Protecting your motors isn't just a maintenance task—it's a core industrial practice. At its heart, motor protection is about using specialized devices to guard against electrical faults, overloads, and mechanical failures.

Think of it as a comprehensive insurance policy for your most critical assets, one that prevents catastrophic downtime, expensive equipment damage, and serious safety hazards. Getting it right means ensuring operational reliability and squeezing every bit of life out of your motors.

Why Effective Motor Protection Is Non-Negotiable

In any plant or factory, electric motors are the unsung heroes. They're the muscle behind the conveyors, pumps, fans, and compressors that keep your operation moving. But just like the high-performance engine in a race car, a motor needs a sophisticated management system to run safely and efficiently. Push that engine too hard without the right controls, and you're headed for a catastrophic breakdown.

Motor protection devices are that management system. They stand as vigilant guardians, constantly watching for dangerous conditions and stepping in before a small hiccup snowballs into a full-blown failure. This isn't just a technical detail buried in a panel—it's a fundamental business strategy.

The Core Objectives of Protection

Solid motor protection isn't just about keeping a machine from tripping. It's built around three key objectives that have a direct impact on your bottom line and the integrity of your entire operation:

- Safeguarding Personnel: First and foremost, you need to prevent electrical faults that could lead to fires, arc flash events, or electric shock. A safe working environment is always priority number one.

- Preventing Equipment Damage: A motor failure rarely happens in a vacuum. It can trigger a chain reaction, damaging connected machinery and leading to complex, expensive repairs that go far beyond the motor itself.

- Minimizing Unplanned Downtime: Every minute a critical motor is offline, production grinds to a halt. Proper protection prevents those sudden stops that can bleed thousands of dollars an hour in lost revenue.

The global focus on these goals is clear from the market numbers. The market for protection devices like relays and circuit breakers was valued at $6.7 billion in 2023 and is on track to hit $9.0 billion by 2033. According to market analysis from Fact.MR, this growth is being fueled by increased automation and infrastructure investments worldwide, underscoring just how critical reliable motor safety has become.

In essence, investing in motor protection isn't an expense—it's an investment in operational continuity, safety, and profitability. An unprotected motor is not just an asset at risk; it's a potential point of failure for your entire operation.

To really grasp the value, it helps to see how each of these protection goals translates into tangible business outcomes.

Core Objectives of Motor Protection and Their Business Impact

This table breaks down the primary goals of any good motor protection system and connects them directly to the real-world benefits they bring to an industrial operation.

| Protection Objective | Primary Risk Mitigated | Direct Business Impact |

|---|---|---|

| Personnel Safety | Electrical shock, arc flash, fire | Reduced workplace accidents, lower insurance premiums, improved safety compliance |

| Equipment Preservation | Motor burnout, mechanical stress | Lower capital expenditure on replacement parts, extended asset lifespan |

| Uptime and Reliability | Sudden production stoppages | Increased production output, predictable maintenance schedules, higher revenue |

Ultimately, these objectives work together to create a more resilient, efficient, and profitable industrial environment.

