A control panel builder is a specialized company that designs, builds, and tests the electrical control systems for industrial machinery. Think of them as the architects of your equipment’s nervous system. They take your operational goals and translate them into a physical control system that’s safe, efficient, and ready to work.

What Does a Control Panel Builder Really Do?

Sure, they build panels. But their real job is to be a critical engineering partner. They take a list of your needs—controlling motor speeds, reading sensors, activating safety locks—and turn it into a functional piece of hardware. This isn't just about connecting wires; it's a careful mix of electrical engineering, deep knowledge of regulations, and hands-on craftsmanship.

These builders create a unified system that becomes the command center for your entire operation. Their work is what ensures every button press and automated sequence happens exactly when and how it should, protecting both your expensive machinery and your people.

The Core Mission of a Builder

When you get right down to it, a builder's main job is to provide certainty. Partnering with a professional builder means handing off a highly specialized and critical task to experts who live and breathe electrical code and automation logic. They handle the complexity so you can focus on running your business.

This breaks down into a few key areas that show their true value:

- Turning Ideas into Hardware: They take your P&IDs (piping and instrumentation diagrams) or even just a functional description and engineer a tangible solution that works in the real world.

- Keeping Things Safe and Legal: A good builder knows the standards inside and out. They design and build panels to meet strict requirements from organizations like UL (Underwriters Laboratories), ensuring the final product is safe, reliable, and insurable.

- Choosing the Right Parts for the Job: They select the best components—from PLCs and VFDs to breakers and terminals—to make sure the panel can handle the specific demands of your operation without fail.

- Supporting You from Start to Finish: The job doesn't end when the panel is built. The best builders provide complete documentation, rigorous testing, and even on-site commissioning to make sure everything integrates smoothly.

A skilled control panel builder is the bridge between your operational vision and the physical hardware that makes it happen. They turn abstract requirements into a robust, safe, and fully functional electrical system.

This isn't a niche market, either. The global industrial control panels market was valued at USD 13.5 billion in 2023 and is on track to hit around USD 20.8 billion by 2032. That growth shows just how much modern industries rely on automation to stay competitive and safe. You can explore more about these market trends and their drivers.

In the end, a control panel builder delivers more than just a box with wires. They provide a critical asset engineered for dependability, forming the very backbone of modern industrial automation.

