At its core, the difference between SCADA and DCS really boils down to what you’re trying to accomplish. A Distributed Control System (DCS) is all about the process. Think of it as the brain for an entire facility, like a chemical plant, managing everything in real-time under one roof.

On the other hand, a Supervisory Control and Data Acquisition (SCADA) system is all about the data. It’s built to keep an eye on assets that are spread out geographically, like a sprawling water utility network or a cross-country pipeline.

Breaking Down the Core Difference

Picking the right system means getting to grips with their foundational design philosophies. One is a master of supervising things over vast distances, while the other is an expert at high-speed, localized control. This single distinction ripples through every part of their design, from architecture to real-time performance.

If you look back, this line was even clearer. SCADA grew up as a high-level tool for keeping tabs on remote sites—think utilities and pipelines. DCS, however, was born on the factory floor, designed for the fast, direct control needed in complex manufacturing. You can find more detail on the evolution of these control systems and how their original purposes still define them today.

To get a quick handle on things, it helps to see their primary traits side-by-side. The table below gives you a high-level summary of the biggest differentiators—perfect for system integrators and plant engineers starting their evaluation.

At a Glance SCADA vs DCS Differentiators

| Criterion | SCADA (Supervisory Control and Data Acquisition) | DCS (Distributed Control System) |

|---|---|---|

| Primary Focus | Data acquisition & supervisory control over wide areas. | Integrated, real-time process control within a plant. |

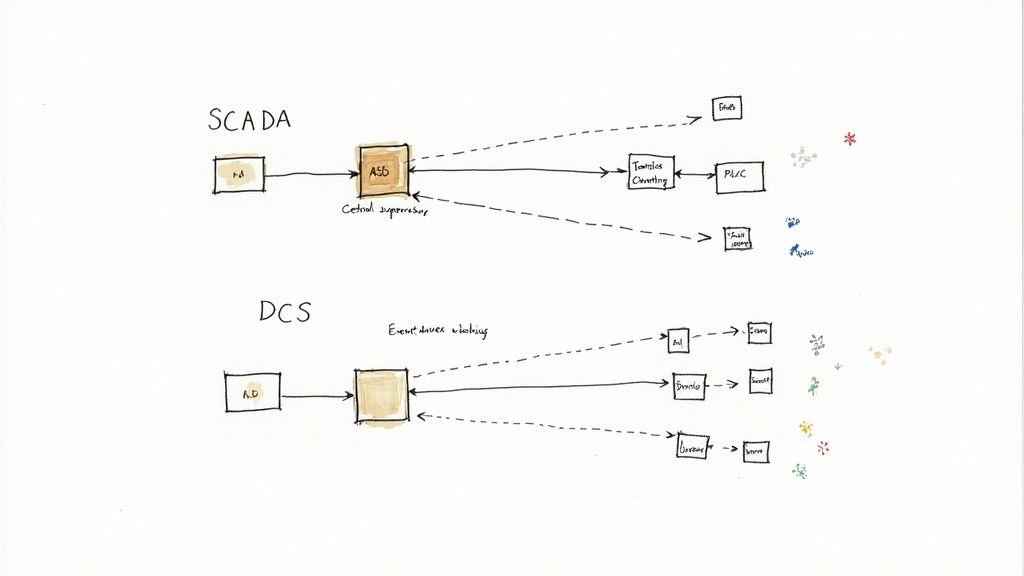

| Architecture | Event-driven, top-down. Central master station communicates with remote RTUs/PLCs. | Process-driven, bottom-up. Distributed controllers form a unified, single system. |

| Control Philosophy | Supervisory. Issues setpoints to remote controllers but doesn't handle loop control directly. | Regulatory. Handles complex, high-speed control loops autonomously. |

| Typical Application | Oil & gas pipelines, water distribution, electrical grids, transportation networks. | Chemical processing, power generation, pharmaceutical manufacturing, refineries. |

| Data Handling | Focused on collecting and logging data from remote locations periodically. | Manages a single, integrated database for control, alarms, and history. |

| Scalability | Highly scalable for adding geographically dispersed remote sites. | Scales within a plant or facility; adding new process units is straightforward. |

| System Integration | Often integrates hardware and software from various vendors. | Typically a single-vendor, proprietary solution for hardware and software. |

While this table is a great starting point, the real decision gets into deeper technical weeds. For any OEM, packager, or engineer, understanding these core differences is the first step. The goal isn't to find which system is "better," but to pick the right tool for the job.

