Picture this: you’re trying to run a building, but the HVAC system, the lights, and the security alarms all speak completely different languages. It's chaos. That's the exact problem the BACnet communication protocol was designed to solve. Think of it as the ultimate universal translator for building automation, letting equipment from totally different manufacturers finally talk to each other.

Why BACnet Is the Bedrock of Any Smart Building

At its heart, BACnet isn't a product you can buy off a shelf. It's an open-standard set of rules—a shared language—that allows all the disparate systems in a building, from massive chillers to tiny access card readers, to understand one another. This common ground is absolutely essential for creating buildings that are genuinely intelligent and efficient.

To really get why BACnet is so important, you have to see where it fits into the bigger picture of Building Automation Systems (BAS). If the BAS is the central brain of a building, BACnet is its nervous system, firing messages and commands to every corner of the facility. Without it, operators would be stuck juggling a dozen isolated systems, making any kind of integrated, smart automation impossible.

A Standard Forged Through Collaboration

Developed by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), the BACnet protocol was born out of a real need to break free from the stranglehold of proprietary systems. In the old days, building owners were often locked into a single vendor's world. If you wanted to upgrade one component, you might have had to rip out the entire system—a ridiculously expensive and inefficient way to do things.

By creating a vendor-neutral standard, BACnet gives facility managers and system integrators some serious advantages:

- True Interoperability: You can mix and match the best-in-class devices from different manufacturers without ever worrying if they’ll play nicely together.

- Future-Proofing Your Investment: New equipment can be dropped right into your existing infrastructure, protecting your investment for the long haul.

- Centralized Command: You get to monitor and manage everything from a single pane of glass, which means better visibility and faster response times when things go wrong.

The whole idea behind BACnet was to create a level playing field for building devices. It makes sure a thermostat from one company can seamlessly report its temperature to an air handler controller from another, which sparks healthy competition and drives innovation.

Market Dominance Isn't an Accident

The protocol's success isn't just a nice idea; the numbers prove it. Since it first came on the scene in 1987, BACnet has become the undisputed standard for building automation. By 2018, its global market share had already blown past 60%, which tells you everything you need to know about its reliability.

This dominance is especially true in North America, where industry heavyweights like Siemens, Schneider Electric, and Johnson Controls have all built their systems around it. You can dig into the specifics in the BACnet adoption market report. This widespread buy-in means you'll always have a massive community for support and a huge selection of compatible products for any project you can dream up.

How BACnet Objects And Services Work Together

To really get a handle on the BACnet communication protocol, you have to understand its two core components: Objects and Services. These two elements are the absolute heart of how BACnet devices share information and get things done, creating a seamless network of smart building equipment.

Think of it this way: every piece of gear in your building—a sensor, a motor, a VAV box—gets a digital profile. That's essentially what a BACnet Object is. It's a standardized, virtual stand-in for a real-world thing, and it holds all the important information about it.

These objects aren't just simple labels; they're structured containers for data. Every object has Properties that spell out its current state and characteristics. Sticking with our profile analogy, properties are the individual fields on that profile, holding specific details that you can either read or change.

The Role of BACnet Objects

In the language of BACnet, objects are the "nouns"—they're the things on the network. A single physical device, like an air handling unit (AHU), isn't just one object. It’s actually a collection of dozens of standard objects that, together, define everything it can do and report.

Let's break down the essential BACnet objects you'll run into constantly.

To make sense of it all, here’s a quick rundown of the most common BACnet objects and what they actually do on the job.

Common BACnet Objects and Their Functions

| Object Type | Abbreviation | Description | Example Use Case |

|---|---|---|---|

| Analog Input | AI | Represents a value that can vary continuously across a range. | Reading the temperature from a room sensor or measuring static pressure in a duct. |

| Binary Input | BI | Represents a simple two-state value (on/off, true/false, occupied/unoccupied). | Checking if a filter is dirty, if a door is open, or if a flow switch is active. |

| Analog Output | AO | Controls a device using a variable signal. | Commanding a valve to open to 50% or setting a variable frequency drive (VFD) to a specific speed. |

| Binary Output | BO | Commands a device to a simple on or off state. | Starting a pump, turning on a bank of lights, or enabling an alarm. |

These fundamental objects are the building blocks that allow a BAS to monitor and control just about anything you can imagine in a facility.

This diagram really helps visualize how BACnet pulls everything together, connecting all the different systems in a modern building.

As you can see, BACnet is the common language that lets HVAC, lighting, and security systems all talk to each other instead of operating in their own little silos.

