An ABB circuit breaker is a whole lot more than just a switch. Think of it as the ever-vigilant guardian of your entire electrical system, a critical piece of hardware designed to protect your equipment, prevent disastrous downtime, and keep your people safe. It does this by instantly and automatically cutting the electrical flow the moment it detects an overcurrent or a short circuit.

Why Your Electrical System Depends on the Right Breaker

In any industrial plant or commercial building, your electrical infrastructure is the absolute bedrock of productivity. When it goes down, everything grinds to a halt. The circuit breaker is your first line of defense against electrical faults that can fry expensive machinery, spark fires, or trigger catastrophic system-wide failures.

This makes choosing the right one more than just a minor technical detail—it's a foundational business decision.

An inadequate or poorly chosen breaker is a ticking time bomb. It might fail to trip during a major fault, letting a destructive surge of energy rip through your system. On the flip side, it could be too sensitive and trip unnecessarily, causing those frustrating nuisance shutdowns that kill efficiency and waste man-hours.

The Real Cost of Electrical Downtime

The fallout from a system failure goes way beyond the immediate repair bill. For a manufacturing plant, just one hour of downtime can easily translate to tens of thousands of dollars in lost production. In a data center, it could mean wiping out critical services and information.

A properly specified ABB circuit breaker is designed to mitigate these exact risks by delivering reliable, predictable protection you can count on.

This need for reliability is a major reason for the sector's incredible growth. The global circuit breaker market, valued at a massive USD 25.2 billion in 2025, is projected to hit USD 57.5 billion by 2035, a surge driven by industrial expansion and infrastructure upgrades. You can dive deeper into this market growth on futuremarketinsights.com.

A Roadmap for Reliable Protection

Consider this guide your practical roadmap to understanding and selecting the perfect ABB circuit breaker for your application. We're going to cut through the complex jargon and focus on what really matters: real-world scenarios and actionable insights.

Think of circuit protection as an insurance policy for your electrical assets. A premium breaker like an ABB Tmax XT or Emax 2 doesn't just prevent damage; it preserves operational continuity and safeguards your bottom line.

Throughout this guide, we'll walk you through:

- ABB's Core Families: We’ll break down the differences between Molded Case Circuit Breakers (MCCBs) like the workhorse Tmax XT and the powerful Air Circuit Breakers (ACBs) like the Emax 2.

- Essential Specifications: You’ll learn how to read a technical data sheet like a pro and understand which ratings and specs are critical for your needs.

- System Integration: Discover how these breakers connect with motor controls and panelboards to create a cohesive, safe, and fully integrated system.

- Best Practices: We’ll cover the essentials of installation, maintenance, and system upgrades to guarantee long-term performance and reliability.

Navigating the ABB Circuit Breaker Portfolio

Diving into the world of ABB circuit breakers can feel like walking into a massive, highly specialized workshop. With rows upon rows of models and series, it's easy to feel a bit lost.

The secret? Don't try to memorize every part number. Instead, let's simplify the entire landscape by splitting it into two main categories. Each one serves a distinct, vital role in keeping an electrical system safe and running.

Think of it like building a fortress. You need guards patrolling the individual corridors and rooms, and you also need massive walls protecting the entire compound. Both are essential, but they operate on completely different scales.

Molded Case Circuit Breakers: The Guardians on Patrol

The first line of defense in any distribution system is the Molded Case Circuit Breaker (MCCB). These are the versatile workhorses, the guardians on patrol. You'll find them protecting individual circuits, feeders, and specific pieces of equipment.

ABB's Tmax XT series is a perfect example. These are the breakers standing guard over the motors, lighting panels, and machinery on a factory floor. They handle the everyday protection jobs, dealing with currents typically ranging from 15A up to around 3200A.

They get their name from their construction—all the critical components are housed inside a compact, sealed "molded case" made of a tough insulating material. This design makes them incredibly reliable.

What makes an ABB MCCB a go-to choice?

- Compact Footprint: They are built to fit. Their smaller size is perfect for panelboards and switchboards where every inch of real estate counts.

- Sealed for Reliability: The sealed case keeps dust, moisture, and prying fingers out. This ensures they work when you need them to, with almost no maintenance required.

- Intelligent Protection: These aren't just simple on/off switches anymore. Many come equipped with sophisticated electronic trip units, like ABB's Ekip line, giving you precise, adjustable control over protection settings.