Key Takeaway: Think of it this way: SCADA is like an air traffic control system, monitoring and directing planes across a wide region. A DCS is like the complex avionics system inside a single aircraft, managing all its internal functions in real-time.

System Architectures and Philosophies: A Tale of Two Philosophies

When you get right down to it, the real difference between SCADA and DCS isn't just about the hardware or software—it's about two fundamentally different philosophies of control. One is built for oversight across vast distances, the other for deep, integrated control within a single facility.

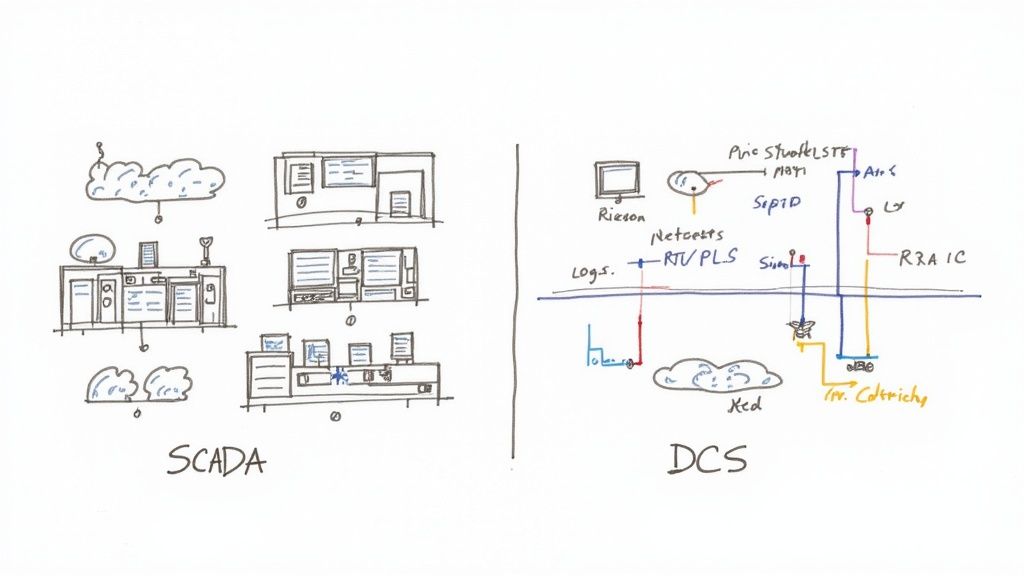

A Supervisory Control and Data Acquisition (SCADA) system is all about the big picture. Think of it as a central command post with a top-down, event-driven architecture. Its job is to supervise assets that are often miles apart, pulling in data and sending out high-level commands.

At the heart of a SCADA setup is a master station (the Master Terminal Unit, or MTU) that talks to remote PLCs and RTUs. The whole point is to collect critical data, see what's happening on the ground, and maybe tell a pump to turn on or adjust a setpoint from a central location.

This setup is incredibly practical for things like pipelines, water treatment networks, or the power grid. Communication doesn't have to be constant; it's often "on-exception," meaning data only comes through when something changes or at set times. This is a lifesaver for bandwidth when you're relying on cellular or radio signals.

The DCS Approach: Process-Driven and Integrated

On the other side of the coin, you have the Distributed Control System (DCS). A DCS is designed from the ground up with a bottom-up, process-driven architecture. Its sole focus is maintaining tight, autonomous, and continuous control over everything happening inside a single plant. A DCS isn’t just supervising; it’s directly running the show.

Instead of one central brain, a DCS uses multiple distributed controllers, with each one handling a specific chunk of the process. These controllers are all tightly networked and pull from a single, shared database. This is a huge deal—it means everything from the operator's HMI to the alarms and historian are all part of one unified, cohesive system, which is a far cry from the mix-and-match approach you often see with SCADA.