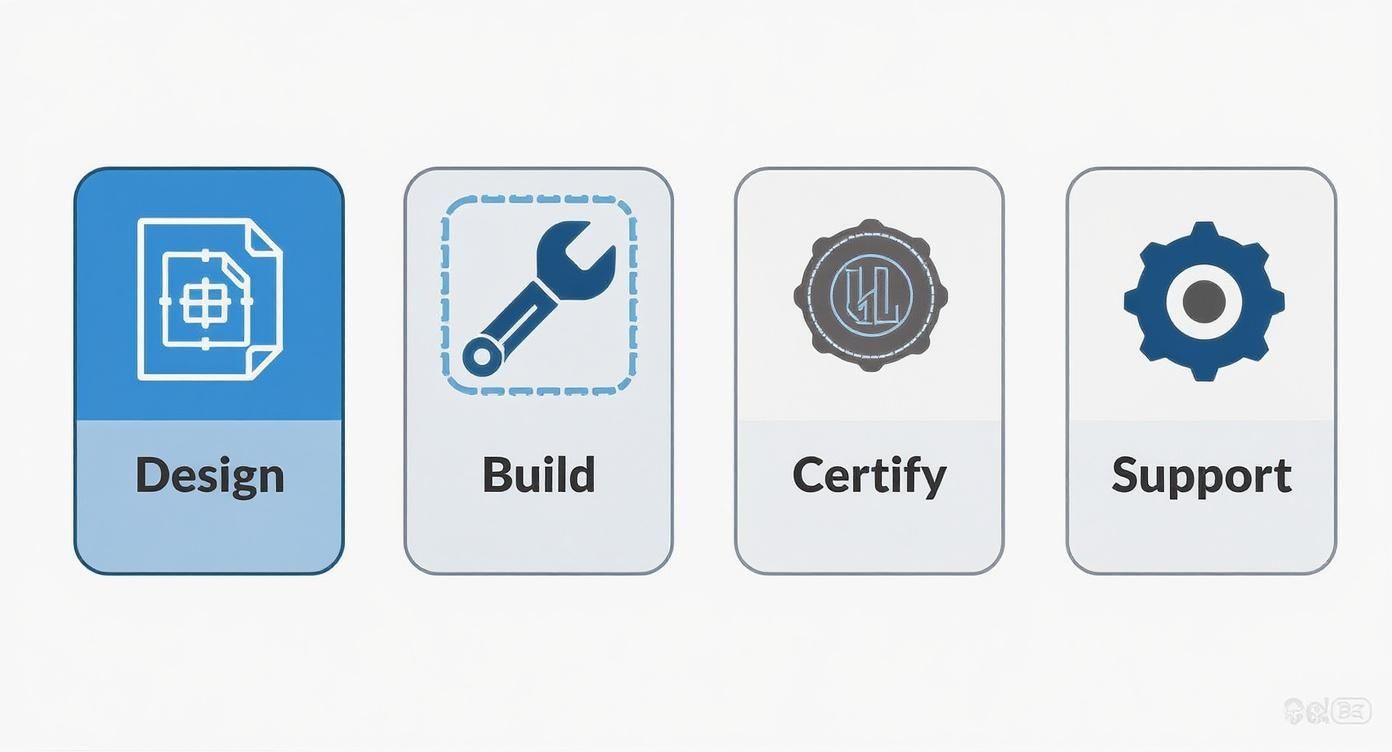

From Blueprint to Operation: Core Builder Services

A professional control panel builder does a lot more than just screw components onto a backplate. They take a project on a structured, multi-stage journey, turning a simple operational need into a control system that’s functional, safe, and built to last.

Think of it like getting a custom suit made. You don't just hand over fabric; you work with a master tailor who measures, designs, cuts, and stitches everything with precision. They ensure the final product fits perfectly and looks sharp. That’s what a great panel builder does for your industrial controls.

Each phase demands a specific mix of engineering know-how, deep regulatory knowledge, and old-fashioned hands-on craftsmanship. Let's walk through the four core services that separate the pros from the amateurs.

Collaborative Design and Engineering

It all starts with an idea. The journey begins by turning your concept into a concrete, manufacturable plan. Honestly, this is the most critical phase—every decision made here ripples through the panel's final performance, safety, and cost.

A skilled builder works with you to nail down the exact operational requirements. This isn't just about taking orders; it’s a deep-dive conversation where they ask the tough questions to head off problems before they start:

- Where will this panel live? Is it indoors, outdoors, or in a hazardous location?

- What are the real power requirements and motor loads we're dealing with?

- What communication protocols need to play nicely together, like Ethernet/IP or Modbus?

- What specific safety interlocks are non-negotiable for protecting people and machinery?

Armed with this information, their engineers draft detailed electrical schematics, enclosure layouts, and a full bill of materials (BOM). This blueprint becomes the single source of truth for the entire project, ensuring every part is specified and placed for peak function and easy servicing down the road.

Precision Fabrication and Assembly

Once the design is locked in, the project moves from the screen to the shop floor. This is where expert craftsmanship truly shines. The fabrication happens in a controlled environment, carried out by certified technicians who live and breathe industrial control panels.

The whole process is methodical and precise. Technicians mount the backplate, lay down DIN rails, and carefully place every single component—from the main breaker and PLC right down to the terminal blocks and wire ducts. The wiring itself is practically an art form. Each connection is cut to the perfect length, clearly labeled, and torqued to spec. A clean, well-organized panel isn't just nice to look at; it's a thousand times easier to troubleshoot and safer to maintain.