This blend of versatility and advanced protection is a big reason why ABB is a leader in the field. They've consistently developed circuit protection that meets the real-world needs of industrial facilities and commercial buildings. In fact, you can find more on ABB's market leadership at marketsandmarkets.com.

Air Circuit Breakers: The Fortress Walls

Now, let's zoom out. When you're not just protecting a single motor, but an entire facility—a hospital, a data center, a sprawling factory—you need the fortress walls. That’s the job of the Air Circuit Breaker (ACB).

ACBs, like ABB’s powerful Emax 2 series, are the heavy-duty protectors installed at the main service entrance. They are the first and last line of defense where power enters the building.

Built for massive currents, often from 800A up to 6300A and even higher, ACBs are fundamentally different from their molded-case cousins. They use the surrounding air to extinguish the enormous electrical arc that forms when interrupting a major fault. This requires them to be physically larger, more robust, and fully serviceable.

An ACB is your system's ultimate safety net. It’s engineered to handle the immense energy of a catastrophic short circuit right at the source, preventing a fault from cascading through your system and causing a complete shutdown.

What sets ACBs apart?

- Massive Interrupting Capacity: They can safely stop fault currents that would vaporize smaller breakers, protecting the entire downstream network.

- Built for the Long Haul: Their open construction is designed for maintenance. Key components can be inspected, serviced, and even replaced, giving them an incredibly long operational life.

- More Than a Breaker: The Emax 2, for instance, is also a full-fledged power manager. It integrates measurement, protection, and communication features to help you monitor and optimize your facility's energy consumption.

To help you see the big picture, here’s a quick breakdown of how these families compare.

ABB Circuit Breaker Families at a Glance

This table offers a high-level comparison of ABB's primary circuit breaker series, highlighting where each one fits best. It's a great starting point for quickly identifying the right category for your needs.

| ABB Series | Breaker Type | Primary Application | Key Feature |

|---|---|---|---|

| Tmax XT | MCCB | Feeders, branch circuits, motors, generators, switchboards | Compact size, advanced electronic trip units (Ekip) |

| SACE Emax 2 | ACB | Main service entrance, large industrial incomers, data centers | High interrupting capacity, power management functions |

| Formula | MCCB | Commercial and residential panels, smaller machinery (OEM) | Simplicity, reliability, and cost-effectiveness |

| SACE Isomax | MCCB (Legacy) | Older industrial installations and distribution panels | Robust, established performance (often subject to retrofit) |

Ultimately, choosing between an MCCB and an ACB is the first and most critical step. Once you know which "fortress" component you need, you can drill down into the specific series and ratings.

Of course, getting the right hardware is only half the battle. Navigating the procurement channels is just as important. For that, it often helps to connect with electrical supply sales representatives who live and breathe this stuff every day.

How to Select the Perfect Breaker for Your Needs

Picking the right ABB circuit breaker is about more than just matching a few numbers on a spec sheet. It's about translating that technical jargon into a real-world understanding of how the device will protect your equipment, your facility, and your people. Let’s break down the specs that matter so you can make the right call, every time.

First up is a common point of confusion: the difference between Ampere Frame (AF) and Ampere Trip (AT). Think of it like this: the Ampere Frame is the physical size of the breaker, like the diameter of a water pipe. It sets the absolute maximum amount of current the hardware can handle.

The Ampere Trip, on the other hand, is the adjustable valve on that pipe. It's the specific setting that tells the breaker when to shut everything down. This is why you can have an ABB breaker with a 250A frame (the pipe) fitted with an interchangeable trip unit rated for 150A, 200A, or 225A (the valve). This gives you the flexibility to precisely match the breaker's protection to the load it's guarding.

Understanding Your System's Ultimate Safety Net

Beyond basic current ratings, the single most critical safety spec you'll encounter is the Interrupting Capacity, often labeled as kAIC (kiloampere interrupting capacity). This number tells you the maximum amount of fault current the breaker can stop cold without failing—or worse, exploding.

Imagine a dam holding back a river. The river's normal flow is your everyday operating current. A fault current is a flash flood—a violent, uncontrolled surge of energy. The interrupting capacity is that dam's ultimate strength rating. It absolutely must be strong enough to contain the worst-case flood.

A breaker's kAIC rating must be equal to or greater than the available fault current at its point of installation. Getting this wrong is one of the most dangerous mistakes in electrical design, creating a serious fire and safety hazard.