This integrated design allows for the kind of high-speed, predictable control loops you absolutely need in a refinery, a chemical plant, or a power station. The control logic itself lives right there in the distributed controllers, so they can keep running their part of the process even if they lose their connection to the main server.

The core philosophical divide is clear: SCADA is designed to supervise and gather data from many independent, remote operations. A DCS is engineered to directly regulate a single, complex, and highly interdependent process.

What This Means in the Real World

These architectural differences aren't just academic. For system integrators and plant engineers, they have very real consequences for how a system is designed, implemented, and maintained. It all comes down to how they manage data, performance, and reliability.

-

How Data is Handled: A SCADA system is a data aggregator. It polls information from lots of different devices, which might be speaking different protocols, and pulls it all together. A DCS, by contrast, works off a single source of truth—a unified database where every process variable, alarm, and configuration lives in harmony.

-

Real-Time Performance: SCADA can certainly handle real-time commands, but the potential for communication lag over long distances makes it a poor choice for high-speed, closed-loop control. That's where a DCS shines, with scan times often measured in milliseconds, giving you the rock-solid, deterministic performance that critical processes demand.

-

Redundancy: Both systems can be made redundant, but they go about it differently. With SCADA, you might have a backup server and redundant communication links. In a DCS, redundancy is baked into the DNA of the system at every level—from the controllers and I/O cards to the network switches and power supplies—because uptime is everything.

The right choice between these two powerful systems comes down entirely to the job at hand. For a deeper dive into modern control solutions, our guide to industrial controls and automation offers more context. If your operation is spread out, SCADA's supervisory muscle is what you need. If you're running a complex, tightly-coupled process under one roof, the integrated regulatory power of a DCS is the only way to go.

A Detailed Technical Breakdown of SCADA vs DCS

When you get past the high-level diagrams, the real decision between SCADA and DCS comes down to the nuts and bolts. For the engineers, integrators, and OEMs on the ground, the devil is in the details—how each system handles visualization, alarms, and data logging will dictate your entire experience. These aren't just features on a checklist; they directly shape operational workflows, how much time you'll spend on maintenance, and the overall performance of the plant or process.

Let's pull back the curtain and dissect these core technical components. We'll look at how their foundational philosophies—one built for supervision, the other for tight regulation—show up in their day-to-day functions.

HMI and Visualization Differences

At a quick glance, an HMI screen for a SCADA system and a DCS might look deceptively similar. You’ll see process graphics, data readouts, and control buttons on both. But how they get there is what truly sets them apart.

A DCS HMI is woven into the very fabric of the control system. It's not a separate piece of software bolted on; it's an organic part of a single, unified ecosystem. When an engineer configures a new control loop or adds a valve in the controller, that element often populates automatically into the HMI library and database. This tight integration is a massive time-saver during development and guarantees consistency across the entire plant.

A SCADA HMI, on the other hand, is more of an independent layer that sits on top of a collection of different controllers, like PLCs and RTUs, which can be from a mix of vendors. This gives you incredible flexibility, but it comes at the cost of more integration legwork. The developer has to manually map every single data tag from each field device to the corresponding graphical element. It's a more labor-intensive process, but it’s what allows SCADA to create a unified view of a dozen different systems that were never designed to talk to each other.

Key Insight: Think of a DCS as offering a "single pane of glass" where the visualization is a native, built-in part of the control system. A SCADA system provides a "window" into many different, often disconnected, underlying systems—offering flexibility at the price of integration complexity.

Before we dive deeper into the technical differences, let's put them side-by-side. The table below breaks down the key features and what they mean for integrators trying to choose the right path.

Technical Feature Analysis SCADA vs DCS

| Technical Feature | Typical SCADA Implementation | Typical DCS Implementation | Key Takeaway for Integrators |

|---|---|---|---|

| HMI/Visualization | Independent software layer. Requires manual tag mapping from various PLCs/RTUs. Highly customizable. | Integrated component of the system. Graphics and faceplates are native to the controller database. | SCADA offers mix-and-match flexibility. DCS provides a unified, "out-of-the-box" experience that's faster to configure. |

| Alarm Management | Aggregates alarms from disparate devices. Advanced logic can be complex to implement across vendors. | Sophisticated, system-wide management. Easily implements state-based alarming and complex suppression logic. | DCS is built for managing thousands of alarms in a complex process. SCADA is better suited for reporting critical events from remote, independent sites. |