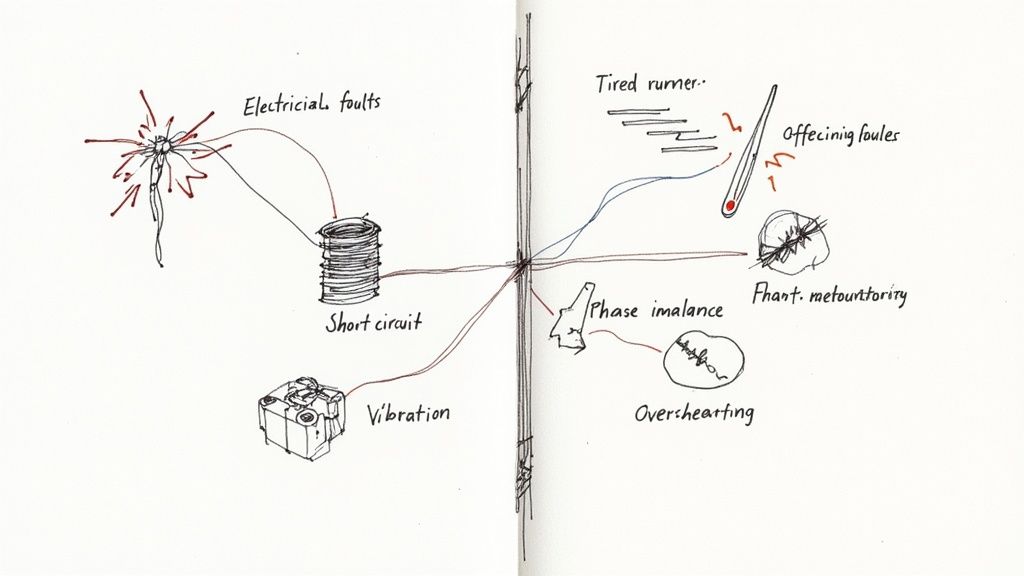

What Causes Motors to Fail in the First Place?

Before you can protect a motor, you have to know what you’re up against. Motors almost never just die on their own; a failure is usually a symptom of a much deeper problem. These root causes generally fall into two buckets: electrical faults and mechanical stresses.

Think of your motor like a high-performance athlete. An electrical fault is like feeding it the wrong fuel—it messes things up internally. Mechanical stress is like forcing it to sprint a marathon on a rocky trail with bad shoes. Either way, a breakdown is inevitable. Good motor protection is your coaching staff, spotting these problems before they lead to a career-ending injury.

A solid first step is understanding hazard identification within your facility. When you know where the risks are, you can build a smarter defense.

The Most Common Electrical Faults

Electrical issues are the usual suspects when a motor burns out. They go after the motor’s heart—the windings—either by slowly cooking them with heat or hitting them with a sudden, destructive jolt of energy.

-

Overloads: This is, without a doubt, the most common killer of motors. An overload happens when a motor is pushed to do more work than it was designed for. It draws too much current, gets hot, and stays hot. It’s like asking a weightlifter to hold a max lift indefinitely. Eventually, that sustained heat breaks down the winding insulation, and it’s game over.

-

Short Circuits: An overload is a slow burn, but a short circuit is an explosion. This is what happens when a low-resistance path is created where it shouldn't be, allowing a massive, uncontrolled amount of current to flow instantly. It's the electrical equivalent of a lightning strike, capable of melting windings and causing immediate, catastrophic failure.

-

Phase Imbalance or Loss: A three-phase motor needs a balanced diet of power across all three phases to run smoothly. When you lose a phase (single-phasing) or the voltages aren't equal (imbalance), it’s like trying to run an engine on two cylinders instead of three. The motor stumbles, vibrates, and draws way too much current through the remaining windings, leading to rapid overheating.

The Impact of Mechanical Stress

While we often focus on the electrical side, mechanical problems can be just as brutal. They introduce friction, vibration, and physical strain that will take down a motor just as surely as any electrical surge.

It’s easy to blame electricity for every motor failure, but that's a mistake. In reality, studies consistently show that mechanical problems—especially bearing failures—account for over 50% of all motor breakdowns. This is a huge number, and it proves that your protection strategy has to look at the whole picture, not just the wiring.

Key Mechanical Failure Points

Here are the mechanical culprits that are constantly trying to shorten your motor's life:

-

Bearing Failure: Bearings are the unsung heroes, letting the motor’s shaft spin freely. But when they get contaminated with dust and moisture, aren't lubricated properly, or have to deal with misalignment, they’re put under incredible strain. A failing bearing generates friction and heat, and that can quickly escalate to a seized motor.

-

Misalignment: When the motor shaft isn't perfectly lined up with the pump, fan, or gearbox it's driving, it creates intense, damaging vibrations. This constant rattling wears out bearings, couplings, and even the motor shaft itself. It's a guaranteed way to cause a premature failure.