For example, a breaker sitting right next to a massive utility transformer might need a 65 kAIC rating or higher. Another one installed way downstream in a small sub-panel, where the potential fault current is much lower, might only need 25 kAIC. There's no room for guesswork here.

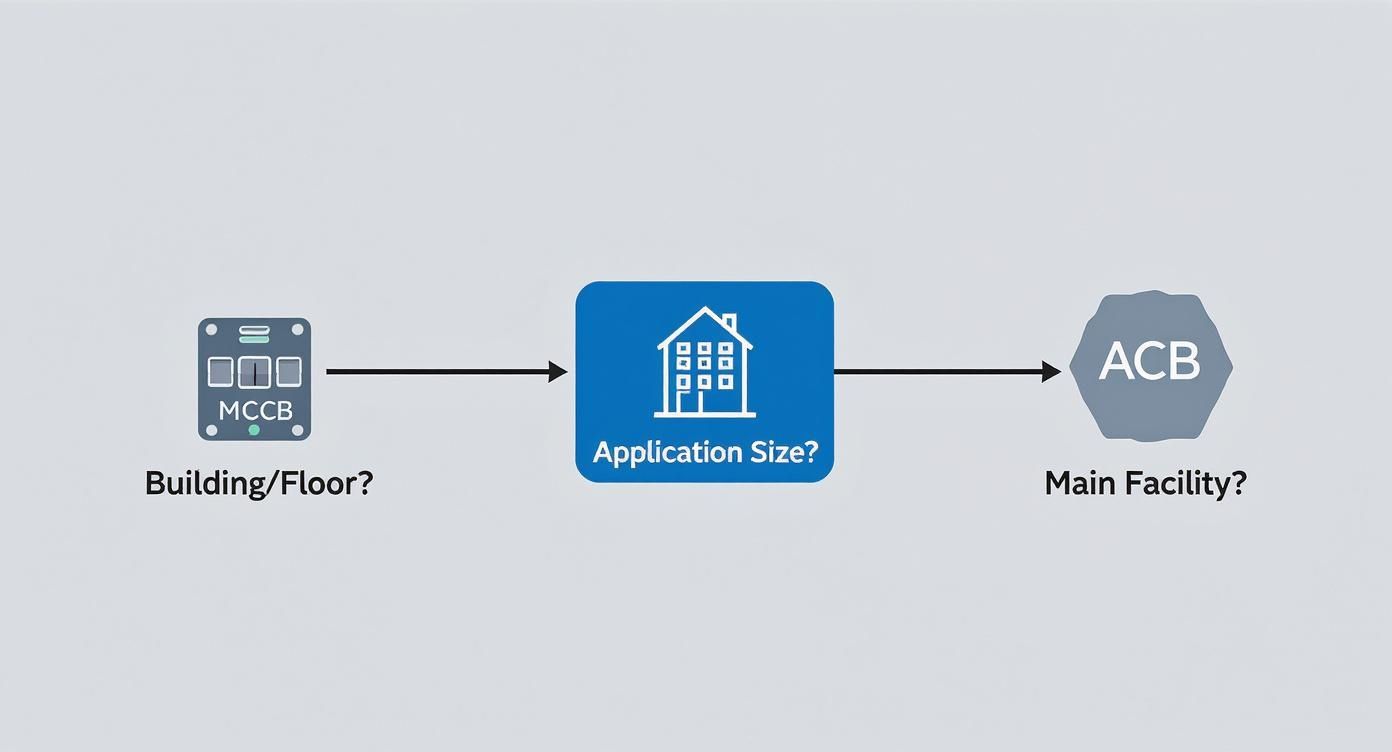

This diagram shows how the scale of your application—from a single floor's distribution panel to an entire facility's main switchgear—helps guide that initial choice between a molded-case (MCCB) or an air circuit breaker (ACB).

As you can see, the MCCB handles branch-level protection, while the heavy-duty ACB stands guard at the main service entrance. This visual makes that first big decision much clearer.

Choosing the Right Brains for the Operation

The final piece of the puzzle is the trip unit—the "brain" of the ABB circuit breaker. This is the component that actually senses an overload or short circuit and gives the command to trip. The two main types offer very different levels of control.