A messy, disorganized panel is a huge red flag. The level of care a builder puts into wire management and labeling speaks volumes about their commitment to quality and long-term reliability.

This stage is all about bringing the schematics to life with an uncompromising focus on the small stuff.

UL Listing and Regulatory Compliance

One of the single most important services a qualified panel builder offers is ensuring the final product meets all industry standards—especially UL 508A. This certification is the gold standard for industrial control panel safety in North America.

A UL 508A Listed panel means it was built in a certified shop, using approved components, and following a strict set of construction rules. This isn't just about getting a sticker for the enclosure. It provides a few critical guarantees:

- Safety Verification: It confirms the panel was designed and built to protect against fire and electrical shock.

- Code Acceptance: Inspectors and regulators across the country recognize the UL mark, which can save you massive headaches and delays during project approvals.

- Insurability: Good luck getting a policy without it. Many insurance providers require critical electrical equipment to be UL Listed.

When a builder maintains an active UL 508A certification, it shows a serious commitment to safety and quality. It gives you peace of mind that your panel isn't just going to work, but it's going to be fundamentally safe.

Commissioning and Field Support

A great builder knows their job isn't done when the panel ships out the door. The final, crucial step is making sure it integrates smoothly into your facility and performs exactly as designed. That’s where commissioning and field support come in.

Commissioning means on-site technicians power up the panel, verify every I/O point, check motor rotations, and confirm all automated sequences run flawlessly. They troubleshoot any hiccups that pop up during startup, working right alongside your team to fine-tune the system. This final check makes the transition from installation to full-throttle operation as smooth as possible.

Beyond that, a reputable builder provides comprehensive documentation—we’re talking as-built drawings and operation manuals—that becomes invaluable for future maintenance. Exploring the full scope of custom controls and their lifecycle support will give you a much deeper insight into what to expect from a true partner.

Decoding Technical Specifications and Standards

To get the most out of a partnership with a control panel builder, you need to speak their language. Don't worry, this isn't about becoming an electrical engineer overnight. It's about understanding the core technical specs and standards that shape your project's safety, reliability, and final cost.

Getting these details right from the very beginning is the single best way to prevent expensive rework down the road. Think of your specifications as the DNA of your control panel—they define everything from the toughness of its steel box to the "brain" running the whole show. A vague request gets you a generic panel, but a precise spec sheet lets a builder craft a system that fits your operation like a glove.

This precision is more important than ever. The global electric control panel market was valued at around USD 7.48 billion in 2025 and is on track to hit USD 11.1 billion by 2032. That growth is all about automation and tighter safety rules, making clear, accurate specs non-negotiable. You can learn more about the electric control panel market growth and its drivers.

NEMA And UL Ratings Explained

When you're talking about enclosures, you'll hear NEMA and UL ratings thrown around a lot. They aren't the same thing, but they both tell you how well an enclosure can protect the sensitive electronics inside from the outside world.

Think of a NEMA rating as the enclosure’s "armor class." It tells you exactly what kind of abuse it can handle. A NEMA 1 enclosure is perfectly fine in a clean, dry office, but it would fail in a heartbeat in a washdown area. On the other hand, a NEMA 4X enclosure is built to shrug off corrosion and high-pressure water jets, making it the go-to for food processing plants or marine environments.

UL ratings, specifically UL 508A, take it a step further. While NEMA sets the performance standard, a UL Listing is proof that a control panel builder has actually built and tested a panel to meet that standard, certifying it's safe from fire and electrical hazards.

To help you get started, here's a quick rundown of some common NEMA ratings you'll encounter.

NEMA Enclosure Ratings Explained

| NEMA Rating | Protection Against | Common Application Environment |

|---|---|---|

| NEMA 1 | Falling dirt, dust, and accidental contact | Indoor, non-hazardous locations like offices or labs. |

| NEMA 3R | Rain, sleet, snow, and external ice formation | Outdoor locations that are generally protected. |

| NEMA 4X | Corrosion, windblown dust, rain, and hose-directed water | Food processing, marine, or chemical plants. |

| NEMA 12 | Dripping non-corrosive liquids, falling dirt, and dust | Indoor industrial settings like factories or warehouses. |

Knowing just these four ratings will give you a solid foundation for specifying the right enclosure for almost any job.