Activating The Network With BACnet Services

So, if Objects are the nouns, then Services are the "verbs." They are the standardized commands that one BACnet device can send to another to make something happen. Services are what bring the network to life, allowing devices to do more than just sit there and broadcast their status.

They're the mechanism for asking for information, sending a command, or confirming that a request was received. It's the action part of the equation.

A key takeaway here is that the combination of Objects and Services creates a powerful request-response model. It’s a highly structured conversation: one device uses a Service to ask about an Object's Property, and the other device responds with the requested information.

This interaction is the magic behind true automation. A building controller doesn't just passively see a temperature reading. It actively requests that data using a service and then uses another service to command an air conditioner to turn on. This clear, defined structure is precisely why BACnet is so reliable and plays so well with equipment from different manufacturers.

Let's walk through a real-world example. Say your building automation system (BAS) needs to check the temperature in a conference room and tell the VAV (Variable Air Volume) box to adjust.

- The Request: The BAS sends a ReadProperty service request to the VAV box controller. It’s a very specific message, targeting the Analog Input object (the temp sensor) and asking for its Present_Value property. It’s basically asking, "What's the temperature right now?"

- The Response: The VAV controller gets the request, checks its sensor, and sends a reply back to the BAS with the current temperature, maybe 74°F.

- The Command: The BAS logic decides that's too warm. It then fires off a WriteProperty service request back to that same VAV controller. This time, it targets the Analog Output object that controls the damper, telling it to change its Present_Value to 80% open.

- The Action: The VAV controller receives that command and physically moves its damper to the new position, letting more cool air flow into the room.

This constant back-and-forth—using services to read from and write to objects—happens thousands of times a day across a building, all managed seamlessly by the BACnet communication protocol.

Getting to Know BACnet Network Architectures

For BACnet to work its magic, its messages—all those requests and commands zipping between devices—need a physical path to travel on. Think of it like a city's road system. You have massive interstates for high-speed, long-haul traffic and smaller local streets for neighborhood deliveries. BACnet works the same way, using different network types to get data where it needs to go. This flexibility is one of its greatest strengths.

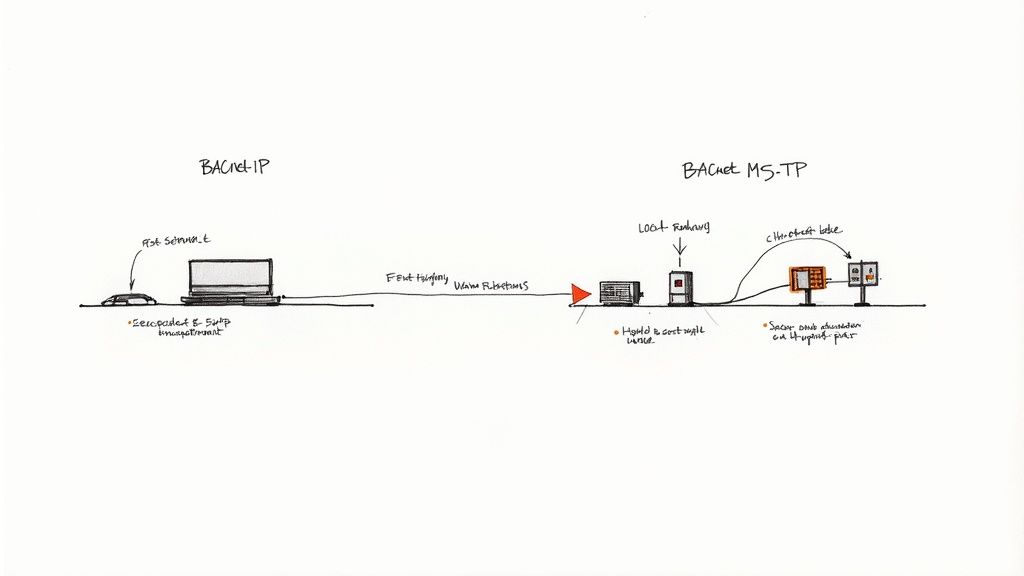

The two workhorses you'll see on almost every job site are BACnet/IP and BACnet MS/TP. Getting a handle on how they work, and more importantly, how they work together, is the key to designing a BAS that's both powerful and practical. They are the perfectly coordinated transportation system for all your building's data.

This hybrid strategy, pairing high-speed backbones with low-cost field networks, is really the secret sauce behind modern building automation.

BACnet/IP: The High-Speed Data Interstate

BACnet/IP is the superhighway of the BACnet world. It cleverly packages BACnet messages into standard UDP/IP packets, the very same data format your computer uses to browse the internet. This is a game-changer because it allows BACnet traffic to ride on standard IT networks like Ethernet and even Wi-Fi.

