanks to their ability to shield components from dust and moisture.

This growth isn't just a number; it highlights a massive industry-wide shift toward prioritizing safety and reliability, all driven by certifications like those from NEMA and UL.

Your Checklist for Selecting the Right Electrical Box

With so many types of electrical boxes out there, picking the right one can feel a little overwhelming. But it doesn't have to be. By asking yourself a few simple questions, you can cut through the noise and land on the perfect choice for your project.

Think of this as your roadmap. Just follow these questions in order, and you'll find they naturally narrow down your options to the box that’s safe, compliant, and built for the job at hand.

1. What’s This Box Actually Doing?

First things first, what's its purpose?

Are you just making wire connections that need to be safely contained inside a wall? That's a classic job for a junction box.

Or, will this box hold a switch, an outlet, or a dimmer that you'll interact with every day? In that case, you need a device box.

If you're hanging a light fixture or a ceiling fan, you'll want an octagon or round box. And for anything that moves or has significant weight, like a fan, make absolutely sure you grab a model that is specifically fan-rated.

2. How Are You Running Your Wires?

The type of cable or conduit you're using is a huge deciding factor. If you're running metal-clad (MC) cable or using a metallic conduit system, you have to use a steel box. No exceptions. This is critical for maintaining the system's ground path.

For the standard non-metallic (NM) cable you see in most homes, a non-conductive PVC or fiberglass box is the go-to choice. It’s simple, effective, and often makes the material decision for you.

Remember, the goal is system integrity. Mismatching materials, like pairing a plastic box with metal conduit, breaks the ground continuity. That’s not just a code violation—it’s a serious safety hazard.

3. Where Is the Box Going to Live?

The environment dictates your next move.

Anything installed outdoors or in a location that gets wet—like a wash-down area—demands a weatherproof box. These come with gaskets and sealed hubs to keep moisture out.

Working in an unfinished basement, a garage, or an industrial space where the box might get knocked around? The durability of a steel box is what you need. For standard interior walls in a dry, protected location, a basic PVC box will do the trick just fine.

4. How Much Stuff Are You Putting Inside?

Finally, it’s time to do a little math. You need to calculate the "box fill," which is the total volume required for everything you're stuffing inside.

You have to account for every wire, the device itself (like the switch or outlet), any internal clamps, and all the grounding conductors. This calculation ensures the box has enough cubic-inch capacity to prevent overcrowding, which can lead to dangerous heat buildup and damaged wire insulation.

Getting this right is absolutely critical for passing an electrical inspection. Proper box fill is also essential for making sure overcurrent protection systems, like the ones in our guide to miniature circuit breakers, can do their job correctly.

Common Questions from the Field

When you're dealing with electrical boxes, a few questions pop up time and time again, especially when you're trying to keep things safe and up to code. Whether you’re on a residential job site or mapping out a complex industrial system, getting these details right is crucial.

Let's break down some of the most common head-scratchers we hear from electricians and engineers out in the field.

How Do I Figure Out the Right Size for an Electrical Box?

This is one of the big ones. The official term is box fill, and it’s not just about making sure everything fits. It’s a critical safety calculation designed to prevent wires from being crammed together, which can lead to dangerous heat buildup and create a serious fire hazard. The National Electrical Code (NEC) lays out the rules for this.

It's basically an addition problem. You have to account for the volume of everything going into the box:

- Every wire starting or ending in the box

- Any internal cable clamps

- The devices themselves (like a switch or receptacle)

- All grounding conductors

Once you add all that up, the total volume in cubic inches absolutely cannot be more than the capacity stamped inside the box. My rule of thumb? If your calculation is even close to the limit, just grab the next size up. It's not worth the risk.

Can I Use a Plastic Box with Metal Conduit?

The short answer is no. You really can't, and you shouldn't. The reason boils down to one critical word: grounding.

A metal conduit system isn't just a pipe for wires; it's an essential part of the grounding path that runs all the way back to the panel. The metal boxes are a key link in that conductive chain. When you insert a plastic box, you break that chain. You’ve created a gap in the safety system, and that's a serious hazard.

So, stick to the basics: metal conduit gets a metal box. If you're running non-metallic PVC conduit, then a plastic box is the perfect partner.

When you're choosing an electrical box, material compatibility isn't just a suggestion—it's a hard and fast rule. Mixing a plastic box with metal conduit is a clear code violation that completely undermines the grounding system.

What’s the Real Difference Between NEMA 3R and NEMA 4X?

Both of these ratings are for outdoor enclosures, but they are built for very different environments. Think of a NEMA 3R enclosure as your standard, reliable outdoor protection. It’s designed to keep out falling rain, sleet, and prevent ice from forming on the outside. It's a great workhorse for general outdoor spots where it won't be getting blasted with a hose.

A NEMA 4X enclosure, on the other hand, is a whole different beast. It's built for toughness. It’s completely watertight and can handle being sprayed down with a high-pressure hose, which is why you see them in washdown areas. The "X" is the key part—it means the enclosure also has corrosion resistance. This is non-negotiable for harsh environments like food processing plants, coastal salt-air locations, or chemical facilities where equipment gets eaten alive.

At E & I Sales, we live and breathe this stuff. We specialize in providing the right enclosures and components for the toughest industrial jobs. From UL-listed control panels to motor control centers, our team has the hands-on expertise to help you specify, design, and integrate solutions that are reliable, code-compliant, and built to last.

See how our turnkey integration services can help your next project at https://eandisales.com.