This entire process, from the first sketch to long-term support, is critical for delivering a system that’s not just functional, but also safe and compliant.

Core Components And Their Functions

Inside the box, a few key components do all the heavy lifting. Knowing what they are and what they do will help you have much smarter conversations with your builder.

A Motor Control Center (MCC) is a perfect example. Instead of having individual motor starters and controllers scattered all over your plant floor, an MCC neatly centralizes them in one floor-standing cabinet. This makes maintenance a breeze, improves safety, and saves a ton of space.

Of course, inside the panel, you'll find the brains of the operation:

- Programmable Logic Controllers (PLCs): These are tough, industrial-grade computers that run your automated processes. You program them to read inputs (like a sensor seeing a box) and control outputs (like telling a conveyor belt to start moving).

- Variable Frequency Drives (VFDs): A VFD gives you precise control over an AC motor’s speed by changing the power it receives. This is huge for fine-tuning operations, enabling soft starts that reduce mechanical wear, and saving a significant amount of energy compared to just running a motor at full blast all the time.

Choosing the right components is a balancing act. An experienced control panel builder will help you select devices that offer the necessary performance without over-engineering the solution and driving up costs.

This careful selection is the heart of good system architecture. For a closer look at these early planning stages, check out our guide on industrial control panel design.

Ensuring Safety And Lifecycle Support

Finally, every good specification covers safety and testing. This means calling out requirements for emergency stops, safety relays, and proper grounding. Before a panel ever leaves the shop, your builder should conduct a thorough factory acceptance test (FAT). This is where they power everything up and check every single circuit, input, and output to make sure it works exactly as designed.

Lifecycle support is the last piece of the puzzle. A great builder won’t just ship you a panel; they’ll provide a complete documentation package with as-built electrical drawings, a bill of materials (BOM), and all the component manuals. This information is gold for future troubleshooting, maintenance, and upgrades, making sure your investment serves you well for years to come.

How Custom Control Panels Solve Real-World Problems

It’s one thing to talk about technical specs and industry standards. It’s another to see how they come together to solve messy, real-world problems. That’s where the true value of a custom control panel builder shines. These panels are the unsung heroes of modern industry, the brains behind the brawn, making sure complex operations run smoothly, safely, and efficiently.

Think of it like this: an off-the-shelf control solution is like buying a suit off the rack. It might do the job, but it’ll never fit perfectly. A custom panel, on the other hand, is a bespoke suit—tailored by an expert to fit your exact operational needs, your specific environment, and your business goals.

Let's look at a few places where this custom-tailored approach is a game-changer.

The Automotive Assembly Line

Picture a high-speed automotive assembly line—a ballet of robots, conveyors, and human-operated stations all needing to work in perfect harmony. A split-second timing error isn't just a minor hiccup; it can cause costly defects or, far worse, a serious safety incident. The custom control panel is the central nervous system that keeps this entire symphony in sync.

A good control panel builder designs a system from the ground up for this demanding environment, focusing on:

- High-Speed Processing: Using a powerful PLC that can juggle thousands of I/O points in milliseconds, ensuring every robotic arm and conveyor belt moves with absolute precision.

- Integrated Safety: Weaving light curtains, e-stops, and safety relays directly into the control logic. This isn't an afterthought; it's a core function that creates a failsafe system to protect people on the floor.

- Precision Motor Control: Implementing Variable Frequency Drives (VFDs) to dial in conveyor speeds, perfectly matching the pace of production to maximize throughput without sacrificing quality. Dig into the details in our article on variable frequency drive basics.

The global automotive control panel market is already a massive industry, valued at around USD 118.99 billion in 2024 and expected to hit USD 217.35 billion by 2034. This explosive growth is fueled by the need for these kinds of sophisticated, integrated systems, especially as the world shifts to electric vehicles. You can discover more insights about the automotive control panel market and what's driving the technology forward.