| Data Historian | Can be a built-in feature or a third-party add-on. Often logs data "on change" to conserve bandwidth. | Integrated system component, optimized for high-speed, continuous data logging from its own controllers. | DCS historians are for high-fidelity process optimization. SCADA historians excel at collecting essential data from geographically dispersed assets. |

| Communication | Multi-protocol support is a core strength (e.g., Modbus, DNP3, OPC UA). Built to be a "communication generalist." | Primarily uses a proprietary, high-speed, deterministic network for its own I/O and controllers. | Choose SCADA when you need to talk to everything. Choose DCS when you need bulletproof, low-latency communication for closed-loop control. |

This comparison highlights a central theme: SCADA is about flexible supervision, while DCS is about integrated control. Now, let's explore what that means for real-world implementation.

Alarm Management and Prioritization

Effective alarm management isn't just a convenience; it's a critical pillar of plant safety and operator sanity. Both systems handle it, but their approaches are a direct reflection of their core design.

DCS platforms are masters of sophisticated, plant-wide alarm handling. Because the entire process lives inside one cohesive environment, engineers can build out complex alarm suppression strategies, state-based alarming (e.g., only show an alarm if the pump is running), and logical groupings with relative ease. This is absolutely essential in a refinery or chemical plant where a process upset can trigger an avalanche of nuisance alarms, completely overwhelming the operator.

SCADA systems, by necessity, are more focused on aggregating alarms from many independent devices. While modern SCADA software has powerful alarm tools, getting them to enforce advanced logic across equipment from different manufacturers can be a real headache. The primary goal is usually simpler: reliably report a critical failure from a remote site back to the central control room.

Data Historian and Reporting Capabilities

Both systems use a data historian to log process values for trending, reporting, and figuring out what went wrong. But again, how they do it differs in practice.

- DCS Historian: This is almost always an integrated part of the vendor's package, fine-tuned to work flawlessly with its own distributed controllers. Data logging is typically high-resolution and continuous, capturing the granular detail you need for serious process optimization.

- SCADA Historian: The historian in a SCADA system might be a built-in module or a completely separate third-party product. Its main job is to collect and store data from assets spread out over a large area. To manage bandwidth over spotty cellular or radio networks, it often logs data "on change" or at much longer intervals.

Communication Protocols and Integration

The way these systems communicate is one of the biggest differentiators. A DCS almost always uses a proprietary, high-speed, and deterministic network to link its own controllers and I/O modules. This guarantees the kind of reliable, low-latency communication that is non-negotiable for precise, closed-loop control.

SCADA systems, on the other hand, have to be communication generalists. Their survival depends on supporting a huge range of open and proprietary protocols—think Modbus, DNP3, OPC UA, and dozens more—to talk to a diverse zoo of PLCs, RTUs, and smart devices scattered across the landscape. This flexibility is SCADA's superpower, letting you integrate brand-new and decades-old equipment from just about any vendor. This is especially important when integrating off-the-shelf equipment like VFDs or custom skids, which requires real thought during the industrial control panel design phase.

Scalability and System Expansion

Scalability means something very different in the SCADA and DCS worlds. SCADA is built for geographical scalability. Adding a new remote well site, a lift station, or a solar farm to the network is a standard, everyday task. The system is designed to grow outward, pulling more and more remote assets under its umbrella.

A DCS scales within the four walls of a facility. Bolting on a new process unit or reactor to a chemical plant is straightforward because the system is designed to seamlessly expand its integrated control network. But trying to stretch a DCS to manage assets miles away? That's not what it’s built for, and it would be a technical and financial nightmare.

The market size for these systems tells the story of their specialized roles. The Distributed Control System (DCS) market was valued at around USD 28.7 billion and is expected to hit USD 43.9 billion by 2030. This growth is all about its dominance in time-sensitive and safety-critical processes, especially in sectors like power generation where that tight, non-negotiable integration is everything. You can find more details about the DCS market on strategicmarketresearch.com.

Exploring Real-World Industry Applications

Theoretical comparisons are one thing, but the real acid test in the SCADA vs DCS debate happens out in the field. The architectural differences we’ve talked about aren't just technical details—they’re the very reason one system shines where the other would stumble.