Since it speaks the language of IT, BACnet/IP is the perfect fit for high-bandwidth communication between the big players in your system. We're talking about the heavy data lifting between:

- Management Workstations: The command center where facility managers are monitoring and controlling everything.

- Supervisory Controllers: The high-level brains managing entire subsystems, like a central plant or all the equipment on one floor.

- BACnet Routers: The crucial traffic cops that connect different network types, like linking a local MS/TP network to the main IP backbone.

The huge win here is speed and volume. BACnet/IP can move mountains of data—trend logs, detailed alarm histories, and complex schedules—across a building or campus in the blink of an eye. It's the undisputed choice for the system's backbone, where performance is non-negotiable. So many of today's industrial controls and automation systems depend on this kind of high-speed connectivity to keep things running smoothly.

BACnet MS/TP: The Reliable Local Roads

If BACnet/IP is the interstate, then BACnet MS/TP (Master-Slave/Token-Passing) is the network of local roads branching out to every last device. Instead of fancy Ethernet, MS/TP runs on a simple, tough, and cost-effective twisted-pair serial bus—usually RS-485 wiring. This makes it the ideal solution for connecting dozens of field-level devices that don't need a firehose of bandwidth.

Just think of all the smaller components scattered across a building that need to communicate:

- VAV box controllers

- Room temperature sensors

- Fan coil unit controllers

- Valve actuators and simple relays

These devices are constantly chattering, but they're sending tiny, frequent packets of data—a temperature reading here, a damper position update there. Pulling expensive Ethernet cable to every single one would be a massive waste of money and effort. MS/TP gives you a rugged, low-cost way to daisy-chain these devices together on a single run of wire.

So what's the "Token-Passing" part all about? It’s a clever traffic management system. A digital "token" gets passed from one device to the next on the network. A device can only "speak" when it's holding the token. This simple rule prevents data collisions and ensures every device gets its turn to report in, keeping communication orderly and reliable.

Why This Hybrid Approach Is So Effective

The real genius of the BACnet communication protocol is how it blends these two architectures into a tiered system. You have your high-level controllers and servers living on the fast BACnet/IP network, where they can quickly gather and process data from multiple MS/TP subnetworks out in the field.

A perfect example is a single supervisory controller on the BACnet/IP network managing three separate MS/TP trunks, with each trunk connecting 30-40 VAV boxes on a different floor. The controller talks at high speed to the main building server, while the VAV boxes just do their thing on their local, low-cost MS/TP networks.

This design is brilliant. It keeps the high-volume data traffic off the field bus and prevents the slower field devices from creating a bottleneck on the main network. You get speed where it matters and cost-effectiveness where it makes sense. It’s this practical combination that makes BACnet such an incredibly versatile tool for any building project.

Bringing Your System Up to Code with BACnet SC

In a world where everything is connected, building systems are no exception. But let's be honest: cybersecurity was often an afterthought in the original BACnet protocol. It was built for automation, not for fending off the kinds of threats we see online today.

That’s where BACnet Secure Connect (BACnet/SC) comes in. It’s the security upgrade our building networks have desperately needed.

https://www.youtube.com/embed/6ftR-Zhe7r4

Think of BACnet/SC as a dedicated security detail for your building's data. It’s a modern, encrypted wrapper that fits snugly around your existing BACnet communications, shielding them from prying eyes and cyberattacks. It doesn’t replace what you already have—it just makes it incredibly secure.

So, How Does It Work?

The secret sauce is Transport Layer Security (TLS) 1.3. If that sounds familiar, it should. It’s the very same encryption standard that protects your online banking and credit card transactions. BACnet/SC applies this battle-tested technology to building automation, making sure every conversation between your devices is authenticated, encrypted, and tamper-proof.

The industry saw the writing on the wall with the rise of threats against operational technology. BACnet/SC was the answer. It’s a whole new protocol layer built on TLS 1.3, giving you the choice between 128-bit and 256-bit elliptic curve cryptography. The best part? It was designed to play nice with older BACnet/IP and MS/TP networks, so you can migrate over time without a massive headache. You can get more background on this security advancement on veris.com.

By authenticating devices with digital certificates, BACnet/SC creates a "zero-trust" environment. What does that mean? No device gets a free pass. Each one has to prove its identity before it can join the network and start talking, effectively locking the door on any rogue hardware.

Practical Perks for Integrators

Putting BACnet/SC in place gives you more than just peace of mind; it solves some very real-world integration headaches.