-

Overheating from Poor Ventilation: Motors are designed to get warm, and they rely on cooling fans and clean vents to get rid of that heat. If those vents get clogged with sawdust, dirt, or grime, the motor can't breathe. Heat gets trapped, and the motor essentially cooks itself from the inside out, leading to the same end result as an electrical overload.

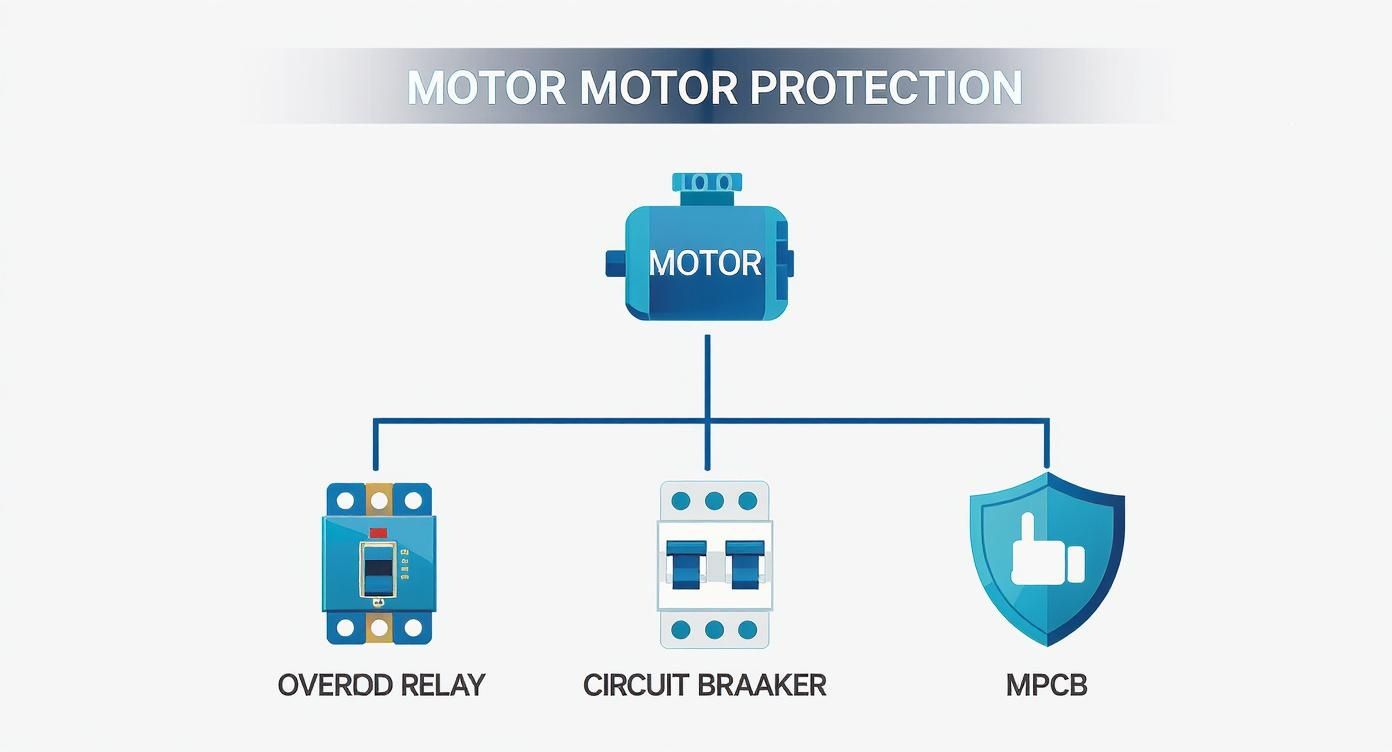

Your Arsenal of Motor Protection Devices

Now that we’ve covered the threats, let's look at the hardware that keeps your motors safe. Think of motor protection less like a single shield and more like a team of specialists. Each device has a specific job, and choosing the right one—or the right combination—is what creates a truly bulletproof system.

You wouldn't use a sledgehammer for a finishing nail, right? The same logic applies here. The device you need to stop a slow, grinding overload is completely different from the one that has to snap into action during a catastrophic short circuit.