Looking at how these systems are applied in specific industries tells the whole story. For a system integrator, OEM, or plant engineer, this is where the rubber meets the road. It shifts the conversation from a dry feature list to a practical decision: which system’s DNA truly matches the operational challenges at hand?

Let's dig into a few classic examples where each system proves its worth.

SCADA in Geographically Dispersed Operations

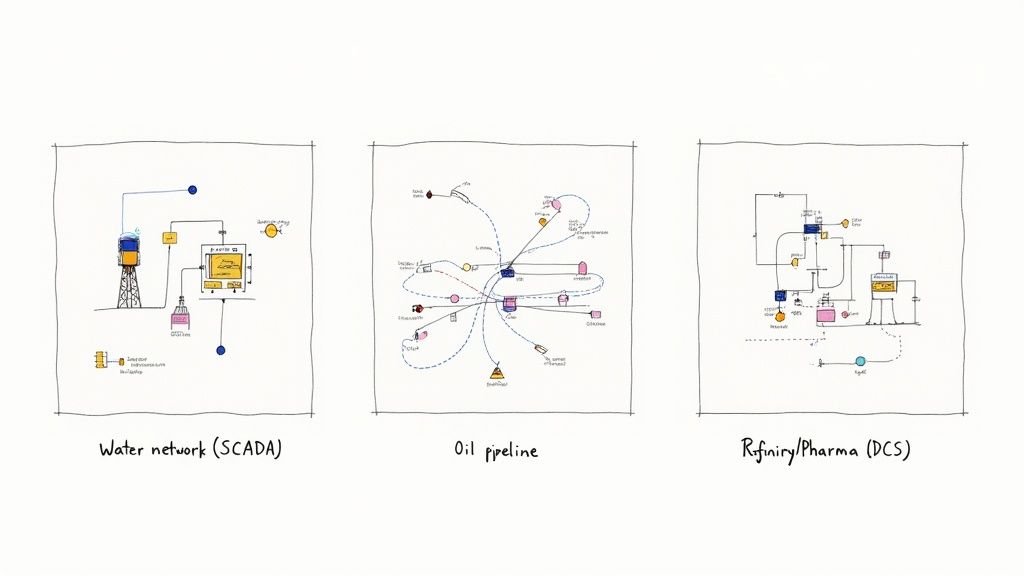

SCADA systems are in their element when operations are flung across a wide area. When you need a bird’s-eye view and supervisory control over remote assets, SCADA’s architecture is purpose-built for the job.

A municipal water distribution network is a textbook case. Think about it: a city's water system is a sprawling collection of remote reservoirs, pump stations, water towers, and thousands of miles of pipe. A central control room has to keep tabs on everything—tank levels, pump status, flow rates, water quality—across that entire map.

Here, a SCADA system is really the only game in town. It uses whatever communication is available—radio, cellular, fiber—to poll data from Remote Terminal Units (RTUs) at each site. From a single command center, operators can then issue high-level instructions, like firing up a pump. The system isn't bogged down in high-speed, continuous control loops; its mission is data acquisition and supervision, and that’s SCADA’s sweet spot.

Now, picture a cross-country oil and gas pipeline. You’ve got compressor stations, block valve sites, and metering stations spread out over hundreds, if not thousands, of miles.

The SCADA system is the central nervous system, monitoring pressures, temperatures, and flow rates to keep the product moving safely and efficiently. It’s what spots a leak by analyzing pressure drops and allows an operator to remotely command an emergency shutdown valve to isolate a section. The entire focus is on wide-area visibility and making critical, but often infrequent, supervisory moves. A DCS would be complete overkill—and financially crippling—for this kind of geography.

For operations defined by distance, where the main goal is to monitor and direct remote assets, SCADA is the superior solution. Its event-driven, top-down architecture is designed for exactly this kind of challenge.

DCS in Complex, Contained Process Facilities

Distributed Control Systems are built for the polar opposite environment: dense, tightly coupled processes all humming away inside a single plant. Their power comes from delivering unified, high-speed, and rock-solid regulatory control.