- Finally, a Firewall-Friendly Protocol: Anyone who's wrestled with BACnet/IP knows the pain of poking holes in firewalls. BACnet/SC ditches that mess by using a standard websocket connection, making it vastly simpler to navigate IT security rules.

- Say Goodbye to BBMDs: Those dreaded BACnet/IP Broadcast Management Devices (BBMDs) have been a source of network nightmares for years. With BACnet/SC, they’re history. Device discovery is handled through a central "hub," which cleans up your network architecture significantly.

- Upgrade Security on Your Own Schedule: This might be the most practical benefit. You can drop a BACnet/SC hub into an existing system and upgrade devices one by one, as time and budget allow. No more "rip-and-replace" pressure.

Of course, technology is only one piece of the puzzle. The most secure protocol in the world can't protect you from human error. That's why implementing BACnet/SC should go hand-in-hand with a comprehensive organizational information security policy. This is about building a complete strategy that defines access rules, monitoring, and what to do when things go wrong. When your tech and your processes work together, you create a truly resilient system.

Integrating Legacy Systems with BACnet Gateways

You’ve got a brand-new building automation system humming along on BACnet, but what about that trusty old chiller in the basement that still speaks Modbus? This is a classic dilemma in facilities management. Tearing out perfectly good, expensive equipment isn't an option. This is exactly where a BACnet gateway comes into play.

Think of a gateway as a universal translator on your network. It’s a smart little box that listens to one protocol, like Modbus or LonWorks, and re-broadcasts the message in fluent BACnet. It works both ways, creating a seamless conversation between your modern BMS and your older, but still critical, assets.

This translation magic lets you unify your controls without the eye-watering cost and disruption of a full rip-and-replace. You get to keep your reliable legacy gear while bringing it into a modern, centralized management system.

When Gateways Become Essential

In many situations, gateways aren't just a nice-to-have; they're an absolute necessity for keeping projects on budget and on time. They are the go-to fix when a full replacement just doesn’t make sense.

Here are a few real-world scenarios where gateways save the day:

- Legacy Chillers and Boilers: That massive chiller might be old, but it works. Instead of a huge capital expense to replace it, a gateway can make it look like a native BACnet device to the BMS. Now you can schedule and control it right alongside your new equipment.

- Specialized Industrial Equipment: A factory floor is often full of machines with their own proprietary controls. A gateway can tap into that system and pull out key data—like runtime hours or fault codes—and feed it directly into the building automation system for monitoring.

- Fire Alarm and Lighting Systems: Many buildings have established fire panels or older LonWorks-based lighting systems. A gateway can bridge them to the main BACnet network, which is perfect for centralizing alarm monitoring and running energy-saving routines.

At its core, a gateway’s job is to map data points from the old protocol to the new one. For example, it takes a value from a Modbus holding register and translates it into a BACnet Analog Input object. Suddenly, that cryptic data point is something your entire BACnet network can understand and act on.

The Growing Importance of Protocol Translation

This need to connect old and new systems is a massive part of the building automation world. The market for BACnet gateways hit USD 1.42 billion globally in 2024, which shows just how critical this technology has become. Some of the more advanced gateways can even translate over 140 different protocols, essentially acting as a Swiss Army knife for system integration. You can read more on the growth of the gateway market on dataintelo.com.

Getting these integrations right is where the real skill comes in. It's often more complex than just plugging in a box. Working with an experienced industrial automation system integrator ensures the gateway is selected, mapped, and commissioned properly. This avoids the headaches of communication errors down the line and helps create a truly unified system where every piece of equipment is finally talking the same language.

BACnet Troubleshooting and Best Practices

Sooner or later, every well-designed BACnet communication protocol network hits a snag. A device might just vanish off the network, or data packets start getting lost in the shuffle, causing all sorts of system headaches. Knowing how to methodically track down and fix these problems is every bit as critical as the initial design and setup. With the right approach and a couple of essential tools, what looks like a network meltdown can become a straightforward fix.

Troubleshooting almost always starts with the simple stuff. Are the cables plugged in tight? Does the device have power? You’d be surprised how many "complex" network issues are solved by these basic physical checks. Once you've ruled out the obvious, the real detective work begins—especially on the MS/TP trunks, which is where most field-level gremlins tend to hide.

Diagnosing Common Network Faults

One of the biggest and most frequent headaches on a BACnet MS/TP network is duplicate MAC addresses. Think of it like a street where two houses have the same address—the mail carrier gets confused. On an MS/TP trunk, every single device needs its own unique address. If two devices share one, the token-passing system that governs communication completely falls apart, causing devices to randomly drop offline or just refuse to talk at all.