Thermal Overload Relays: The Marathon Pacer

The old faithful of motor protection is the thermal overload relay. This is your motor's long-distance guardian, designed to protect it from the slow-burn damage of a sustained overcurrent. It’s smart enough to ignore the brief current spike a motor draws when it first kicks on.

Instead, it works with a bimetallic strip that gradually heats up and bends as excess current flows through it. If the overload drags on for too long, the strip bends far enough to trip a contact and shut down the motor—saving the winding insulation from getting cooked. It's a simple, tough, and affordable way to stop the #1 cause of motor failure in its tracks.

Fuses and Circuit Breakers: The Emergency Brakes

While an overload relay handles the slow stuff, fuses and circuit breakers are the emergency brakes. Their one and only job is to react instantly to the massive, destructive currents that come with a short circuit.

-

Fuses: These devices make the ultimate sacrifice. Inside a fuse is a small piece of metal engineered to vaporize in milliseconds when a huge overcurrent hits, breaking the circuit. They are incredibly fast, but they're a one-and-done solution and need to be replaced after they blow.

-

Circuit Breakers: A circuit breaker is essentially a heavy-duty, resettable switch. It uses a thermal trip for minor overloads and a magnetic trip for the big stuff, like short circuits. Once you've cleared the fault, you just flip the switch back on. This convenience makes them a go-to for many applications.

Motor Protection Circuit Breakers: The All-in-One Solution

A Motor Protection Circuit Breaker (MPCB) is exactly what it sounds like—a single, compact device that does the job of multiple components. It rolls adjustable thermal protection (like an overload relay) and instantaneous magnetic protection (like a circuit breaker) into one unit.

This integrated approach cleans up panel wiring, saves a ton of space, and gives you coordinated protection straight out of the box. MPCBs are purpose-built for the rigors of motor circuits, making them a very popular choice in modern industrial panels.

A critical piece of this puzzle is the motor starter, which handles the basic start/stop function. The global market for these components was valued at $7.8 billion in 2023 and is expected to climb to $12.8 billion by 2034. This growth underscores just how vital these integrated systems are. You can get more insights on this trend from custommarketinsights.com.

Motor Protection Relays: The Smart Coach

If the classic devices are individual players, think of a modern Motor Protection Relay (MPR) as the team's data-driven coach. These are smart, microprocessor-based units that go way beyond just watching for overcurrent.

An MPR is constantly monitoring a whole host of parameters, looking for signs of trouble like:

- Phase loss or imbalance

- Ground faults

- Undercurrent (which could mean a broken belt or a pump running dry)

- Too many starts in a short period

- Over-temperature, often using sensors buried right in the motor windings

This level of detailed monitoring lets you diagnose problems before they turn into catastrophic failures, making them an incredibly powerful preventative tool.

Variable Frequency Drives: The Advanced Controller

At its core, a Variable Frequency Drive (VFD) is a speed controller, but its onboard electronics give it some seriously impressive motor protection capabilities. Because a VFD is constantly managing the current, voltage, and frequency going to the motor, it can provide incredibly precise thermal overload protection.

VFDs also inherently protect against issues like phase loss, overvoltage, and undervoltage. You'll still need a fuse or breaker upstream for short-circuit protection, but a VFD can often take the place of a separate overload relay entirely. If you want a deeper dive, check out our guide on variable frequency drive basics. They're an amazing tool for both sophisticated control and comprehensive motor defense.

To help tie all this together, it's useful to see these devices compared side-by-side. Each has its place, and understanding their strengths and weaknesses is key to making the right choice for your application.