-

Thermal-Magnetic Trip Units: These are the reliable, workhorse standard. The "thermal" part uses a bimetallic strip that heats up and bends during a long, slow overload. The "magnetic" part reacts instantly to the huge current spike of a short circuit. They’re perfect for straightforward jobs like protecting lighting circuits or simple resistive loads.

-

Electronic Trip Units: When you get into industrial settings with motors and sensitive machinery, electronic trip units like ABB's Ekip series are in a league of their own. These are microprocessor-based brains that give you incredible control. You can fine-tune the trip settings for long-time (overload), short-time, and instantaneous (short-circuit) events. This precision is key for proper system coordination, ensuring the breaker closest to a fault opens first without taking down an entire production line.

For instance, you can program an electronic trip unit with a slight delay to ride through the normal inrush current of a large motor starting up. A basic thermal-magnetic unit might just see that as a fault and cause a nuisance trip. That's the kind of granular control that keeps a complex facility running smoothly.

Critical ABB Breaker Specifications Explained

This table provides a quick-reference guide to the essential ratings you'll find on any ABB breaker spec sheet and why they are so important.

| Specification | What It Means | Why It Matters for Selection |

|---|---|---|

| Ampere Frame (AF) | The maximum continuous current the breaker's physical structure can carry. | Defines the breaker's physical size and ultimate current limit. You pick a frame that can house your required trip rating. |

| Ampere Trip (AT) | The current level where the breaker trips due to an overload. | This has to be matched to the load being protected (e.g., wire ampacity or motor full-load amps) to prevent damage. |

| Interrupting Capacity (kAIC) | The maximum fault current the breaker can safely interrupt without catastrophic failure. | This is a non-negotiable safety rating. It must be higher than the calculated available fault current where it's installed. |

| System Voltage | The nominal voltage of the electrical system (e.g., 480V, 600V). | The breaker's voltage rating must always be equal to or greater than the system voltage it's protecting. |

By carefully evaluating these four key elements—frame size, trip rating, interrupting capacity, and trip unit technology—you can confidently choose an ABB circuit breaker that delivers the exact safety and performance your system demands.

Weaving Breakers Into Your Industrial Systems

An ABB circuit breaker doesn't work in isolation. You really unlock its value when it becomes a seamless, intelligent part of your larger electrical ecosystem. Think of it less like a standalone gadget and more like a key player on a team, constantly communicating and coordinating to keep your entire system robust, reliable, and safe.

This integration is absolutely crucial in two specific areas of any industrial facility: UL-listed panelboards and Motor Control Centers (MCCs). In these applications, the breaker isn't just a simple safety switch; it's a foundational building block that your operational continuity depends on.

Breakers in the Heart of the Operation: Motor Control Centers

Motor Control Centers are the central nervous system for a plant's machinery. They house the starters, drives, and protective gear for countless motors. The circuit breaker's job here is incredibly specific: protect very expensive motors from electrical faults without causing unnecessary downtime.

This is exactly where an advanced ABB circuit breaker with an electronic trip unit proves its worth. It gives you the granular control needed to tell the difference between a dangerous short circuit and the harmless (but high) inrush current you get when a big motor kicks on. This smart distinction prevents the kind of nuisance tripping that can grind production to a halt.

You can get a solid primer on the basics in our article exploring what a motor control center is.

Here’s the bottom line: coordinated protection is everything. In a properly designed system, a fault on one motor circuit should only trip its dedicated breaker. This isolates the problem instantly, letting the rest of the facility run without missing a beat.

Getting Your System to Talk: Coordination and Communication

Modern industrial plants need more than just basic overcurrent protection; they demand data and communication. The latest ABB breakers come equipped with communication protocols like Modbus and Profibus, allowing them to "talk" directly to your central control system, whether it’s a PLC or SCADA.

This digital link completely changes the game, turning the breaker from a passive device into an active source of intel. It can report on:

- Energy Consumption: Pinpoint exactly how much power individual machines are using to spot inefficiencies.

- Operational Status: Get real-time feedback on whether the breaker is open, closed, or has tripped.

- Fault Diagnostics: When a trip does happen, the breaker can tell you why—overload, short circuit, or ground fault. This slashes troubleshooting time for your maintenance crews.

This level of integration opens the door to predictive maintenance and much smarter energy management. By keeping an eye on a breaker’s performance data, your engineers can spot trends that might signal a developing problem with a motor long before it fails catastrophically.