The Water Treatment Plant

Now, shift gears to a municipal water treatment facility. This is critical infrastructure that has to run 24/7/365, no exceptions. The stakes are incredibly high, so the control system needs to be bulletproof, with layers of redundancy and options for remote oversight.

Here, the top priority isn't just speed; it's unwavering reliability. The panel has to survive its environment and give operators total visibility, whether they’re standing in front of it or miles away.

A builder will craft a panel to meet these specific demands by:

- Building in Redundancy: This could mean dual power supplies or even a hot-standby PLC, ensuring that if one component fails, another takes over instantly without a system-wide shutdown.

- Enabling Remote Access: The panel is fitted with secure communication modules, allowing engineers to monitor everything—pump status, chemical levels, alarm conditions—from a central control room or even a tablet.

- Choosing a Durable Enclosure: A NEMA 3R or NEMA 4 rated enclosure is non-negotiable here. It shields the sensitive electronics inside from the moisture, dust, and temperature swings that are a given in these facilities.

The Food Packaging Facility

Finally, let’s walk into a food packaging plant where hygiene is king. Everything gets washed down, often with high-pressure, high-temperature water and harsh cleaning agents. A standard control panel would be toast in this environment, quickly leading to contamination risks and costly downtime.

The solution is a custom-built panel designed to NEMA 4X standards. The builder uses a stainless-steel enclosure with specialized gaskets and waterproof conduit entries, creating a fortress that is completely sealed against corrosion and water ingress.

This purpose-built solution allows the plant to uphold the strictest sanitation protocols without ever having to worry about its automation systems. It's a perfect example of how a skilled control panel builder goes beyond just wiring components to deliver a solution that solves a business's unique operational reality.

Your Checklist for Vetting a Control Panel Builder

Choosing the right partner for your control panel build is single-handedly the most important decision you'll make in the entire project. It's a big deal. The quality of their work directly echoes in your uptime, your team's safety, and what you’ll be spending on maintenance for years to come.

A rock-bottom quote might look tempting, but it can quickly become an expensive headache if the builder cuts corners on components or quality control.

To make a smart choice, you have to look past the price tag. It's about digging into a builder's true capabilities, their processes, and their real-world experience. This means asking sharp questions and knowing what a good answer sounds like. A methodical approach ensures you find a partner who will deliver a reliable, compliant, and well-documented system.

Verify Certifications and Technical Expertise

First things first, you need to confirm their core qualifications. This isn't just about feeling good about your choice; it's about getting verifiable proof that they meet industry-wide standards for safety and quality. Without these basic credentials, everything else is just talk.

Start with the big one: UL 508A. Don't be shy—ask for their file number and check that it's active. This certification is your assurance that they operate a facility and follow strict procedures that meet demanding safety standards recognized across the country.

Next, get a feel for the depth of their in-house engineering team. You're looking for a partner, not just an assembly line. Ask about the background of their engineers and designers. Do they have people who specialize in PLC programming, HMI development, or—most importantly—your specific industry? A solid engineering team can spot design flaws you might miss, recommend better components, and add incredible value far beyond just building to a print.

Scrutinize Quality Control and Project Management

Consistent quality doesn't just happen, especially when you're ordering more than one panel. It’s the product of a deliberate, documented system. Any reputable control panel builder should be able to walk you through their quality management system (QMS) without hesitation.

Ask them to lay out their process. You'll want to zero in on a few key areas:

- Component Sourcing: How do they guarantee they're using authentic, high-quality parts and not gray-market knockoffs?

- In-Process Checks: What specific verification steps do they take during fabrication and wiring to catch mistakes early?

- Final Testing: Do they perform a full factory acceptance test (FAT) on every single panel before it leaves their shop? Ask for a copy of their standard FAT checklist.