Comparison of Common Motor Protection Devices

| Device Type | Primary Protection | Typical Application | Reset Method | Relative Cost |

|---|---|---|---|---|

| Thermal Overload Relay | Sustained Overcurrent | Paired with a contactor for basic motor starting circuits. | Manual or Automatic | Low |

| Fuse | Short Circuit (High Faults) | High-speed protection for sensitive equipment or high-fault current areas. | Replace | Very Low |

| Molded Case Circuit Breaker (MCCB) | Short Circuit & Overload | Main disconnects and branch circuit protection. General purpose. | Manual (Resettable) | Moderate |

| Motor Protection Circuit Breaker (MPCB) | Coordinated Overload & Short Circuit | All-in-one protection for individual motor circuits. Saves panel space. | Manual (Resettable) | Moderate to High |

| Motor Protection Relay (MPR) | Comprehensive (Current, Voltage, Phase, Temp) | Critical motors where advanced diagnostics and pre-emptive warnings are needed. | Manual, Automatic, or Remote | High |

| Variable Frequency Drive (VFD) | Advanced Overload, Phase Loss, Voltage Faults | Applications requiring speed control. Protection is a built-in benefit. | Programmable (Resettable) | Very High |

As you can see, there's no single "best" device. The choice depends entirely on the motor's importance, the nature of the load, and your budget. For a simple fan, an overload relay and fuse might be perfect. For a mission-critical process pump, a smart MPR or a VFD is a much wiser investment.

How to Select and Coordinate Protective Devices

Knowing what the different protective devices are is only half the battle. The real skill is picking the right components and getting them to work together as a single, smart system. This all comes down to two key ideas: selection and coordination.

Think of it like putting together a championship football team. Selection is about getting the right player for each position—a tough lineman, a fast receiver. Coordination is teaching them to execute plays so the offensive line’s blocking gives the quarterback time to throw. You need both to win.

Selecting the Right Device for the Job

You always, always start with the motor's nameplate. That little metal tag is the motor’s birth certificate, and it has all the vital stats you need to choose the right protection. The most important number on there is the Full Load Amperage (FLA), which tells you exactly how much current the motor is designed to pull when it’s doing its job.

Here’s a straightforward way to select and set a basic overload relay:

- Find the Motor FLA: First thing's first, get the Full Load Amperage right off the motor nameplate. This is your baseline.

- Check the Service Factor (SF): Now, look for a Service Factor, which is usually 1.0 or 1.15. This number tells you how much of an overload the motor can handle for a short time without getting hurt.

- Calculate the Trip Setting: According to standards like the National Electrical Code (NEC), if the SF is 1.15 or higher, you can set the overload trip up to 125% of the FLA. If the SF is 1.0 (or isn't listed), you stick to no more than 115% of the FLA.

For instance, say you have a 10 HP motor with an FLA of 28 amps and an SF of 1.15. You could set its overload relay as high as 35 amps (28 x 1.25). This gives the motor enough breathing room to handle temporary strains without annoying nuisance trips, while still protecting it from a truly damaging, sustained overload.

Sometimes, especially with complex loads, you also need to understand the relationship between power and rotational force. We have another guide that can help you with a torque calculation for motor applications if you need to dig deeper.

Coordinating Devices for Intelligent Protection

Coordination is where a truly great protection scheme shows its genius. It’s the art of making sure that only the device closest to a fault opens up, leaving the rest of your system running.

It’s like the fire sprinklers in an office building. If a fire starts in a single office, you want the sprinkler in that room to go off, not the main system that floods the entire building. The same logic applies here. A short circuit in one motor shouldn't trip the main breaker and plunge the whole plant into darkness.

Selective Coordination: The whole point is to create a hierarchy of protection. The "downstream" device (like the breaker protecting a single motor) should always react faster to a local problem than the "upstream" device (like the main panel breaker). This isolates the fault, minimizes downtime, and stops one small failure from causing a system-wide catastrophe.

To pull this off, engineers rely on Time-Current Curves (TCCs). These are graphs that show precisely how long a device will take to trip at any given current. By laying the TCC for the motor's breaker over the TCC for the main panel's breaker, you can see with your own eyes that they won't trip at the same time for the same fault.

This infographic gives you a simple look at this hierarchy in action.

As you can see, devices like overload relays and circuit breakers provide different layers of defense, all working to shield the most important asset: the motor. When you choose and set these devices correctly, you create a robust safety net that is both tough and smart.