A petrochemical refinery is the quintessential DCS environment. A refinery is an intricate dance of interdependent units—distillation columns, reactors, crackers—all running at once. A tiny hiccup in one unit can send a massive ripple effect through the others.

This is where a DCS excels. Its distributed controllers seamlessly manage thousands of high-speed control loops with deterministic precision. The all-in-one nature of a DCS gives operators a single, unified window into the entire plant, with alarms, historian data, and control logic working in lockstep. This integrated regulatory control is non-negotiable for maintaining product quality, efficiency, and—above all else—safety in such a volatile setting.

Another perfect fit is a pharmaceutical manufacturing plant. Making medicine demands incredibly precise and repeatable batch control. Temperatures, pressures, and ingredient additions have to follow a rigid recipe with razor-thin tolerances.

A DCS provides the robust, validated control needed to satisfy strict FDA regulations. Its built-in batch management software executes recipes flawlessly, while the integrated historian captures every shred of data required for compliance reports. In this high-stakes world, the single-vendor, tightly integrated ecosystem of a DCS provides a level of reliability and consistency that a pieced-together SCADA system just can't guarantee.

Evaluating Cost, Cybersecurity, and Lifecycle

When you're deciding between a SCADA or a DCS platform, you’re looking at more than just technical specs. This is a business decision, plain and simple—one that involves a serious look at cost, risk, and what the system will look like ten years down the road. The reality is that the Total Cost of Ownership (TCO), security vulnerabilities, and lifecycle management will hit your bottom line harder than the initial price tag ever will.

The money talk starts with the initial buy-in, but it definitely doesn't stop there. A DCS will almost always have a bigger upfront cost because you're buying a proprietary, all-in-one package. The upside? Its integrated engineering environment can slash configuration and commissioning time, which means lower labor bills to get things running.

On the flip side, a SCADA system looks cheaper at first glance. The software and hardware have a lower entry price, but that mix-and-match freedom can come back to bite you. Integrators often burn more hours mapping tags and wrestling with components from different vendors to make them play nice, driving up those initial engineering costs.

Understanding the Total Cost of Ownership

The long-term costs of maintenance and upgrades are where these two paths really diverge. With a DCS, you're married to a single vendor for support, spare parts, and any future expansions. This can feel expensive with each purchase order, but it gives you a clear and predictable support roadmap.

SCADA systems let you shop around, sourcing components from multiple vendors, which can definitely save you money. But this flexibility puts the burden squarely on your team to manage the lifecycle and compatibility of every single piece of that puzzle.

Contrasting Cybersecurity Risk Profiles

In the SCADA vs. DCS security matchup, the real difference is the attack surface. SCADA systems are built to be spread out, often relying on public or semi-public networks like cellular or radio to connect remote sites. By its very nature, this creates a massive attack surface with countless potential entry points for a bad actor.

The market is responding to this challenge. The global SCADA security market was around USD 2.87 billion and is expected to hit USD 3.74 billion by 2025, pushed along by the rise of IIoT and the need for better security.

DCS platforms have historically been walled gardens—isolated, proprietary networks tucked safely inside the plant. This made them inherently more secure. But as these systems get plugged into enterprise networks for data analytics and business insights, that risk profile is changing fast. For either system, implementing effective network segmentation isn't just a good idea; it's a critical defense for isolating your control systems.

Key Takeaway: SCADA's security headache is managing its wide, distributed perimeter. The modern DCS security challenge is protecting its historically isolated core as it gets more connected to the outside world.

Planning for Lifecycle and Upgrades

Finally, think about how you'll manage the system over its entire life. DCS vendors provide a clear—though often expensive—evolution path. Upgrades are handled within their closed ecosystem, which guarantees that all the new and old parts will work together.

The SCADA lifecycle is a lot more fragmented. You get the freedom to upgrade your HMI software without touching the PLCs, but that flexibility demands meticulous management. If you're not careful, you can end up with a Frankenstein's monster of a system, full of obsolete, unsupported components that are both an operational and a security nightmare.

Ultimately, the choice comes down to your organization's philosophy: do you want a structured, vendor-managed path, or do you prefer a more flexible, self-managed approach?