A builder's quality process is a direct reflection of their commitment to reliability. If they can’t show you a documented, repeatable system for ensuring quality, that’s a massive red flag.

Just as crucial is their approach to project management. You should have a dedicated project manager—a single point of contact who provides regular updates and keeps the timeline in check. This kind of structure prevents miscommunication and keeps your project moving from kickoff to commissioning. A clear process for handling change orders is also essential to stop scope creep and budget blowouts in their tracks.

Evaluate Industry Experience and Support

At the end of the day, a builder's past performance is the best predictor of future success. Don't just take their word for it; ask them to prove they understand the unique headaches and hurdles of your industry. Request case studies or examples of projects similar to yours in scope and complexity.

Talking to their references is a step you simply cannot skip. When you get them on the phone, ask targeted questions:

- How was the communication throughout the project?

- Was the documentation package complete and accurate?

- Did the final panel meet every expectation for quality and performance?

- How did they handle any curveballs that popped up during or after installation?

This is where you get the real story. The feedback from past clients gives you invaluable insight into what it’s actually like to work with them. A great builder will be excited to connect you with happy customers. Their willingness to provide solid, relevant references says everything about their confidence and their focus on building lasting partnerships.

To help you compare potential partners side-by-side, we've put together a simple checklist.

Control Panel Builder Evaluation Checklist

| Evaluation Criteria | Builder A | Builder B | Notes |

|---|---|---|---|

| Certifications | |||

| Active UL 508A Listing (Verified) | ☐ Yes / ☐ No | ☐ Yes / ☐ No | File #: |

| ISO 9001 or other QMS certified? | ☐ Yes / ☐ No | ☐ Yes / ☐ No | |

| Technical Expertise | |||

| In-house engineering & design team? | ☐ Yes / ☐ No | ☐ Yes / ☐ No | Staff size? |

| PLC/HMI programming capabilities? | ☐ Yes / ☐ No | ☐ Yes / ☐ No | |

| Specific experience in your industry? | ☐ Yes / ☐ No | ☐ Yes / ☐ No | Ask for examples. |

| Quality & Project Management | |||

| Documented Quality Management System? | ☐ Yes / ☐ No | ☐ Yes / ☐ No | Request a summary. |

| Standard Factory Acceptance Test (FAT)? | ☐ Yes / ☐ No | ☐ Yes / ☐ No | Request checklist. |

| Dedicated Project Manager assigned? | ☐ Yes / ☐ No | ☐ Yes / ☐ No | |

| Experience & Support | |||

| Provided relevant case studies? | ☐ Yes / ☐ No | ☐ Yes / ☐ No | |

| Provided at least 2-3 references? | ☐ Yes / ☐ No | ☐ Yes / ☐ No | |

| Offers field support/commissioning? | ☐ Yes / ☐ No | ☐ Yes / ☐ No | |

| Offers lifecycle/post-warranty support? | ☐ Yes / ☐ No | ☐ Yes / ☐ No |

Using a structured evaluation like this helps you cut through the sales pitches and focus on what truly matters. By following this checklist, you can move forward with confidence, knowing you've found a partner you can trust to get the job done right.

Common Sourcing Mistakes and How to Avoid Them

Knowing what not to do is often just as important as knowing what to do. When you're sourcing a control panel, a few common but critical mistakes can quickly turn a straightforward project into a mess of delays, budget overruns, and long-term reliability headaches. Getting ahead of these pitfalls is the key to a successful build.

The most frequent error we see is providing vague or incomplete specifications. Just think of your spec sheet as the blueprint for your house; if it's blurry, what gets built will be a complete guess. This kind of ambiguity forces a builder to make assumptions about components and design—assumptions that almost always lead to change orders and surprise costs when they don’t line up with what you actually needed.

Another major misstep is picking a control panel builder based on the lowest bid alone. While your budget is always a factor, a price that seems too good to be true usually is. It often signals compromises in component quality, a rushed assembly job, or totally inadequate testing. Taking that gamble can lead to premature failures and lifecycle costs that will completely dwarf any money you thought you saved upfront.