Navigating Motor Protection Standards and Compliance

Getting motor protection right isn't just a matter of good engineering—it's a hard requirement, backed by strict safety standards. These codes aren't there to make life difficult; they exist to make sure every installation is safe, reliable, and insurable.

Think of them as a universal blueprint for safety. A motor installed in Texas should follow the same core safety principles as one running in Germany, and these standards make that possible.

The market reflects this focus on safety. Valued at $5.8 billion in 2024, the global motor protection market is expected to climb to $7.4 billion by 2030. That growth is being pushed by two things: more industrialization and tougher safety rules worldwide. You can dig into the numbers in this motor protection systems market report.

Key Standards to Know

When it comes to motor protection, two major players set the rules of the road globally:

- NEC (National Electrical Code): In the United States, this is the bible for safe electrical design, installation, and inspection. Article 430 is the section you'll live in—it's dedicated entirely to motors, their circuits, and controllers.

- IEC (International Electrotechnical Commission): This body creates the international standards used across Europe and much of the rest of the world for all things electrical.

While they might have slightly different ways of doing things, both the NEC and IEC are shooting for the exact same goals: safety and reliability.

Decoding NEC Article 430

If you're working in the U.S., you have to know NEC Article 430. It can look intimidating at first glance, but it's actually a logical roadmap that breaks down a motor circuit piece by piece. It tells you exactly what you need, from the power lines all the way to the motor shaft.

NEC Article 430 is the most cited article in the entire code for a reason. It provides a comprehensive framework covering everything from conductor sizing and disconnects to overload and short-circuit protection, leaving no room for guesswork in ensuring a safe installation.

Here are the non-negotiable parts Article 430 requires for any compliant motor circuit:

- Disconnecting Means: You need a way to completely and safely kill power to the motor and controller for maintenance.

- Short-Circuit and Ground-Fault Protection: This is your first line of defense against a catastrophic failure, usually a fuse or a circuit breaker.

- Motor Controller: The device that actually starts and stops the motor, like a simple contactor or a modern VFD.

- Motor Overload Protection: This is what saves the motor from burning itself out from overcurrents. An overload relay is the classic example.

Making sure your team is up to speed on these rules is crucial. Proper regulatory compliance training can make all the difference. Following these guidelines isn't just a box to check—it's a professional duty that keeps your systems effective, legally sound, and safe for everyone on the floor.

And in today's world of advanced controls, compliance also means managing electrical noise. Our guide on the harmonic filter for VFD is a great resource for tackling that side of things.

Practical Maintenance and Testing for Your Systems

Getting your motor protection system installed is a massive win, but it’s definitely not a "set it and forget it" deal. Think of your protective devices like smoke detectors in your home; you count on them to work in an emergency, but that trust is built on knowing they're actually working. A solid motor protection strategy absolutely has to include a proactive plan to make sure every component is ready to spring into action when you need it most.

If you let the system go, you're operating with a false sense of security. A device that fails to trip during a critical event can turn a totally preventable hiccup into a catastrophic failure. By locking in a routine maintenance schedule, you'll spot trouble early, get more life out of your motors, and ensure your protective gear performs exactly as it was designed to.

Your Actionable Maintenance Checklists

A structured game plan for maintenance is the best way to keep small tasks from being forgotten. Breaking it down into weekly, quarterly, and annual checks makes the whole process manageable and incredibly effective.

Weekly Visual Inspections:

- Look for Hot Spots: Keep an eye out for any discoloration on terminals, wiring, or device casings. That's a classic sign of a bad connection or an overload condition.

- Listen for Odd Noises: Pay attention to any weird buzzing or humming coming from contactors or breakers. That sound could be the first sign of a mechanical problem brewing.

- Check Enclosure Integrity: Make sure all panel doors are latched tight. Vents should be clean and clear of any dust or debris—proper airflow is non-negotiable.

Quarterly Mechanical Checks:

- Confirm Connection Torque: Grab a calibrated torque wrench and verify that every electrical connection on your breakers, relays, and terminals is tightened to the manufacturer’s spec. You'd be amazed how many failures start with a simple loose connection.