Making the Right Choice: A Practical Framework

Let’s get one thing straight: choosing between SCADA and DCS isn't about picking the "better" system. It's about finding the one that perfectly aligns with your operational reality. The decision really boils down to a clear-eyed assessment of your specific needs, from the physical spread of your assets to the level of control precision you absolutely must have.

A practical framework helps you move away from a "technology-first" mindset and toward a "solution-oriented" one.

To get started, you have to ask the right questions. This isn't just a technical exercise; it's a strategic one that should pull in people from engineering, operations, and even the finance department. Kicking off with these fundamental queries will steer your evaluation in the right direction from day one.

Key Evaluation Questions for Your Team

- Geographical Scope: Is my entire operation under one roof, or am I dealing with multiple remote sites spread out over miles?

- Control Philosophy: Do I just need to supervise and pull data from independent assets? Or do I need tightly integrated, high-speed regulatory control over a process where every step depends on the last?

- Process Nature: Is my process continuous and complex, like in a refinery? Or is it more discrete and event-driven, like simply monitoring tank levels?

- System Integration: Will I be mixing and matching hardware from different vendors, or can I realistically commit to a single-vendor ecosystem for the long haul?

This decision tree gives you a great visual of the key pillars to consider: cost, security, and the system's entire lifecycle.

As the graphic shows, your technical requirements have to be balanced with business realities. This is what guides you to a holistic, sustainable choice. Working with a skilled industrial automation system integrator can be a game-changer here, helping you navigate these complex trade-offs and ensuring the final design hits both your operational and business targets.

The Rise of Hybrid Systems

It’s also crucial to recognize that the old, hard lines in the SCADA vs. DCS debate are getting blurry. Modern automation platforms are increasingly borrowing features from both sides of the aisle. Today, you can find powerful SCADA software that handles advanced process control, and DCS platforms that are much friendlier when it comes to connecting with third-party devices.

Final Takeaway: Your selection framework shouldn't be rigid. Anchor your decision on core requirements—geography, control precision, and integration needs—but stay open to hybrid solutions that might just offer the best of both worlds for your unique application.

This kind of forward-looking perspective ensures your investment isn't just a fit for today but is also ready for whatever challenges tomorrow throws at it.

SCADA vs. DCS: Your Questions Answered

Even after breaking down the technical details, a few practical questions always pop up when engineers are weighing their options. Let's tackle some of the most common ones I hear from system integrators and plant managers.

Can I Use SCADA for Process Control?

You can, but you probably shouldn’t. While a modern SCADA system is perfectly capable of sending a command—like a new setpoint or an on/off signal—to a remote PLC, its real job is supervision, not high-speed regulation.

A DCS is purpose-built for the kind of tight, deterministic, closed-loop control required in complex processes. Trying to force a SCADA system into that role is asking for trouble; it simply doesn't have the real-time performance baked into its architecture.

Is DCS Just Naturally More Secure Than SCADA?

Historically, this was absolutely true. A DCS was designed as a self-contained "island" inside the plant, a closed-off, proprietary system with a very small attack surface. In contrast, SCADA systems were built to be geographically spread out, often relying on public networks, which naturally introduced more potential security holes.

But the game has changed. Today, as DCS platforms get connected to enterprise networks for data sharing and analytics, their risk profile is growing. Security is no longer about the label (DCS vs. SCADA) but about solid network design, proper segmentation, and strict access controls.

Where Do PLCs Fit into All This?

Programmable Logic Controllers (PLCs) are the tough, reliable workhorses handling control at the field level. How they fit in depends entirely on the system architecture.

-

In a SCADA system, PLCs (or their cousins, RTUs) are the stars of the show. They are the endpoints executing all the local control logic and reporting back to the central SCADA server.

-

In a classic DCS, the system’s own distributed controllers handle the tasks a PLC would. However, it's now very common to see a hybrid approach where a DCS integrates with specialized skids or equipment packages that come with their own onboard PLCs. In that case, the DCS has to communicate with them, often using a standard protocol like OPC UA to bridge the gap.

For over 50 years, E & I Sales has helped teams navigate these complex system decisions. From custom UL control panels to full-scale system integration, we build reliable solutions that connect your entire operation. Find out how our engineering support can get your next project off the ground at https://eandisales.com.