This push for smart, interconnected electrical gear is a global trend. The Asia Pacific region, for instance, represents the largest piece of the pie, commanding about 45.7% of the total circuit breaker market revenue in 2024, largely driven by massive power grid projects in China and India. You can dig into more insights on the global circuit breaker market on mordorintelligence.com.

The Non-Negotiable: UL-Listed Assemblies

Finally, proper integration isn't just about clever features; it's about certified safety. When you install an ABB circuit breaker in a panelboard or switchboard, the entire finished assembly has to meet incredibly strict safety standards. A UL-listed assembly is your guarantee that the breaker, the enclosure, and all the internal wiring have been tested to work together safely as a single unit.

Mixing and matching components without that certification is a huge gamble. It can easily lead to overheating, bad connections, and a total failure to contain an electrical fault, creating serious fire and arc flash hazards.

For any system integrator or facility manager, specifying a fully tested and UL-listed assembly is simply non-negotiable. It ensures:

- Code Compliance: Your system will meet national and local electrical codes, sailing through inspections without the headache of costly rework.

- Verified Performance: The breaker's interrupting capacity and thermal limits are guaranteed to perform as expected within that specific enclosure.

- Enhanced Safety: The assembly is proven to handle fault conditions safely, protecting both your people and your property.

By focusing on smart coordination, open communication, and certified assemblies, you can leverage the full power of an ABB circuit breaker and make it the cornerstone of a safe, efficient, and incredibly reliable industrial system.

Getting Installation and Maintenance Right

Here’s the thing about even the most advanced ABB circuit breaker: it's only as good as its installation and the care it receives afterward. Think of it like a high-performance race car engine. All that power is worthless without a flawless setup and regular tune-ups. Following best practices isn't just a recommendation; it's the only way to guarantee the long-term safety and performance of your entire electrical system.

This is about more than just ticking a box on a work order. It’s about actively fighting the two biggest enemies of any electrical gear: heat and neglect. A single loose connection or a bit of conductive dust is all it takes to spark a catastrophic failure, turning a critical asset into a dangerous liability.

Let's walk through a practical field guide for getting it right from day one.

Nailing the Installation the First Time

A breaker’s entire life story is written in the first few moments of its installation. When you rush this part, you introduce tiny, hidden weaknesses that might not show up for months or even years. When they do, it’s always a serious problem.

Pay close attention to three things: proper mounting, secure connections, and adequate clearance. Each one is non-negotiable for the breaker to do its job safely, both under normal load and during a fault.

Key Installation Steps:

- Check Your Clearances: Make sure there's enough room around the breaker for air to circulate freely. Overheating is the number one killer of circuit breakers, and boxing it in without ventilation basically turns the enclosure into an oven.

- Inspect for Damage: Before you even think about installing it, give the breaker a thorough once-over. Look for any cracks or defects in the case and terminals that might have happened during shipping. A compromised case means its structural and insulating properties are shot.

- Torque to Spec. No Exceptions: This is the big one. Use a calibrated torque wrench and tighten every line and load connection to the exact manufacturer's spec. Too loose, and you create resistance and heat. Too tight, and you can crack the terminal and damage the breaker.

And of course, always follow the established safety standards. To make sure your work is fully compliant, you should always consult the relevant building codes and regulations.