- Inspect Device Housings: Get hands-on and physically check for any cracks, chips, or other signs of wear and tear on the protective devices themselves.

"A huge chunk of electrical faults can be traced back to simple mechanical issues like loose terminations. A quarterly torque check is one of the highest-impact, lowest-cost preventative tasks you can perform to keep your motor circuits reliable and safe."

Advanced Annual Functional Testing

Annual testing is where the rubber meets the road. It goes way beyond just looking and touching; this is about confirming your protective devices will actually do their job under fault conditions. You're here to validate trip settings and response times.

Thermography (Infrared Scanning):

One of the most powerful tools you can have in your predictive maintenance arsenal is thermography. An infrared camera can spot a hot, failing connection long before you could ever see it with your own eyes. Running regular thermal scans of your motor control panels will identify high-resistance points, helping you head off potential fires and unplanned downtime.

Injection Testing:

This is the ultimate functional test. It involves injecting a very precise current into a circuit breaker or overload relay to prove it trips at the right current level and within the specified time. Honestly, this is the only way to be 100% certain that your overload and short-circuit settings are dialed in correctly and that the device will protect your motor when a real fault happens. Building a proactive program on these checks is how you guarantee your systems are always ready to go.

Motor Protection Questions From the Field

Even when you have a solid plan, a few practical questions always pop up on the shop floor. Let's tackle some of the most common ones our engineers and technicians run into.

Fuses Versus Circuit Breakers: What's the Real Difference?

This one comes up all the time. People often wonder whether to use a fuse or a circuit breaker for motor protection, and while both protect against overcurrent, they couldn't be more different in how they work.

A fuse is a one-and-done, sacrificial device. When a major fault occurs, a small metal element inside melts, breaking the circuit permanently. It does its job, but you have to replace it every time.

A circuit breaker, on the other hand, is a reusable mechanical switch. It trips open when there's a problem but can be reset once you’ve cleared the fault. For motors, we typically lean on Motor Protection Circuit Breakers (MPCBs). They're built to handle a motor's initial inrush current without nuisance tripping, and their adjustable settings give you far more flexibility than a standard fuse.

How Do I Set an Overload Relay Correctly?

Setting an overload relay isn't guesswork—it's a critical step to keep a motor safe without causing unnecessary downtime. The whole process starts with a quick look at the motor’s nameplate for two key pieces of information: the Full Load Amperage (FLA) and the Service Factor (SF).

Here's the field-tested procedure:

- Find the FLA: This is your baseline—the current the motor is designed to draw under a normal, full load.

- Check the Service Factor: If the SF is 1.15 or higher, it means the motor can handle a bit more. You can set the overload trip point up to 125% of the FLA.

- Stick to the Standard: If the SF is 1.0 or isn't listed, play it safe. The setting shouldn't go above 115% of the FLA.

This method gives the motor enough breathing room to handle slight load changes but ensures the relay will trip before any sustained overload can cook the windings.

Always double-check the manufacturer’s guides and local code requirements like the NEC. The sweet spot is always a balance between reliable operation and bulletproof protection.

Can a VFD Just Replace the Starter and Overload Relay?

For most modern setups, the answer is a definite yes. A Variable Frequency Drive (VFD) is packed with smart electronics that provide fantastic motor protection right out of the box.

VFDs offer incredibly sophisticated overload protection—often using a precise thermal model of the motor—and they also guard against things like phase loss, overvoltage, and undervoltage.

But here’s the crucial part: a VFD is not a substitute for short-circuit protection. You absolutely still need fuses or a circuit breaker installed on the line side of the drive. This is non-negotiable for protecting the VFD's sensitive internal components (and the rest of your system) from a catastrophic fault. Always dig into the VFD's installation manual to see what it requires for upstream protection.

At E & I Sales, we live and breathe this stuff. We specialize in designing and building the custom UL control panels and integrated systems that turn motor protection theory into a reliable reality. From picking the right components to commissioning a fully coordinated system, our team ensures your most critical assets are safe and ready to run.

Learn more about our custom control panel solutions at eandisales.com