Improper wiring is another huge one. The strict rules for MS/TP aren't just suggestions; they're the bedrock of a stable network.

- Termination: You absolutely must have a termination resistor at both physical ends of an MS/TP trunk. Without them, signals bounce back down the wire, corrupting the data.

- Wiring Quality: Always use low-capacitance, shielded twisted-pair cable that’s actually rated for RS-485 communication. This is your best defense against electrical noise from other equipment.

- Daisy-Chaining: Devices have to be wired in a single, continuous line—a true daisy chain. Any star configurations or "T-taps" are a recipe for disaster and will wreck your signal integrity.

When you're dealing with trickier problems, especially on BACnet/IP networks, a protocol analyzer like Wireshark is your best friend. It lets you capture and look at the raw network traffic. You can literally see the BACnet messages flying back and forth, making it easy to spot a device that’s spamming the network with broadcasts or find the bottleneck that’s slowing everything down.

When a device goes offline, the first step is to isolate the problem. Check its neighbors on the MS/TP trunk. If they are also offline, the issue is likely upstream in the wiring or with the controller. If only one device is down, the problem is probably with the device itself or its connection to the bus.

Best Practices for a Resilient BACnet Network

Fixing problems is one thing, but preventing them in the first place is the real goal. Building a bulletproof BACnet network from day one means sticking to a few proven best practices that stop common failures before they ever happen. This proactive mindset will save you endless hours of frustration down the road.

Start with a logical and consistent naming convention for every device, object, and point. It’s a game-changer. When you get an alarm for AHU-03-Supply_Fan-Status, you know exactly what and where that is. This kind of clarity is non-negotiable for efficient maintenance and scales beautifully as the system grows.

While the inner workings of BACnet are complex, understanding how it differs from other protocols is useful. For a deeper dive into industrial protocols, our article comparing SCADA vs DCS is a great place to start.

Answering Your Top BACnet Questions

When you're deep in the trenches of a building automation project, questions are bound to come up. BACnet is the backbone of modern BAS, but some of its concepts can be tricky. Let's clear the air and tackle some of the most common questions we hear from system integrators and engineers.

Think of this as a quick-reference guide to help you make smarter decisions on your next job. We'll cover network types, what "open protocol" really means, and how to deal with that old-school gear you inevitably run into.

What's the Real Difference Between BACnet/IP and BACnet MS/TP?

Let's use an analogy. Think of your building's data network like a road system.

BACnet/IP is the multi-lane interstate highway. It uses the same Ethernet and Wi-Fi your IT department runs on, making it perfect for moving huge amounts of data at high speeds. This is what you'll use to connect your main controllers, servers, and workstations—the heavy-hitters of your system.

BACnet MS/TP, on the other hand, is like the local side streets that get you to every single house. It runs over simple, low-cost twisted-pair wiring and is designed to reliably connect all your field-level devices—think VAVs, sensors, and actuators. Most modern designs smartly use both, with BACnet/IP as the high-speed backbone and MS/TP as the cost-effective way to connect the dozens (or hundreds) of devices out in the field.

Is BACnet Really "Free" and "Open"?

Yes, and this is probably its single biggest advantage. BACnet is an open standard developed and maintained by ASHRAE, not a proprietary product owned by a single corporation. That means any manufacturer can build BACnet-compliant products without paying a dime in licensing fees for the protocol itself.

What does this mean for you? Freedom. It creates a competitive marketplace where you can pick the best piece of equipment for the job, regardless of the brand on the box. You're not locked into one vendor's ecosystem, giving you the flexibility to integrate and upgrade your system with a huge variety of products.

Of course, you still have to buy the actual hardware and software from manufacturers, but the standard they're all building on is open to everyone.

Can I Get My Non-BACnet Gear onto the Network?

Absolutely. This is a situation every integrator faces, and the solution is a device called a BACnet gateway.

Think of a gateway as a professional translator. It sits between your modern BACnet system and, say, an older chiller that only speaks Modbus. The gateway listens to the Modbus data, translates it into the BACnet language in real-time, and then presents it to the rest of your network.

Suddenly, that old chiller's temperature, pressure, and status points show up as standard BACnet objects in your building management system. It's a powerful and budget-friendly way to bring legacy equipment into a centralized control and monitoring platform without the massive cost of a full rip-and-replace.

At E & I Sales, we're the ones designing and building the UL-listed control panels and integrated systems that make BACnet networks tick. Whether you're upgrading an aging facility or commissioning a brand new one, our team has the hands-on expertise to make sure your motor control and automation systems talk to each other without a hitch. Learn more about our custom solutions at https://eandisales.com.