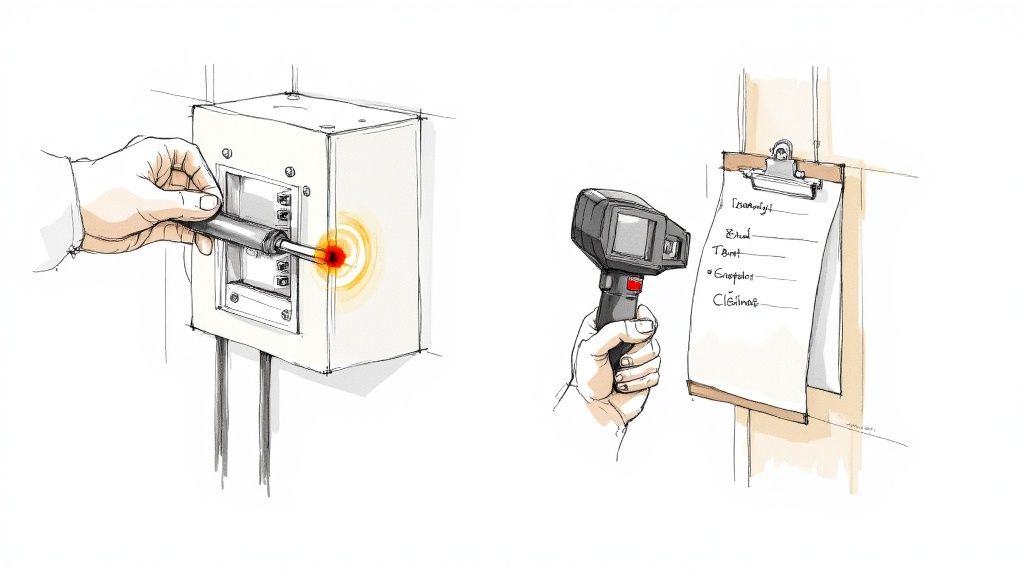

Proactive Maintenance for Unshakeable Reliability

Once it's installed, an ABB circuit breaker isn't a "set it and forget it" device. A proactive maintenance schedule is your insurance policy against sudden failures and crippling downtime. While a well-cared-for breaker can last 30 to 40 years, that lifespan gets cut short fast in a harsh environment or without regular attention.

Maintenance is all about shifting your mindset from reactive (fixing things when they break) to predictive (spotting trouble before it starts). This means a smart mix of visual checks, mechanical tests, and more advanced diagnostics.

A well-maintained circuit breaker is a predictable asset. A neglected one is an unpredictable risk. Regular maintenance isn't a cost—it's an investment in operational stability and personnel safety.

Your maintenance plan needs to be built around your facility's unique conditions. Is it dusty? Damp? Full of vibration? For a deeper look at what that entails, especially for complex machinery, our guide to motor control center maintenance is a great resource.

Your Essential Maintenance Checklist

Here’s a practical, tiered approach for building out your maintenance schedule, starting with simple routine checks and moving to more involved annual tasks.

Annual Maintenance Tasks:

- Infrared (IR) Scanning: Get an IR camera on the breaker while it’s under load. This is the fastest way to spot hot spots at terminals and connections before they can turn into a major failure.

- Mechanical Testing: Manually switch the breaker on and off a few times. "Exercising" the mechanism like this ensures the internal lubricants don't gum up and seize.

- A Thorough Cleaning: De-energize the system completely and use a vacuum (not compressed air, which just blows dust around) to clean out the breaker and its enclosure. This prevents electrical tracking and flashovers.

- Connection Re-Torquing: Heat and vibration can cause connections to loosen slightly over time. After the initial settling-in period, it's smart to verify that all terminals are still torqued to the original spec.

Let's be honest—your facility's electrical system won't last forever. Components get old, technology marches on, and safety standards become more stringent. But what happens when your switchgear is showing its age, but a full, multi-million-dollar replacement just isn't in the budget? It’s a tough spot many facility managers find themselves in.

The good news? You don't always have to rip everything out and start from scratch. A smarter, more targeted approach is to upgrade the single most important component: the circuit breaker. This strategy, known as retrofitting, lets you infuse modern protection and intelligence into your existing gear.

By swapping out those old, tired breakers for a modern ABB model like the Tmax XT or Emax 2, you can give your entire system a new lease on life. You get the benefits of today's tech without the massive cost and downtime of a complete overhaul, stretching the reliable life of your switchgear for years.

Choosing Your Retrofit Strategy

When it's time to upgrade an older breaker, you've really got two main paths: a direct replacement or a full-on retrofit solution. Which one is right for you boils down to the age and model of your existing equipment.

-

Direct Replacement: This is the easiest route. For breakers from lines ABB recently acquired (like GE Industrial Solutions), you can often find a direct, form-fit replacement. A classic example is swapping an old GE Spectra breaker for a new Tmax XT with very little modification needed.

-

Retrofit Kits: For ancient or obsolete breakers from other manufacturers, a simple swap is off the table. This is where engineered retrofit kits are a lifesaver. These kits come with custom-designed hardware—think busbar adapters and mounting plates—that allow a modern ABB circuit breaker to be installed safely and securely inside an older switchgear cabinet.

Retrofitting isn't just a patch-up job; it's a strategic modernization. It lets you tackle the highest-risk parts of your system first, boosting safety and reliability in a big way while pushing massive capital spending further down the road.