Overlooking Documentation and Support

It’s surprisingly common, but one of the costliest mistakes is forgetting about what happens after the panel shows up at your door. Sourcing a panel without a complete documentation package is like buying a car without an owner's manual. When a problem crops up months or even years later, your maintenance team is left flying blind, wasting precious time tracing unlabeled wires or trying to identify obsolete parts.

This oversight creates a serious operational risk. Without as-built schematics, a detailed Bill of Materials (BOM), and all the component manuals, any future troubleshooting, modifications, or upgrades become an absolute nightmare. This is where a builder’s commitment to real lifecycle support truly proves its worth.

The quality of a control panel’s documentation is a direct reflection of the builder’s professionalism and their commitment to your long-term success. A great partner delivers a complete system, not just a product in a box.

To sidestep these issues, you have to be proactive and crystal clear in your requirements right from the very beginning.

Proactive Steps for Smarter Sourcing

You can steer clear of these common traps by taking a few deliberate steps during your procurement process. These actions will save you a ton of time, money, and frustration down the line.

- Develop a Detailed RFQ: Your Request for Quote needs to be thorough. Be sure to include electrical schematics, a list of preferred components, specific NEMA/UL rating requirements, and clear criteria for testing. The more detail you provide upfront, the more accurate and reliable your quotes will be.

- Prioritize Quality Over Price: Look past the price tag and evaluate builders on their certifications (like UL 508A), their internal quality control processes, and their experience in your industry. Don't be afraid to ask for references and case studies to verify their track record.

- Demand Comprehensive Documentation: Make a complete, as-built documentation package a required deliverable in your purchase order. Specify that this must include updated drawings, a final BOM, and all relevant software files and licenses.

Using modern tools like construction inventory software can also help you streamline component tracking and sidestep many of these procurement headaches. By focusing on clear communication and long-term value from day one, you set your project up for success.

Got Questions About Control Panels? We've Got Answers.

When you're knee-deep in planning a control panel project, a lot of questions pop up, especially around safety, compliance, and timelines. Getting straight answers is the only way to lock in your budget and make sure everything runs smoothly with your builder.

Let’s tackle a few of the most common questions we hear every day.

What's the Real Difference Between a UL Listed Panel and One with UL Recognized Parts?

This is a big one, and the distinction is critical. Think of it this way: a panel built with UL Recognized parts is like a meal made with individually inspected ingredients. The flour is good, the eggs are good, but there's no guarantee the final cake is baked correctly or is even safe to eat.

A UL 508A Listed panel, on the other hand, is the fully prepared, tested, and certified final product. It means a certified shop built the entire assembly according to UL's rigorous safety and quality standards. This is the certification that inspectors, insurance companies, and your own team look for to know the finished panel is safe and up to code.

How Long Does a Custom Project Usually Take?

The honest answer? It depends. The timeline for a custom panel can swing pretty widely based on how complex the system is and how quickly we can get the parts.

For a relatively simple, smaller panel, you’re likely looking at 3-5 weeks from the moment the design is approved to the day it ships.

But for more complex systems—ones that need custom programming, intensive testing, or involve sourcing hard-to-find components—the timeline can easily stretch to 8-12 weeks or even longer. Any good panel builder should give you a detailed project schedule right after they’ve reviewed your specs.

Can We Upgrade or Modify Our Existing Control Panel?

Absolutely. In fact, it’s a smart move a lot of facilities make. Instead of a full rip-and-replace, we can often retrofit older panels to add new features, beef up safety protocols, or swap out obsolete components.

A qualified builder can come in, assess your current setup, and map out a plan for the upgrade. This could mean adding new I/O, installing a more powerful PLC, or integrating modern VFDs for smarter motor control. It’s a fantastic, cost-effective way to breathe new life into your machinery.

At E & I Sales, we believe in providing clear, expert answers to make sure your project is a success from day one. Learn how our custom UL control solutions can work for you.