Weighing the Costs and Benefits

The decision to retrofit or replace always comes down to a hard look at the costs and benefits. A full switchgear replacement is a massive capital project that almost always involves extended downtime—the kind that can bring production to a grinding halt.

A targeted breaker retrofit, on the other hand, is more like a surgical procedure. It can often be done in a fraction of the time, usually during a planned maintenance window, keeping operational disruptions to a minimum. While a high-tech breaker and a custom retrofit kit aren't cheap, the cost is almost always just a fraction of a full system replacement.

And just look at the tangible benefits you get:

- Enhanced Safety: Modern breakers are simply better at what they do, offering far superior arc flash mitigation and more dependable fault interruption.

- Improved Reliability: New components mean you're no longer gambling on old, worn-out mechanical parts. A well-cared-for breaker can last 30 to 40 years, and a retrofit essentially resets that clock.

- Advanced Monitoring: When you upgrade to a breaker with an electronic trip unit, like an Emax 2, you suddenly unlock communication capabilities. That old switchgear can now feed you critical data on energy consumption and system health.

- Simplified Maintenance: New breakers, especially the plug-in models, can slash maintenance time and effort by getting rid of the need to constantly re-torque connections.

Ultimately, retrofitting an ABB circuit breaker into your existing system is a powerful move. It delivers the most important safety and performance upgrades right where they count, buying you invaluable time and extending the life of your most critical electrical assets.

Got Questions About ABB Breakers? We've Got Answers.

Even after you've done your homework, a few specific questions always seem to pop up when it's time to choose, install, or upgrade an ABB circuit breaker. We get it. That's why we’ve put together some quick, straightforward answers to the questions we hear most often from engineers and facility managers out in the field.

Think of this as your go-to guide for getting clear on the details so you can make decisions with confidence.

What's the Real Difference Between an ABB MCCB and an ACB?

The biggest distinction boils down to three things: where it's used, how it's built, and how much power it can handle.

A Molded Case Circuit Breaker (MCCB), like ABB's workhorse Tmax XT series, is what you'll find protecting individual circuits, feeders, and motors all over a facility. They typically handle currents up to 3200A. Just like the name says, all its guts are sealed inside a compact, non-serviceable molded case.

On the other hand, an Air Circuit Breaker (ACB), like the beastly Emax 2, is the guardian at the gate. You'll find it at the main service entrance of a large facility, where it protects the entire building from a catastrophic fault. These are rated for massive currents, up to 6300A or even more. An ACB uses the surrounding air to extinguish the huge electrical arc when it trips and is designed with components that can be serviced, giving it a much longer operational life.

How Do I Pick the Right Trip Unit?

Choosing the right trip unit—the "brain" of the breaker—is absolutely crucial. It's what matches the protection to the exact piece of equipment it's supposed to be guarding.

- Thermal-Magnetic Trip Units: These are the dependable, cost-effective standard for basic overload and short-circuit protection. They are the perfect fit for simpler, less critical loads like lighting panels or resistive heaters.

- Electronic Trip Units: When you need precision and flexibility, you step up to an electronic unit like ABB’s Ekip series. These let you fine-tune everything—long-time, short-time, and instantaneous trip settings. This level of control is essential for protecting expensive motors and getting selective coordination right in a complex system.

Here's a simple rule of thumb: If you just need basic protection, thermal-magnetic will do the job. But if you're protecting motors, coordinating a multi-layered system, or you need advanced diagnostics and communication, an electronic trip unit is a must.

Can I Swap Out Another Brand's Breaker for an ABB Model?

This is a question we hear all the time, especially when dealing with older facilities. A direct, one-for-one physical swap is almost never possible because of differences in size and how they mount. But the answer is still usually yes—with a retrofit.

ABB has engineered retrofit solutions that come with custom adapter plates and busbar connections. These kits allow a modern, feature-rich ABB circuit breaker to be installed safely into an older switchgear cabinet that was built for a competitor's breaker that is now obsolete. It’s a smart way to bring your system's protection and reliability into the 21st century without the staggering cost and downtime of replacing the entire switchgear.

At E & I Sales, this is what we do day in and day out. Whether you’re just selecting a new breaker, planning a full-scale retrofit, or designing a complete UL-listed control panel from scratch, our team has the hands-on expertise to make sure you get a reliable, code-compliant solution that just works. Reach out and let's talk about your project at https://eandisales.com.